Halogen generator

A generator and halogen technology, applied in nuclear power generation, nuclear reactor monitoring, reactors, etc., can solve the problems of difficult after-sales service, high price, long order cycle, etc., and achieve the effect of easy control of occurrence conditions, wide range and stable occurrence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

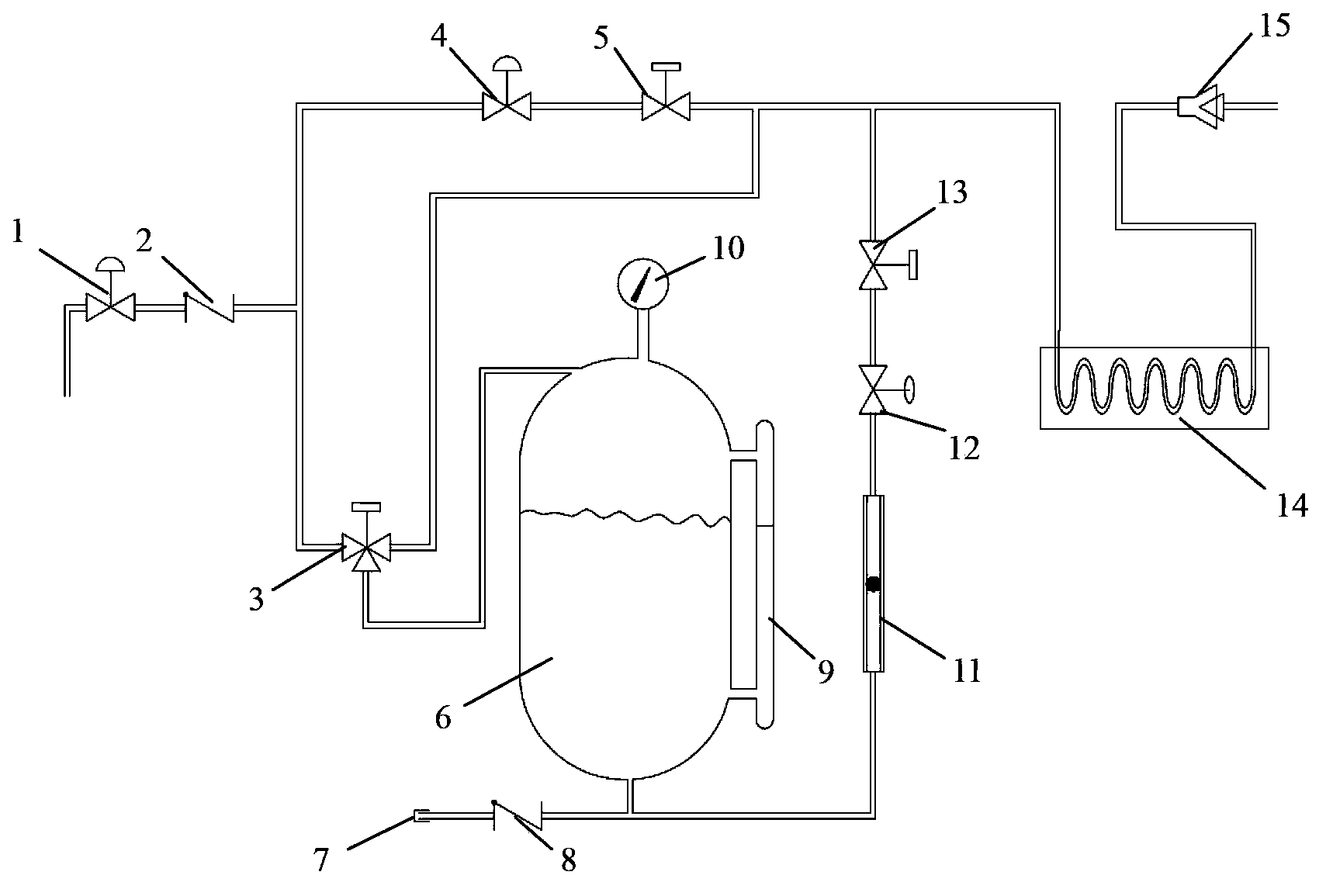

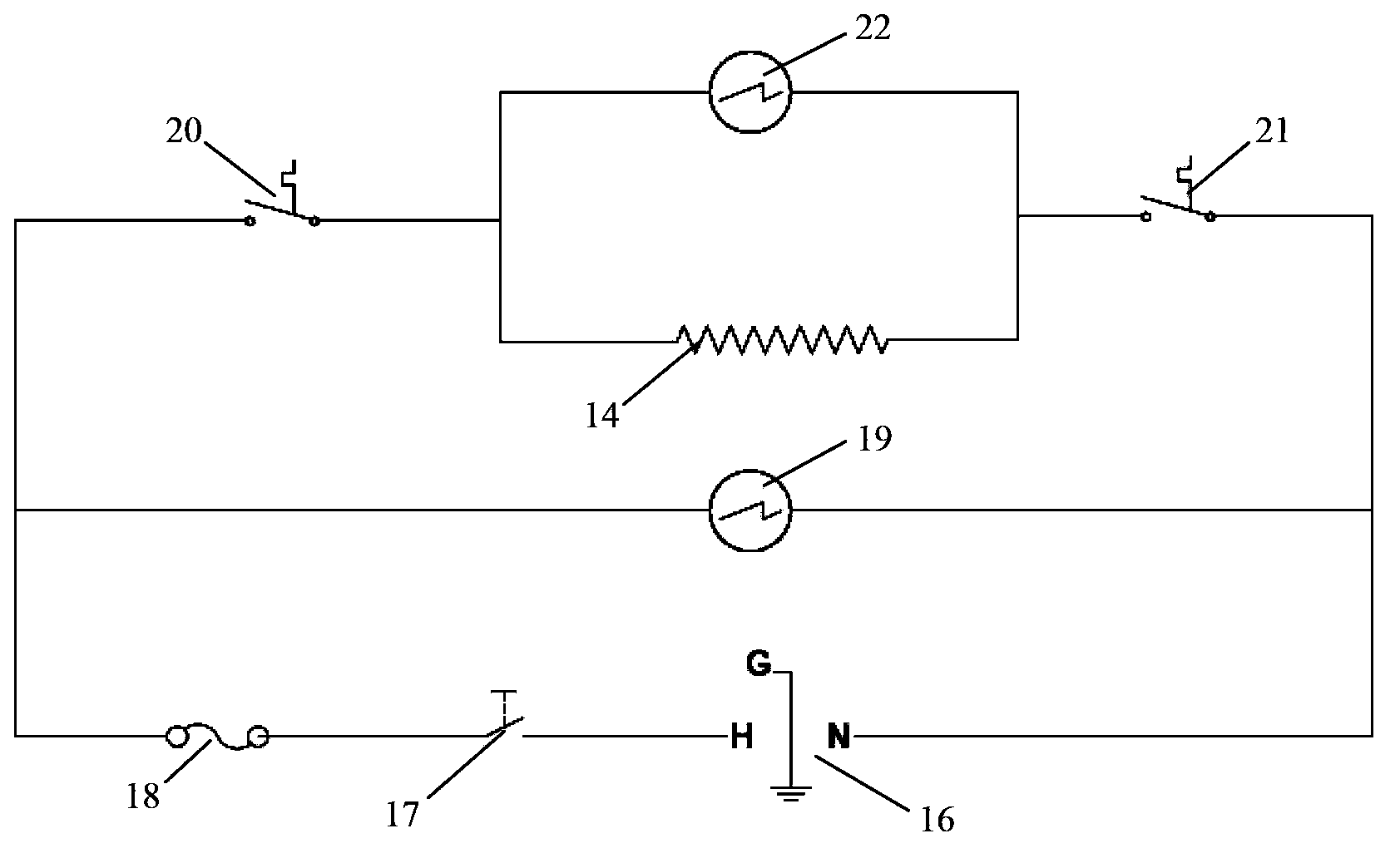

[0020] Such as figure 1 As shown, the pressure-bearing storage tank 6 of the halogen generator in this embodiment is a stainless steel cylinder, which can store 1.8L of Freon liquid reagent. The pressure inside the pressure storage tank is controlled by a preset pressure regulating valve, the pressure requirement is 0.4-1.0MPa, and the preset pressure is 0.4MPa, that is, the pressure inside the pressure storage tank is generally controlled at about 0.4MPa. A cuboid aluminum / tin heater 14 is arranged on the freon gasification outlet pipeline of the generator, and two preset temperature switches ( figure 2 20, 21) to maintain a constant heater temperature, constant temperature 85 ℃

[0021] The compressed air is divided into two streams after passing through the compressed air conversion joint, preset pressure reducing valve 1 and check valve 2 (see attached figure 1 ), one way enters the pressurized liquid storage tank 6 through the three-way switch valve 3, and the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com