Ceramic nanometer composite material for heat barrier coating and preparation method of ceramic nanometer composite material

A nano-composite material and thermal barrier coating technology, applied in the field of ceramic nano-composite materials, can solve the problems of difficulty in meeting the turbine inlet temperature, high thermal expansion coefficient, complicated preparation process, etc., and achieve good high-temperature chemical stability, high phase purity, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

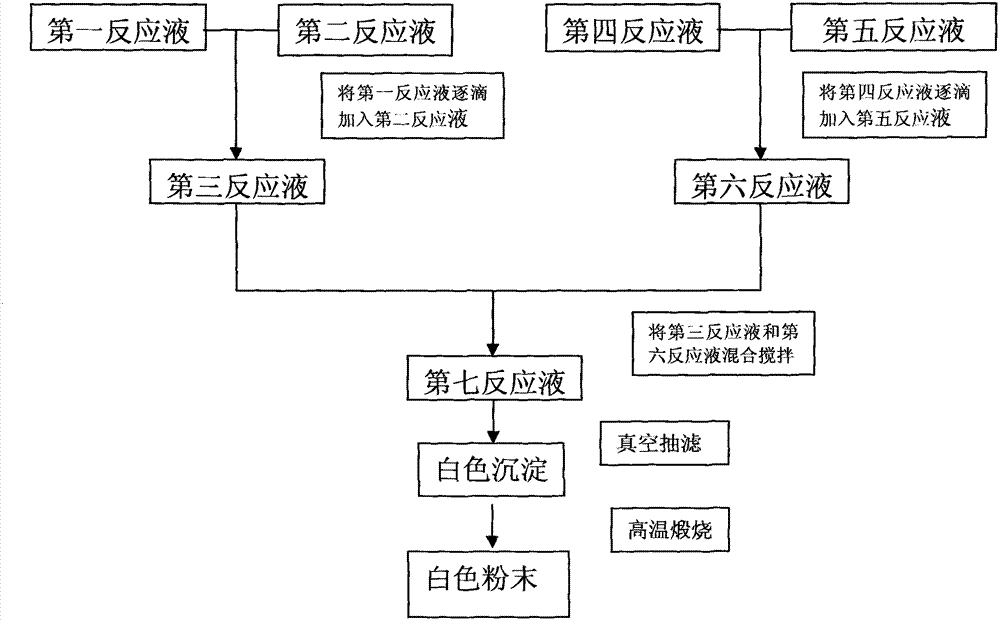

[0048] The preparation method comprises the following steps:

[0049] Step 1: Prepare the first reaction solution

[0050] With Sr(NO 3 ) 2 and Zr(NO 3 ) 4 ·5H 2 O is the raw material, mixed according to the molar ratio of (1-x): (1-x) (where 0.1≤x≤0.9, Ln is one of La, Nd, Sm, Eu, Gd, Dy), and put into the reaction vessel 1 and distilled water was added, stirred with a magnetic stirrer until clear and transparent to prepare the first reaction solution.

[0051] The second step: prepare the second reaction solution

[0052] A certain amount of ammonium oxalate and distilled water were put into the reaction vessel 2, stirred with a magnetic stirrer until clear and transparent to obtain a second reaction solution.

[0053] The third step: prepare the third reaction solution

[0054] Pour the first reaction solution into a separatory funnel, and add it dropwise to the second reaction solution. The whole dropping process is continuously stirred and ammonia water is continu...

