Chloride crystal and glass composite transparent optical function material as well as preparation method and application thereof

A technology of chloride and light function, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems that chloride is easy to absorb moisture, the performance of chloride crystal needs to be improved, and the cost is high, so as to achieve high luminous intensity and good optical transparency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Rubidium chloride (RbCl) crystal of the present embodiment and phosphorus pentoxide (P 2 o 5 ) The preparation method of the transparent photofunctional material of glass composite, comprises the steps:

[0055] (1) Select high-purity anhydrous RbCl crystal powder, high-purity P 2 o 5 Powder as raw material, RbCl:P 2 o 5 The molar ratio=95:5;

[0056] (2) Take the raw material that total amount is 20g in the glove box, grind 40 minutes in the agate mortar, then put into the corundum crucible and add a cover, and place in the sealed box and take out the glove box for preservation; Put the corundum crucible into 1150 ℃ in the furnace for 10 minutes (the furnace is directly connected to the atmosphere, the internal atmosphere is an air atmosphere), the melted high-temperature melt is poured on a copper plate and cooled naturally to obtain a transparent RbCl crystal and phosphate glass composite. Optical functional materials.

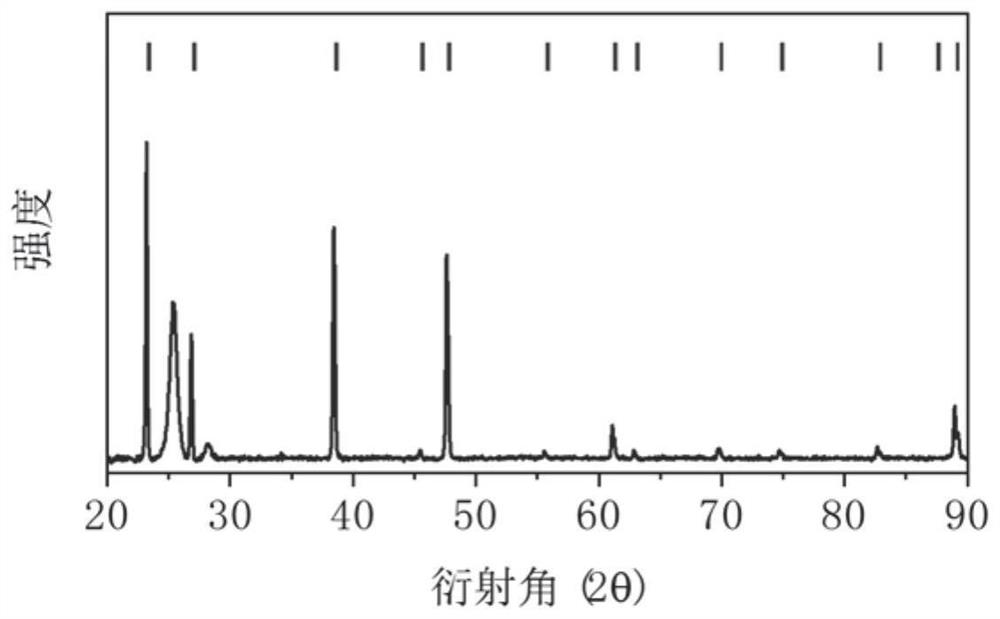

[0057] figure 1 is the XRD spectrum of...

Embodiment 2

[0060] Strontium chloride (SrCl) doped with luminescent ions in this embodiment 2 ) crystals and boron oxide (B 2 o 3 ) The preparation method of the transparent photofunctional material of glass composite, comprises the steps:

[0061] (1) Select high-purity anhydrous SrCl 2 Crystal powder, high purity B 2 o 3 Powder, high purity anhydrous EuCl 3 Crystal powder is used as raw material, and the molar ratio between raw materials is SrCl 2 :B 2 o 3 :EuCl 3 =90:10:1;

[0062] (2) Take the raw material that total amount is 20g in the glove box, grind 40 minutes in the agate mortar, then put into the corundum crucible and add a cover, and place in the sealed box and take out the glove box to preserve; Put the corundum crucible Put it into a furnace at 1150 ° C for 15 minutes, pour the melted high-temperature melt on a copper plate and cool it naturally to obtain transparent SrCl 2 A transparent optical functional material composed of crystal and borate glass.

