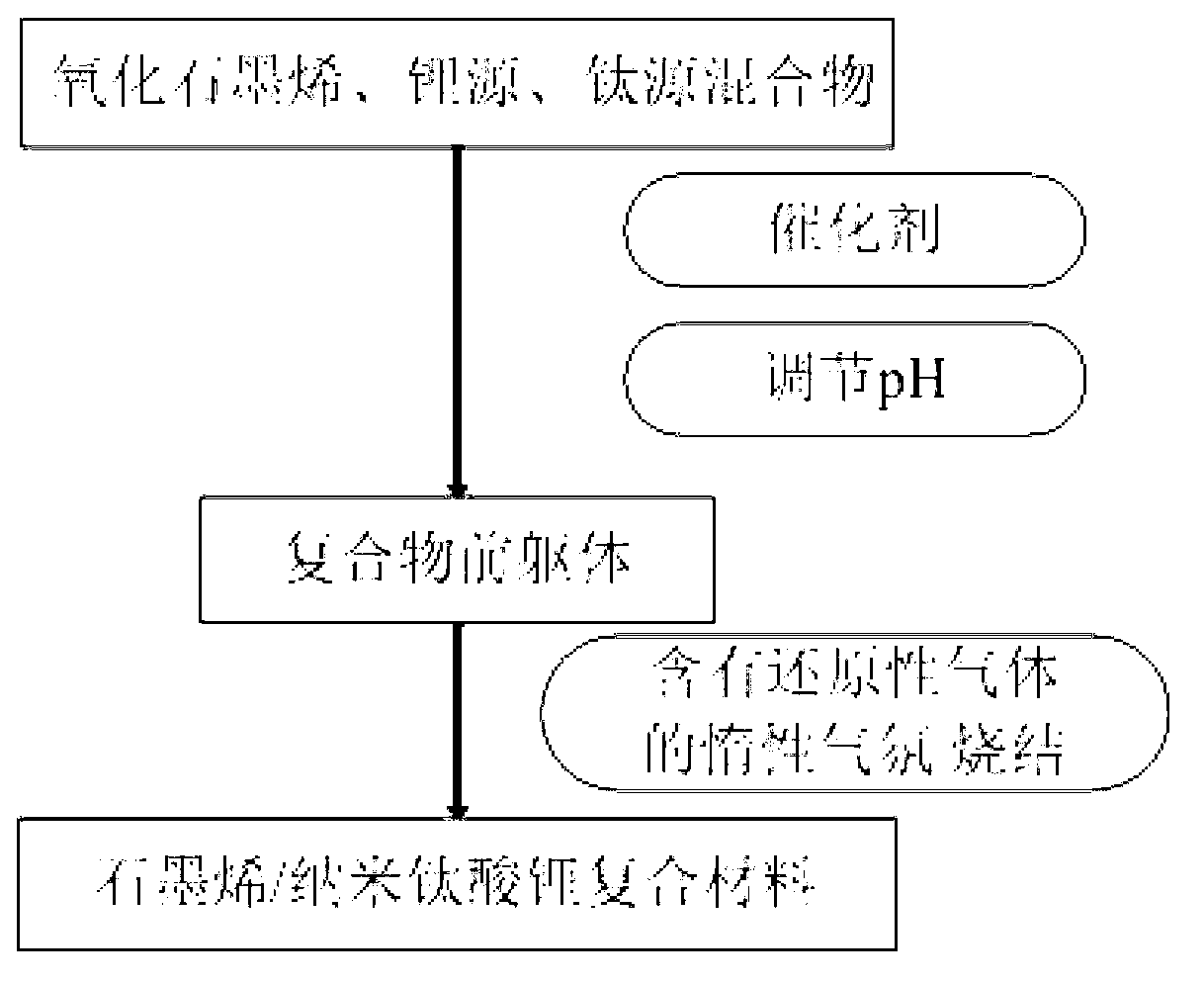

Preparation method of graphene/lithium titanate composite anode material

A negative electrode material, graphene technology, applied in the field of preparation of graphene/lithium titanate composite negative electrode materials, can solve problems such as difficult to achieve large-scale industrial production, long diffusion distance, complex process, etc., and achieve easy realization of large-scale industrial production , good magnification, and high phase purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

