Two-stage compression refrigerating unit for multi-temperature refrigeration storage and control method thereof

A compressor unit and refrigeration unit technology, applied in the direction of compressors, refrigerators, compressors, etc., can solve the problems of frequent load changes in multi-temperature cold storage, uneven load distribution in warehouses, damage to high-pressure compressor units under refrigerant return pressure, etc. Achieve the effects of precise control of oil return temperature, small size, improved work efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

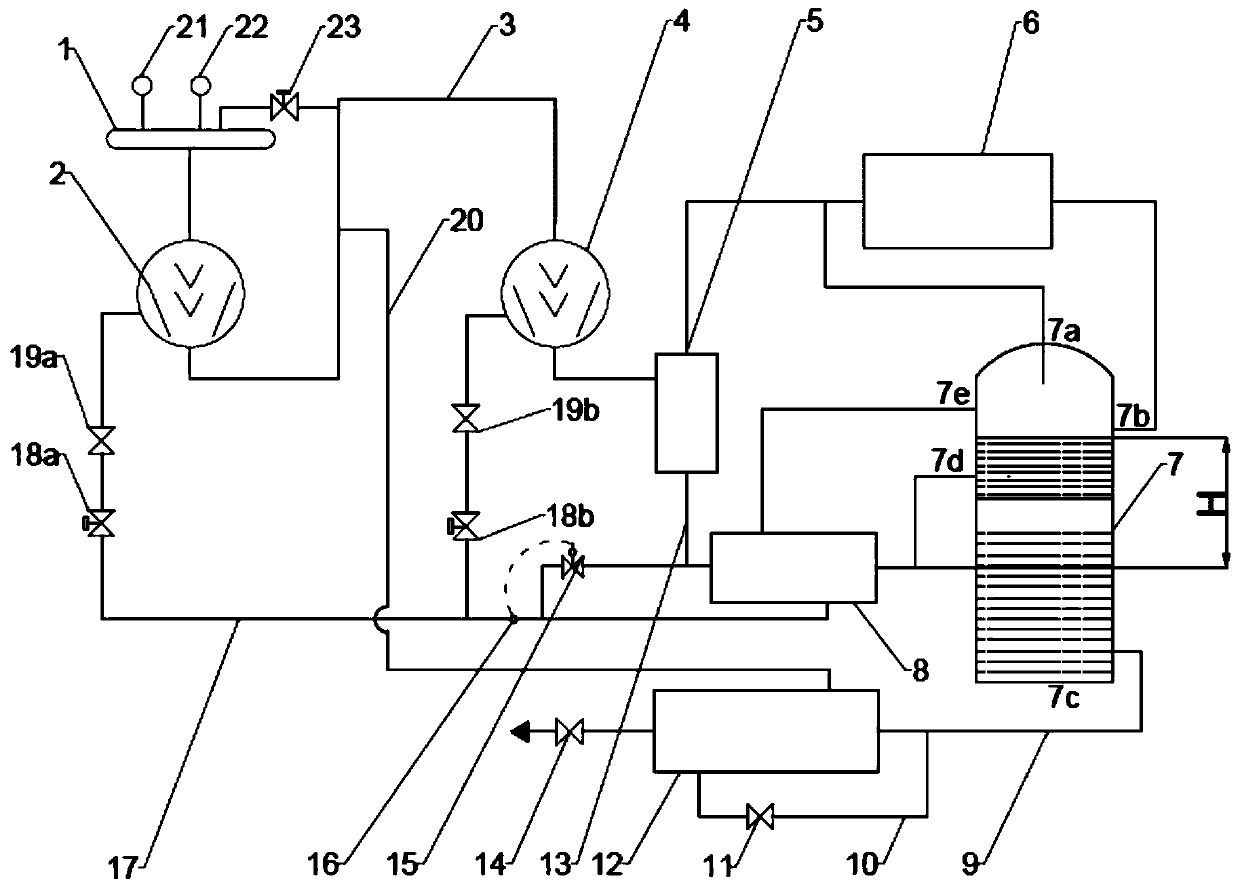

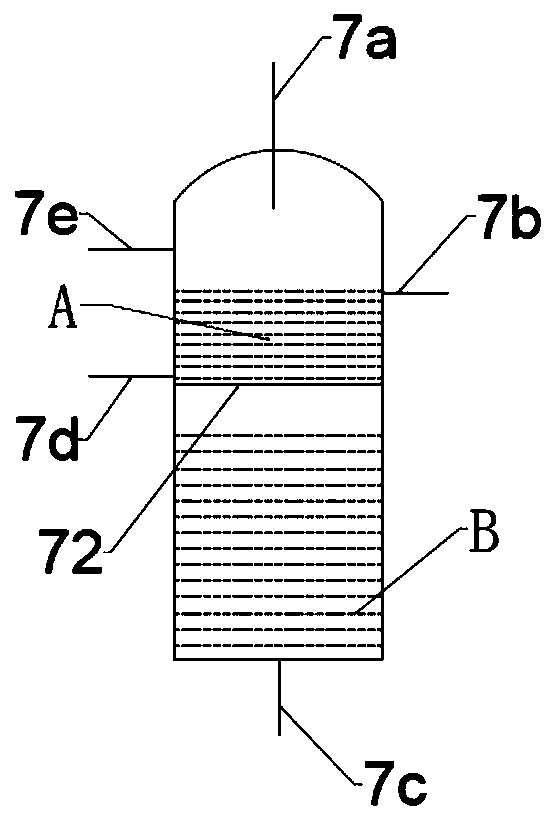

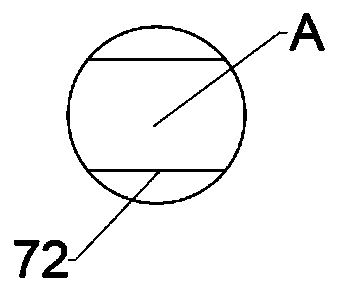

[0047] see figure 1 , figure 2 with image 3 In this embodiment, the two-stage compression refrigeration unit for multi-temperature cold storage includes: a low-pressure compressor unit 2, a high-pressure compressor unit 4, an oil separator 5, a condenser 6, a high-pressure liquid receiver 7, a subcooler 12 and an oil cooler 8 .

[0048] Such as figure 1 As shown, the return air of the cold storage user’s refrigerant is introduced into the gas collection main pipe 1, and the gas collection main pipe 1 is directly connected with the air inlet of the low-pressure compressor unit 2; connected to each other; a pressure sensor 21 and a temperature sensor 22 are set respectively for the gas collecting main pipe 1 .

[0049] The exhaust of the low-pressure compressor unit 2 is connected to the air inlet of the high-pressure compressor unit 4 through the medium-pressure pipeline 3; the exhaust port of the high-pressure compressor unit 4 is connected to the air inlet of the oil se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com