Air conditioner

By detecting the temperature change rate of the compressor and refrigerant to determine whether heating is required, the problem of reduced lubricating oil viscosity and power consumption caused by refrigerant accumulation during the air conditioner shutdown period is solved, and more effective power management is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0027] (The overall structure of the air conditioner 50)

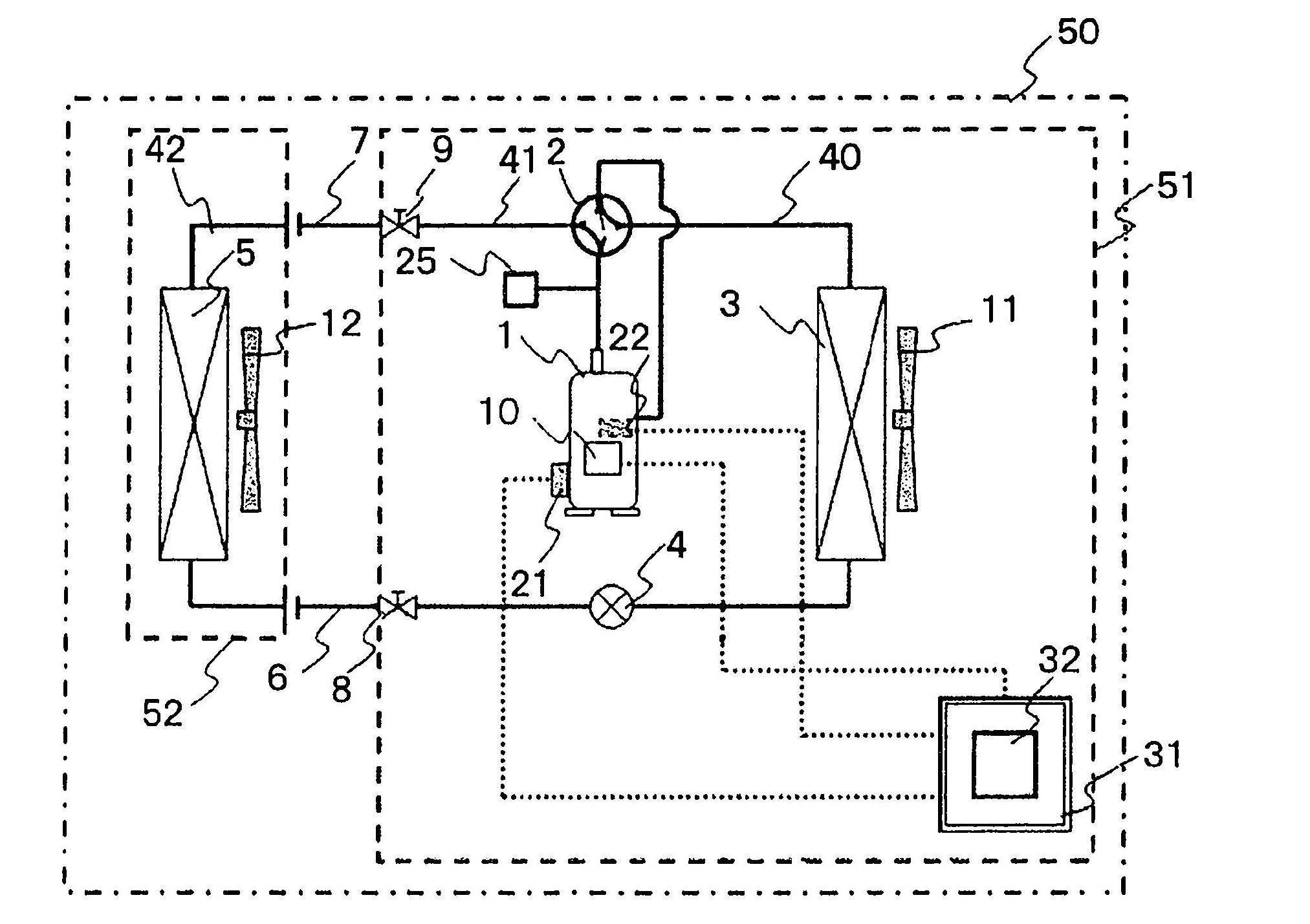

[0028] figure 1 It is an overall configuration diagram of an air conditioner 50 according to an embodiment of the present invention.

[0029] Such as figure 1 As shown, the air conditioner 50 has an outdoor unit 51 and an indoor unit 52, and has a refrigerant circuit 40 that is a circulation circuit for circulating refrigerant in the outdoor unit 51 and the indoor unit 52.

