PVA foaming material and foaming method thereof

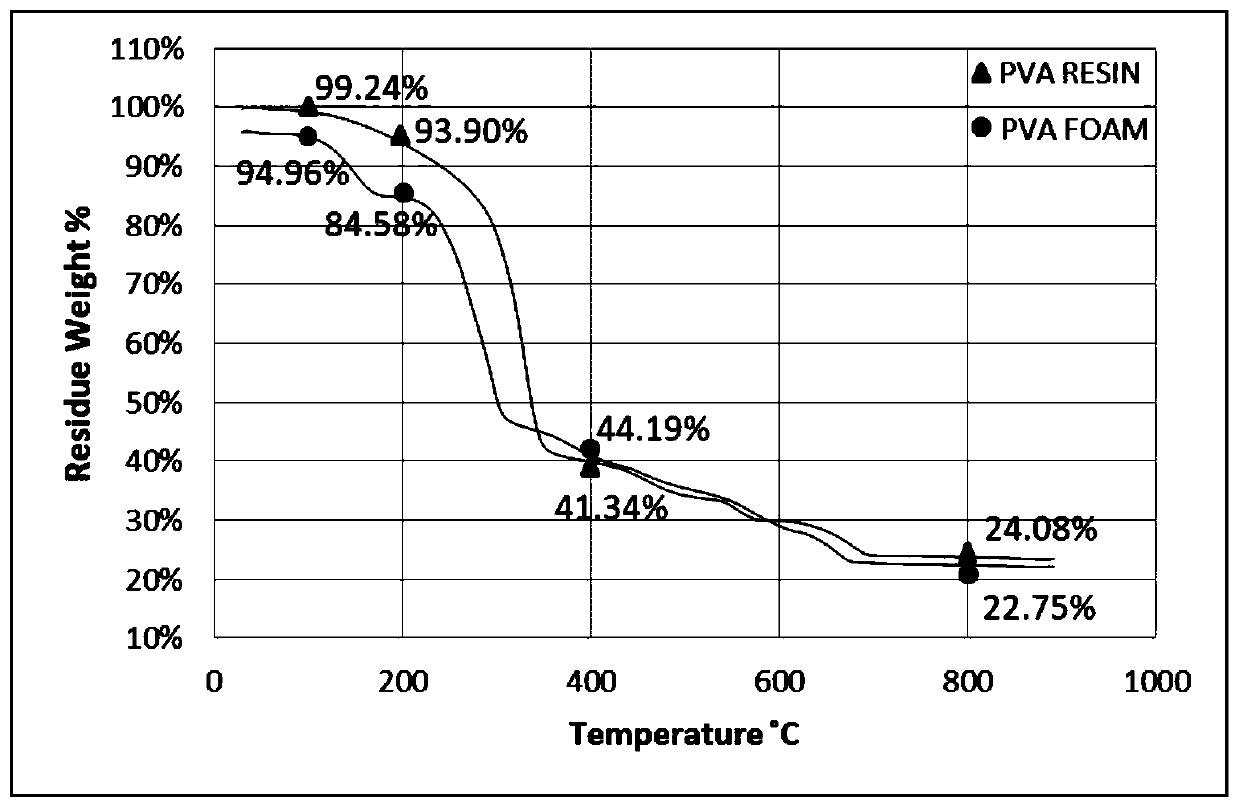

A foaming material and foaming agent technology, applied in the field of foaming materials, can solve the problems of PVA gasification, high production cost, complicated process, etc., and achieve the effects of high compressive strength, light weight and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

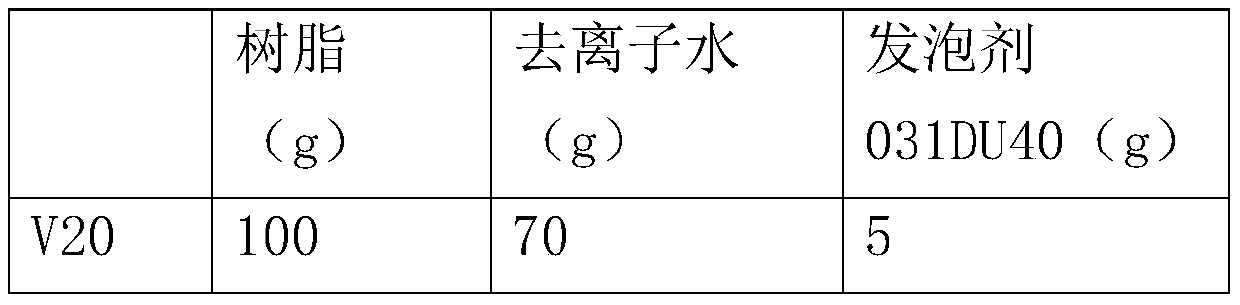

[0012] First, prepare three groups of raw materials according to the following table, and prepare three groups of foaming samples:

[0013]

[0014]

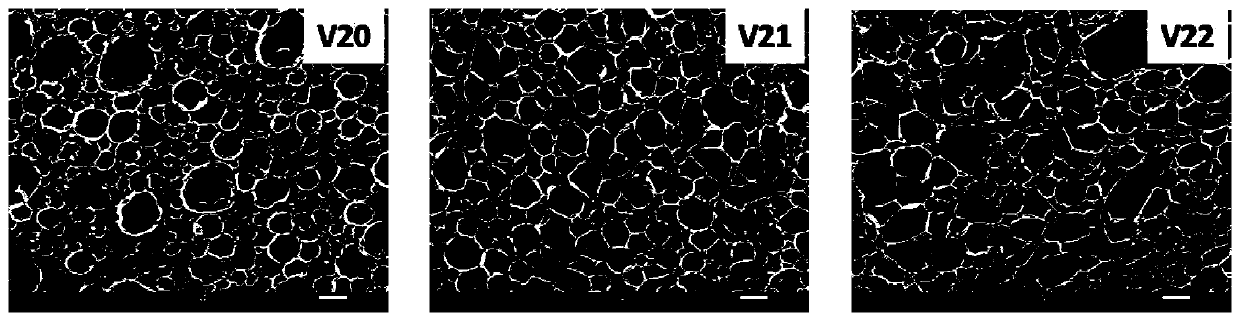

[0015] Then, prepare three groups of foaming samples V20, V21 and V22 according to the following procedure: take PVA resin and deionized water, stir the mixture in a 90°C water bath for 2 hours, add foaming agent to the above mixture, and stir well . The temperature of the single-screw extruder is 80-100-105-110°C, the screw speed is 100rpm, and then the uniform solution is added to the single-screw extruder for pre-foaming. After pre-foaming, weigh 350g of pre-foaming samples and add Put the mold into a 200x200x23mm mold for the second foaming, then put the mold in a hot press at 100°C / 2 minutes, and finally put the mold in an oven at 60°C / 12 hours to get foamed V20, V21 and V22 PVA samples.

[0016] The solubility of described PVA resin provided by SRJJ company is the PVA resin of W grade; Foaming agent 031DU40 powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com