Modified no-rainbow organic silicon release film taking biaxially oriented poly benzoic acid gylcol ester film and preparation method thereof

A poly terephthalic acid and glycol ester technology, applied in chemical instruments and methods, coatings, layered products, etc., can solve the problems of low surface tension and poor resistance to organic solvents of silicone release films. Easy modification operation, strong organic solvent resistance, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

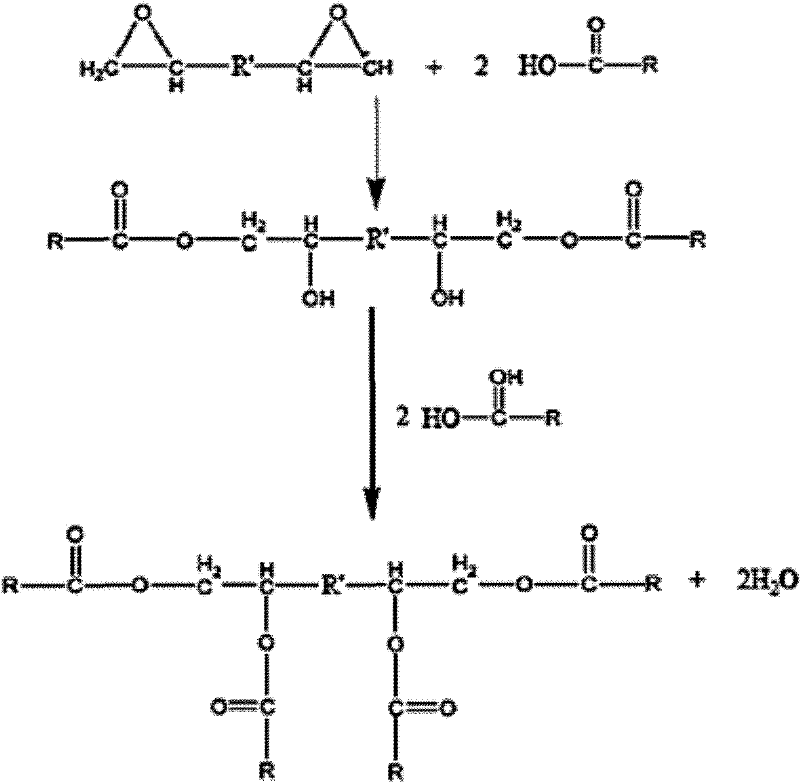

[0012] Specific embodiment one: The non-iridescent modified silicone release film based on biaxially stretched polyethylene terephthalate film in this embodiment is composed of biaxially stretched polyethylene terephthalate film and coated Cloth liquid, wherein the coating liquid is composed of 20-70 parts by mass of acrylic acid, 7-25 parts of butyl acrylate, 5-25 parts of methyl methacrylate, 5-25 parts Parts of styrene, 10-30 parts of vinyl dimethyl siloxane prepolymer, 2-3 parts of epoxy resin E-44, 2-3 parts of benzoyl peroxide and 170 parts ~600 parts of toluene.

[0013] The non-iridescent modified silicone release film based on the biaxially stretched polyethylene terephthalate film of this embodiment can be cured at a medium temperature under the condition of 140°C to 150°C. In this embodiment, acrylic acid (ester) monomers are used to modify the silicone prepolymer. Since the acrylic resin has polar groups such as carbonyl and carboxyl groups, it has relatively larg...

specific Embodiment approach 2

[0014] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the coating solution consists of 25-65 parts by mass of acrylic acid, 10-20 parts of butyl acrylate, 6-20 parts Methyl methacrylate, 8 to 22 parts of styrene, 12 to 28 parts of vinyl dimethyl siloxane prepolymer, 2.2 to 2.8 parts of epoxy resin E-44, 2.2 parts to 2.8 parts of benzoyl peroxide and 218-535 parts of toluene. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the coating solution is composed of 40 parts by mass of acrylic acid, 15 parts of butyl acrylate, 15 parts of methyl methacrylate, 15 parts of Styrene, 20 parts of vinyl dimethyl siloxane prepolymer, 2.5 parts of epoxy resin E-44, 2.5 parts of benzoyl peroxide and 367 parts of toluene. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com