Beam shaping mechanism, laser source system and laser 3D printing equipment and method

A beam shaping and 3D printing technology, applied in the optical field, can solve the problems of incomplete melting of powder materials, single laser beam mode, low energy at the edge of the spot, etc., to avoid high intermediate overlap rate, expand functions, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. However, those skilled in the art know that the present invention is not limited to the drawings and the following embodiments.

[0027]

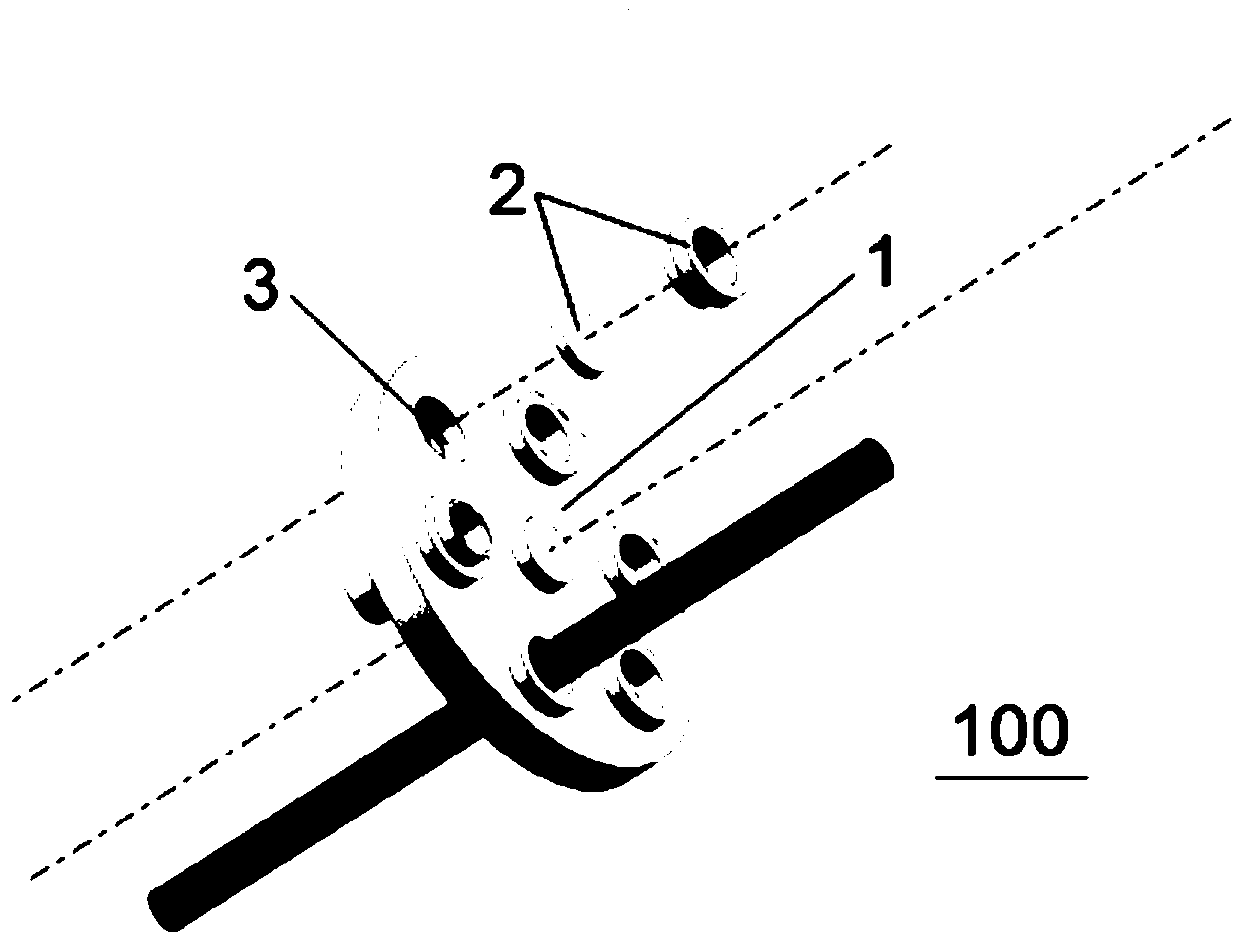

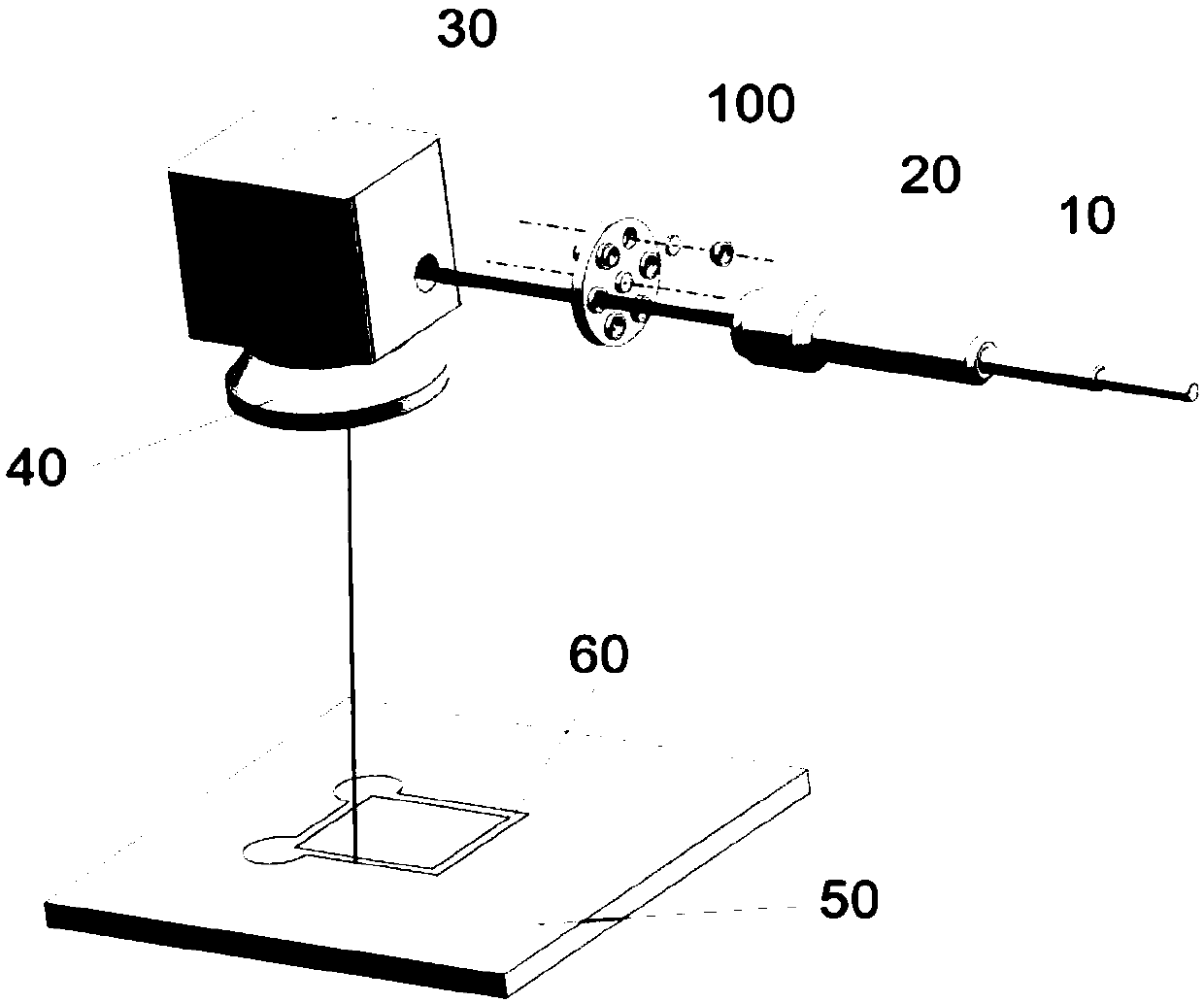

[0028] refer to figure 1 , the embodiment of the present invention proposes a beam shaping mechanism 100, which can be used in laser processing equipment such as laser 3D printing equipment, which includes a disc-shaped wheel 1 and one or more A beam shaper 2 for laser beam shaping, the runner 1 is provided with a plurality of holes 3 along the circumferential direction, the centerlines of the holes 3 are parallel to the central axis of the runner 1, and the centerlines of each hole 3 are parallel to the central axis of the runner 1. The distances between the central axes of the runne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com