Device and method for suppressing refuse end gas injurant using pyrolysis and aerification technology

A technology of pyrolysis gasification and harmful substances, which is applied in the field of environmental protection, can solve the problems of increasing atmospheric acidic substances and threatening the atmospheric environment, and achieve the effects of low occurrence, elimination of dioxin, and obvious harmless effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

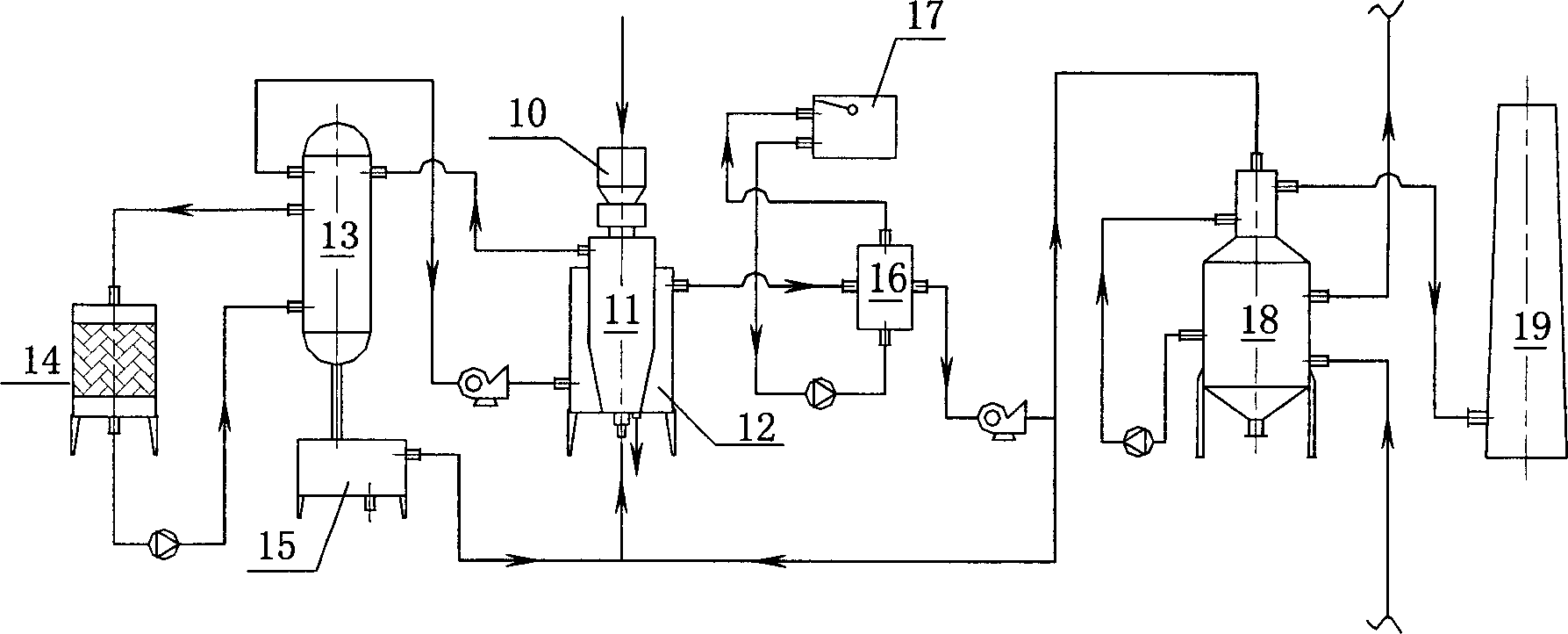

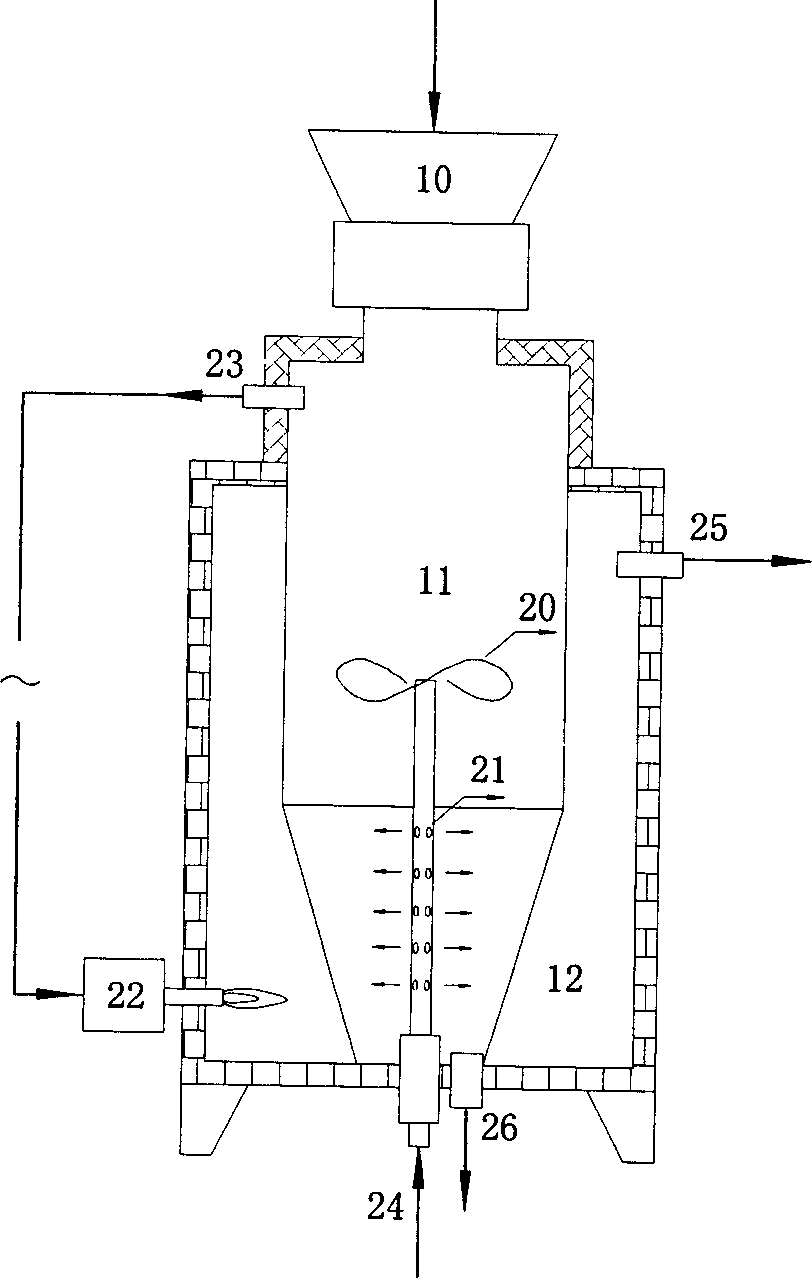

[0035] like figure 2 and image 3 As shown: the medical waste in the present invention is put into the hopper 10 at the top of the pyrolysis gasification furnace, stirred evenly by the agitator 20, scattered to the bottom of the pyrolysis gasification chamber 11, pyrolyzed and gasified at 600-800°C, and produced The combustible gas enters the condenser 13 through the outlet 23 to remove water vapor and tar, and enters the combustion chamber 12 through the combustion nozzle 22 for combustion at 800-1000 ° C. The high-temperature flue gas after combustion is discharged from the flue gas outlet 25 at the top of the combustion chamber After the tar and water vapor removed in the condenser 13 entered the oil-water separator 15, the separated condensed water was sent to the air-water delivery equipment 21 at the bottom of the pyrolysis gasification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com