Specific gravity vacuum net oil segregator with built-in electric hot tray

A technology of oil separator and electric heating plate, applied in the direction of vacuum distillation, vacuum distillation, separation method, etc., can solve the problems of uneven heating of external heater, high energy consumption of external heater, poor quality of purified oil, etc., and achieve cooling and cooling Good performance, prolong service life, and prevent gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below by embodiment, the present invention will be further described.

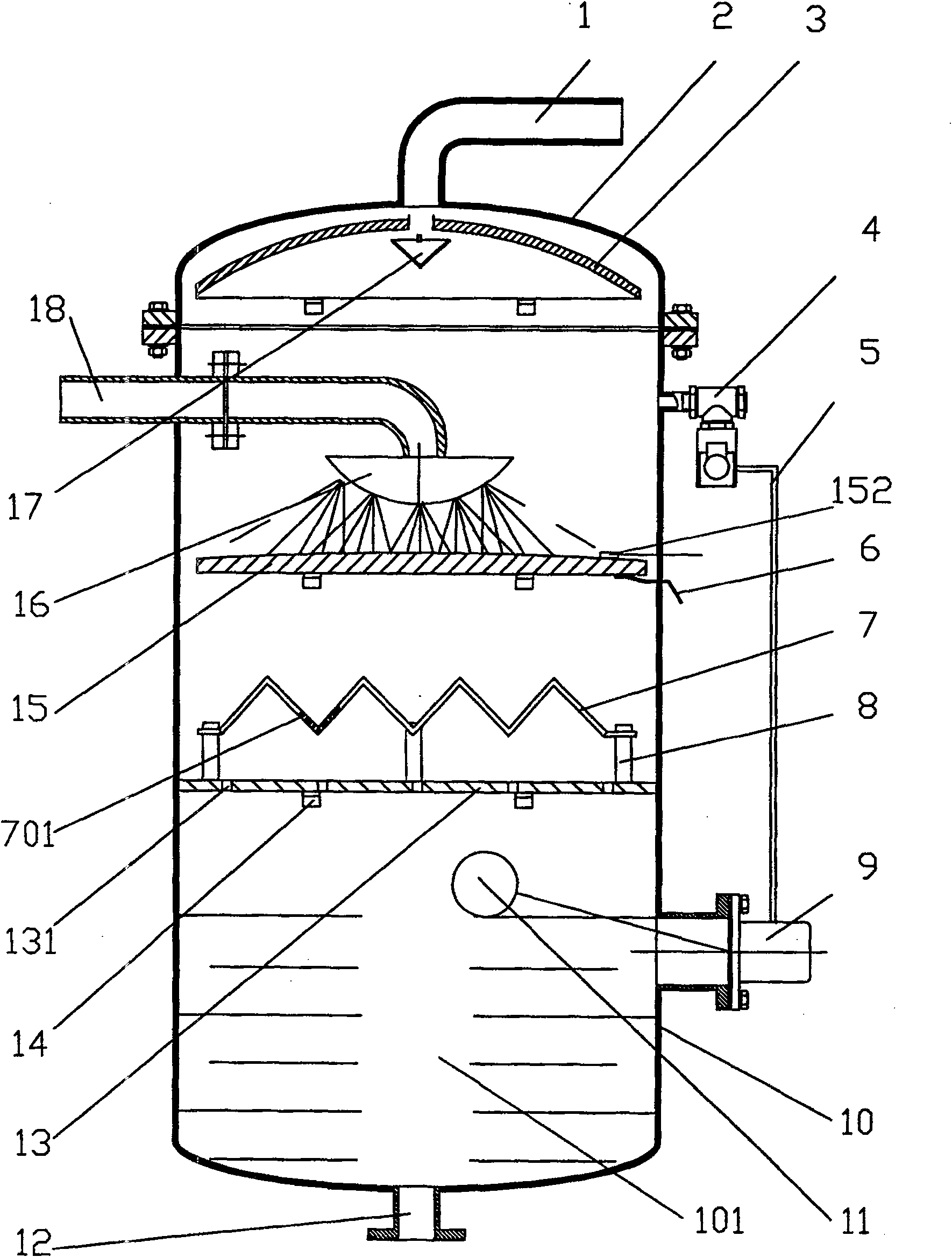

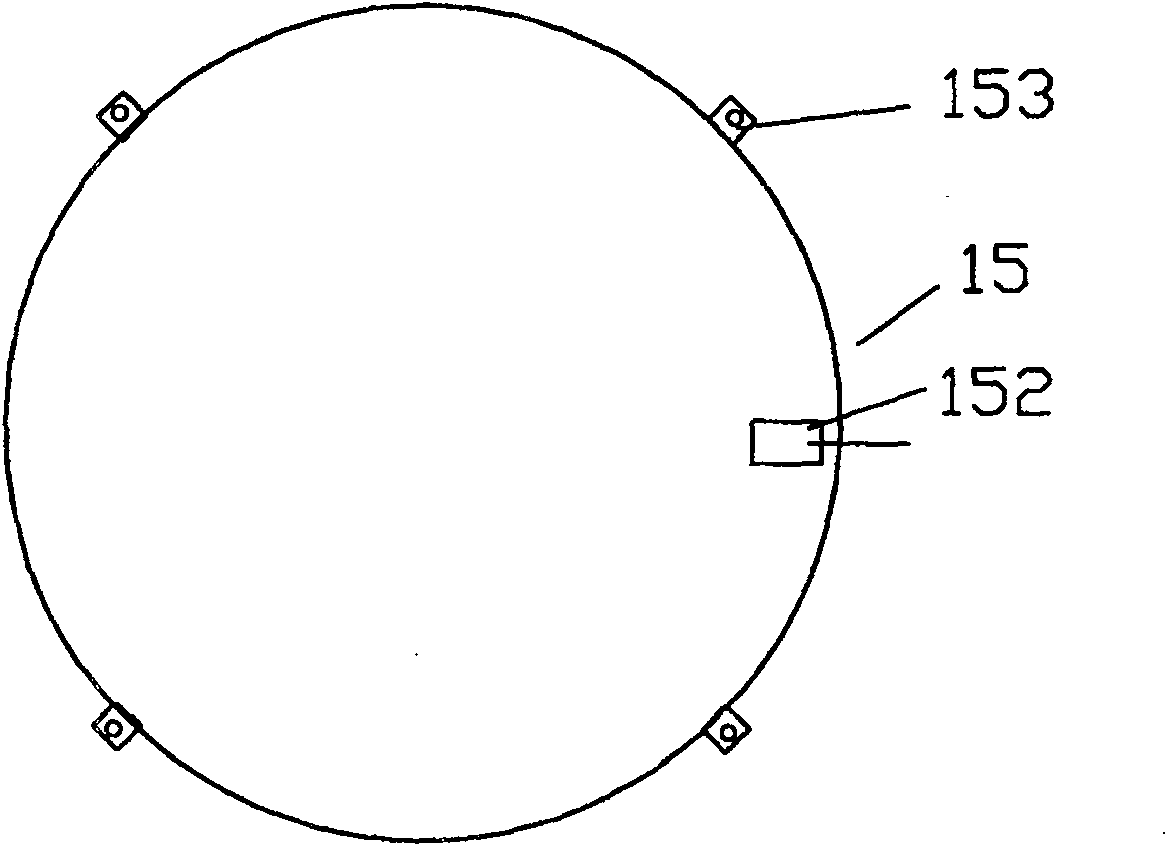

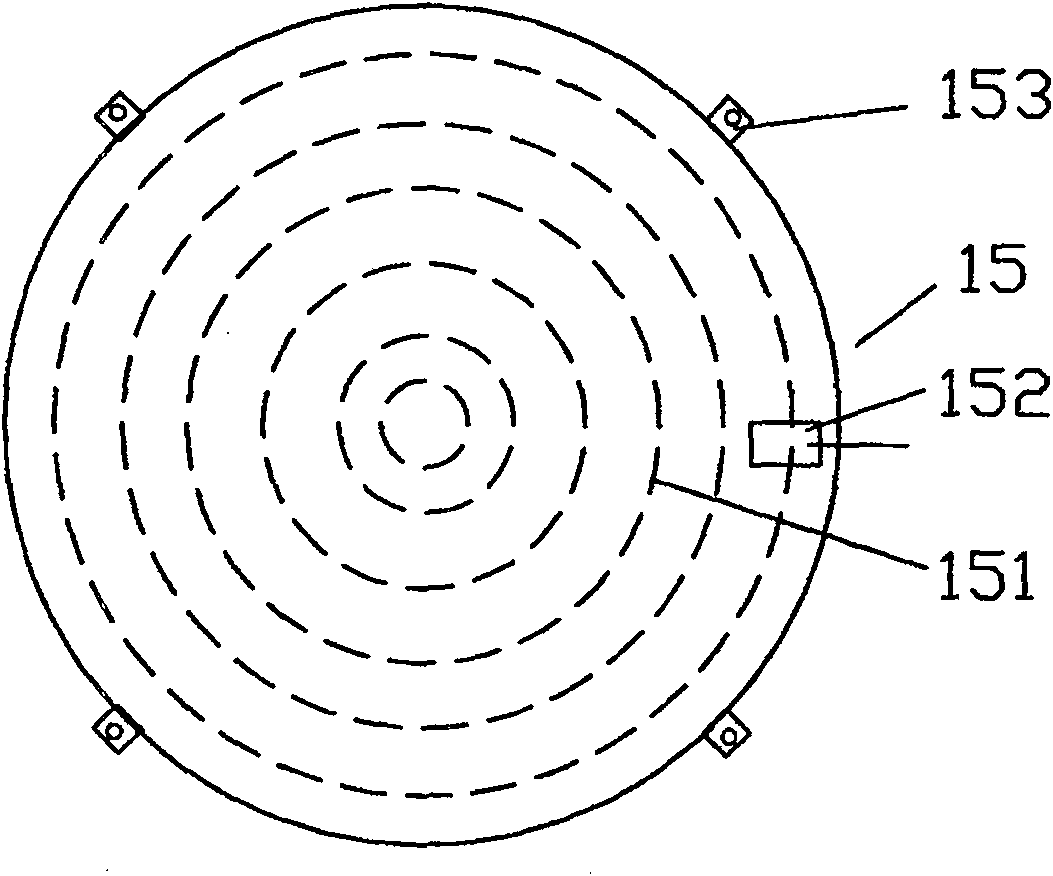

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a built-in electric heating disc type specific gravity vacuum degassing tank, it includes a tank cover 2, a tank body 10, an oil level control device, a vacuum outlet 1 is provided on the tank cover 2, and an inlet The oil pipe 18 is provided with an oil discharge port 12 at the bottom of the tank body 10, a nozzle 16, a reaction disc 7, a support plate 13, and an oil storage bin 101 are arranged in the tank body 10, and an electric heating plate 15 is also provided in the tank body 10 , The electric heating plate 15 is arranged between the shower head 16 and the reaction plate 7 . Under the tank cover 2, a large inner cover 3 and a small inner cover 17 are arranged, and a vent hole 301 is provided in the middle part of the large inner cover 3, and a small inner cover 17 is arranged directly below the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com