Engine fuel feed device

A fuel supply device and fuel supply technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of pressure rise, accumulation in the tank, internal temperature rise, etc., easy to achieve output control, avoid excessive rise, Avoid the effect of gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with the accompanying drawings.

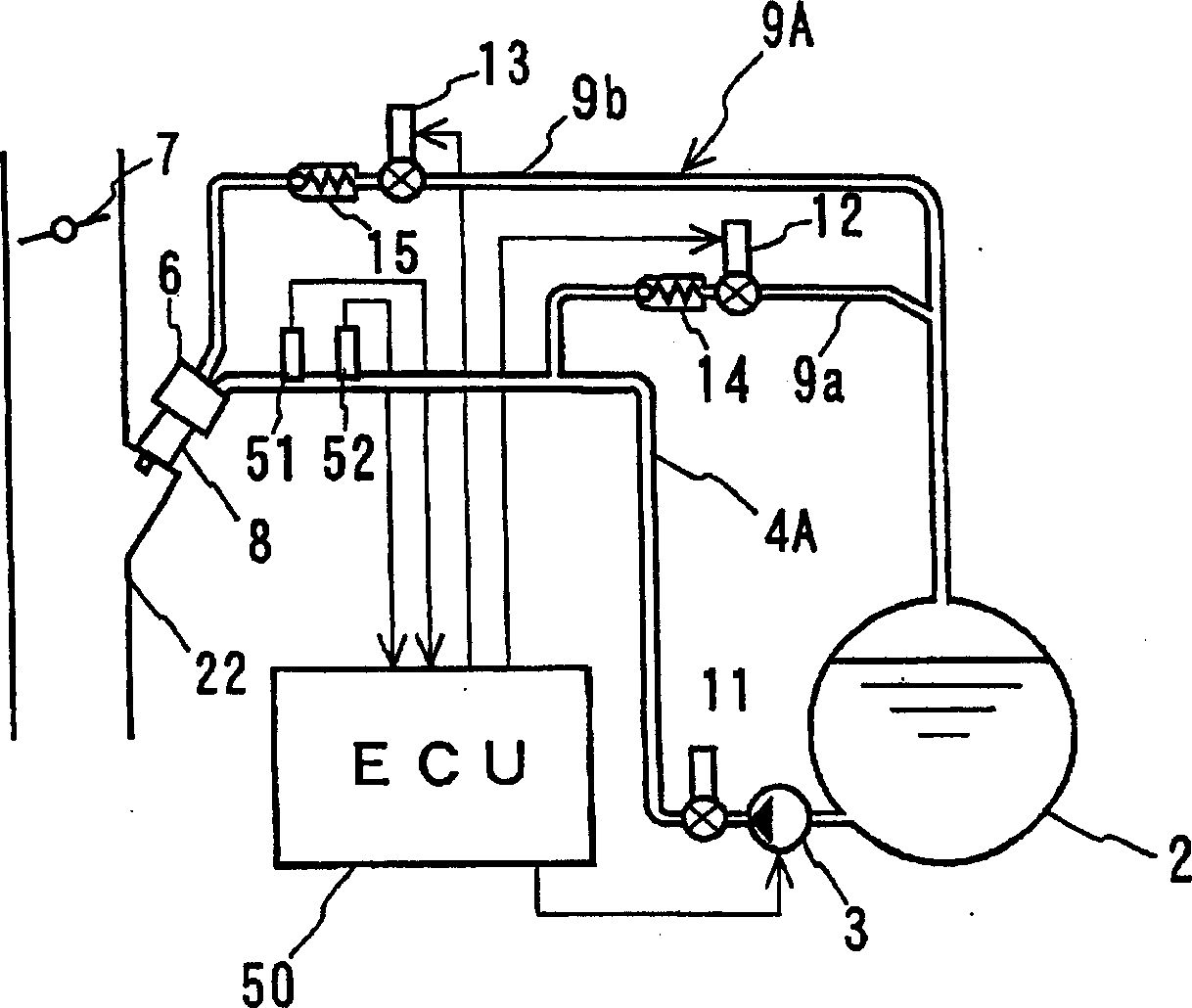

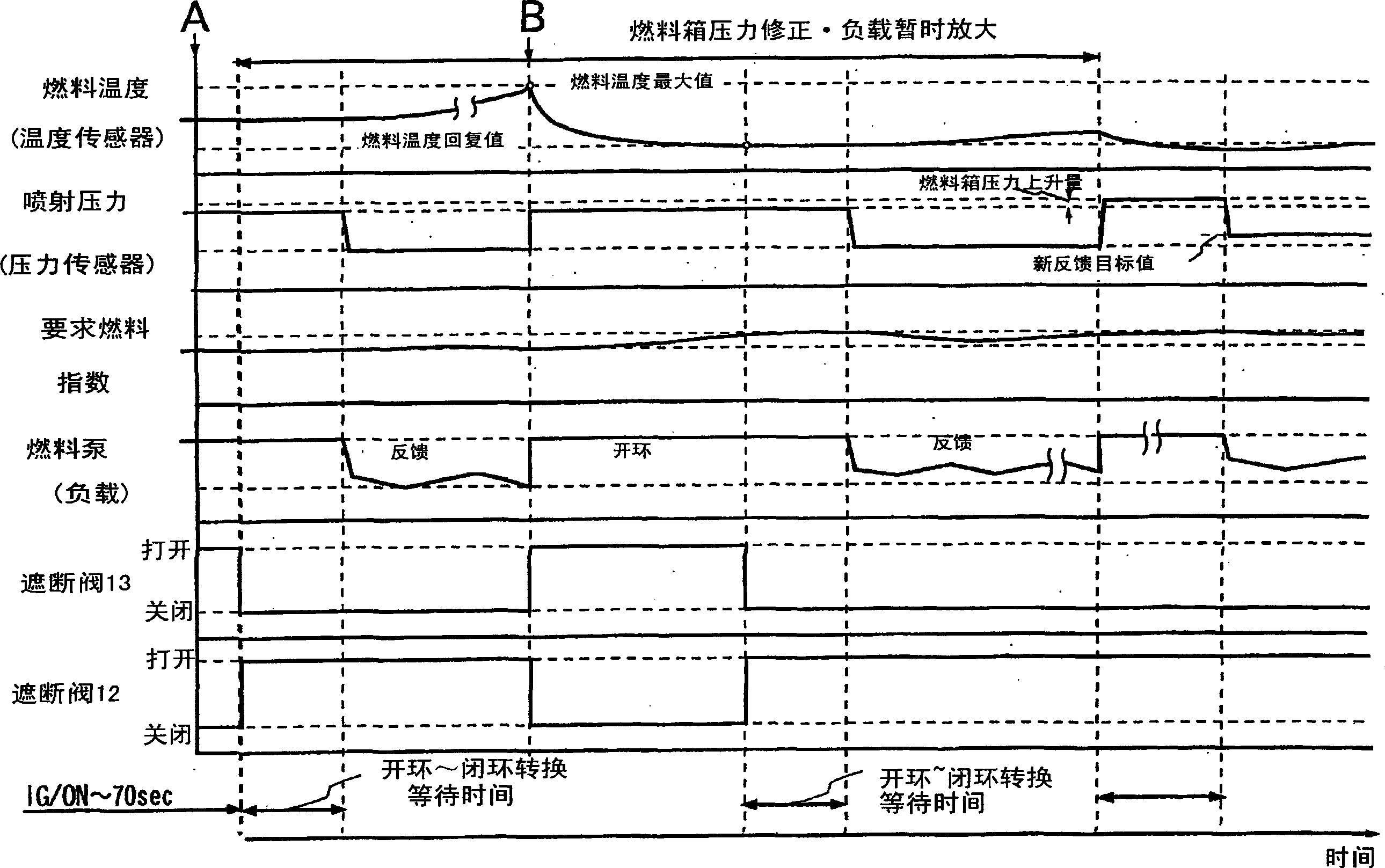

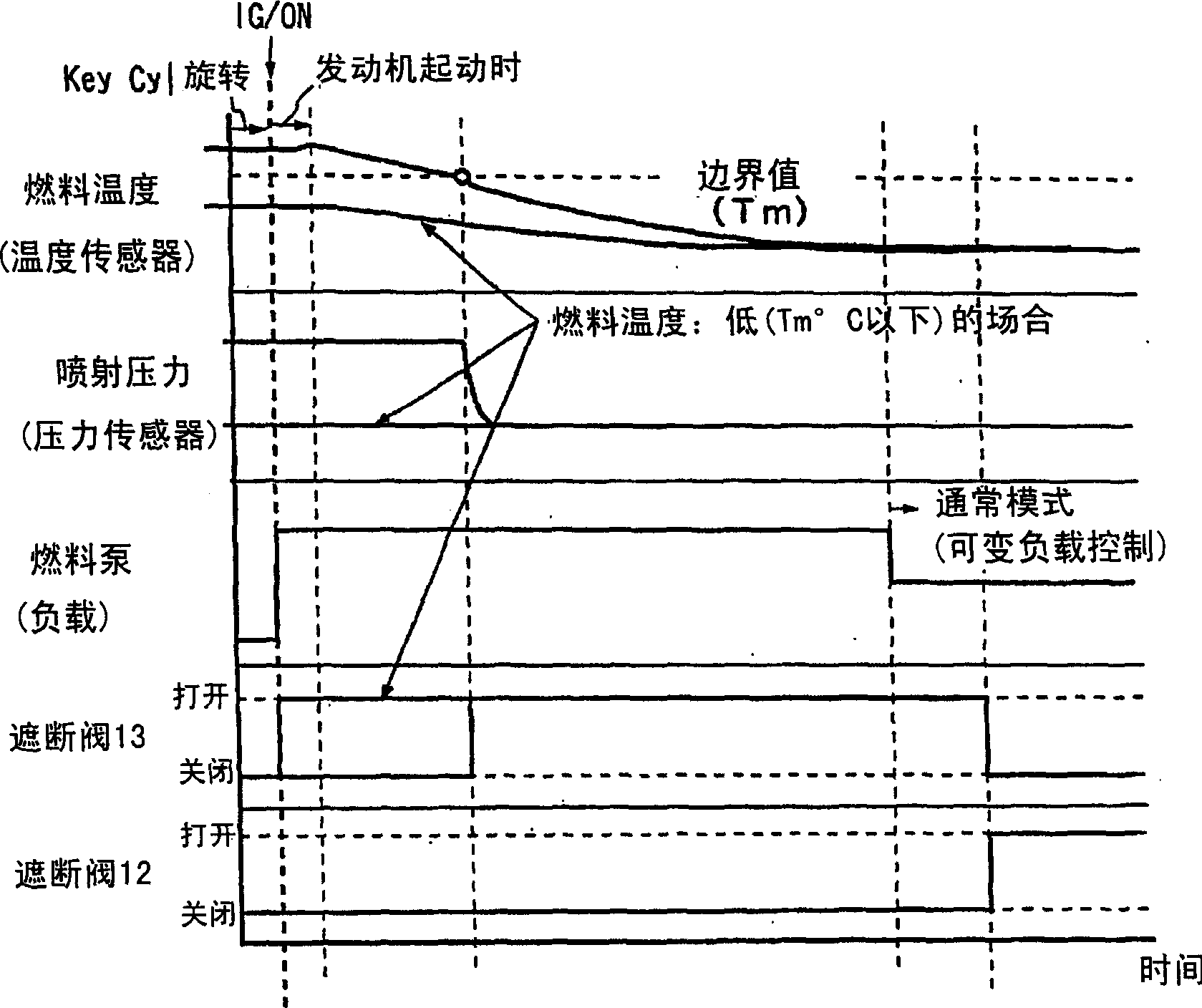

[0030] figure 1 Shows the layout of the fuel supply system of the engine equipped with the fuel supply device of this embodiment. The fuel pump 3 is arranged on the outlet side of the fuel tank 2, and the fuel supply line 4A is in the intake pipe 22 of the engine not shown. The middle part is arranged downstream of the throttle valve 7 and connected to a fuel guide 6 in which a plurality of injectors 8 are arranged.

[0031] In addition, in the fuel supply line 4A near the fuel tank 2 (for example, in the rear cargo tank of the vehicle, etc.), the first fuel return line 9a that is branched here and connected to the fuel tank 2 has a check valve 14 and Block valve 12. In addition, the second fuel return line 9b that extends from the tip side of the fuel guide 6 and merges on the downstream side of the shutoff valve 12 of the first fuel return line 9a has a check val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com