Magnesium-aluminum layered double hydroxide/graphene oxide/wood-based composite material as well as preparation method and application thereof

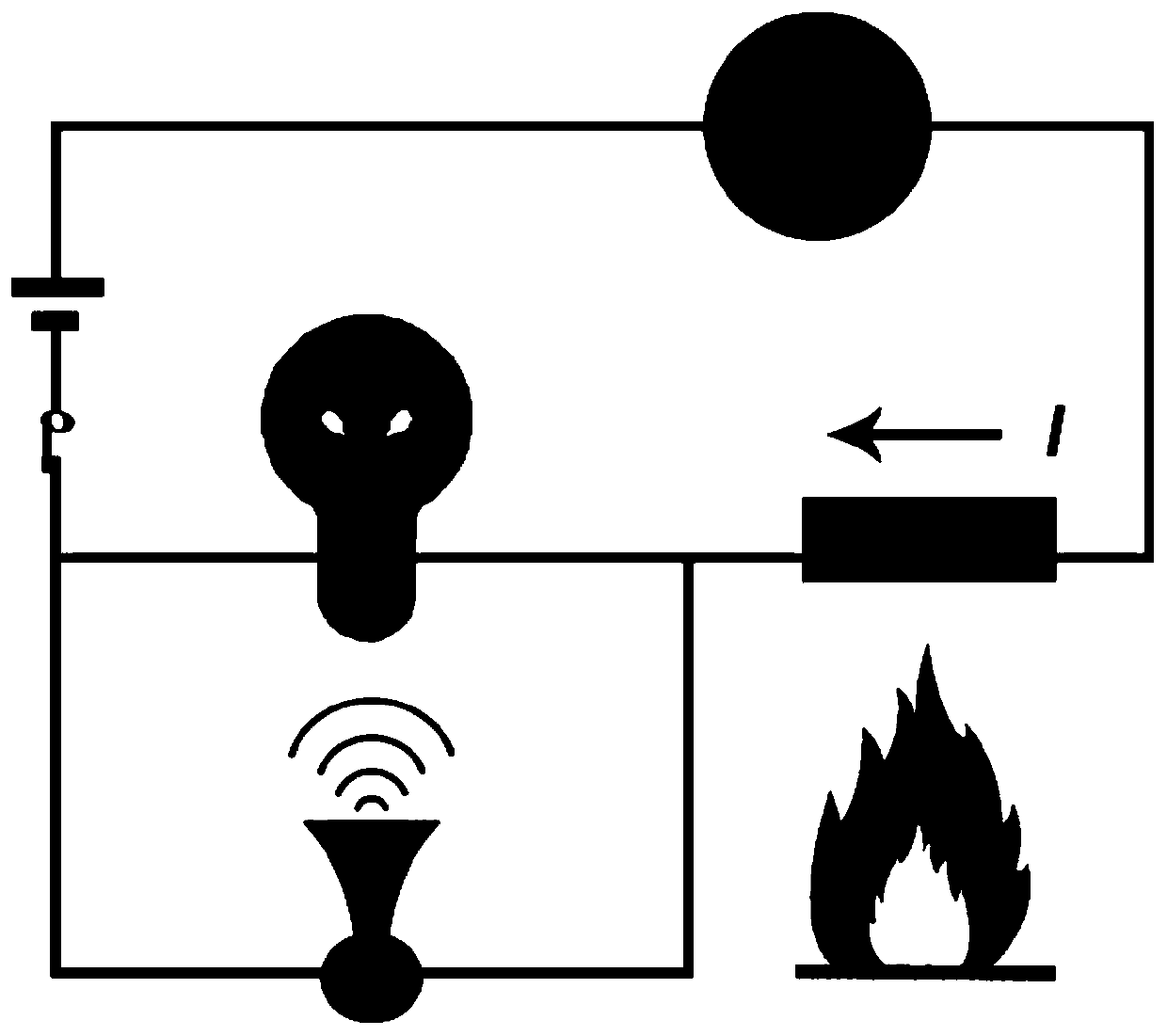

A technology of hydroxide and composite materials, which is applied in the field of wood composite materials, can solve the problems of lack of research on fire early warning, and achieve the effects of preventing fire from spreading, low energy consumption, and prolonging the alarm time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

