Loop-shaped heat pipe and electronic device

A technology of annular heat pipes and electronic components, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of reduced cooling performance, lack of thermal insulation, pressure resistance and airtight reliability, etc., to achieve effective cooling , the effect of stable circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

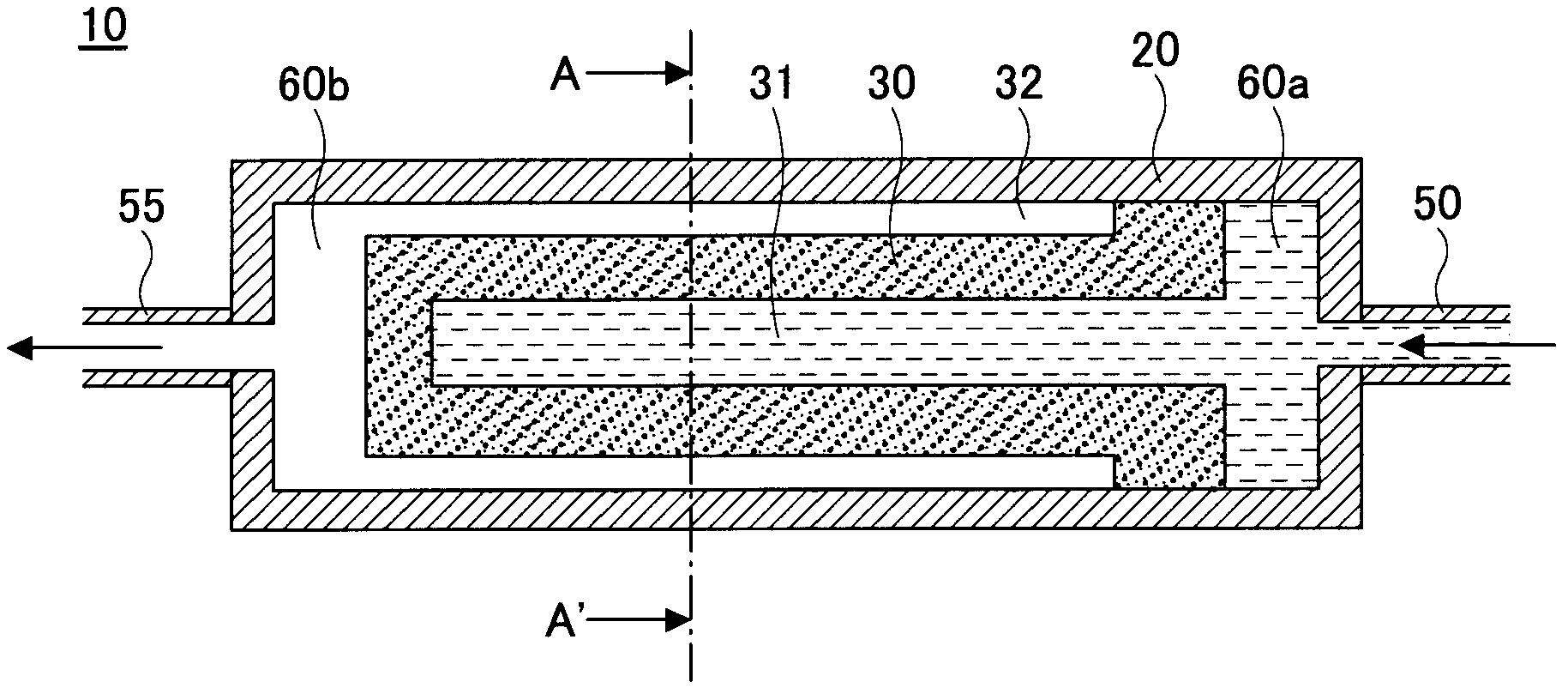

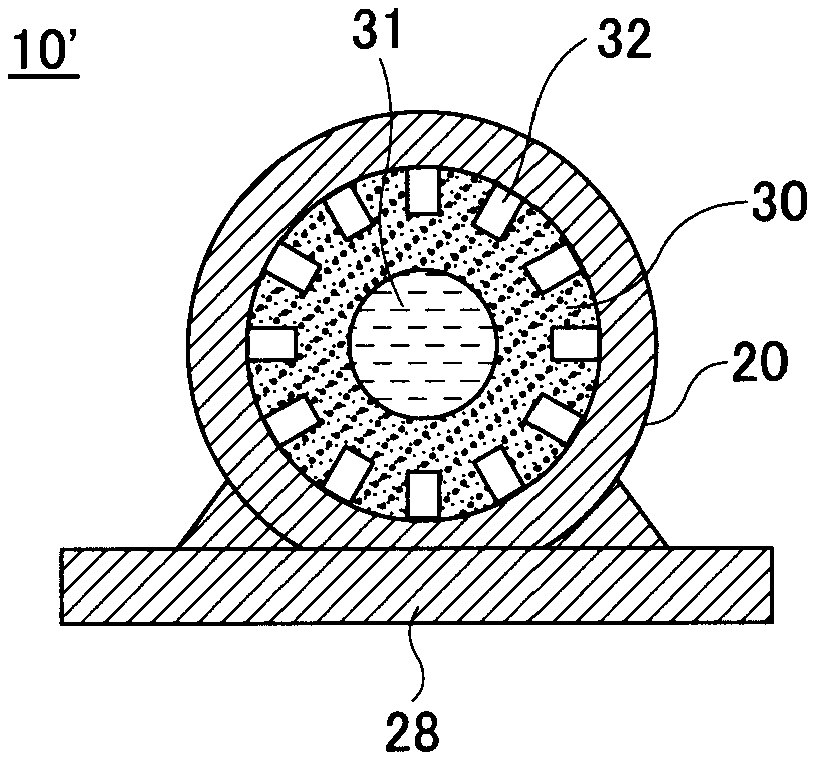

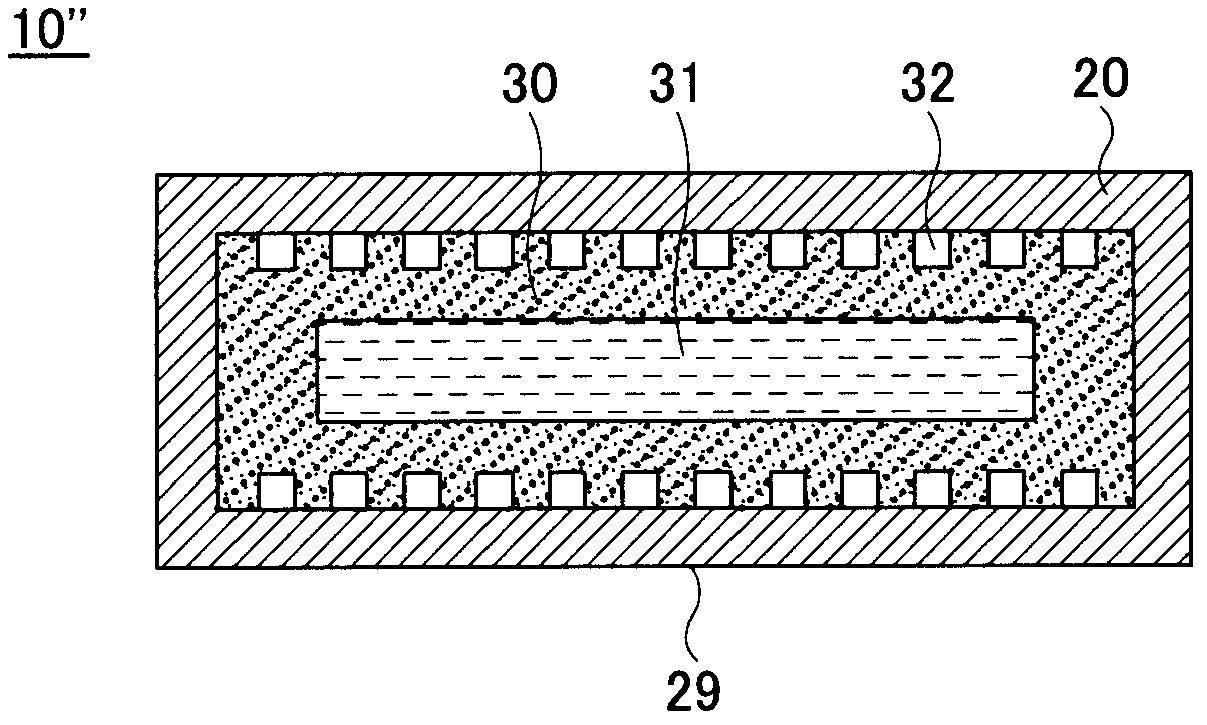

[0054] Hereinafter, embodiments will be described in detail with reference to the drawings. However, various constituent elements in the drawings are not necessarily drawn on the same scale. Also, the same or similar reference signs are used for the same or corresponding components in a plurality of drawings.

[0055] First, refer to Figure 3A — Figure 3D The evaporator 110 included in the loop heat pipe according to one embodiment will be described. Figure 3A The main components of the evaporator 110 are shown in an exploded view. Figure 3B shown from other directions in Figure 3A The shunt 140 shown in . and, Figure 3C is observed along the flow of the working fluid by Figure 3A The cross-sectional view of the evaporator 110 obtained from the constituent elements shown in Figure 3D shown in Figure 3C The BB' section. Among them, please note Figure 3C Not a cross-sectional view when cutting the evaporator with a plane.

[0056] In the illustrated example, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com