Patents

Literature

204 results about "Sodium Acetate Trihydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

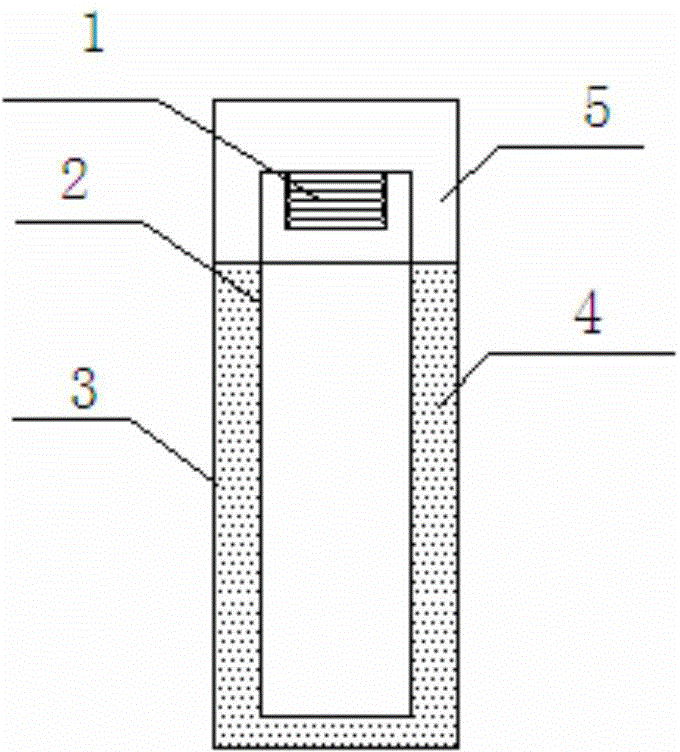

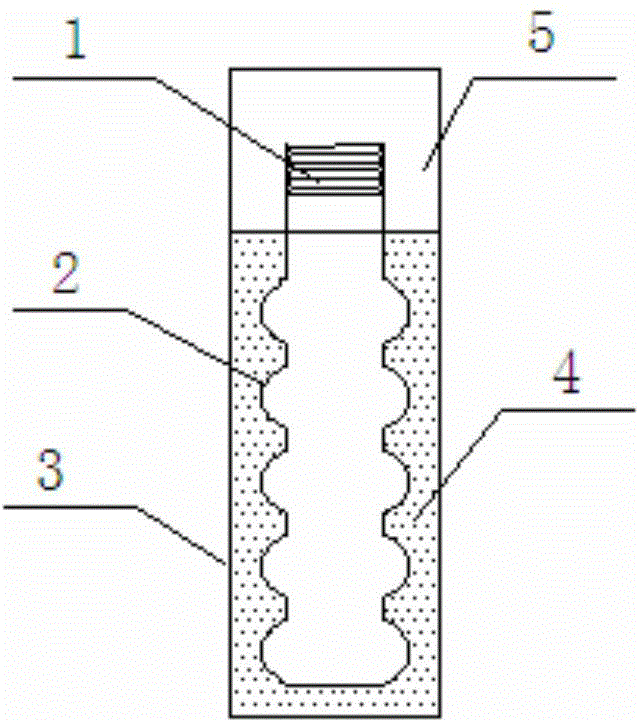

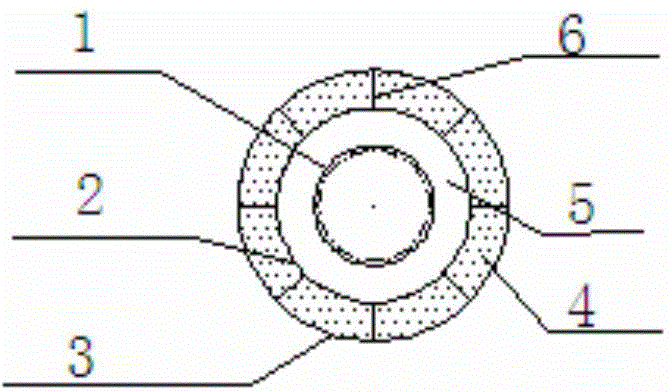

Phase transition temperature adjusting system and phase transition temperature adjusting cup

ActiveCN104887011AHeat absorption and release performance are highly matchedGuaranteed to drink normallyDrinking vesselsCarbon nanotubeSodium Thiosulfate Pentahydrate

Owner:YUTIAN ENERGY CO LTD

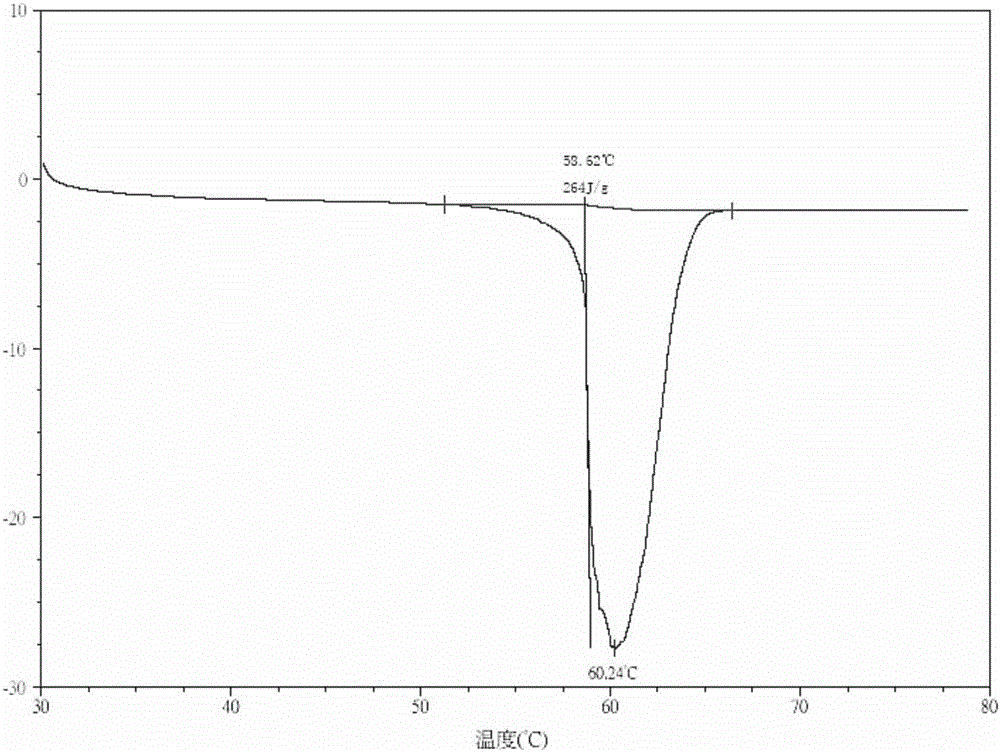

Sodium acetate trihydrate phase change energy storage material compositions

InactiveCN102212340AImprove performanceHeat-exchange elementsSodium acetrizoateSodium Acetate Trihydrate