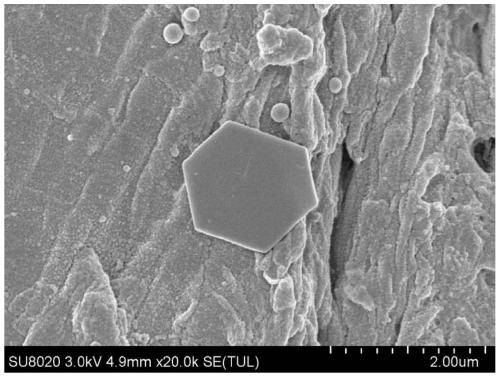

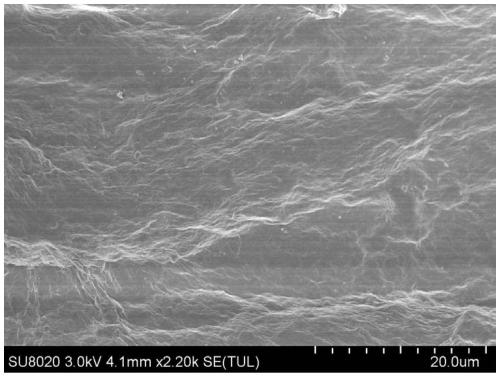

[0039] Step S1: Immerse poplar wood in an aqueous solution containing 0.06 mol / L magnesium nitrate, 0.03 mol / L aluminum nitrate and 0.5 mol / L urea, and react at a low temperature of 120 °C for 24 h under hydrothermal conditions;

[0040] Step S2: The poplar treated in step S1 is vacuum-dried at 50° C. for 12 hours, and the wood modified with magnesium-aluminum double hydroxide can be obtained;

[0041] Step S3: adding 60 mg of graphene oxide to 30 mL of water, and after 1 h of mechanical stirring and 30 min of ultrasonic treatment, a graphene oxide suspension can be obtained;

[0042] Step S4: drop the graphene oxide suspension dropwise on the surface of the wood modified with magnesium-aluminum layered double hydroxide, and then place the wood to dry at 50° C. for 4 hours; repeat the dropping-drying process 3 times The magnesium-aluminum layered double hydroxide / graphene oxide / wood-based composite material is prepared.

Embodiment 2

[0044] Step S1: Immerse poplar wood in an aqueous solution containing 0.06 mol / L magnesium nitrate, 0.03 mol / L aluminum nitrate and 0.5 mol / L urea, and react at a low temperature of 120 °C for 24 h under hydrothermal conditions;

[0045] Step S2: The poplar treated in step S1 is vacuum-dried at 50° C. for 12 hours, and the wood modified with magnesium-aluminum double hydroxide can be obtained.

Embodiment 3

[0047] Step S1: Immerse poplar wood in an aqueous solution containing 0.06 mol / L magnesium nitrate, 0.03 mol / L aluminum nitrate and 0.5 mol / L urea, and react at a low temperature of 120 °C for 24 h under hydrothermal conditions;

[0048] Step S2: The poplar treated in step S1 is vacuum-dried at 50° C. for 12 hours, and the wood modified with magnesium-aluminum double hydroxide can be obtained;

[0049] Step S3: adding 60 mg of graphene oxide to 30 mL of water, and after 1 h of mechanical stirring and 30 min of ultrasonic treatment, a graphene oxide suspension can be obtained;

[0050]Step S4: Add the wood treated in step S2, 60 mg of dopamine hydrochloride, and 36 mg of trimethylolmethylamine to the graphene oxide suspension treated in step S3, stir in a water bath at 60°C for 12 h, and then take out the wood and rinse with clean water After cleaning, it was dried at 50 °C to obtain a magnesium-aluminum layered double hydroxide / graphene oxide / wood-based composite material prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com