Ethylene cracking furnace and ethylene cracking method

An ethylene cracking furnace, ethylene cracking technology, applied in the directions of cracking, hydrocarbon cracking to hydrocarbon, non-catalytic thermal cracking, etc., can solve the problems of coking, reduce heat exchange area, etc. Effects across temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

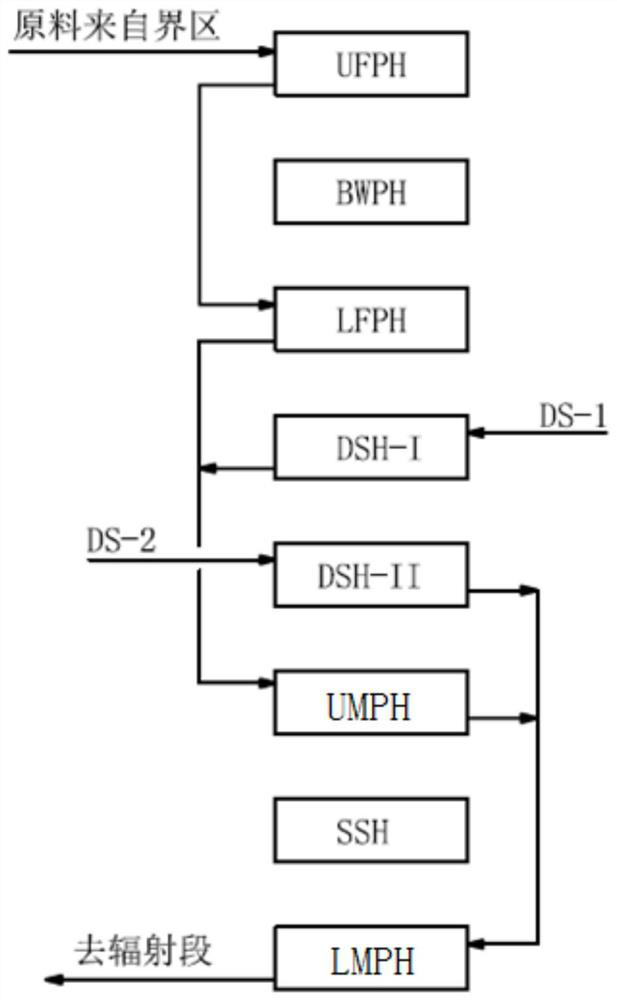

[0046] Convection section 2 adopts such as figure 2 The convection section arrangement shown. The convection section is divided into eight sections from top to bottom, which are: upper raw material preheater (UFPH), boiler feed water preheater (BWPH), lower raw material preheater (LFPH), primary dilution steam superheater (DSH -I), secondary dilution steam superheater (DSH-II), upper mixing preheater (UMPH), super high pressure steam superheater (SSH) and lower mixing preheater (LMPH). The dilution steam from the boundary area is divided into primary steam (DS-1) and secondary steam (DS-2). After the primary steam (DS-1) is overheated in the primary dilution steam superheater (DSH-I), it The raw materials from the raw material preheater (LFPH) are mixed, and the obtained oil-gas mixture enters the upper mixing preheater (UMPH) for superheating, and the secondary steam (DS-2) is superheated in the secondary dilution steam superheater (DSH-Ⅱ) , the superheated dilution steam ...

Embodiment 2

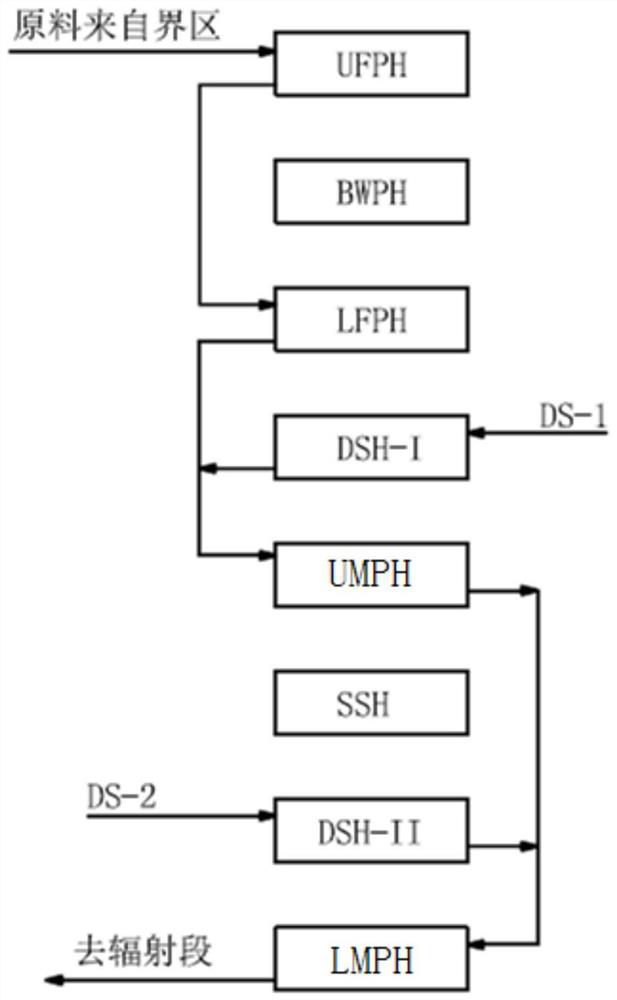

[0048] Convection section 2 adopts such as image 3 The convection section arrangement shown. The convection section is divided into eight sections from top to bottom, which are: upper raw material preheater (UFPH), boiler feed water preheater (BWPH), lower raw material preheater (LFPH), primary dilution steam superheater (DSH -I), upper mixing preheater (UMPH), super high pressure steam superheater (SSH), secondary dilution steam superheater (DSH-II) and lower mixing preheater (LMPH). The dilution steam from the boundary area is divided into primary steam (DS-1) and secondary steam (DS-2). After the primary steam (DS-1) is overheated in the primary dilution steam superheater (DSH-I), it The raw materials from the raw material preheater (LFPH) are mixed, and the obtained oil-gas mixture enters the upper mixing preheater (UMPH) for superheating, and the secondary steam (DS-2) is superheated in the secondary dilution steam superheater (DSH-Ⅱ) , the superheated dilution steam i...

Embodiment 3

[0050] Convection section 2 adopts such as Figure 4 The convection section arrangement shown. The convection section is divided into eight sections from top to bottom, which are: upper raw material preheater (UFPH), boiler feed water preheater (BWPH), lower raw material preheater (LFPH), primary dilution steam superheater (DSH -I), secondary dilution steam superheater (DSH-II), upper mixing preheater (UMPH), super high pressure steam superheater (SSH) and lower mixing preheater (LMPH). After the dilution steam (DS) from the boundary area is superheated in the primary dilution steam superheater (DSH-I), part of the steam is mixed with the raw material from the lower raw material preheater (LFPH), and the obtained oil-gas mixture enters the upper mixing together The preheater (UMPH) is superheated, and the remaining steam is superheated in the secondary dilution steam superheater (DSH-Ⅱ), and the superheated dilution steam is mixed with the hydrocarbon mixture at the outlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com