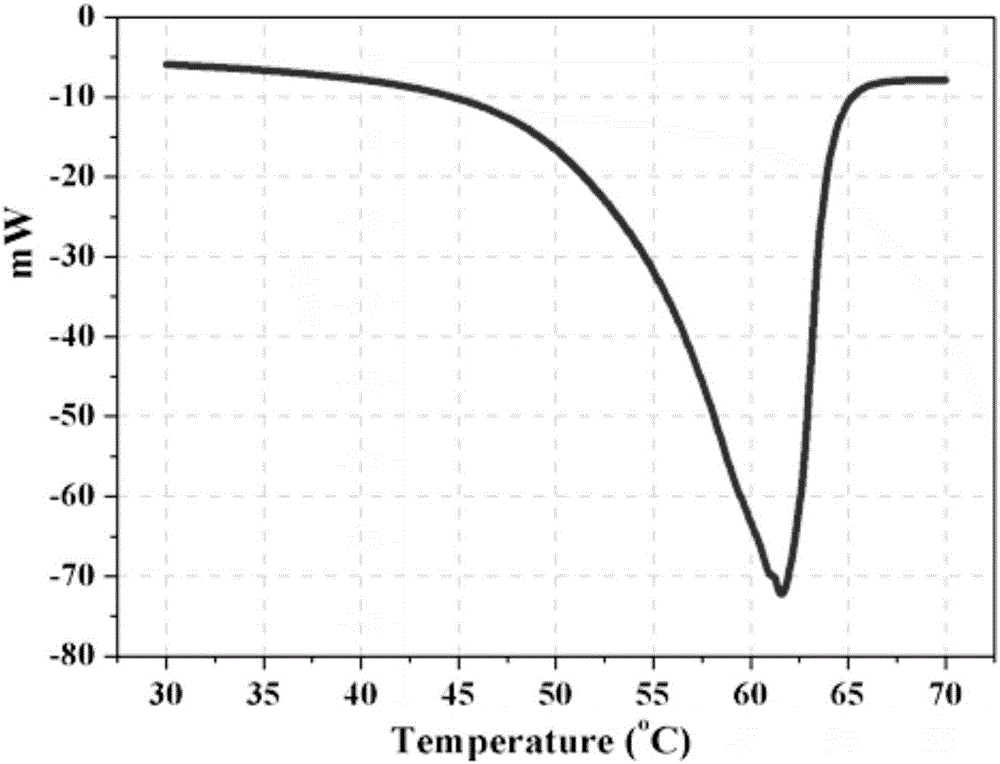

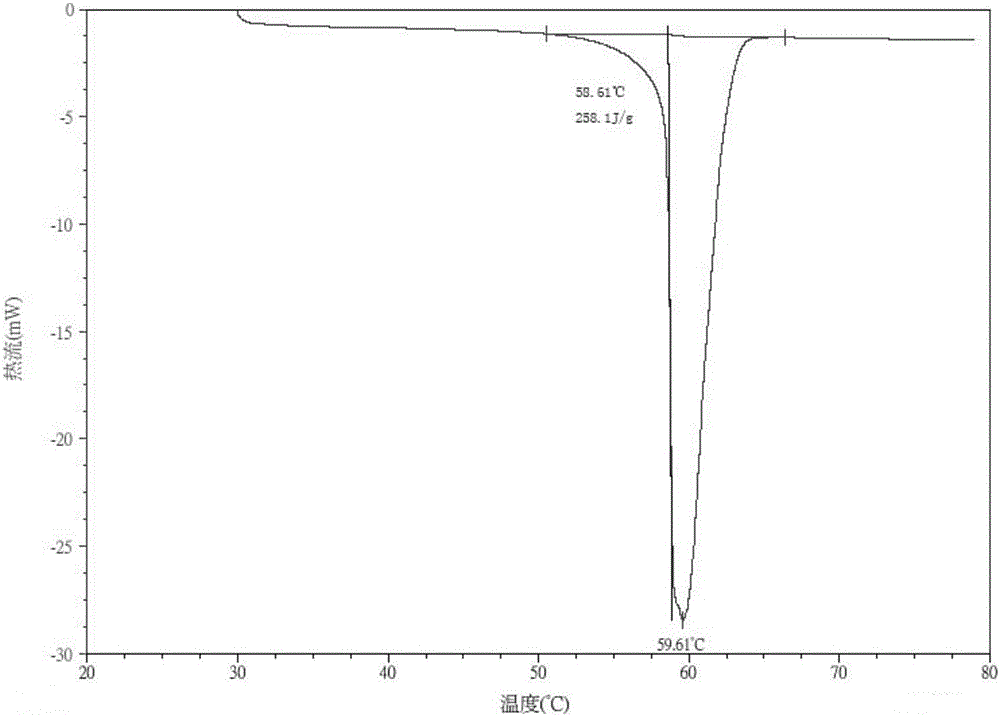

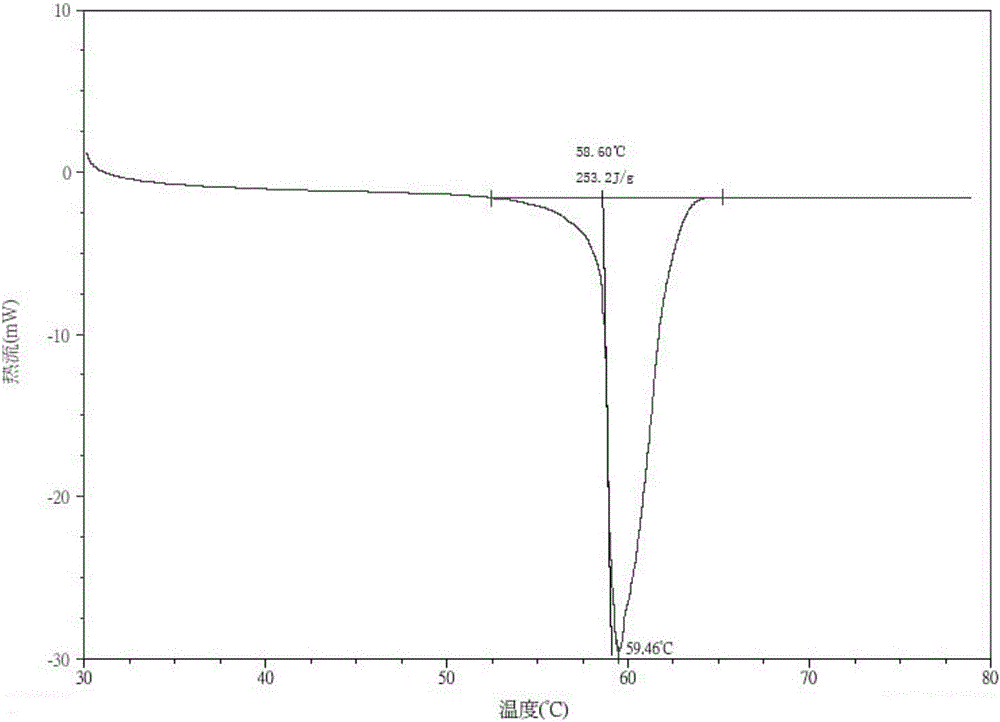

The invention discloses sodium acetate trihydrate phase change energy storage material compositions. The compositions mainly comprises sodium acetate trihydrate, a nucleating agent, a thickening agent and the like; and the phase change temperature is between 56 and 58 DEG C, the degree of supercooling is less than 3 DEG C and the phase change latent heat is more than 220kJ / kg. 3,000 times of cold and heat cycle tests prove that the compositions have particularly excellent phase change stability.

Owner:WIDE SPACE PHASE CHANGE TECH

Low-phase-transition-temperature heat storage material and preparation method thereof

InactiveCN106753259AHigh heat storage densityWide application temperature rangeHeat-exchange elementsHeat storage materialSodium Acetate Trihydrate

The invention discloses a low-phase-transition-temperature heat storage material and a preparation method thereof. The low-phase-transition-temperature heat storage material comprises the following components in parts by weight: 55 to 93 parts of sodium acetate trihydrate, 1 to 40 parts of a temperature regulator, 2 to 6 parts of deionized water, 1 to 2 parts of a thickener, and 2 to 3 parts of a nucleating agent. The phase transition heat storage material provided by the invention has the adjustable phase transition temperature of 35 to 56 DEG C, and the phase transition latent heat of 200 to 280 kJ / kg. The application temperature range of a sodium acetate trihydrate system is expanded, and the phase transition heat storage material provided by the invention belongs to solid-liquid phase transition, has high heat storage density and can be effectively applied to the field of civil life.

Owner:贺迈新能源科技(上海)有限公司

Solar water heater phase change heat storage material and its preparing method

InactiveCN1821340AHigh thermal efficiencyReduce volumeSolar heat devicesHeat-exchange elementsSolar waterZinc Acetate Dihydrate

The present invention discloses a kind of phase change heat storing material for solar water heater and its preparation process. The phase change heat storing material consists of sodium acetate trihydrate 80-90 wt%, barium hydroxide octahydrate 1-10 wt%, sodium borate decahydrate 1-5 wt%, zinc acetate 1-5 wt%, sodium dodecyl benzene sulfonate 1-5 wt% and gelatin 1-5 wt%. During the preparation, the mixture of the above said materials are heated to smelt completely to form the eutectic mixture, which is mounted inside solar water heater. The phase change heat storing material for solar water heater has phase change temperature fitting the operation temperature of solar water heater, high phase change latent heat, no overcooling and phase separation, no toxicity, no corrosion, stable performance and high repeatability, and is especially suitable for use in solar water heater.

Owner:NANJING UNIV

Clear liquid fermentation medium for clostridium butyricum and fermentation culture method thereof

InactiveCN102363754AHigh effective contentSimple post-processingBacteriaMicroorganism based processesBiotechnologySodium bicarbonate

The invention relates to a clear liquid fermentation medium for clostridium butyricum. The clear liquid fermentation medium, the pH value of which is 7-8, is made from glucose, tryptone, a yeast extract powder, ammonium sulfate, sodium bicarbonate, a maize liquid powder and the like. The clear liquid fermentation medium for clostridium butyricum contains metal salts for promoting the growth of gemma, wherein the metal salts are manganese sulfate, magnesium sulfate and ferrous sulphate. The enrichment medium of the clear liquid fermentation medium for clostridium butyricum contains yeast extract, beef extract, tryptone, glucose, soluble starch, sodium chloride, sodium acetate trihydrate, cysteine hydrochloride, methylene blue at the concentration of 0.5% and distilled water; and the pH is adjusted to 7.1. A fermentation culture method of the clear liquid fermentation medium for clostridium butyricum comprises the following steps of: glycerin tube refrigerated strain activation, heating and optimization, Erlenmeyer flask first-order seed culture, liquid fermentation and spray drying. The production of clostridium butyricum has advantages of simple operation, high amount of zymocyte, high gemma yield, simple post-treatment, less impurities in a bacterial powder sample and high amount of effective live bacteria, and saves cost at large.

