Silicon-slag microcrystalline glass and preparation method thereof

A technology of glass-ceramics and silicon slag, which is applied in the field of glass-ceramics and its preparation, can solve the problems of land occupation and environmental pollution, and achieve the goals of reducing pollution, reducing production costs, excellent physical and mechanical properties and chemical stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

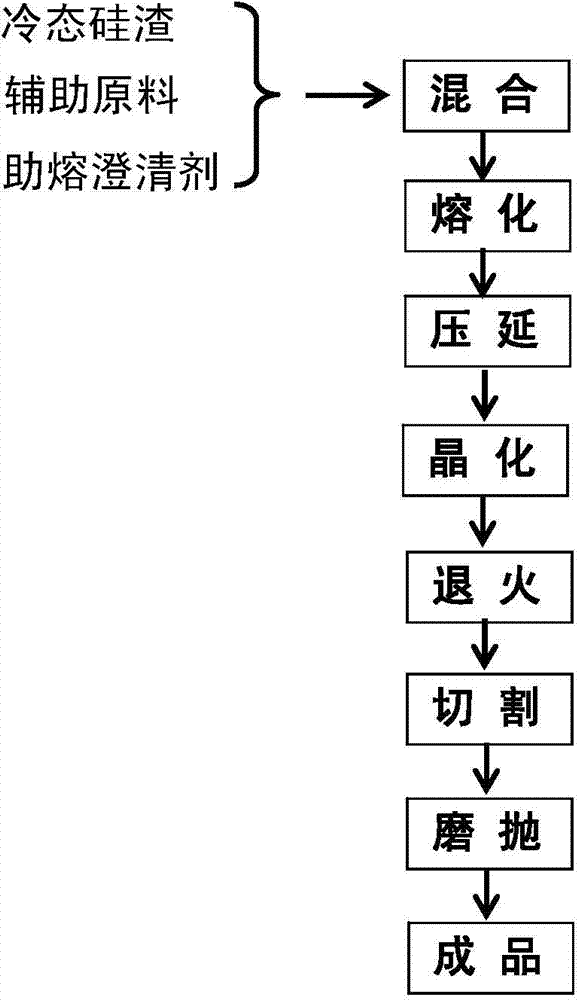

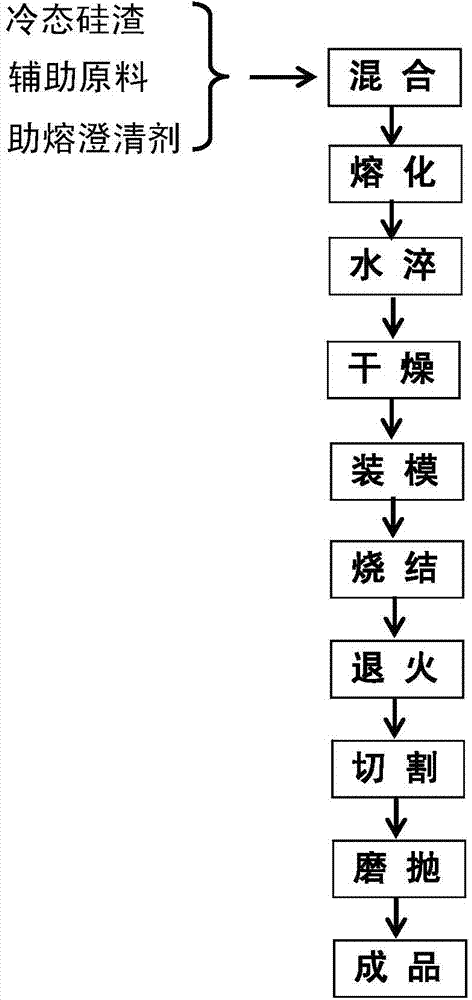

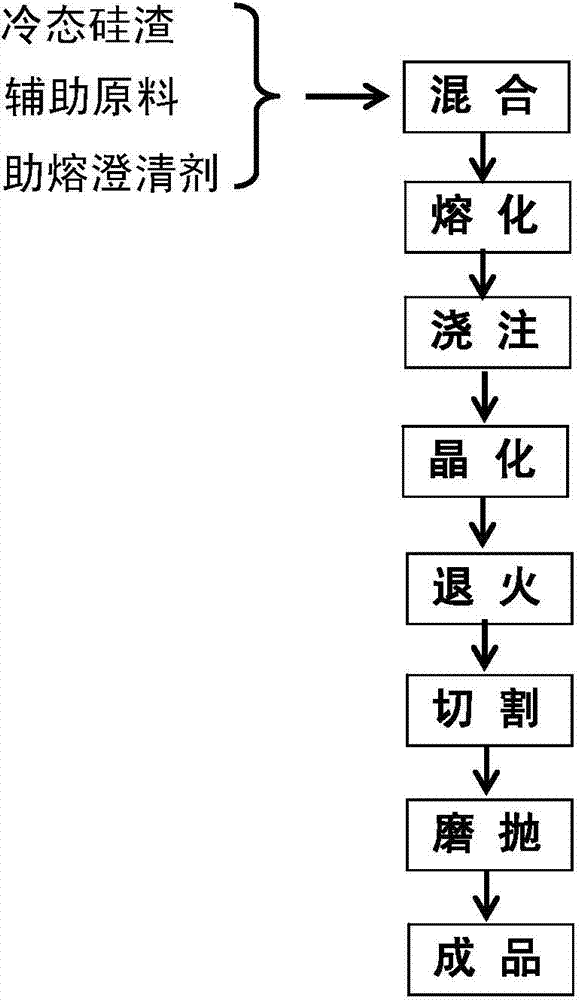

Method used

Image

Examples

Embodiment 1

[0038] The silicon smelting waste residue and various mineral auxiliary materials are crushed, and then passed through a 20-mesh sieve, and 72.0-76.0 kg silicon smelting waste residue, 13.0-15.0 kg limestone or calcite (CaCO 3 ), 9.0-11.0 kilograms of fluorite (CaF 2 ), 2.0-4.0 kg of zinc oxide (ZnO), 1.0-3.0 kg of aluminum oxide (Al 2 O 3 ), 0.5-2.0 kg of ammonium nitrate (NH 4 NO 3 ). The silicon smelting waste residue, auxiliary raw materials and flux clarifier are fully mixed, and 4.0% of the total weight of the raw materials is added during the mixing process, and stirred for 10 minutes to mix evenly to form a basic glass batch.

[0039] The basic glass batch is sent to the melting furnace via a conveyor belt or a unit tank, and the melting temperature is controlled at 1470-1500 ℃ and melted for 2.0-6.0h, homogenized and clarified to make a qualified glass liquid; the clarified glass liquid flows through the liquid The hole enters the working part of the melting furnace, the ...

Embodiment 2

