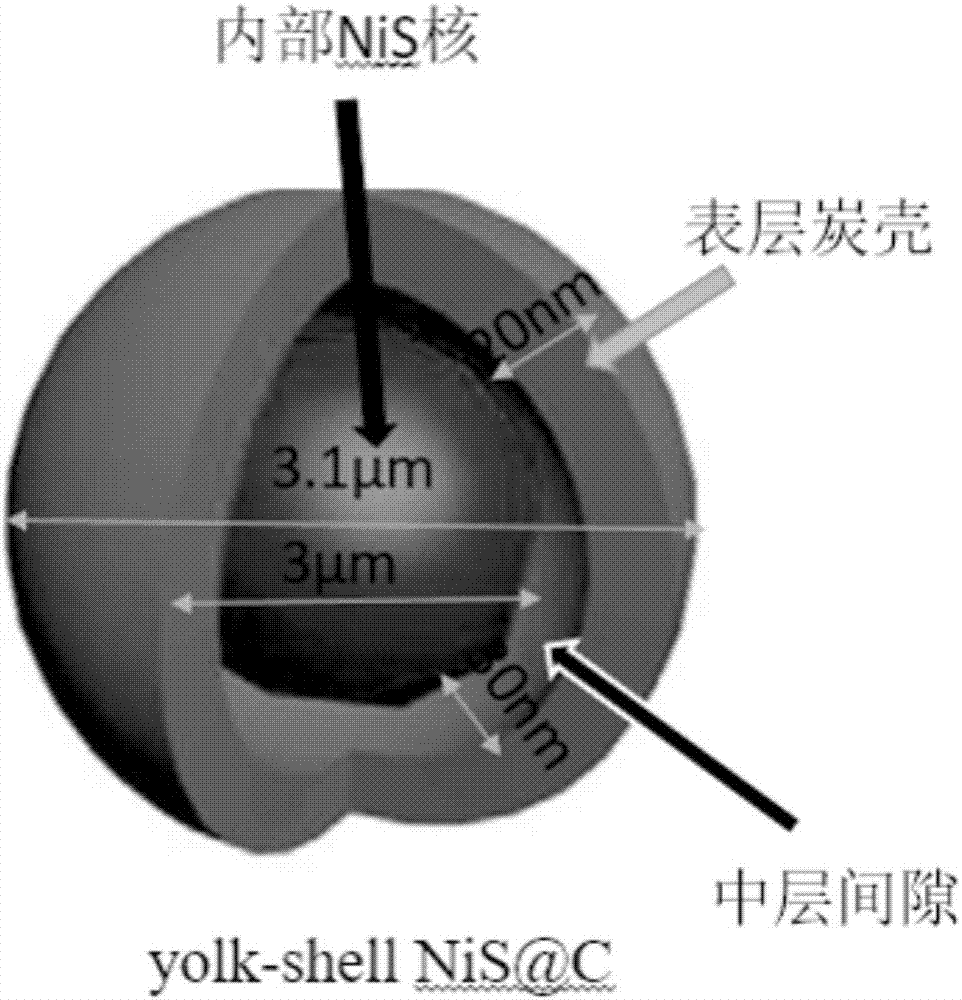

Carbon shell coated NiS classification microsphere and preparation method and application thereof

A technology of microspheres and carbon shells, which is applied in the field of nanomaterials and electrochemistry, can solve the problems of irreversible phase transition of materials, low yield of synthetic products, and decreased cycle life, so as to reduce preparation costs, high phase purity, and uniform size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of carbon shell-coated NiS hierarchical microspheres includes the following steps:

[0039] 1) Add 2mmol of nickel chloride hexahydrate and 5mmol of sodium thiosulfate pentahydrate to 40mL of absolute ethanol and stir for 60min to fully dissolve it to obtain a green solution;

[0040] 2) Put the solution obtained in step 1) into a 50mL reaction kettle for solvothermal reaction at 180°C for 12 hours, take out the reaction kettle, and naturally cool to room temperature;