Owner:HUAZHONG AGRI UNIV

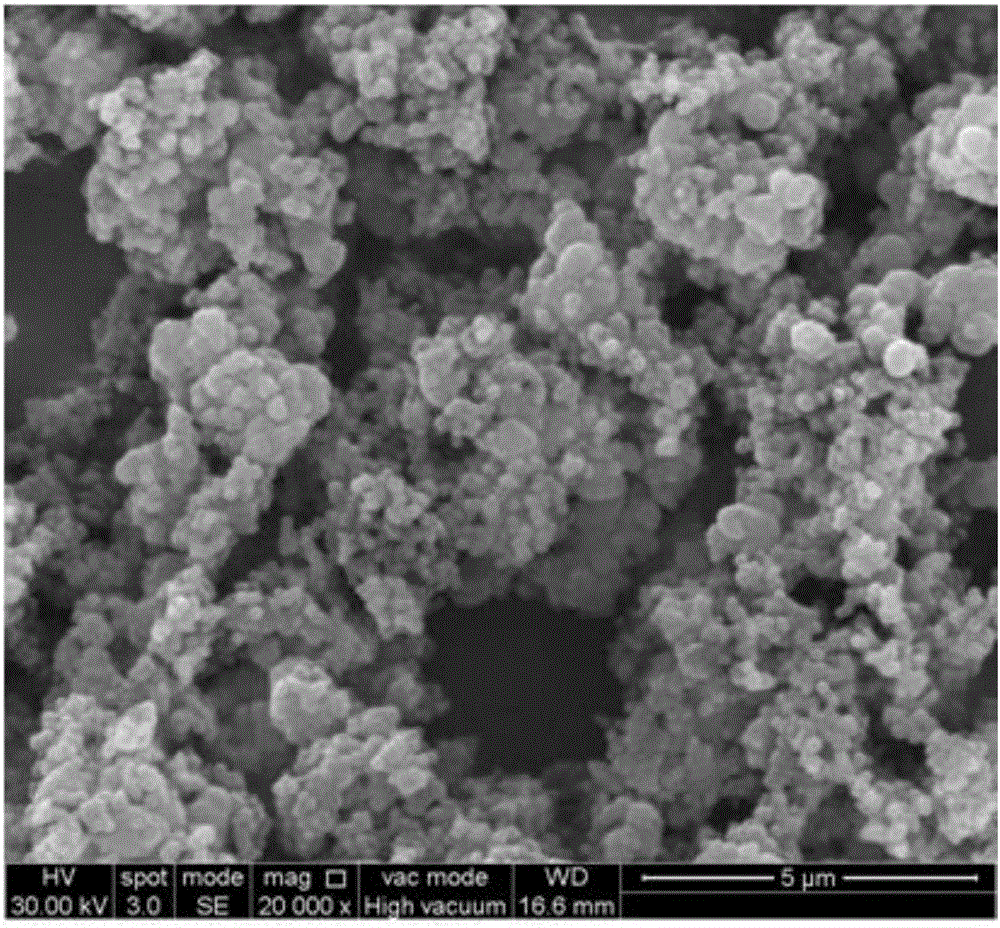

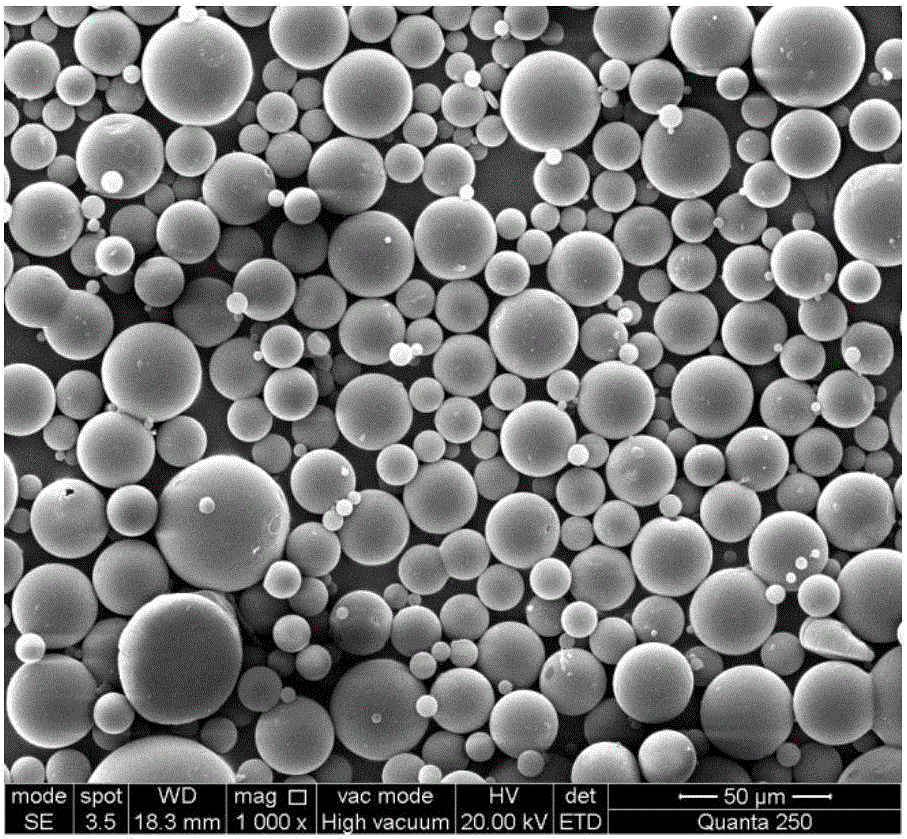

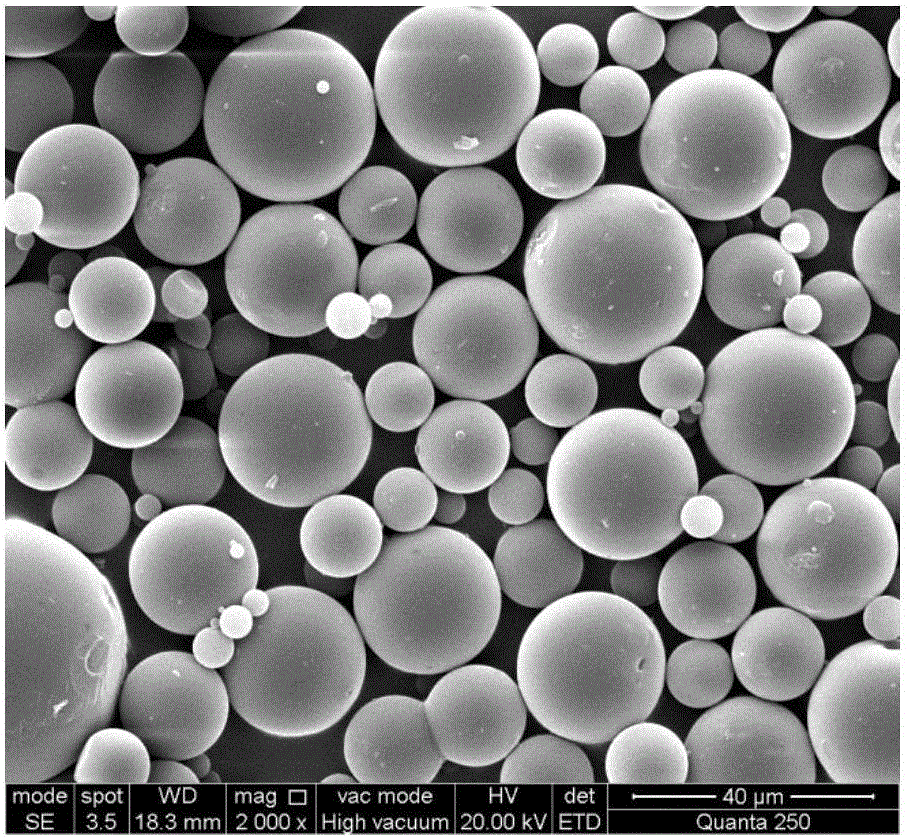

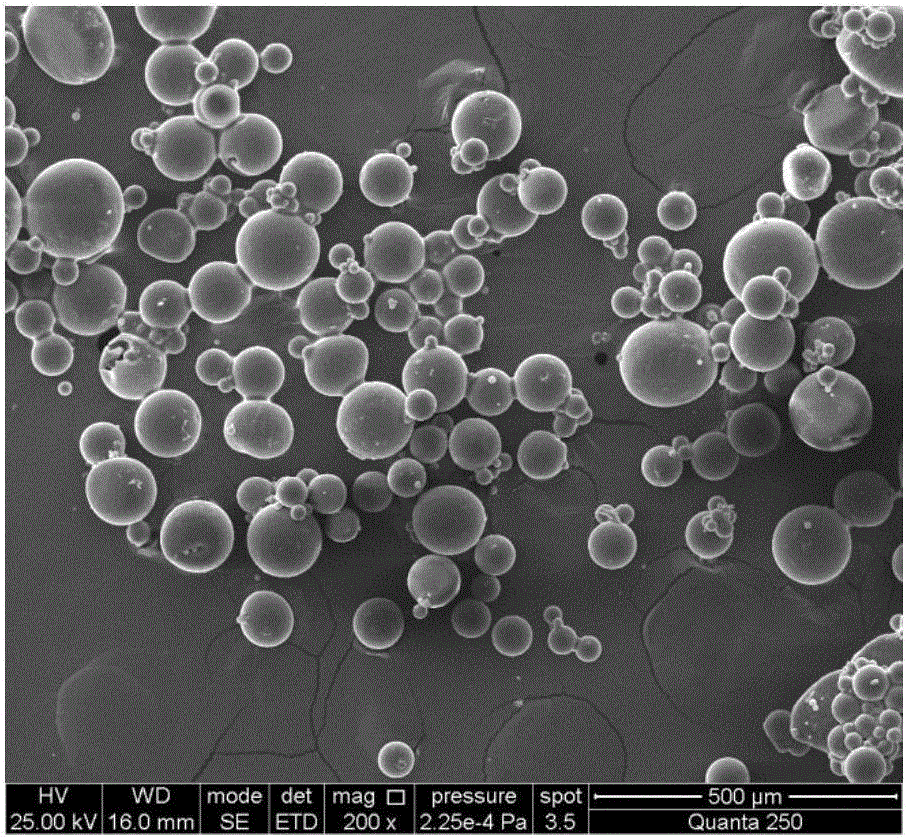

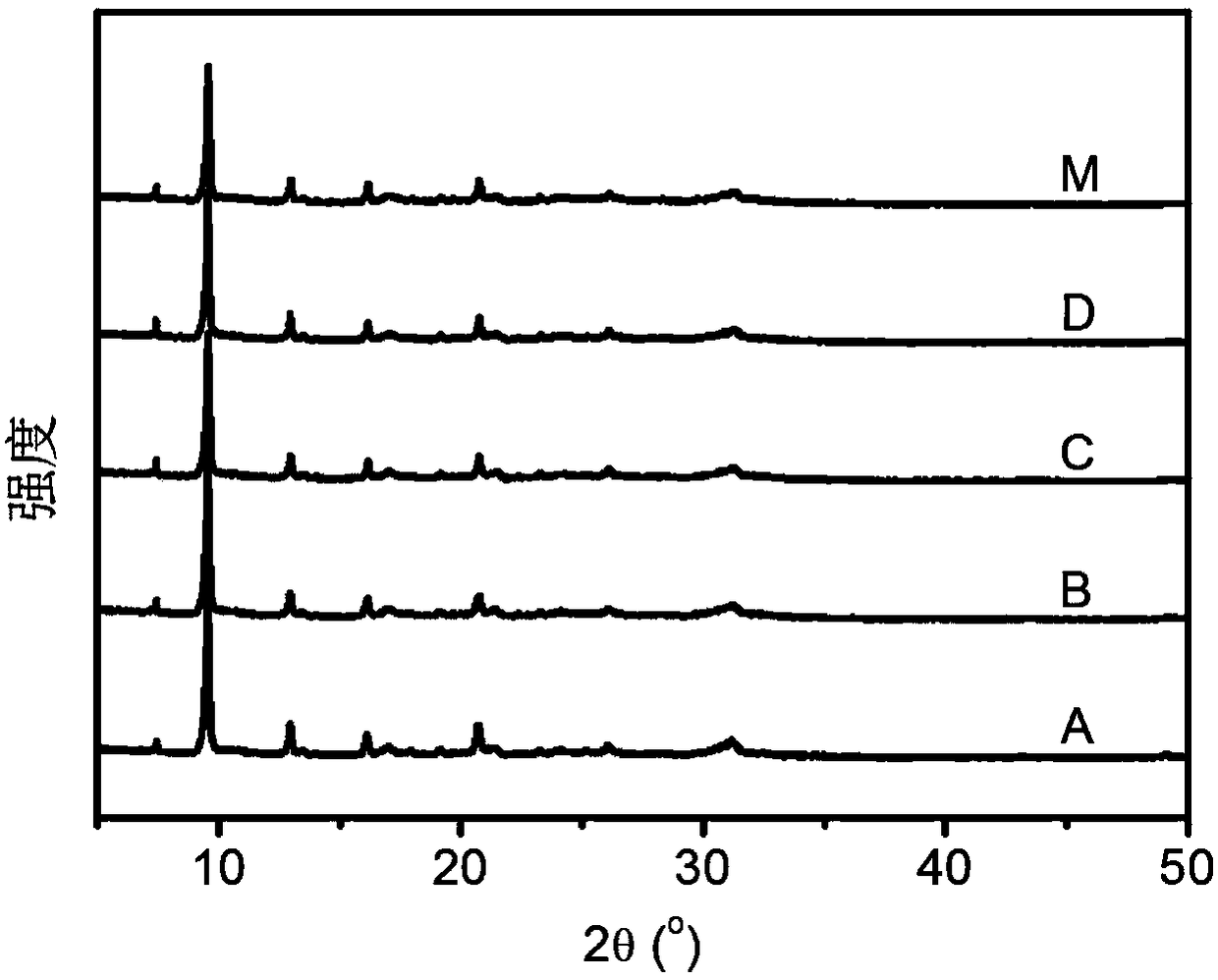

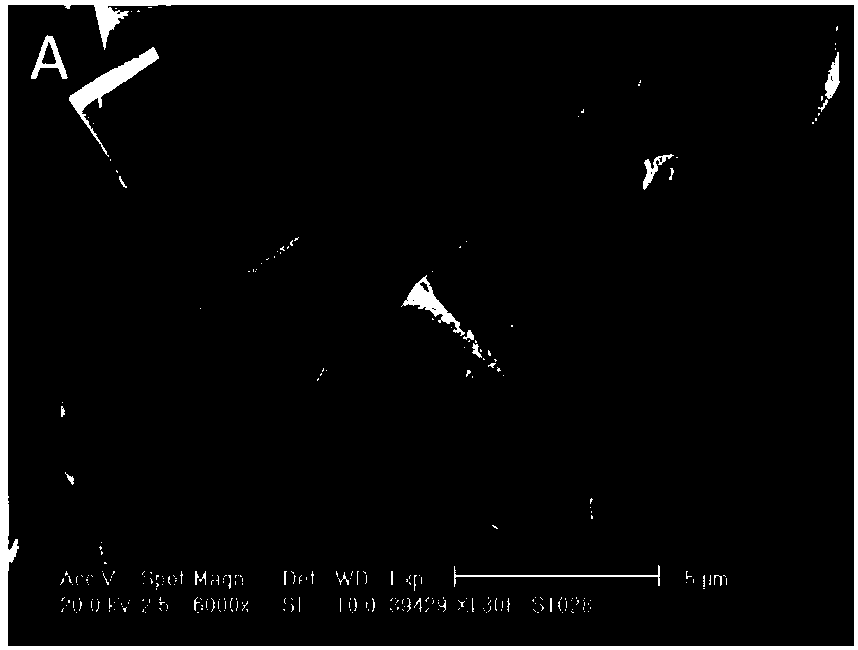

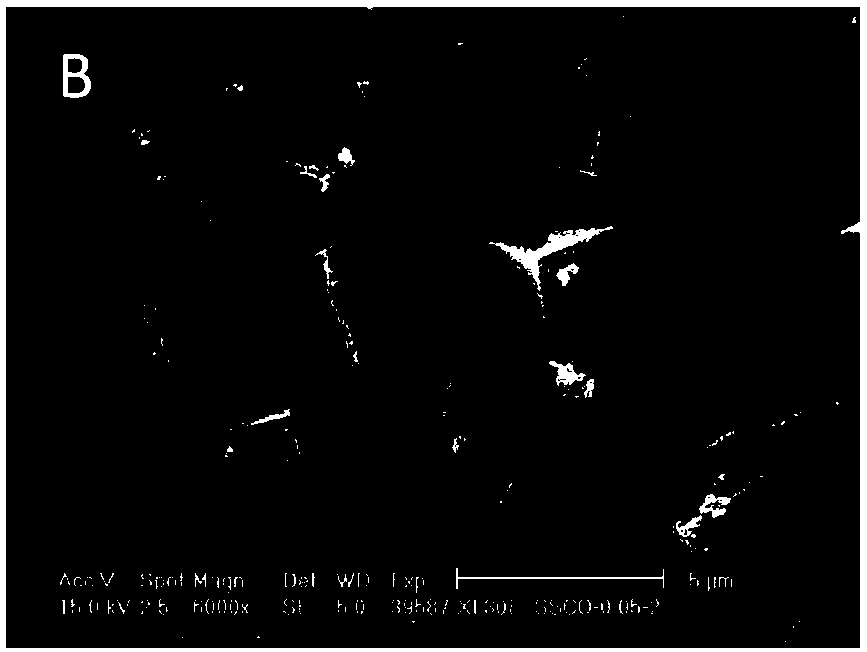

Inorganic hydrated salt phase change energy storage microcapsule and preparation method thereof

InactiveCN106244117AIncrease coverageSimple processHeat-exchange elementsCalcium Chloride HexahydratePotassium fluoride

Belonging to preparation methods of energy storage microcapsule materials, the invention provides an inorganic hydrated salt phase change energy storage microcapsule and a preparation method thereof. The energy storage microcapsule includes an inorganic hydrated salt serving as the core material and an inorganic material serving as the wall material. The core material is one or more of potassium fluoride dehydrate, sodium acetate trihydrate, sodium thiosulfate pentahydrate, calcium chloride hexahydrate, magnesium sulfate heptahydrate, barium hydroxide octahydrate, sodium sulfate decahydrate, sodium sulfate decahydrate, disodium hydrogen phosphate dodecahydrate, ammonium aluminium sulfate dodecahydrate, aluminum potassium sulfate dodecahydrate, and aluminum sulphate ocatadecahydrate. The wall material is one or more of silicon dioxide, calcium carbonate, alumina and titanium dioxide. The core material accounts for 30%-80% of the mass of the microcapsule composite material, and the wall material accounts for 20%-70% of the mass of the microcapsule energy storage material. The prepared phase change energy storage microcapsule material has a phase transition temperature of 25-100DEG C and a diameter of 0.1-50 micrometers. The phase change energy storage microcapsule has the advantages of high encapsulation rate, good sealing performance, large phase change potential heat value, and simple preparation method, and has great industrial application prospect.

Owner:CHINA UNIV OF MINING & TECH

Inorganic hydrous salt phase change microcapsule energy-storage material and preparing method

InactiveCN106221674AAchieve solidificationImprove heat transfer efficiencyHeat-exchange elementsCalcium Chloride HexahydrateSodium Thiosulfate Pentahydrate

The invention relates to a preparing method of an inorganic hydrous salt phase change microcapsule energy-storage material and belongs to preparing methods of energy-storage materials. The energy-storage material comprises a core material and a wall material, wherein the core material is prepared from one or more of calcium chloride hexahydrate, sodium sulfate decahydrate, sodium thiosulfate pentahydrate, disodium hydrogen phosphate dodecahydrate, sodium acetate trihydrate and sodium carbonate decahydrate inorganic hydrous salt, and the wall material is prepared from one or more of polystyrene, polymethyl methacrylate, poly(ethyl acrylate), polyurethane, cellulose acetate butyrate (CAB) and a diphenylmethane diisocyanate polymer, the core material accounts for 30-80% of the microcapsule energy-storage material by mass, and the wall material is prepared from the polymer and accounts for 20-70% of the microcapsule energy-storage material by mass. The phase change point of the obtained phase change microcapsule energy-storage material ranges from 20 DEG C to 90 DEG C, and the particle size ranges from 1 micrometer to 100 micrometers. The phase change microcapsule energy-storage material prepared with the method is high in encapsulation rate, good in sealing performance, large in phase change latent heat value, simple in preparing method and large in industrial application prospect.

