Device for preparing clean coal by thermally decomposing, gasifying and semi-carbonizing waste

A technology of pyrolysis gasification and gasification device, which is applied in the direction of waste fuel, biofuel, direct heating dry distillation, etc., and can solve the problems of reducing thermal efficiency, thermal shock, and shortening the life of semi-carbonization furnaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

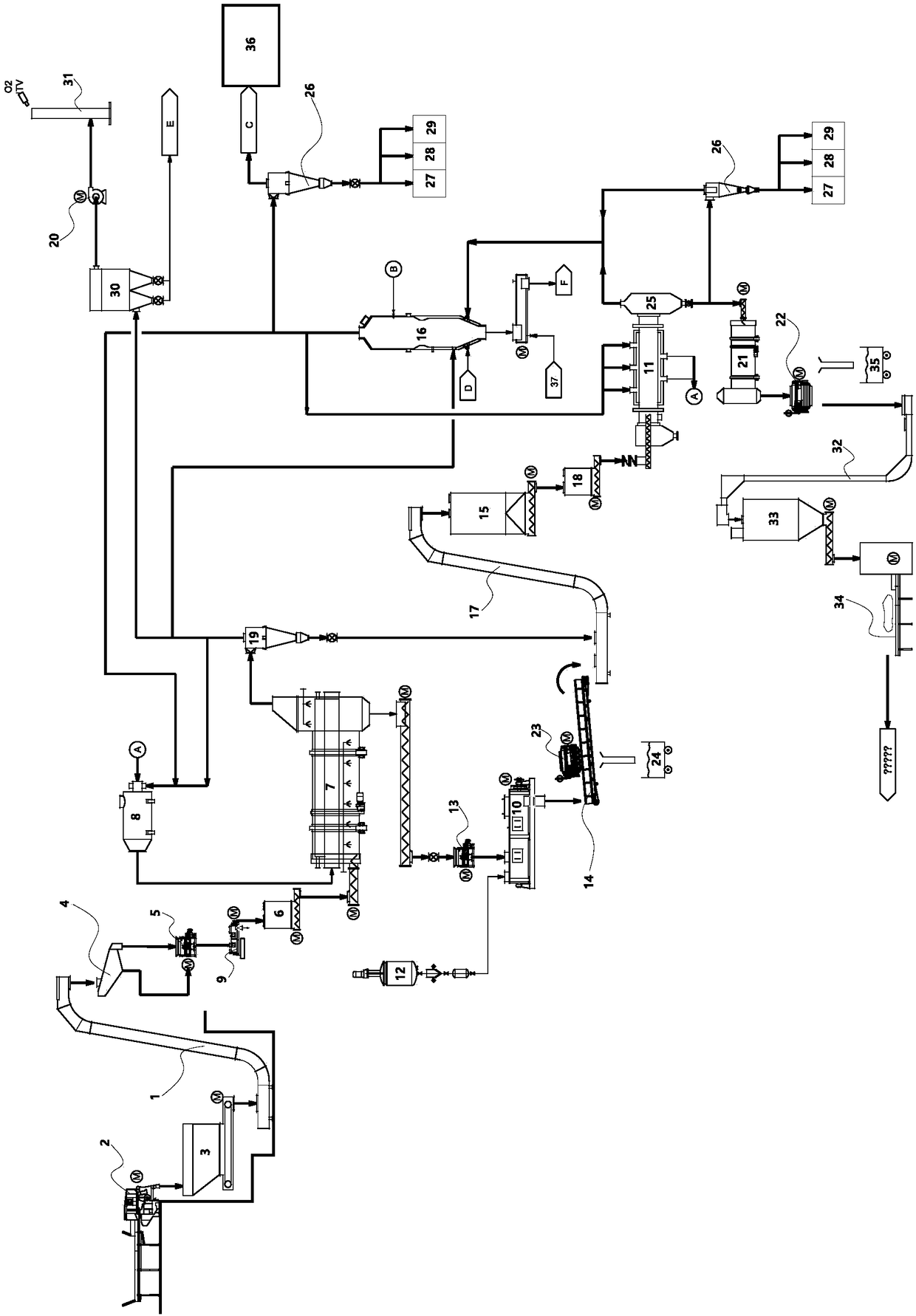

[0033] The following with attached figure 1 A device for preparing clean coal by pyrolysis, gasification and semi-carbonization of waste according to the present invention will be further described in detail. The percentages in the text are all percentages by weight.

[0034] A device for preparing clean coal by pyrolysis, gasification and semi-carbonization of waste according to the present invention, please refer to figure 1 The relevant figures in the figure include a raw material supply system, a raw material pretreatment system, a pyrolysis semi-carbonization device, a combustion gasification device, a food additive addition device 12, a clean coal cooling collection system and a synthesis gas reuse system 37. The raw material supply system It is connected with the raw material pretreatment system for drying raw materials, and food additives are filled in the food additive addition device 12, and the food additive addition device 12 and the raw material pretreatment syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com