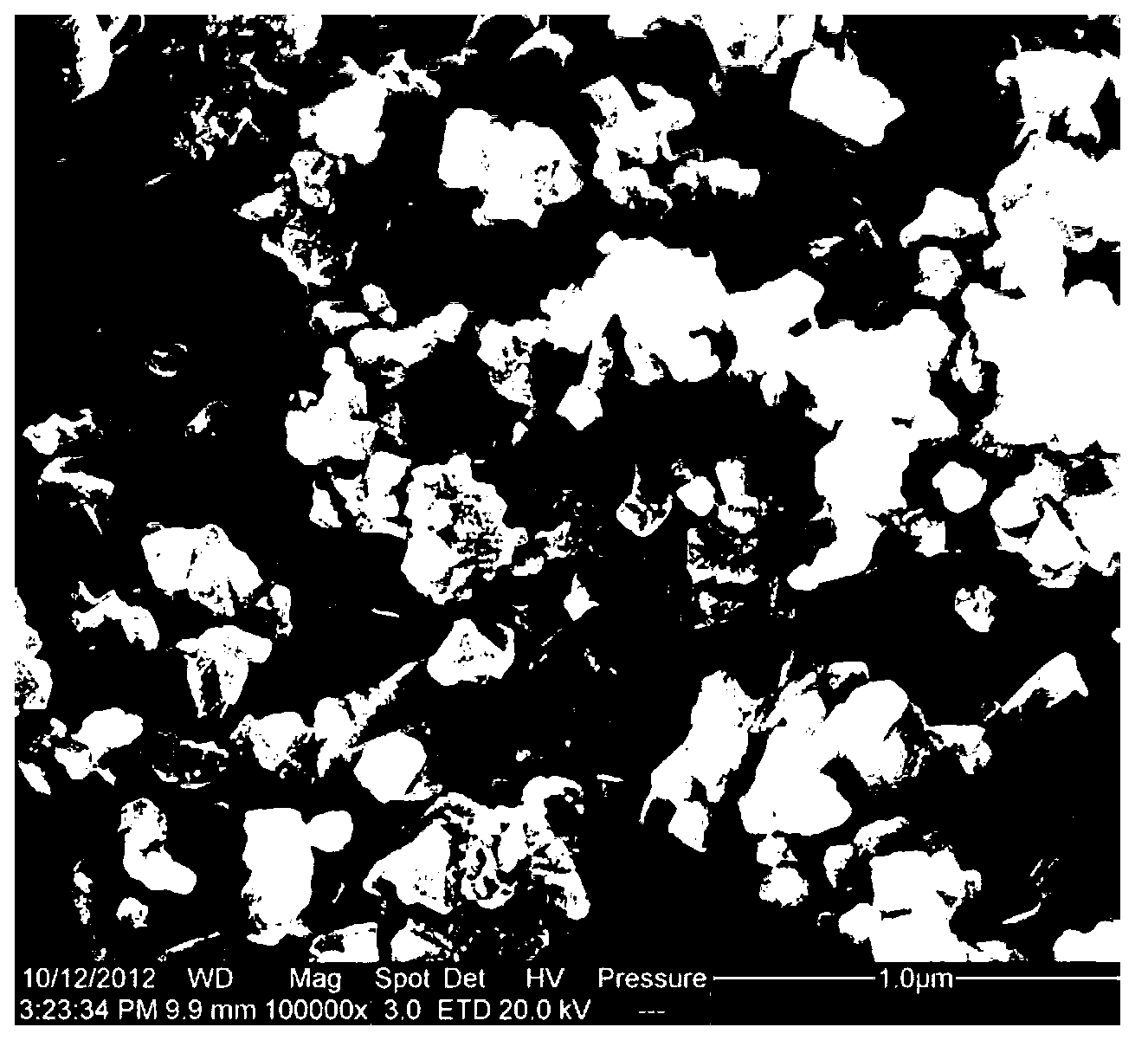

[0046] Graphene oxide with a particle size of about 100 μm was added to ethanol, and ultrasonically dispersed for 2 hours to obtain a solution with a concentration of 1 g / L. Butyl titanate and lithium acetate were selected as the titanium source compound and lithium source compound, respectively. The aforementioned titanium source and lithium source compounds were dissolved in ethanol to prepare a solution with a concentration of 1 kg / L. According to the molar ratio of lithium to titanium N Li :N Ti =0.84:1, the mass percentage of graphene in the graphene / lithium titanate composite negative electrode material is 5wt.%, the ethanol solution of the prepared butyl titanate, lithium acetate solution and oxalic acid is successively added to the oxidation graphene in ethanol solution. The pH value of the above mixed solution was adjusted to 5.6 with ammonia water. Stir at 30°C for 3 hours, then raise the temperature to 60°C, and stir until gelatinous. The wet gel is converted i...