Owner:CHINA UNIV OF MINING & TECH

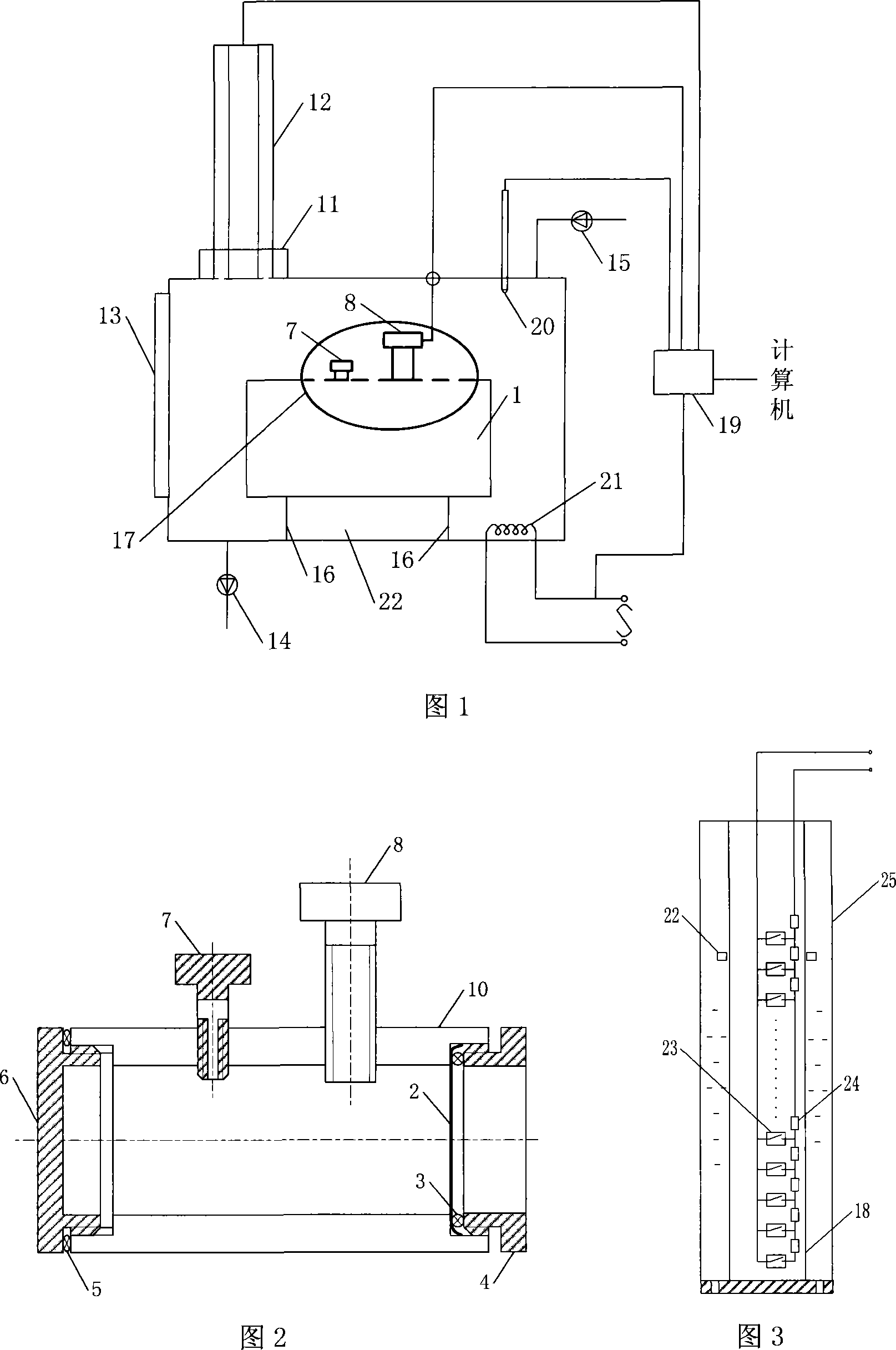

Solid-liquid phase change material normal pressure thermal expansion rate and work volume digital measuring device

InactiveCN101187643AShortcutEasy to operateMaterial thermal coefficient of expansionWork measurementWorking fluidMeasurement device

The invention discloses a digital measuring device for a heat expansion rate and working quantity of solid-liquid phase transformation materials under normal pressure, which belongs to the physical measuring field. The invention comprises an inner container, an outer container, an air discharging lock, a pressure sensing device, a water level gauge, a water valve, a sampling control unit, a heat electric couple, and an automatic electric heater. The inner container is arranged crosswise inside the outer container, an emulsion film is arranged on one end of the inner container through a compression ring and an O-shaped rubber ring, the inner container is filled fully with measuring working fluid, the outer container is filled fully with water, the rubber ring is expanded out due to an expansion of the working fluid along water temperature rising inside the outer container, and water level inside the water gauge rises. The heat expansion rate and the working quantity of the solid-liquid phase transformation materials under normal pressure can be calculated out according to liquid levels as volume expansion signal, temperature and pressure signal, which provides a convenient and reliable approach for performance measurement of the solid-liquid phase transformation materials. The invention is applicable to materials as n-pentadecane, n-hexadecane, heptadecane, sodium acetate trihydrate, storing thermal paraffin RT 54 which is produced by a German company, and the similar materials.

Owner:SHANGHAI JIAO TONG UNIV

Formula and preparation method of composite carbon source for denitrification

PendingCN108793401AIncrease concentrationReduce transportationWater treatment compoundsTreatment with anaerobic digestion processesSodium acetateReaction temperature

The invention relates to a formula and a preparation method of a composite carbon source for denitrification, and relates to prevention and control of water pollution. The formula comprises the following components: 0 to 20% of calcium acetate, 5% to 25% of sodium acetate, 5% to 40% of glucose, 0 to 20% of ethanol, and 40% to 70% of water, of which the total amount is 100%. The formula at least comprises sodium acetate, glucose and water, and the mass percent of the carbon source material in the carbon source formula is 30% to 60%. The preparation method comprises the following steps: injecting tap water into a reaction kettle and stirring, adding calcium hydroxide, and injecting acetic acid; controlling the reaction temperature and pH, and reacting to generate a calcium acetate solution;adding sodium acetate trihydrate until completely dissolved; adding glucose monohydrate and stirring until completely dissolved; when the temperature of the solution is lowered to room temperature, adding ethanol. The solution is pumped out of the reaction kettle to a storage tank for standing, and a supernatant liquid is the prepared composite carbon source for denitrification.

