Nanometer bismuth tungstate with hollow square ball structure and preparation method thereof

A technology of bismuth tungstate and nano-tungsten, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, and can solve problems such as high temperature requirements, poor sample dispersion and easy agglomeration, and poor particle uniformity. Achieve the effect of high phase purity, novel product appearance and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

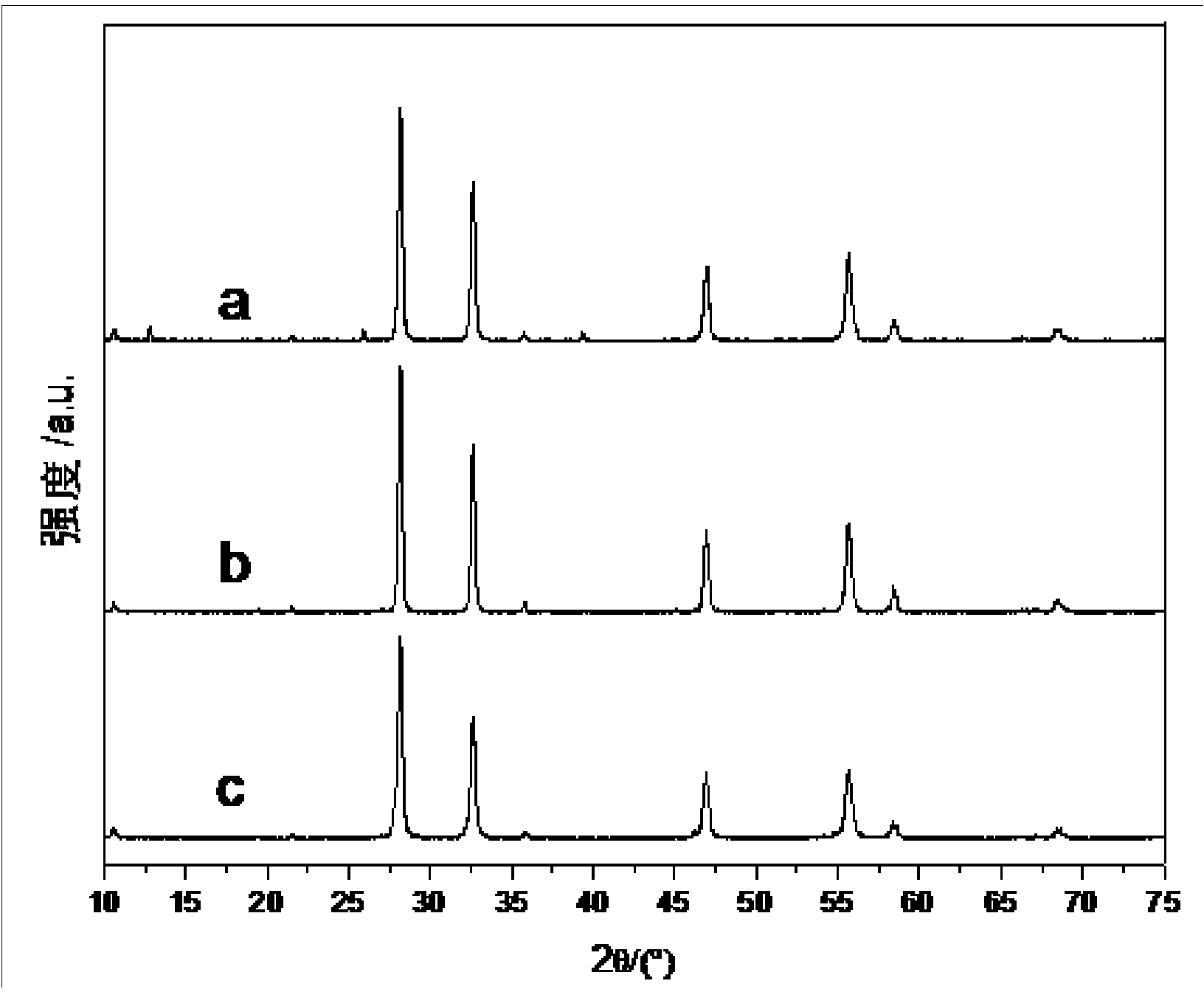

Embodiment 1

[0037] Step 1, take 0.75gBi(NO 3 ) 3 ·5H 2 O was added to the nitric acid solution and stirred thoroughly until clear.

[0038] Step 2, 0.25gNa 2 WO 4 2H 2 O was dissolved in deionized water and an appropriate amount of STAB alcohol aqueous solution was added and stirred until clear.

[0039] Step 3: Mix the clarified liquid obtained in Step 1 and Step 2 to obtain a milky white suspension.

[0040] Step 4, adjust the pH of the suspension obtained in Step 3 to 3 with ammonia water and sodium hydroxide solution, and then transfer it to a hydrothermal reaction kettle to control the temperature at 160° C. for 5 hours.

[0041] Step 5: After the reaction in Step 4 is completed, filter the reacted product, wash it several times with 30 wt% alcohol aqueous solution, and dry it at 60°C to obtain light yellow bismuth tungstate powder.

Embodiment 2

[0043] Step 1, take 1.5gBi(NO 3 ) 3 ·5H 2 O was added to the nitric acid solution and stirred thoroughly until clear.

[0044] Step two, take 0.5gNa 2 WO 4 2H 2 O was dissolved in deionized water and an appropriate amount of STAB alcohol aqueous solution was added and stirred until clear.

[0045] Step 3: Mix the clarified liquid obtained in Step 1 and Step 2 to obtain a milky white suspension.

[0046] Step 4: Adjust the pH of the suspension obtained in Step 3 to 3 with ammonia water and sodium hydroxide solution, and then transfer it to a hydrothermal reaction kettle to control the temperature at 160° C. for 8 hours.

[0047] Step 5: After the reaction in Step 4 is completed, filter the reacted product, wash it several times with 30 wt% alcohol aqueous solution, and dry it at 60°C to obtain light yellow bismuth tungstate powder.

Embodiment 3

[0049] Step 1, take 3gBi(NO 3 ) 3 ·5H 2 O was added to the nitric acid solution and stirred thoroughly until clear.

[0050] Step 2, take 1gNa 2 WO 4 2H 2 O was dissolved in deionized water and an appropriate amount of STAB alcohol aqueous solution was added and stirred until clear.

[0051] Step 3: Mix the clarified liquid obtained in Step 1 and Step 2 to obtain a milky white suspension.

[0052] Step 4, adjust the pH of the suspension obtained in Step 3 to 3 with ammonia water and sodium hydroxide solution, and then transfer it to a hydrothermal reaction kettle to control the temperature at 160° C. for 12 hours.

[0053] Step 5: After the reaction in Step 4 is completed, filter the reacted product, wash it several times with 30 wt% alcohol aqueous solution, and dry it at 60°C to obtain light yellow bismuth tungstate powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com