Metamaterial and manufacturing method thereof

A technology of metamaterials and composite materials, applied in the field of metamaterials and its preparation, can solve the problems of conductive geometric structure destruction, conductive geometric structure melting, gasification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

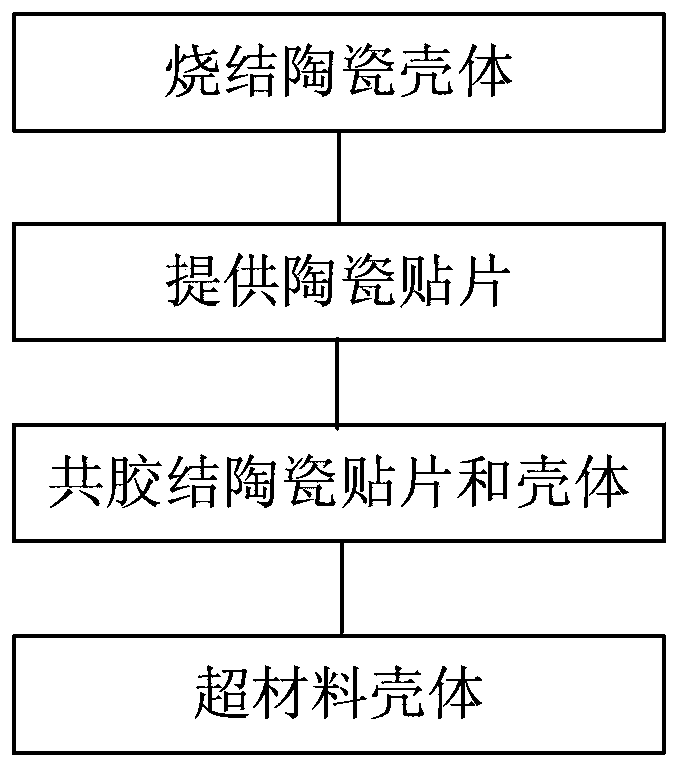

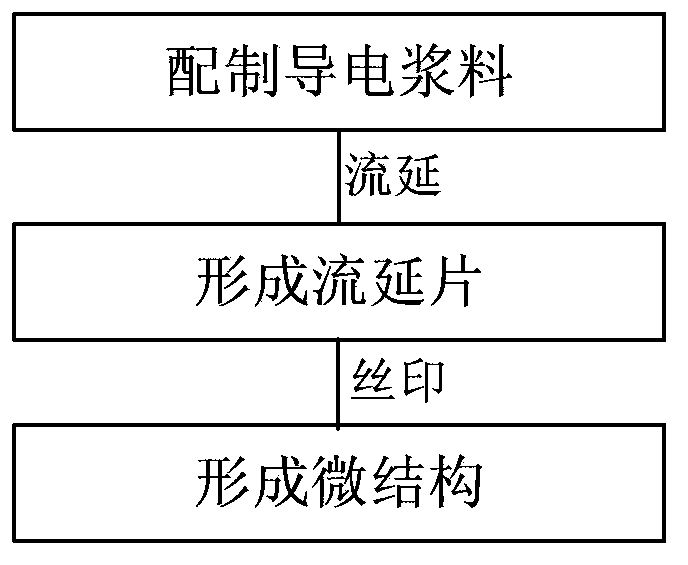

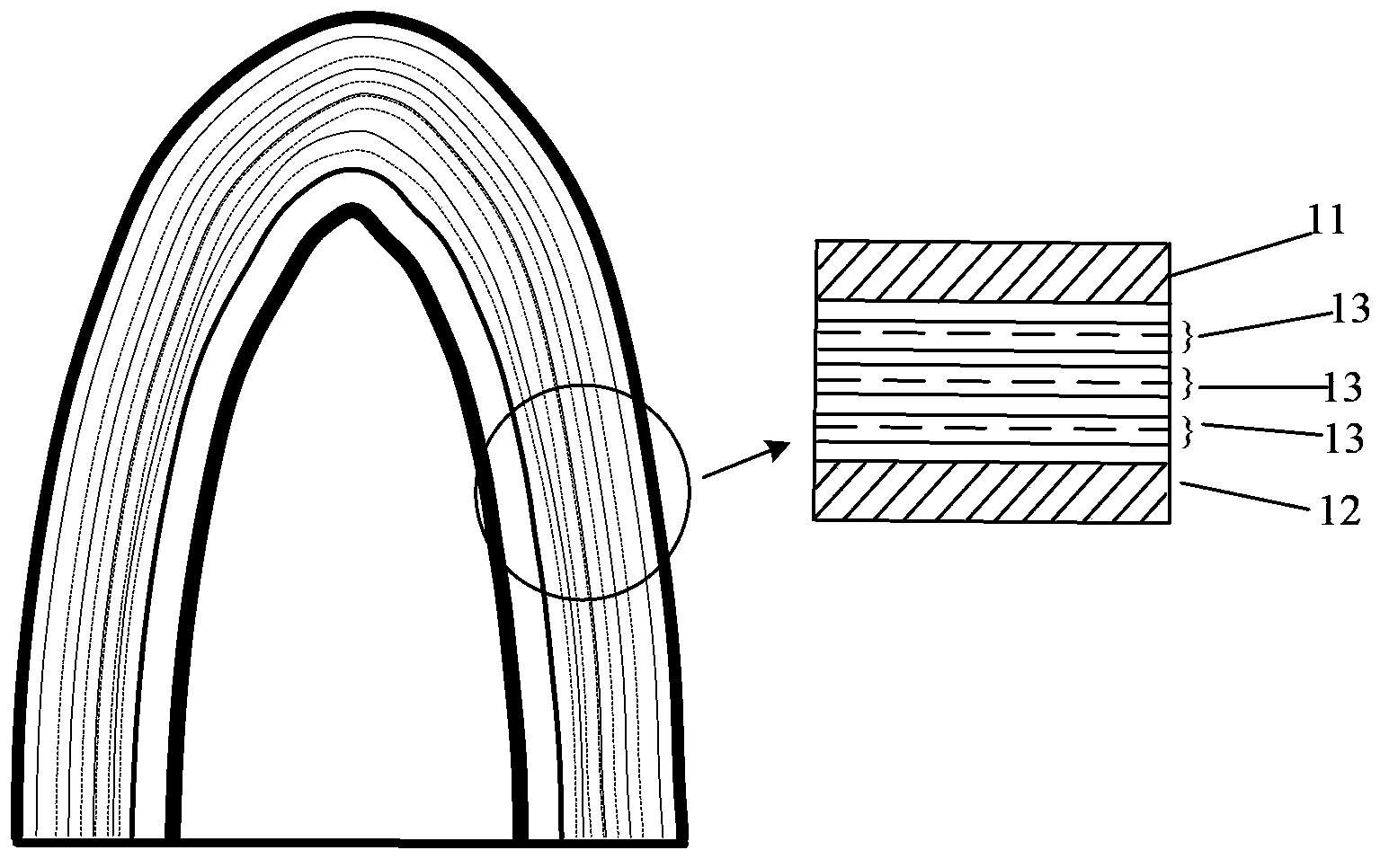

[0033] like figure 1 As shown, the metamaterial preparation method includes step 1, providing a dielectric shell 11 and a ceramic shell 12 . like image 3 As shown, the dielectric shell (outer shell) 11 and the ceramic shell (inner shell) 12 form a space curved surface shape. It should be noted that in Figure 3 to Figure 6 Among the structures shown, these and other subsequent drawings are only examples, they are not drawn to scale, and should not be construed as limiting the scope of protection actually claimed by the present invention. The dielectric shell 11 may be a ceramic shell, and its forming method may be sintering. In other embodiments of the present invention, the dielectric housing 11 is a composite material. The molding of the dielectric housing 11 specifically includes curing the dielectric housing. The composite material is a thermosetting or thermoplastic material, such as polyimide, polyester, polyester, etc. Tetrafluoroethylene, polyurethane, polyarylate...

no. 2 example

[0048] This embodiment follows the component numbers and part of the content of the previous embodiments, wherein the same numbers are used to denote the same or similar components, and descriptions of the same technical content are selectively omitted. For the description of the omitted part, reference may be made to the foregoing embodiments, and this embodiment will not be repeated. Parts similar to the first embodiment can refer to figure 1 , figure 2 , image 3 , Figure 4 .

[0049] refer to figure 1 , The method for preparing a metamaterial includes step 1, providing a dielectric shell 11 and a ceramic shell 12 . like image 3 As shown, the medium housing 11 is in the shape of a space curved surface. The dielectric shell 11 may be a ceramic shell, and its forming method may be sintering. In other embodiments of the present invention, the dielectric housing 11 is a composite material, and the molding of the dielectric housing 11 specifically includes curing the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com