Owner:石泰山

Method utilizing acetic acid in PTA oxidation residues to prepare sodium acetate trihydrate

The invention relates to a method utilizing acetic acid in purified terephthalic acid oxidation residues to prepare sodium acetate trihydrate. The method includes the following steps of: 1. purification of dilute acetic acid; 2. neutralization; 3. evaporation; 4. impurities removing; 5. crystallization; 6. drying.

Owner:辽阳合成催化剂有限公司

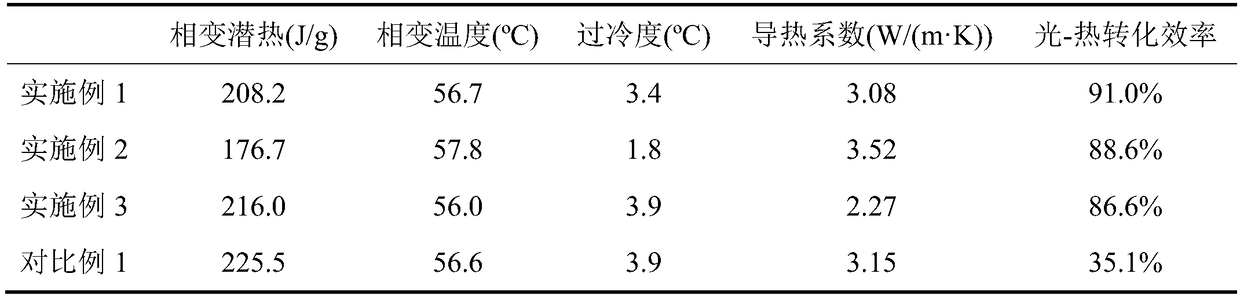

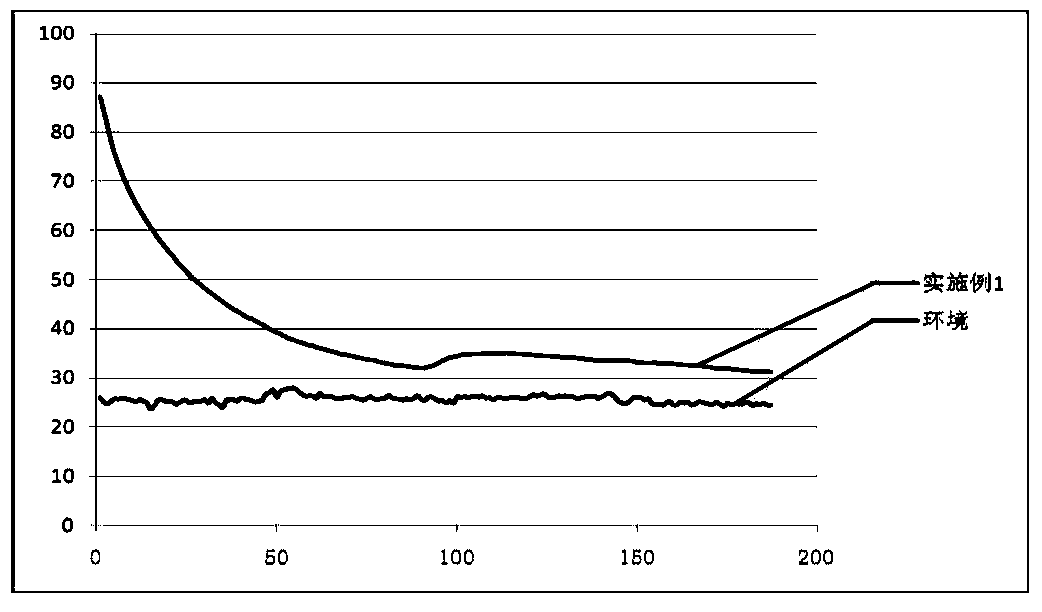

High thermal conductivity light-heat converting compound phase-changeable heat storage material for solar water heater and preparation method thereof

InactiveCN109181649AHigh latent heat of phase changeImprove thermal conductivityHeat-exchange elementsLight energyRoom temperature

The invention discloses a high thermal conductivity light-heat converting compound phase-changeable heat storage material for a solar water heater and a preparation method thereof. The preparation method comprises the following steps: mixing sodium acetate trihydrate with a nucleating agent, heating to 60-80 DEG C and keeping temperature for 1-3h; adding expanded graphite and uniformly stirring, thereby acquiring a uniform sodium acetate trihydrate / expanded graphite mixture; adding a nanometer light-heat converting material while stirring under the temperature of 60-80 DEG C, and continuouslystirring for 2-4h; cooling to room temperature and then pressing the stirred mixed material into a block in density of 0.5-2g / cm<3>, thereby acquiring the high thermal conductivity light-heat converting compound phase-changeable heat storage material. The high thermal conductivity light-heat converting compound phase-changeable heat storage material not only has ideal heat storage density and heatconductivity but also can effectively convert luminous energy into heat energy and has a heat conductivity coefficient of 2.27-3.52W / (m.K) and a light-heat converting rate of 86.6-91.0%.

Owner:SOUTH CHINA UNIV OF TECH

Method for treating acidic wastewater of acrylic acid device

ActiveCN103803741AImprove energy savingEmission reduction effect is obviousOrganic chemistryMultistage water/sewage treatmentSodium acetrizoateEmission standard

The invention relates to a method for treating acidic wastewater of an acrylic acid device. According to the method, a coupling technology is adopted for treating the acidic wastewater; according to the coupling technology, an oxidant is used for oxidizing and removing formaldehyde, acetaldehyde and acraldehyde out of the acidic wastewater; an alkali is used for neutralizing acetic acid and acrylic acid in oxidizing liquid; neutralizing liquid is separated by a membrane to remove water; and finally reduced-pressure concentrating, crystallizing and drying are carried out to prepare acetate. The formaldehyde removing rate of the oxidizing liquid in the method is more than 99.5%; after the neutralizing liquid is subjected to RO (Reverse Osmosis) membrane separation, transmitting liquid reaches national environment protection emission Standard II; the yield of sodium acetate trihydrate is more than 7.7% on the basis of the raw material acidic wastewater; and the sodium acetate trihydrate product can be used as a raw material of a snow-melting agent.

Owner:PETROCHINA CO LTD

Phase change heat storage material and preparation method and application thereof

ActiveCN103666378AThe phase transition process is reversibleReduce subcoolingHeat-exchange elementsHeat storage materialSodium Acetate Trihydrate

The invention discloses a phase change heat storage material and a preparation method thereof. The phase change heat storage material comprises the following raw materials in parts by weight: 55-70 parts of sodium acetate trihydrate, 1-5 parts of a phase change point conditioning agent, 20-30 parts of a softening agent, 1.08 parts of a nucleating agent, 0.5-1 part of an overcooling-proof agent and 5-15 parts of water. The phase change temperature of the prepared phase change heat storage material is 50-55 DEG C, the latent heat of phase change is 200-250 KJ / kg, the phase change process is reversible, the degree of overcooling is low, softness can be kept after phase change crystallization, and the application potentiality is high in various heat storage fields. The phase change heat storage material is soft and elastic, and can be used for heat storage type heating pads which are particularly used after shower; the phase change heat storage material can also be used for indoor heating appliances of foot pads, cushions and the like.

Owner:ZHEJIANG TRIPLE WIN MEDICAL APPLIANCE

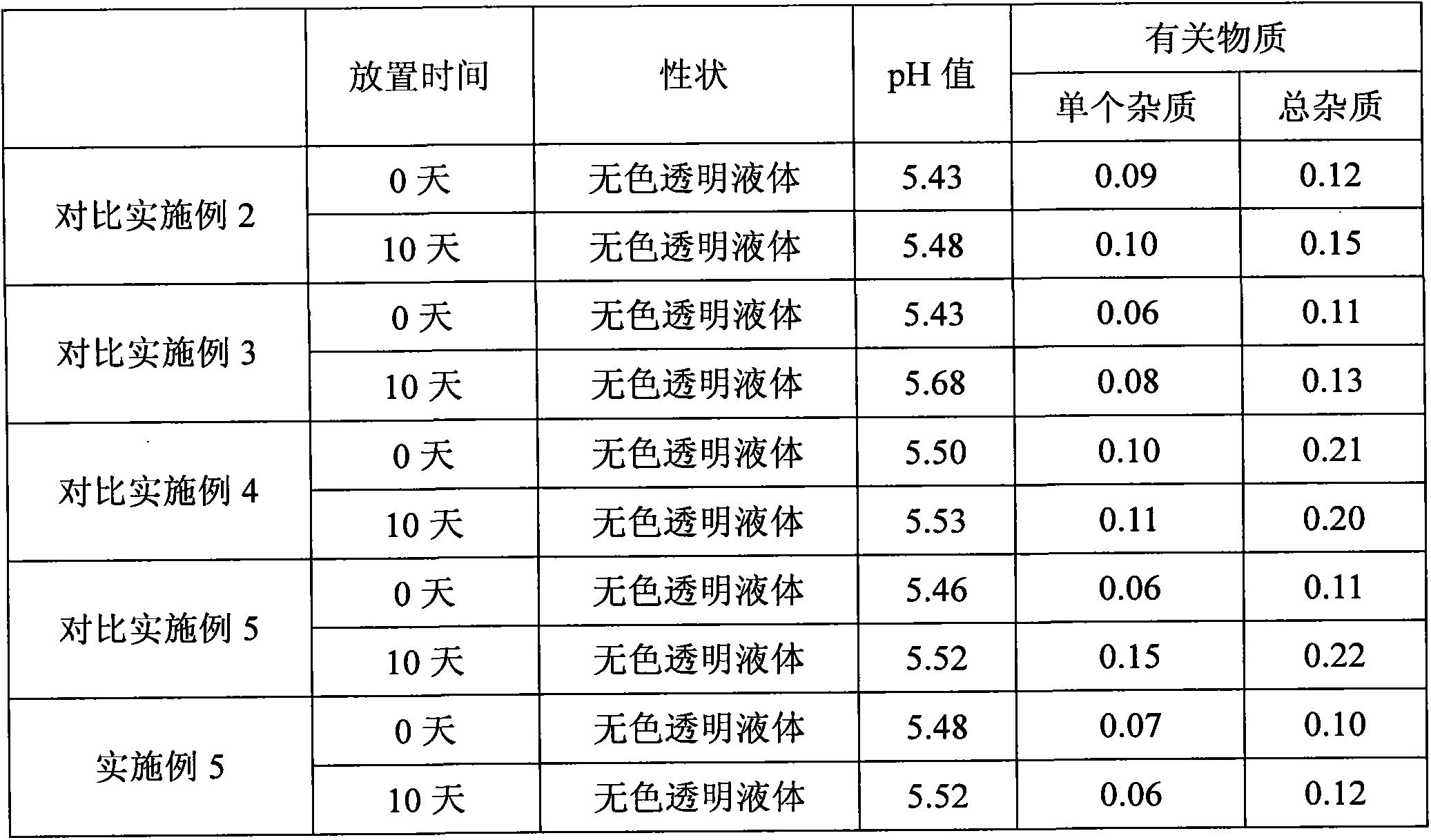

Stable anti-VEGF antibody preparation and application thereof

ActiveCN104922668AReduce spawn rateImprove physical stabilityInorganic non-active ingredientsAntibody ingredientsAnti vegf antibodySodium Acetate Trihydrate

The invention relates to a stable anti-VEGF antibody preparation and an application thereof, specifically the preparation comprises (i) therapeutically effective amounts of an anti-VEGF antibody, (ii) a buffer system containing 1.0-5.0mg / ml of sodium acetate trihydrate, (iii) an osmotic pressure regulator, and optionally (iv) surfactant, wherein the pH of the preparation ranges from 5.0 to 6.0. The preparation disclosed by the invention can be used for effectively reducing the physical and chemical degradation reaction rates of an anti-VEGF monoclonal antibody, improving antibody stability and prolonging the shelf life of a finished product; in addition, the invention also discloses a method for stabilizing the antibody and an application of the preparation.

