Process for post-treatment of acephate and method for recovering waste water resources

An acephate, resource recovery technology, applied in chemical instruments and methods, extraction water/sewage treatment, neutralized water/sewage treatment, etc. problem, to achieve the effect of reducing ammonia nitrogen emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

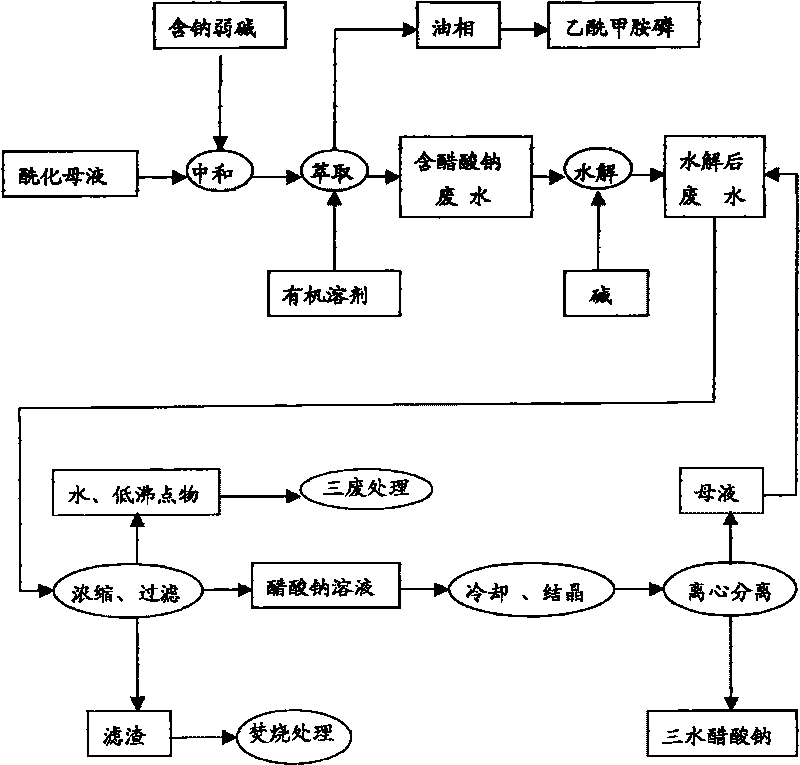

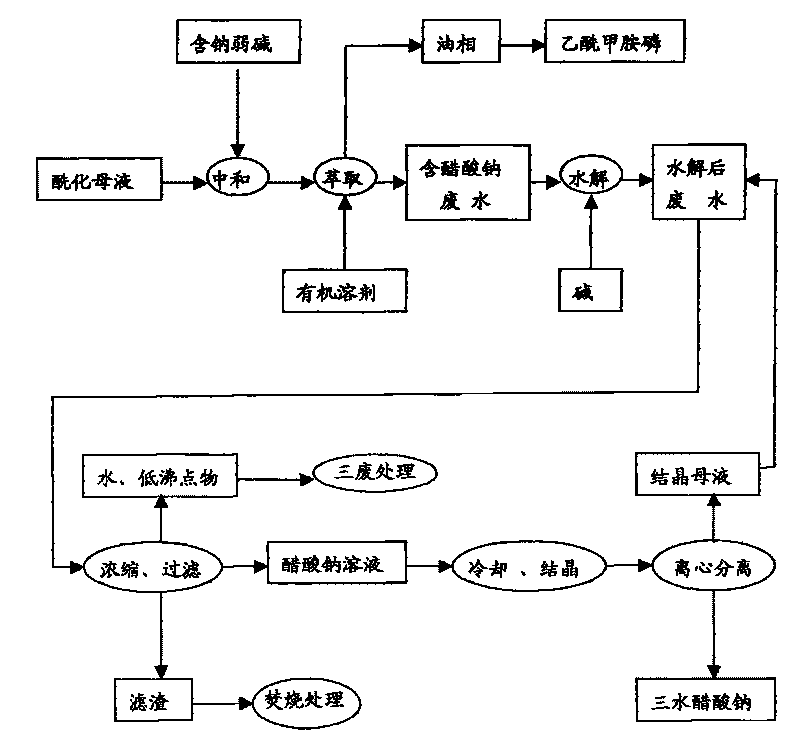

Image

Examples

Embodiment 1

[0022] a. Neutralization: In the enamel reactor with stirring, add 2200kg of water, start stirring, drop into 450kg of anhydrous sodium carbonate solid, stir for 30min to dissolve, pour into the metering tank, add 1000kg of acylation mother liquor in the enamel reactor (take From our company's acephate synthesis process), turn on the cold ice water, start to add sodium carbonate solution dropwise to the enamel reaction kettle, keep the temperature below 30°C, measure the pH value after the dropwise addition, and the pH value is 7.5.

[0023] b. Extraction: Add 1800L of dichloromethane to the above-mentioned neutralization solution, stir for 10 minutes, stand still and separate layers, and the lower layer is desolvated and crystallized to obtain acephate, and the solvent is recovered and applied mechanically to obtain 3497 kg of the upper layer, which contains sodium acetate. Wastewater, sodium acetate content is 19.5%.

[0024] C, hydrolysis: open the reflux condenser, the abo...

Embodiment 2

[0028] a. Neutralization: Add 2200kg of water to the enamel reaction kettle with stirring, start stirring, put in 710kg of sodium bicarbonate solid, stir for 30min to dissolve, put it into the metering tank, add 1000kg of acylation mother liquor to the enamel reaction kettle, start the cooling Ice water, start to add sodium carbonate solution dropwise to the enamel reaction kettle, keep the temperature below 30°C, measure the pH value after the dropwise addition, PH=7.

[0029] b. Extraction: Add 1800L of chloroform to the above-mentioned neutralization solution, stir for 10 minutes, static layering, the lower layer solution is desolvated and crystallized to obtain acephate, the solvent recovery is applied mechanically, and the upper layer solution is 3462kg, which is waste water containing sodium acetate. The sodium acetate content is 19.9%.

[0030] C, hydrolysis: open reflux condenser, the above-mentioned waste water containing sodium acetate is warmed up to 70 ℃, dropwise ...

Embodiment 3

[0034] a. Neutralization: Add 1500kg of water into the enamel reaction kettle with stirring, start stirring, put in 1200kg of sodium carbonate decahydrate solid, stir for 30 minutes to dissolve, put it into the metering tank, add 1000kg of acylation mother liquor into the enamel reaction kettle, and start Cold ice water, start to add sodium carbonate solution dropwise to the enamel reaction kettle, keep the temperature below 30°C, measure the pH value after the dropwise addition, PH=6.5.

[0035] b. Extraction: Add 1800 L of dichloroethane to the above neutralization solution, stir for 10 minutes, and let the layers stand still. The lower layer is desolvated and crystallized to obtain acephate, and the solvent is recovered and applied mechanically to obtain 3537 kg of the upper layer, which is acetic acid-containing Sodium wastewater, sodium acetate content is 19.4%.

[0036] C, hydrolysis: open the reflux condenser, the above-mentioned waste water containing sodium acetate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com