Embodiment 1

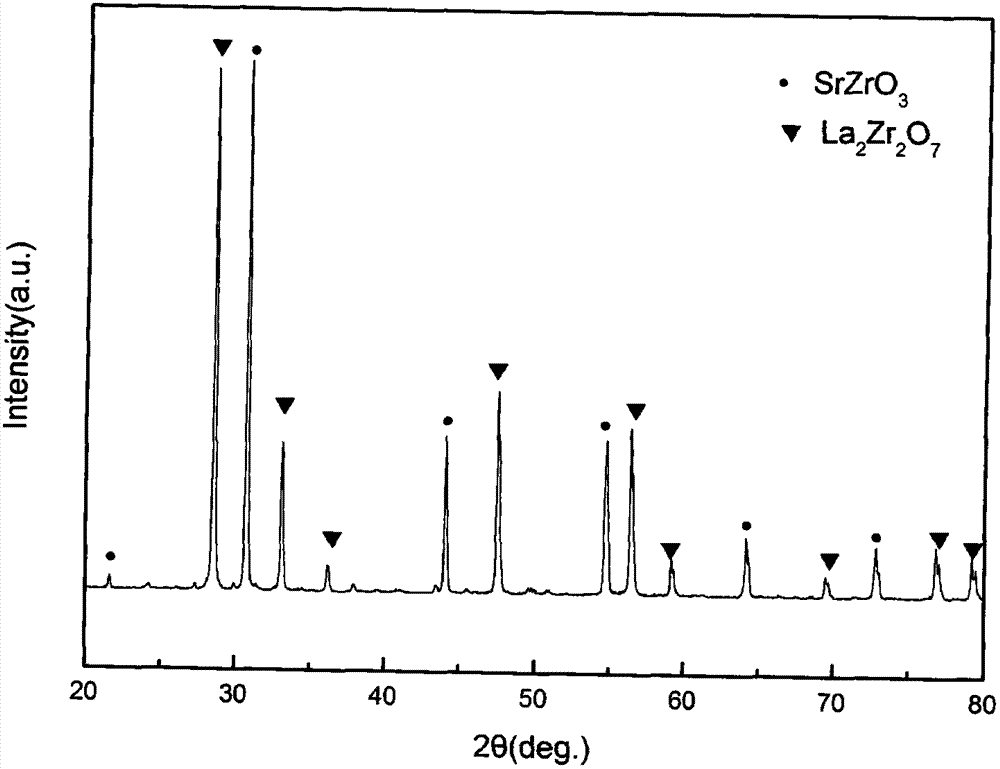

[0091] Preparation of nanocomposites (Sr 0.5 La 0.5 ) ZrO 3.25 , accurately measure the molar ratio as La(NO 3 ) 3 ·6H 2 O:Zr(NO 3 ) 4 ·5H 2 O=1:1, using distilled water as a solvent, prepare 100ml of a solution with a total solution concentration of 0.5mol / L, and place it on a magnetic stirrer to stir to fully dissolve the raw materials, and transfer the solution to a separatory funnel. Add the solution in the separatory funnel drop by drop to the diluted ammonia water, while stirring continuously with a magnetic stirrer, keep the pH value of the solution at about 10 during the whole dropping process. In addition, accurately measure the molar ratio as Sr(NO 3 ) 2 : Zr(NO 3 ) 4 ·5H 2 O=1:1 (wherein La(NO 3 ) 3 ·6H 2 O:Sr(NO 3 ) 2 =1:1), prepare 100ml of solution whose total solution concentration is 0.5mol / L, and place it on a magnetic stirrer to stir to make the raw material fully dissolve, and transfer the solution to a separatory funnel. Add the solution i...

Embodiment 2

[0093] Prepare nanocomposite material (Sr with the method for embodiment 1 0.3 La 0.7 ) ZrO 3.35 , accurately measure the molar ratio as La(NO 3 ) 3 ·6H 2 O:Zr(NO 3 ) 4 ·5H 2 O=1:1, using distilled water as a solvent, prepare 100ml of a solution with a total solution concentration of 0.084mol / L, and place it on a magnetic stirrer to stir to fully dissolve the raw materials, and transfer the solution to a separatory funnel. Add the solution in the separatory funnel drop by drop to the diluted ammonia water, while stirring continuously with a magnetic stirrer, keep the pH value of the solution at about 10 during the whole dropping process. In addition, accurately measure the molar ratio as Sr(NO 3 ) 2 : Zr(NO 3 ) 4 ·5H 2 O=1:1 (wherein La(NO 3 ) 3 ·6H 2 O:Sr(NO 3 ) 2 =7: 3), the preparation total solution concentration is the solution 100ml of 0.036mol / L, and is placed on the magnetic stirrer and stirred to make raw material fully dissolve, and solution is trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com