Owner:INNOVENT BIOLOGICS (SUZHOU) CO LTD

Low-temperature phase-change heat storage material and preparation method thereof

The invention provides a low-temperature phase-change heat storage material and a preparation method thereof. The heat storage material comprises the following three components in percentage by weight: 90-92% of sodium acetate trihydrate, 4.5-5.8% of sodium phosphate dibasic dodecahydrate and 2.2-4.2% of gelatin. The preparation method comprises the following steps of: grinding all the three components into 30-50 meshes, uniformly mixing the three powders, heating the mixture in a 69-72 DEG C water bath so that all components are fully melted to become a colloidal liquid, uniformly agitating the colloidal liquid, injecting the colloidal liquid into a container, cooling the colloidal liquid into room temperature and sealing the container, wherein the injection volume of the colloidal liquid is 88-90% of the volume of the container. The low-temperature phase-change heat storage material has fewer additive varieties, high stability, great latent heat of phase change and moderate crystallization temperature, and the degree of supercooling does not exceed 2 DEG C. The phase-change heat storage material becomes a colloidal liquid when melted, the phase separation phenomenon is avoided, the preparation process is simple, and the phase-change heat storage material is easy to package and convenient to produce.

Owner:路生吉

Solar water heater phase change heat storage material and its preparing method

InactiveCN100334179CHigh thermal efficiencyReduce volumeSolar heat devicesHeat-exchange elementsSodium acetrizoateSolar water

The present invention discloses a kind of phase change heat storing material for solar water heater and its preparation process. The phase change heat storing material consists of sodium acetate trihydrate 80-90 wt%, barium hydroxide octahydrate 1-10 wt%, sodium borate decahydrate 1-5 wt%, zinc acetate 1-5 wt%, sodium dodecyl benzene sulfonate 1-5 wt% and gelatin 1-5 wt%. During the preparation, the mixture of the above said materials are heated to smelt completely to form the eutectic mixture, which is mounted inside solar water heater. The phase change heat storing material for solar water heater has phase change temperature fitting the operation temperature of solar water heater, high phase change latent heat, no overcooling and phase separation, no toxicity, no corrosion, stable performance and high repeatability, and is especially suitable for use in solar water heater.

Owner:NANJING UNIV

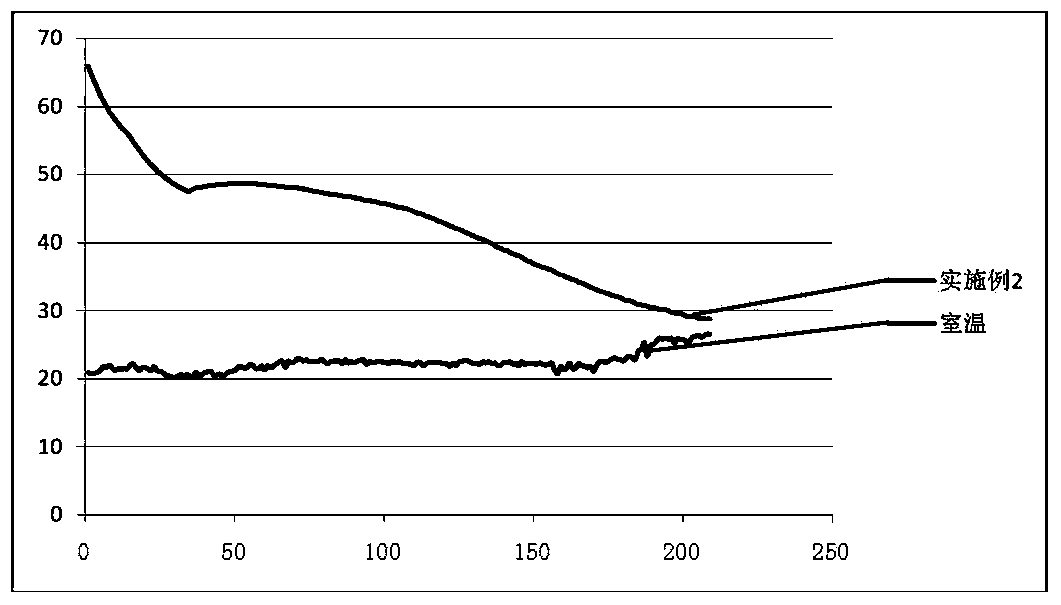

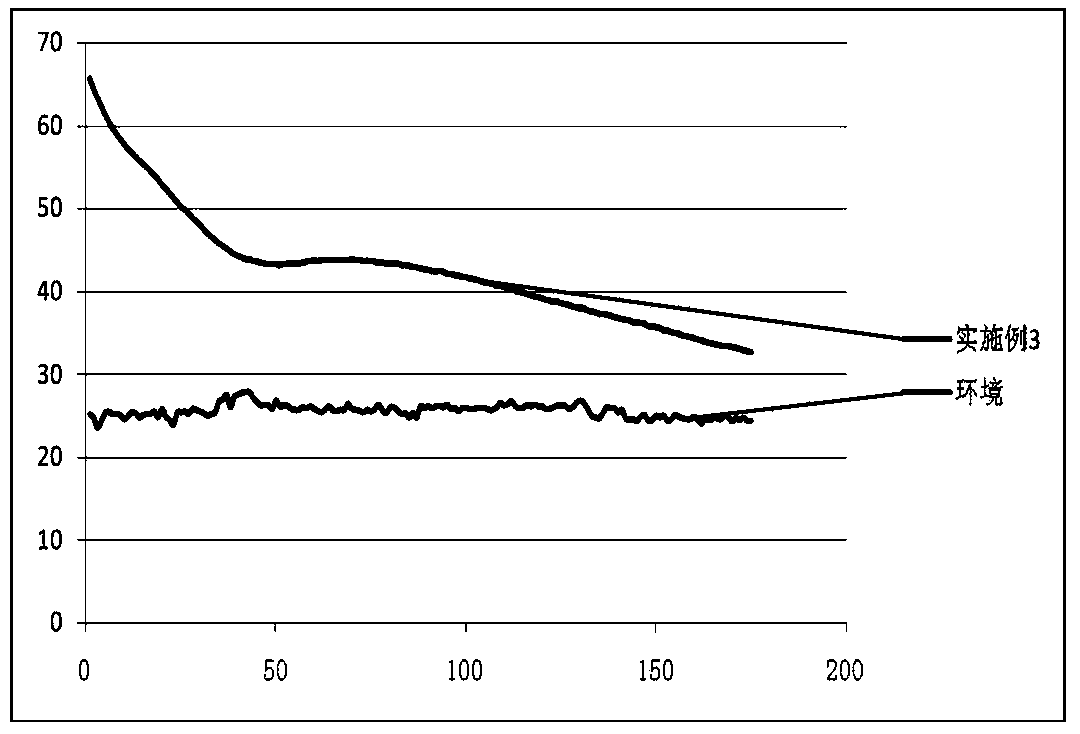

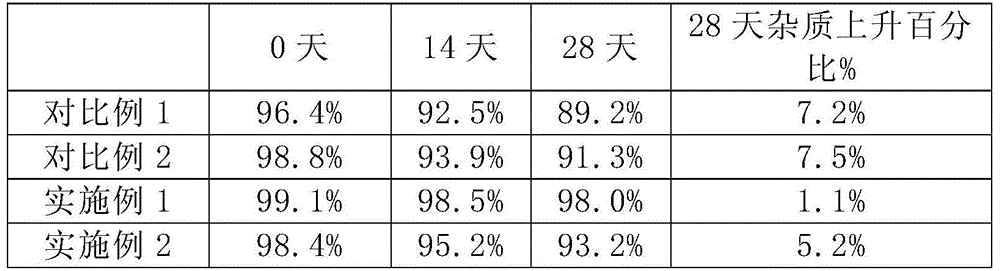

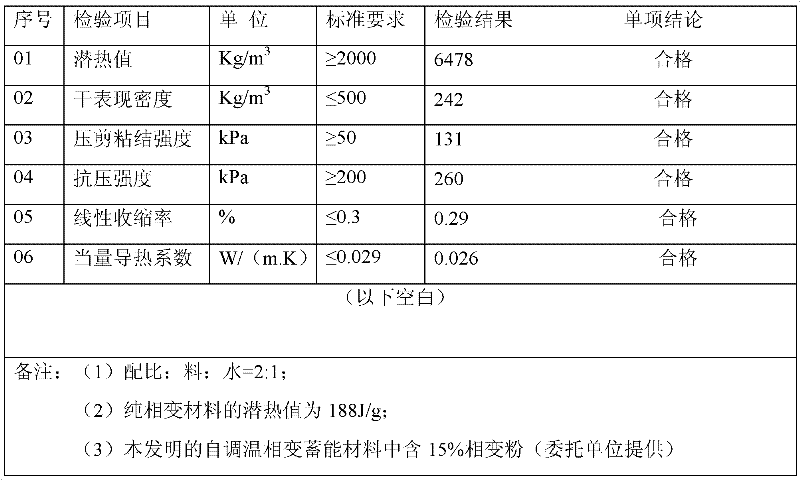

A self-regulating temperature phase change energy storage material and its preparation method

InactiveCN102268239ASolve the phenomenon of mildewLow cost of organic phase transformationHeat-exchange elementsThermal insulationThermostat

The invention discloses a self-regulating temperature phase change energy storage material and a preparation method thereof. The phase change material includes: inorganic phase change material, organic phase change material and expanded perlite, cementitious material, anti-cracking material or slow setting viscosity increasing material. The preparation method of the self-regulating phase change energy storage material of the present invention comprises the steps of: 1) mixing paraffin, butyl palmitate and sodium acetate trihydrate for use; 2) adding expanded porous perlite in a vacuum reactor, Evacuate the air in the kettle, then slowly add the mixture in 1) and stir, slowly pressurize the kettle to make the mixture in 1) penetrate into the expanded porous perlite, and wait until the mixture in 1) completely penetrates into the expanded perlite phase change material component to complete; 3) Mix and stir the substance obtained in 2) with the coagulation material, thermal insulation components, and polymer polymers to obtain a thermal insulation and energy-saving material. The phase-change energy-saving material of the present invention uses a mixture of organic phase-change materials and inorganic material intersecting materials as phase-change components. The product has high heat storage, good chemical stability, and low heat transfer rate. Features such as limitations in the scope of use.

Owner:北京博美宏业建材有限公司

Preparation method of levetiracetam injection

ActiveCN103550143ASimple production processImprove product qualityOrganic active ingredientsNervous disorderSodium acetateAcetic acid

The invention discloses a preparation method of levetiracetam injection. The preparation method of the levetiracetam injection comprises the following steps: every 5ml of injection contains the following components by mass: 500mg of levetiracetam, 8.2mg of sodium acetate trihydrate and 45mg of sodium chloride; cooling water for injection to the temperature below 30 DEG C, adding sodium acetate and sodium chloride, and dissolving; then adding levetiracetam bulk drug in prescribed dose and dissolving; regulating pH value of a solution to be 5.0-6.0 with glacial acetic acid; filtering by virtue of a microfiltration membrane with the thickness of 0.22 microns, filling and sterilizing. The preparation method of the levetiracetam injection is simple in technology, and product quality is stable.