Embodiment 2

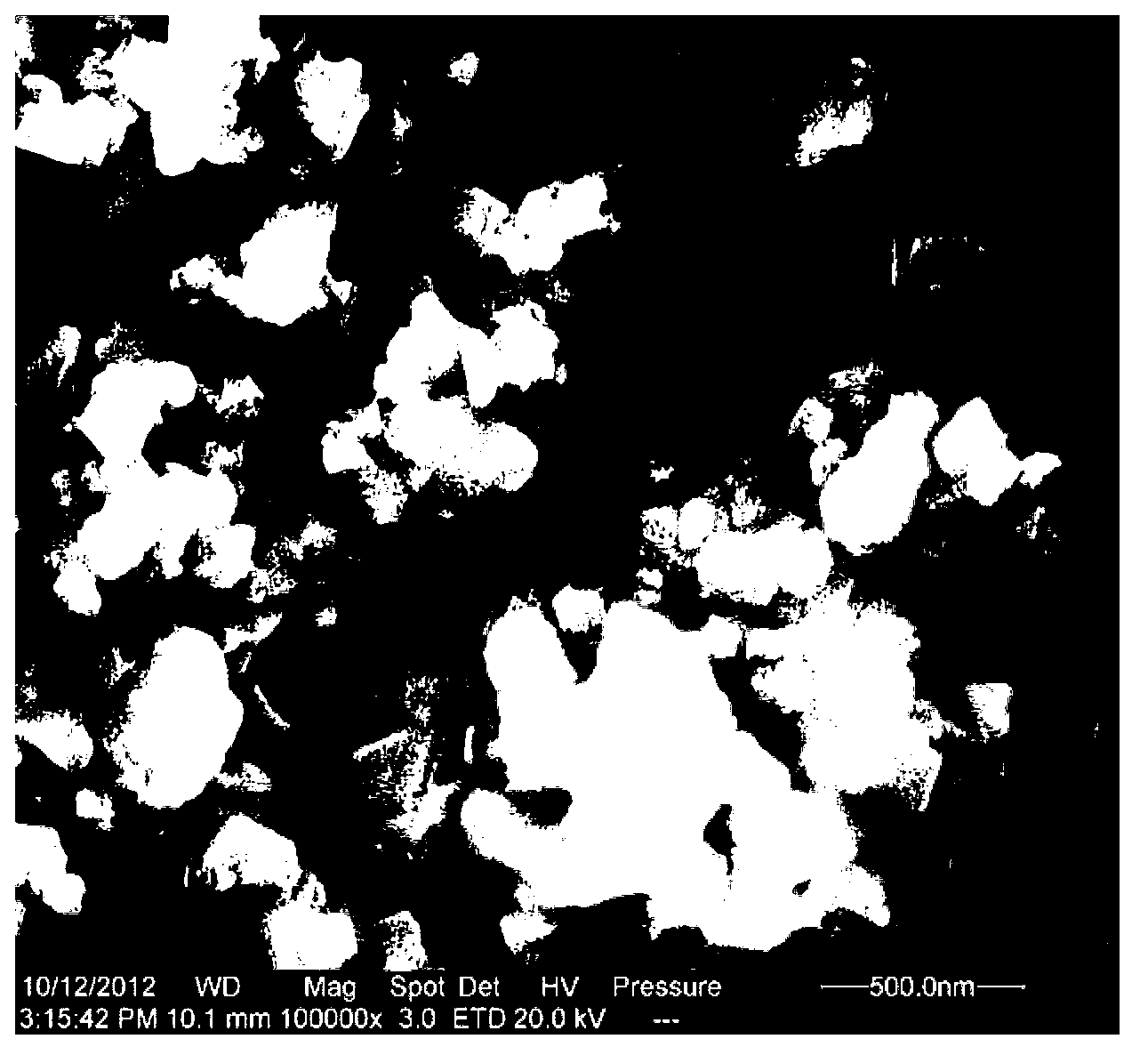

[0064] Graphene oxide with a particle size of about 100 μm was added to water and ultrasonically dispersed for 0.5 hour to obtain a 3 g / L graphene oxide aqueous solution. Tetraisopropyl titanate and lithium hydroxide were selected as the titanium source compound and the lithium source compound, respectively. Under stirring conditions, according to the molar ratio of lithium to titanium N Li :N Ti =0.80:1, successively add 1ml of 30% hydrogen peroxide and 1mmol of tetraisopropyl titanate to 20ml of 0.4M lithium hydroxide aqueous solution, and stir until completely dissolved. Finally, the above solution was mixed with the graphene oxide aqueous solution according to the mass ratio of graphene to lithium titanate of 7:93. The resulting mixed solution was poured into a 50ml stainless steel reaction kettle with polytetrafluoroethylene as a liner, sealed and placed in a blast drying oven, and reacted for 2 hours at 150°C. After naturally cooling to room temperature, the reaction ...

Embodiment 3

[0066] According to the mass percentage of graphene and lithium titanate being about 10wt%, graphite oxide with a particle size of about 150 μm was dissolved in secondary water to form a 1 g / L solution, and ultrasonically dispersed for 1 hour. Tetraisopropyl titanate and lithium hydroxide were selected as the titanium source compound and the lithium source compound, respectively. Under stirring conditions, according to the molar ratio of lithium to titanium N Li :N Ti =0.82:1, successively add 1ml of 30% hydrogen peroxide and 1mmol of tetraethyl titanate to 20.5ml of 0.4M lithium hydroxide aqueous solution, stir until completely dissolved. Finally, the above solution was mixed with the graphene oxide aqueous solution according to the mass ratio of graphene to lithium titanate of 10:90. The resulting mixed solution was poured into a 50ml stainless steel reactor with polytetrafluoroethylene as a liner, sealed and placed in a microwave oven at 180°C for 10 minutes to insulate t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com