[0030] The refrigerant circuit 40 is composed of an outdoor refrigerant circuit 41 as a heat source side refrigerant circuit of the outdoor unit 51, an indoor refrigerant circuit 42 as a utilization side refrigerant circuit of the indoor unit 52, and connecting the The liquid side connection pipe 6 and the gas side connection pipe 7 of the outdoor refrigerant circuit 41 and the indoor refrigerant circuit 42 are connected.

[0031] The outdoor refrigerant circuit 41 is composed of at least the following parts: a compressor 1, a four-way valve 2, an outdoor ...

Embodiment approach 2

[0077] In the present embodiment, the description will be focused on points different from the air conditioner 50 of the first embodiment.

[0078] The configuration of the air conditioner 50 of this embodiment is the same as the configuration of the air conditioner 50 of the first embodiment.

[0079] (Change with time of the state quantity of the heating operation of the compressor 1)

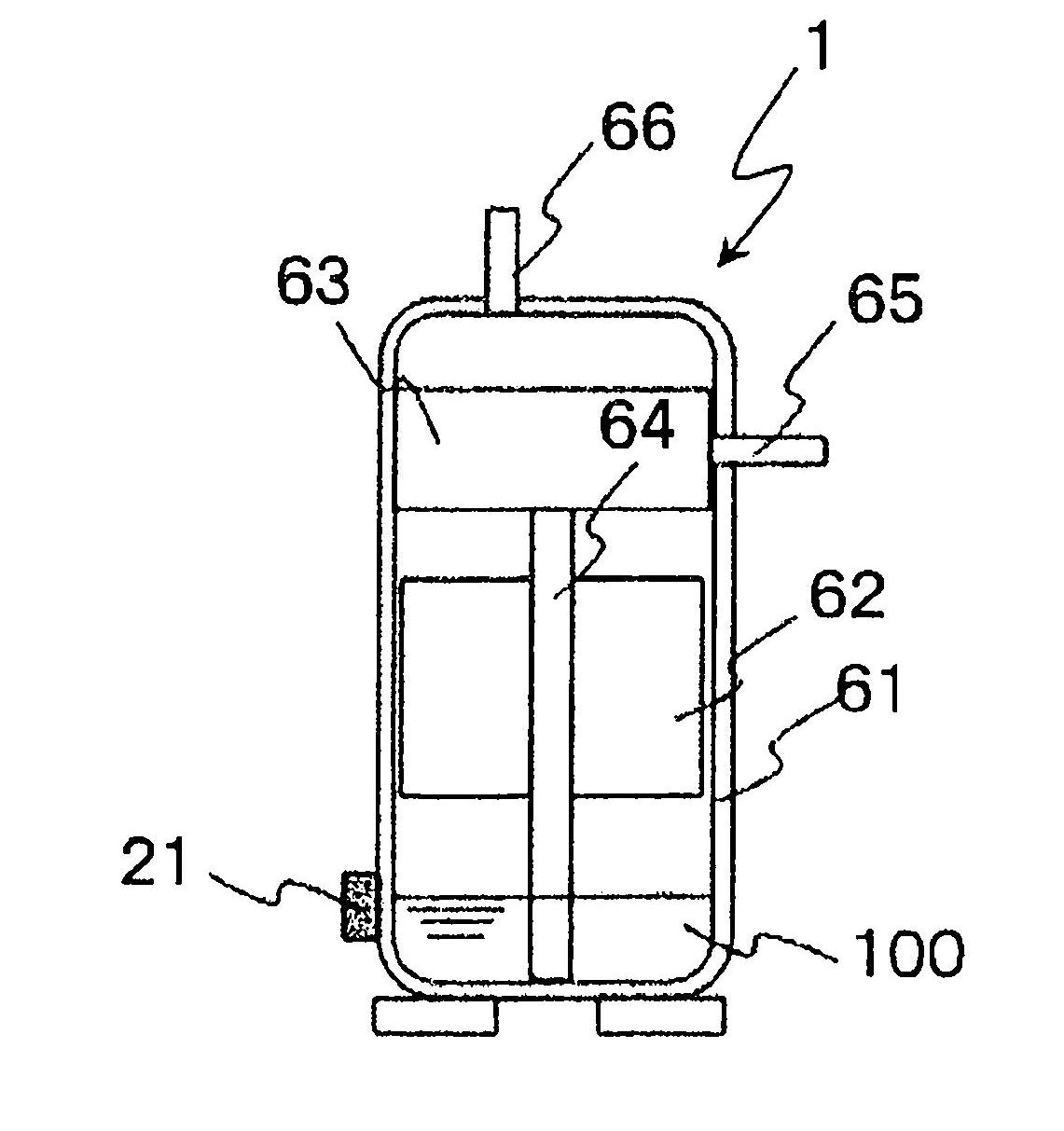

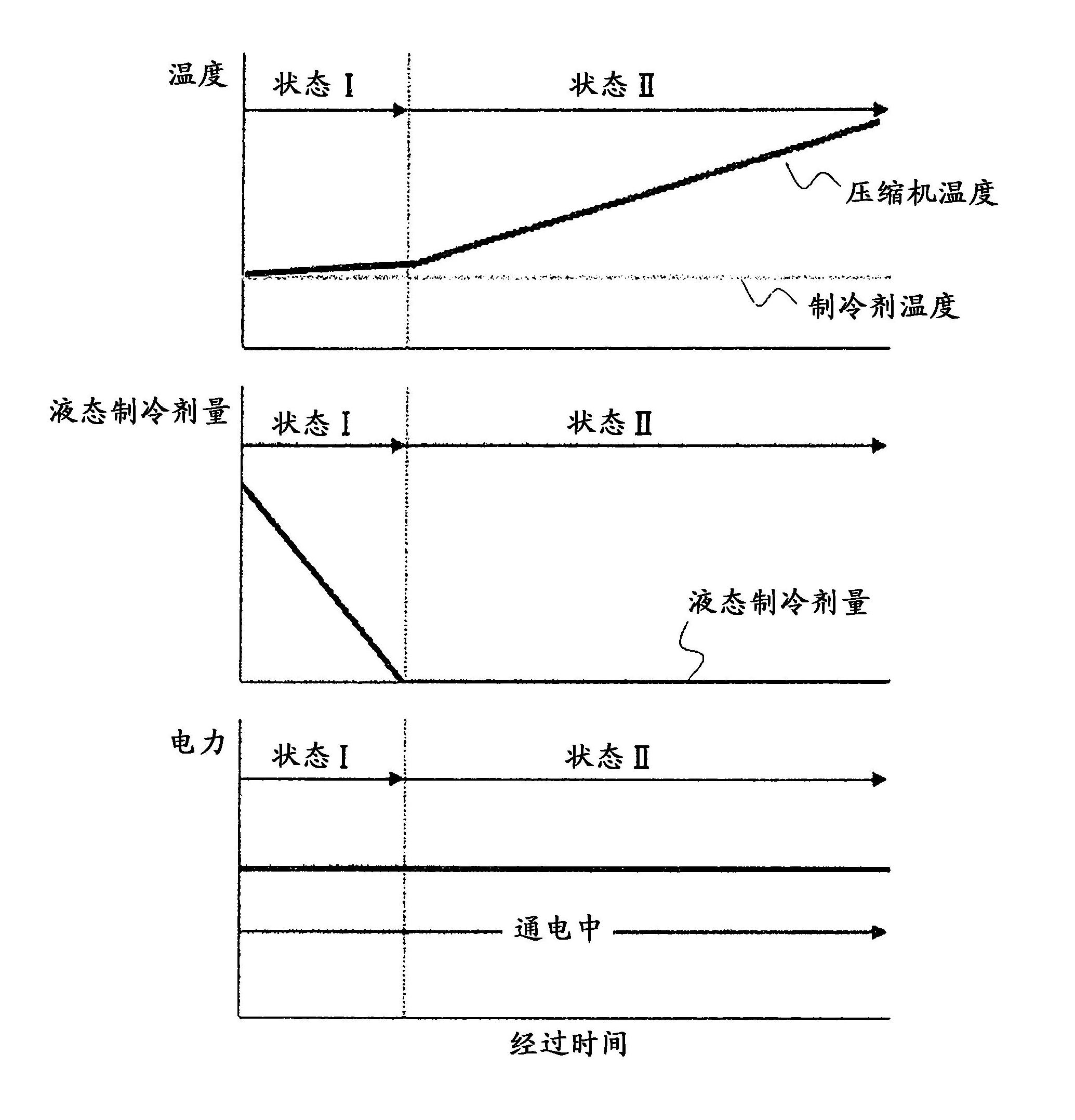

[0080] Image 6 It is a graph showing changes over time in the compressor temperature of the compressor 1, the amount of liquid refrigerant in the compressor 1, and the viscosity of the lubricating oil 100 during the stop period of the air conditioner 50 according to Embodiment 2 of the present invention.

[0081] Such as Image 6 As shown, while the air conditioner 50 is stopped, when the control device 31 heats the compressor 1 through the compressor heating unit 10, the amount of liquid refrigerant dissolved in the lubricating oil 100 in the compressor 1 is reduced due to vaporization. Then, due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com