Owner:ZHEJIANG HUAHAI PHARMACEUTICAL CO LTD

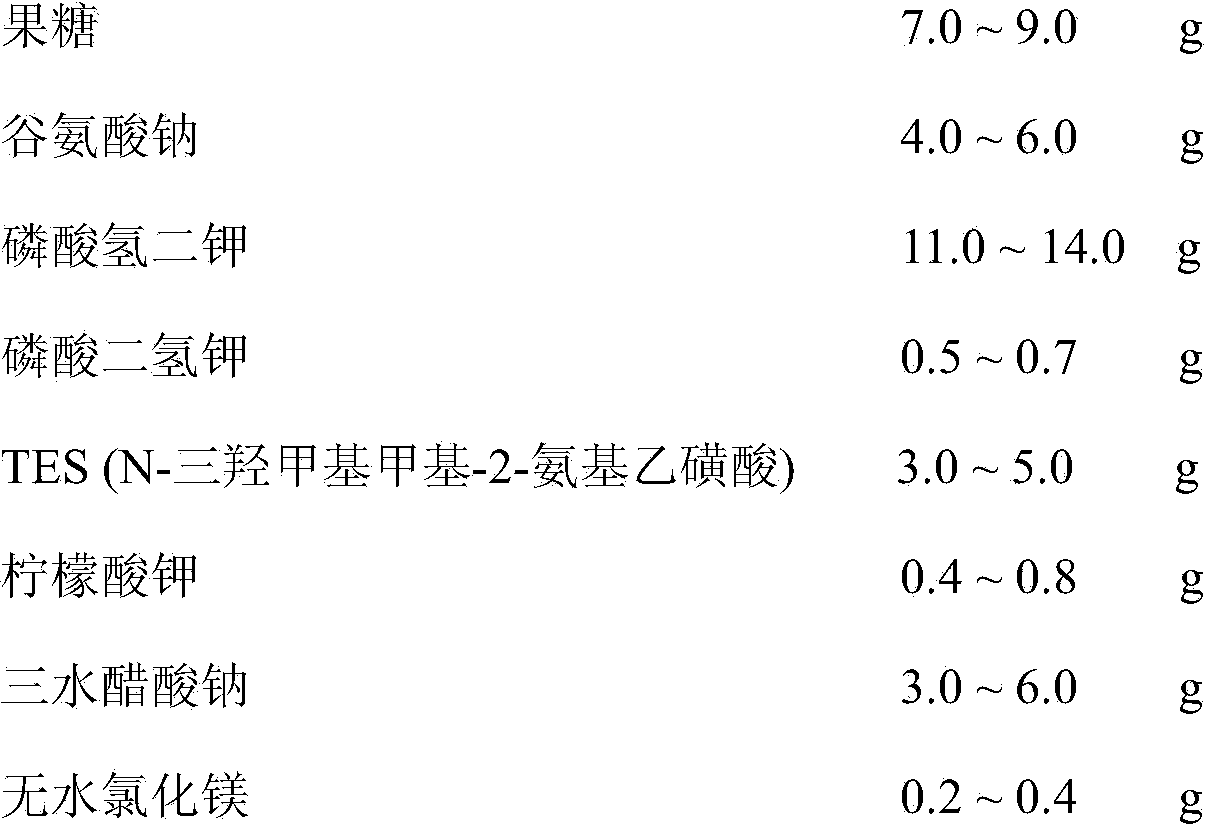

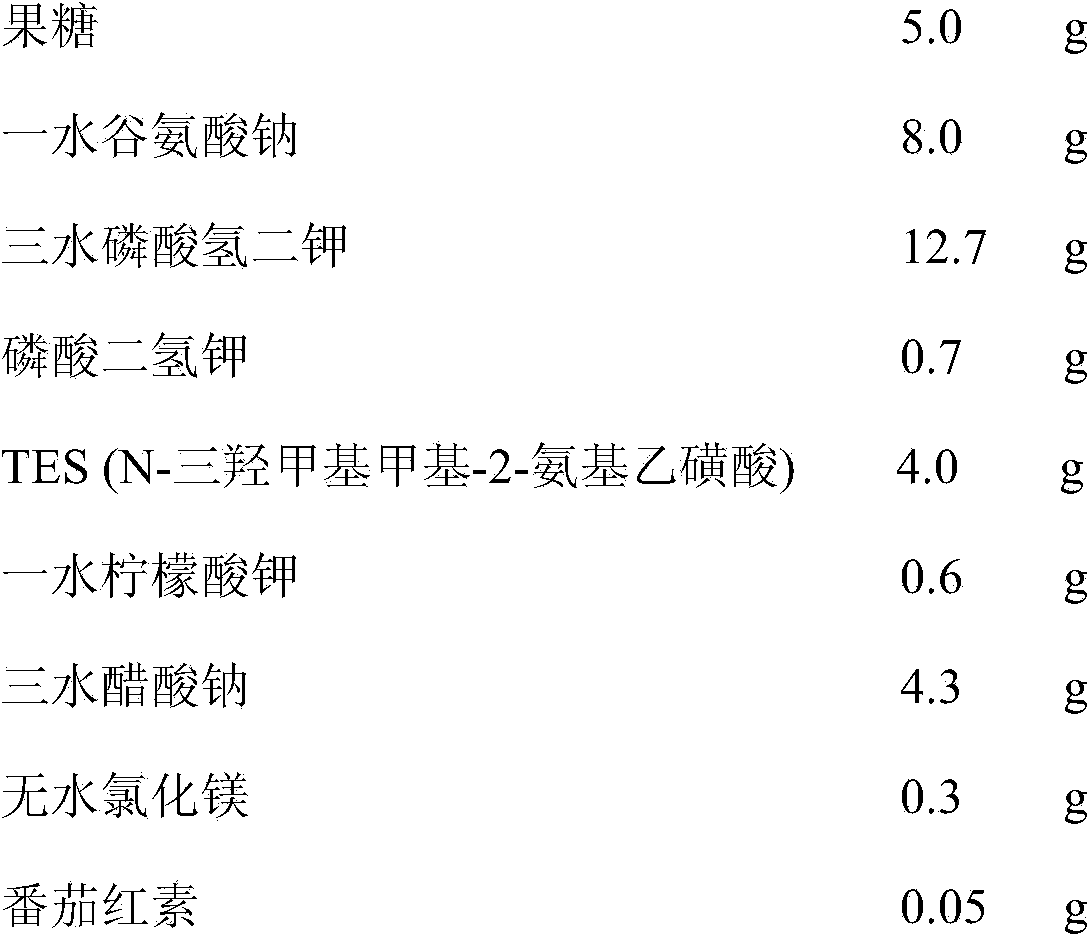

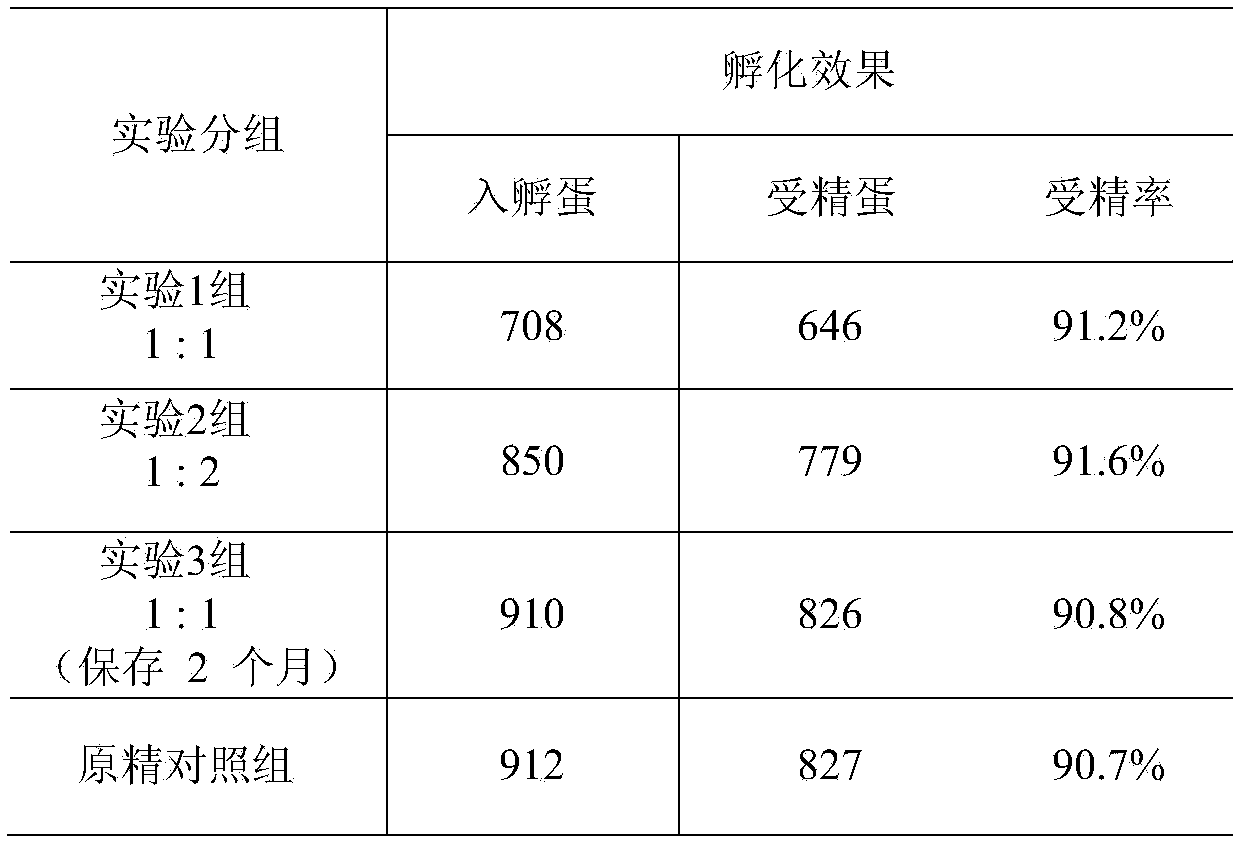

Chicken semen diluent and preparation and utilization methods thereof

InactiveCN104094926AExtended shelf lifeThe preparation method is simple and easyDead animal preservationLycopeneDipotassium phosphate

Chicken semen diluent comprises 7.0 to 9.0 g per L of fructose, 4.0 to 6.0 g per L of sodium glutamate, 11.0 to 14.0 g per L of dipotassium phosphate, 0.5 to 0.7 g per L of monopotassium phosphate, 3.0 to 5.0 g per L of TES (N-[tris(hydroxymethyl)methyl]-2-aminoethanesulfonic acid), 4.0 to 0.8 g per L of potassium citrate, 3.0 to 6.0 g per L of sodium acetate trihydrate, 0.2 to 0.4 g per L of anhydrous magnesium chloride, 0.05 to 0.1 g per L of lycopene. A PH (Potential of Hydrogen) value of the diluent is from 7.3 to 7.5 and the osmotic pressure is from 260 to 380 mOsm. The invention also provides preparation and utilization methods for the chicken semen diluent. The preparation and utilization methods for the chicken semen diluent are characterized in that the lycopene is added to the diluent, adjusting modes of the PH value and an osmotic pressure are changed, the diluent is stored in a cryopreservation mode, the semen deposition can be performed immediately after the chicken semen is diluted or after the cold storage, and the diluent also can be used as fundamental liquid for semen cryoprotectant. The chicken semen diluent has the advantages of being simple in preparation method, long in expiration data, free of antibiotics and stable in fertility rate.

