Movable carbon dioxide storage tank used for coal mine

A carbon dioxide, mobile technology, used in fixed-capacity gas storage tanks, gas/liquid distribution and storage, ship construction details, etc., can solve problems such as lack of protective devices, damage, affecting carbon dioxide storage effect, etc., to improve thermal insulation. Performance, good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

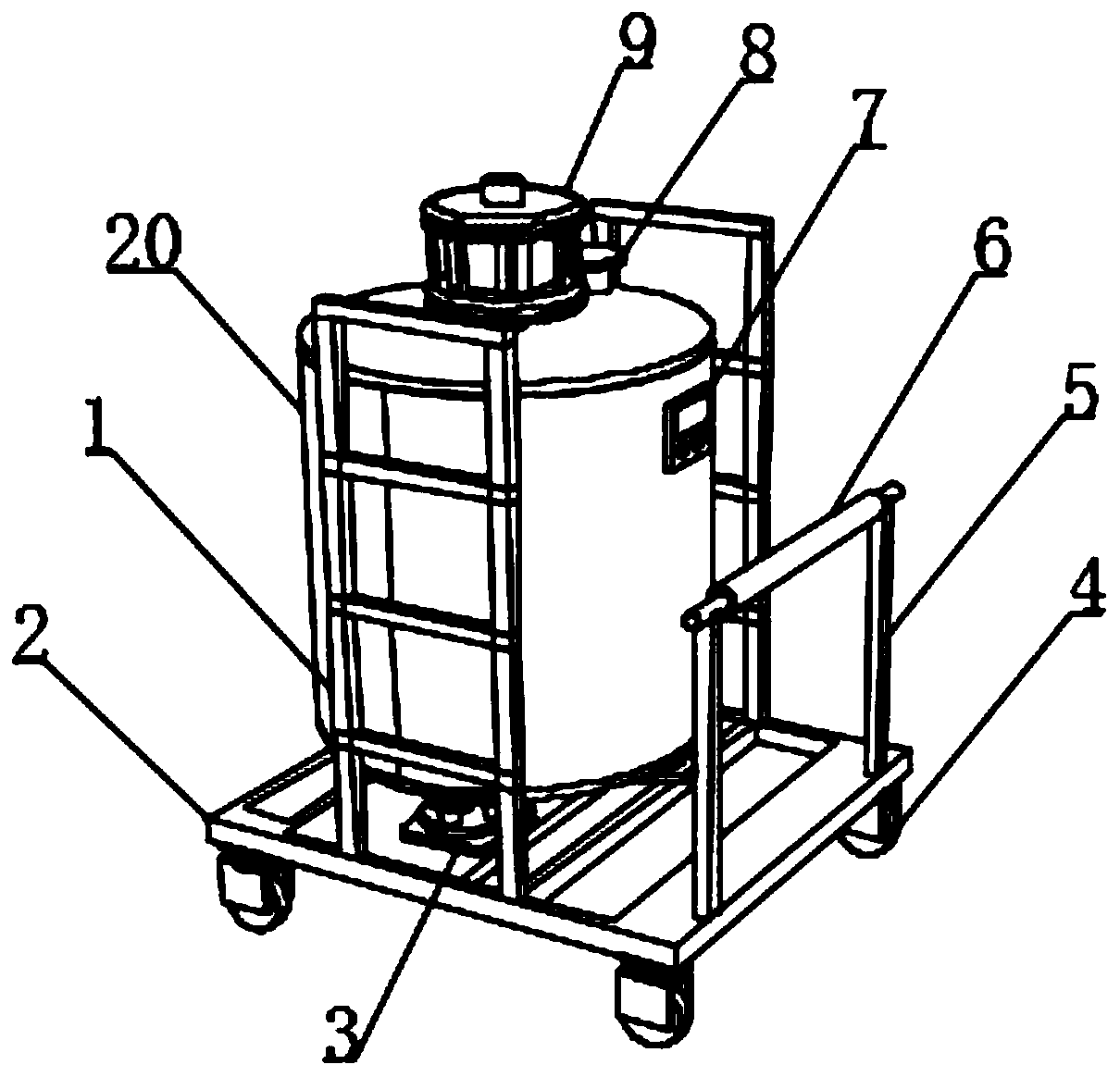

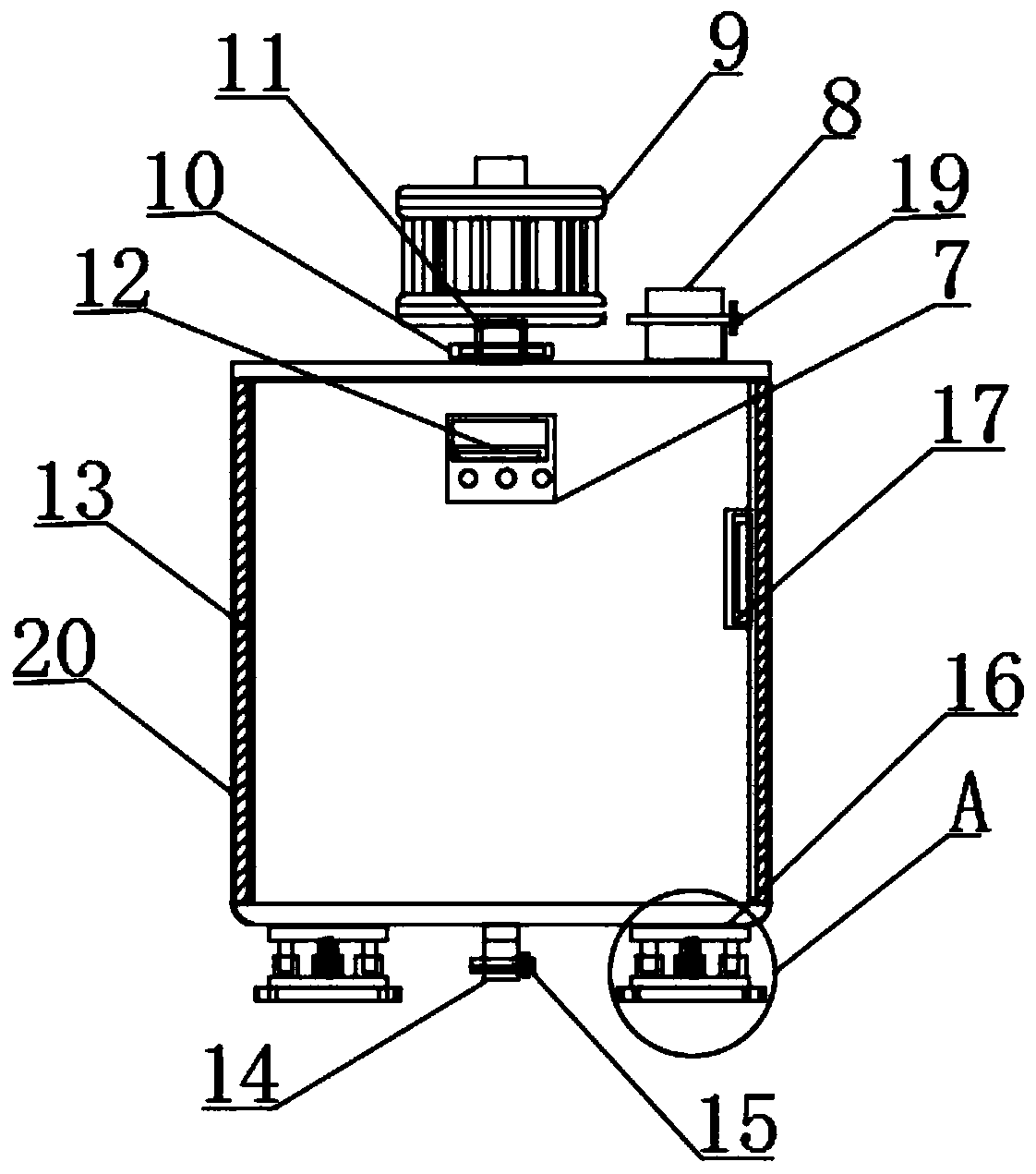

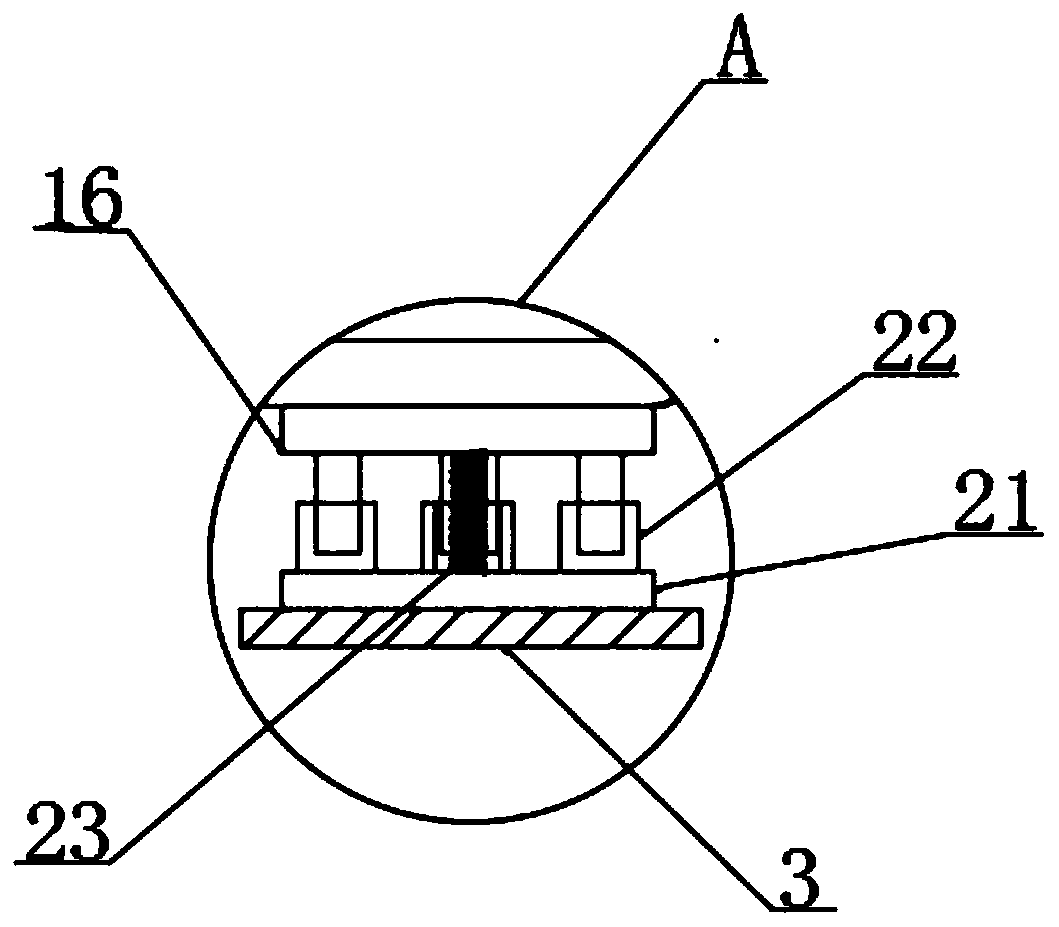

[0021] see Figure 1~4 , in an embodiment of the present invention, a mobile carbon dioxide storage tank for coal mines, comprising a mobile frame 2 and a storage tank 20 arranged above the mobile frame 2, a ladder frame 1 is fixedly arranged on both sides of the upper end of the mobile frame 2, and the mobile frame One end of 2 is fixedly provided with a push handle 5, the bottom position of the mobile frame 2 is fixedly provided with a mobile wheel 4, the position of the upper surface of the mobile frame 2 is fixedly provided with a buffer pad 3, and the position of the upper surface of the buffer pad 3 is fixedly provided with There is a second fixed plate 21, the upper end of the second fixed plate 21 is fixedly connected with a telescopic column 22, the upper end of the telescopic column 22 is fixedly connected with a first fixed plate 16, and an air compressor 9 is fixedly arranged above the storage tank 20, and the air compressor A connecting pipe 11 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com