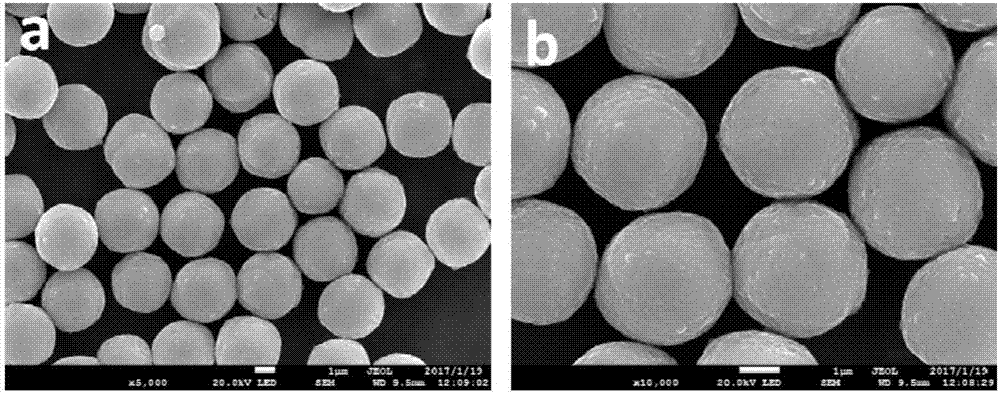

[0041] 3) Centrifugally filter the product obtained in step 2), wash it with water and absolute ethanol 6 times, and dry it in an oven at 80°C to obtain the precursor microsphere black powder;

[0042] 4) Add the black precursor obtained in step 3) to 70mL of absolute ethanol and 10mL of deionized water, add 1.5mL of ammonia, 0.15g of resorcinol, 0.4mL of ethyl orthosilicate (TEOS), 0.2mL of formaldehyde solution , Magnetic stirring for 24 hours;

[0043] 5) Centrifugally filter the product...

Embodiment 2

[0052] The preparation method of carbon shell-coated NiS hierarchical microspheres includes the following steps:

[0053] 1) Add 2mmol of nickel chloride hexahydrate and 5mmol of sodium thiosulfate pentahydrate to 40mL of absolute ethanol and stir for 50min to fully dissolve it to obtain a green solution;

[0054] 2) Put the solution obtained in step 1) into a 50mL reaction kettle for solvothermal reaction at 180°C for 16 hours, take out the reaction kettle, and naturally cool to room temperature;

[0055] 3) Centrifugal filter the product obtained in step 2), wash it with water and absolute ethanol 6 times, and dry it in an oven at 60°C to obtain the precursor microsphere black powder;

[0056] 4) Add the black precursor obtained in step 3) to 80mL absolute ethanol and 20mL deionized water, add 3mL ammonia, 0.2g resorcinol, 0.4mL ethyl orthosilicate (TEOS), 0.3mL formaldehyde solution, Magnetic stirring for 24 hours;

[0057] 5) Centrifugal filter the product obtained in step 4), wash...

Embodiment 3

[0063] The preparation method of carbon shell-coated NiS hierarchical microspheres includes the following steps:

[0064] 1) Add 2mmol of nickel chloride hexahydrate and 5mmol of sodium thiosulfate pentahydrate to 40mL of absolute ethanol and stir for 60min to fully dissolve it to obtain a green solution;

[0065] 2) Put the solution obtained in step 1) into a 50mL reaction kettle for solvothermal reaction at 180°C for 20 hours, take out the reaction kettle, and naturally cool to room temperature;

[0066] 3) Centrifugally filter the product obtained in step 2), wash it with water and absolute ethanol 6 times, and dry it in an oven at 70°C to obtain the precursor microsphere black powder;

[0067] 4) Add the black precursor obtained in step 3) to 60mL of absolute ethanol and 8mL of deionized water, add 3mL of ammonia, 0.1g of resorcinol, 0.3mL of ethyl orthosilicate (TEOS), 0.2mL of formaldehyde solution, Magnetic stirring for 24 hours;

[0068] 5) Centrifugal filter the product obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com