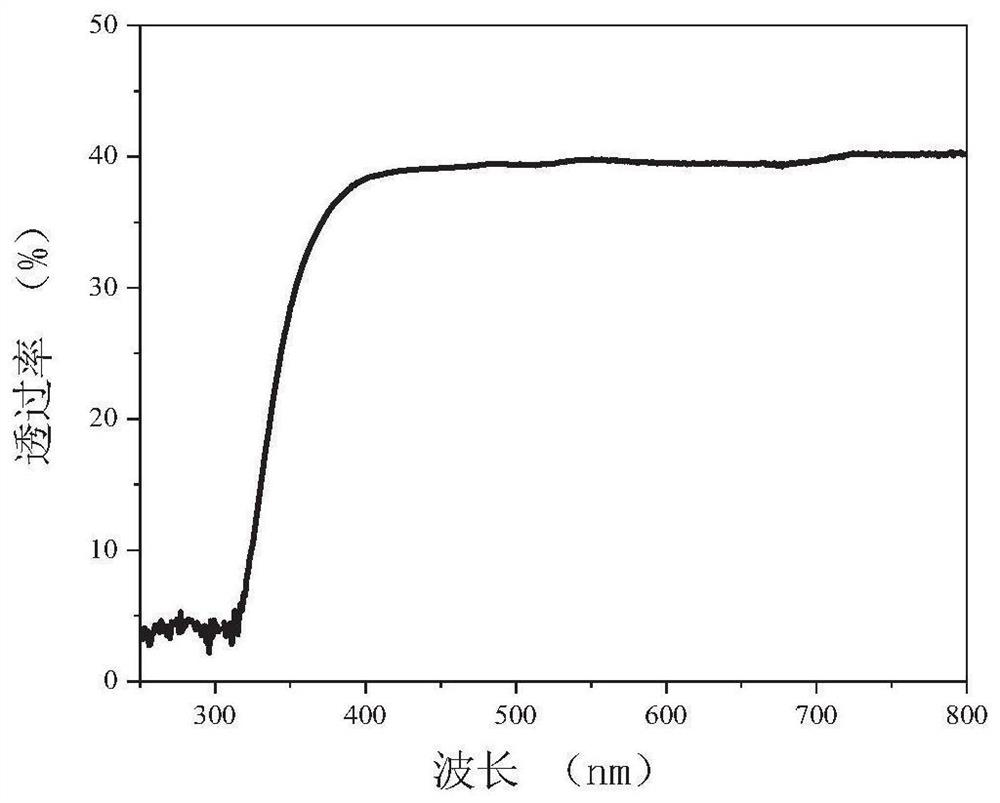

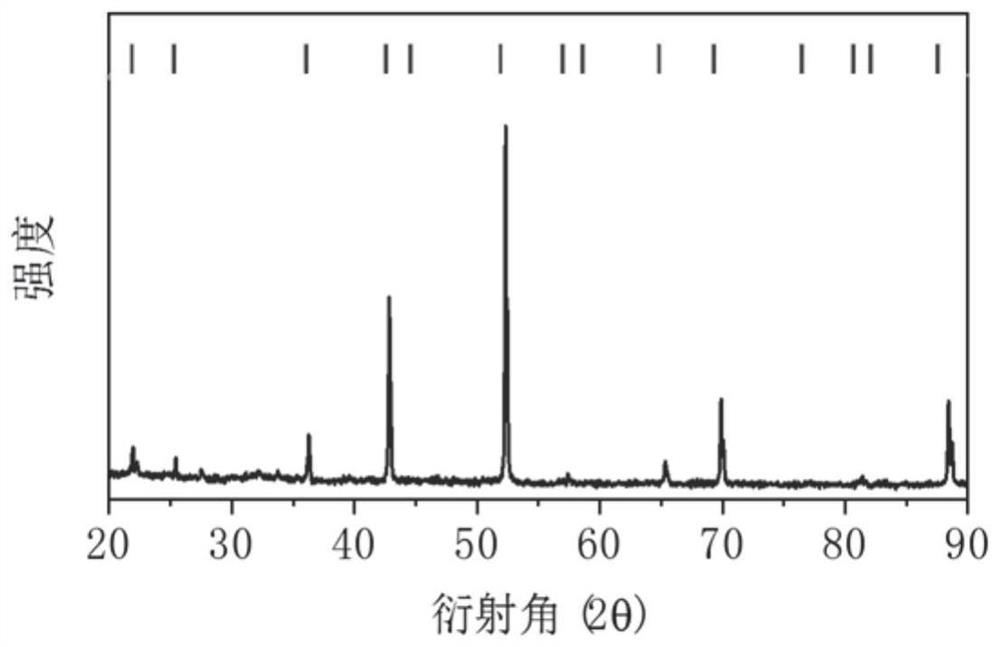

[0063] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com