[0044] Crush various mineral auxiliary materials, then pass through a 20-mesh sieve, and accurately weigh 14.0-15.5 kg of limestone or calcite (CaCO 3 ), 10.0-11.0 kg fluorite (CaF 2 ), 10.0-13.0 kg potassium carbonate (K 2 CO 3 ), 2.5-3.5 kg of zinc oxide (ZnO), 1.0-2.0 kg of aluminum oxide (Al 2 O 3 ), 0.5-2.0 kg of ammonium nitrate (NH 4 NO 3 ), 1.0-3.0 kg of ammonium nitrate (NH 4 NO 3 ). Mix the above-mentioned auxiliary raw materials and the flux clarifier thoroughly, add the auxiliary raw materials and the water of 3.0-4.0% of the total weight of the flux clarifier, stir for 10-15 minutes and mix uniformly to form a premix.

[0045] The premix is added to 39.0-41.0 kg of high-temperature molten silicon slag, the melting temperature is controlled at 1460-1480℃, and the melting is 2.0-4.0h, homogenized and clarified to make a qualified glass liquid; the clarified glass liquid flows through the liquid The hole enters the working part of the melting furnace, and the temperatu...

Embodiment 3

[0050] Crush various mineral auxiliary materials, then pass through a 20-mesh sieve, and accurately weigh 11.0-13.0 kg of quartz sand (SiO 2 ), 14.0-16.0 kg of limestone or calcite (CaCO 3 ), 10.0-11.0 kg fluorite (CaF 2 ), 3.0-5.0 kg potassium carbonate (K 2 CO 3 ), 1.5-3.0 kg of zinc oxide (ZnO), 1.3-2.5 kg of aluminum oxide (Al 2 O 3 ), 0.5-0.8 kg of ammonium nitrate (NH 4 NO 3 ), 0.5-1.3 kg sodium nitrate (NaNO 3 ). Mix the above-mentioned auxiliary raw materials and the flux clarifier thoroughly, add 5.0-6.0% water of the total weight of the auxiliary raw materials and the flux clarifier, stir for 10-15 minutes and mix uniformly to form a premix.

[0051] The premix is added to 60-62 kg of high-temperature molten silicon slag, the melting temperature is controlled at 1470-1530℃, and the melting is 2.0-6.0h, homogenized and clarified to make qualified glass liquid; the clarified glass liquid flows through the liquid The hole enters the working part of the furnace, and the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com