Owner:燕海峰

Phase change material for solar energy storage

The invention relates to a phase change material for solar energy storage. The material is composed of 80-85% of sodium acetate trihydrate, 5-8% of nucleating agent and 7-15% of sizing carrier, wherein the nucleating agent is a mixture of ethyl alcohol and fluoric acid kali salt, and the sizing carrier is expanded graphite. The problems of condensate depression and phase separation when sodium acetate trihydrate is used as a solar energy storage material can be solved. According to the phase change material, crystal form nucleation is conducted by means of fluoric acid kali salt, and nucleation is achieved quickly by means of surface tension of a phase interface formed when ethyl alcohol makes contact with the phase change material. The combination of the two nucleation modes generates a mutual induction effect, and failure of a single nucleation mode caused by ultrahigh transient temperature in practical use is avoided.

Owner:河北昊宇新能源科技有限公司

Preparation method of silicon aluminum phosphate molecular sieve of multilevel porous structure, prepared molecular sieve and application of molecular sieve

InactiveCN108264058AImprove reaction stabilityHigh yieldMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesSodium acetateALUMINUM PHOSPHATE

The invention relates to a preparation method of a silicon aluminum phosphate molecular sieve of a multilevel porous structure, the prepared molecular sieve and application of the molecular sieve. Thepreparation method and the prepared molecular sieve are mainly used for solving the problems that the operation process is complicated and the cost is high since mesoporous template agents are adopted for synthesis in the prior art. The method includes the step of adopting the silicon aluminum phosphate molecular sieve of the porous structure for being in contact with a solution containing a modifier, wherein at least one of ammonium hydroxide, oxalic acid, acetic acid, ethanedioic acid, citric acid, sodium carbonate, sodium acetate trihydrate, sodium acetate, sodium hypochlorite, tetraethylammonium hydroxide, tetrapropylammonium hydroxide and tetrabutyl ammonium hydroxide is adopted as the modifier. By means of the technical scheme, the problems above are well solved, and the preparationmethod can be applied to industrial production of silicon aluminum phosphate molecular sieves of multilevel porous structures.

Owner:CHINA PETROLEUM & CHEM CORP +1

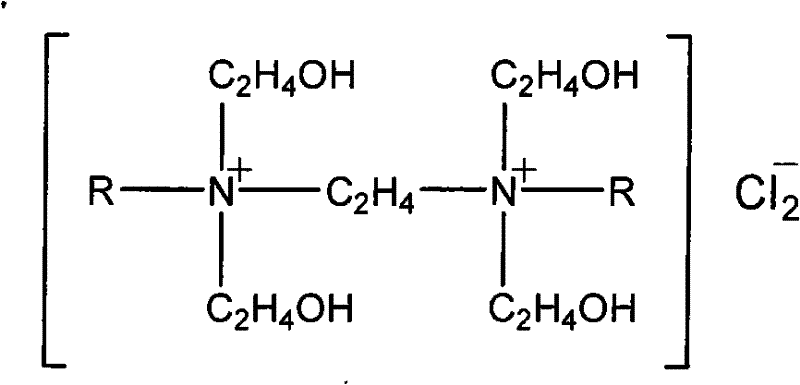

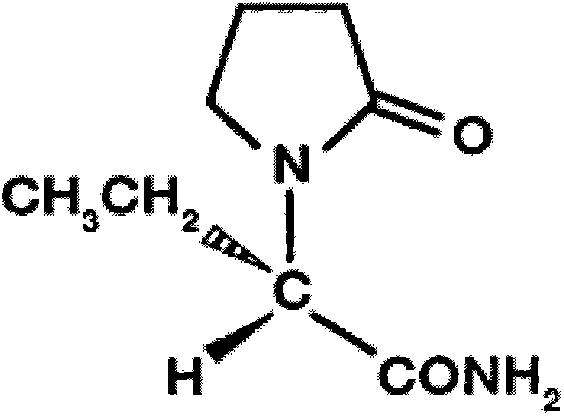

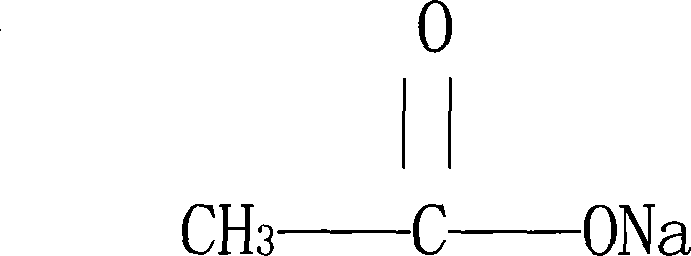

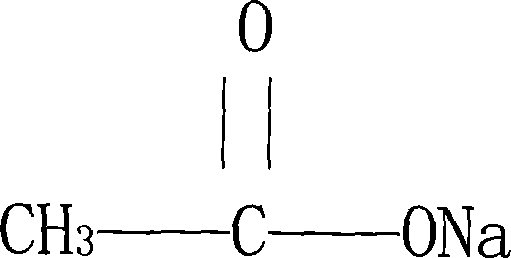

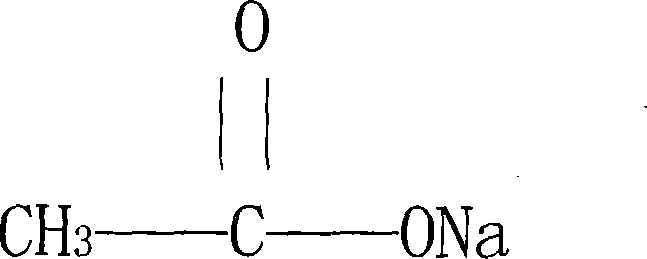

Sodium acetate anhydrous and preparation method and usage thereof

ActiveCN101139280ANo pollution in the processGood chemical stabilityMetabolism disorderCarboxylic acid salt preparationChemical structureSodium acetate

The molecular formula of an anhydrous sodium acetate is C2H3NaO2; the molecular weight is 82.03; and the anhydrous sodium acetate has the following chemical structure. The preparation method is: the sodium acetate trihydrate is got and heated to be between 120 and 130 DEG C; then the sodium acetate trihydrate is decompressed and concentrated, cooled and crystallized, and dried to get the anhydrous sodium acetate. The anhydrous sodium acetate is clinically applied in the circulating blood volume, the supplement of the outer liquid of the cell when the issue liquid is reduced, and the metabolic acidosis. The advantages are: the anhydrous sodium acetate has the good solubility in water; the chemical stability is good, suitable for the human medication requirements; the anhydrous sodium acetate is easy to be stored. Because the anhydrous sodium acetate can be dissolved in water; the anhydrous sodium acetate is more suitable for the pharmaceutical preparation, in particular for the preparation of the injection. The preparation method is characterized in the high collection rate, the good product quality, the low production cost, no environmental pollution, and so on. The anhydrous sodium acetate is clinically applied in the circulating blood volume, the supplement of the outer liquid of the cell when the issue liquid is reduced, and the metabolic acidosis.

Owner:HUBEI DUORUI PHARMA

Low-temperature phase change thermal storage material and preparation method thereof

InactiveCN102757766AReduce typesAdd a small proportionHeat-exchange elementsRoom temperatureCrystallization temperature

The invention provides a low-temperature phase change thermal storage material and a preparation method thereof. The low-temperature phase change thermal storage material comprises the following components by weight: 96-98% of sodium acetate trihydrate, 1-2% of sodium pyrophosphate decahydrate and 1-2% of polyacrylamide. The preparation method comprises the following steps: weighed sodium acetate trihydrate is heated in a reaction kettle to 68.5-71 DEG C; weighed sodium pyrophosphate decahydrate and polyacrylamide are sequentially added in the reaction kettle after the sodium acetate trihydrate is completely melted; stirring and mixing are performed at the same time; the mixture at 68.5-71 DEG C is filled into a container after being stirred fully and uniformly, with the volume dose of the mixture filled into the container being 88-90% of the volume of the container; and the container is sealed after the liquid mixture is cooled to be at room temperature. The invention has the advantages that fewer additives are added; the material is high in stability and phase change latent heat and moderate in crystallization temperature, and doesn't exceed 2 DEG C in degree of supercooling; the phase change thermal storage material is a gelatiniform liquid when melted, so as to avoid a phase separation phenomenon; the preparation process is simple, and the encapsulation is easy; and the production is convenient.

Owner:路生吉

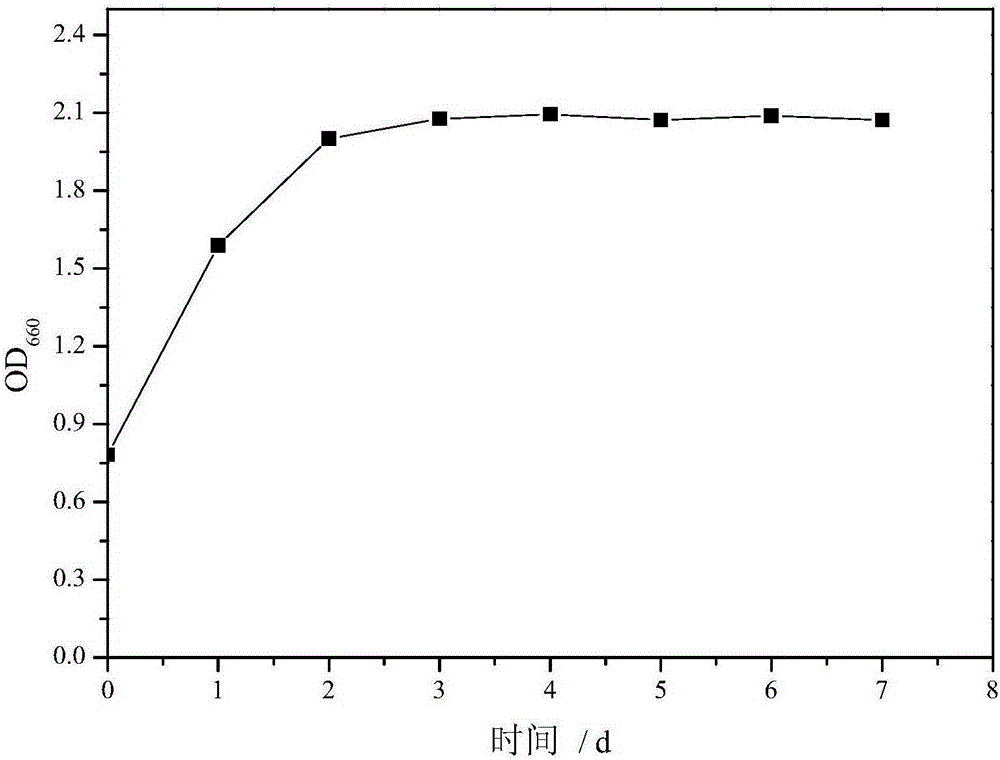

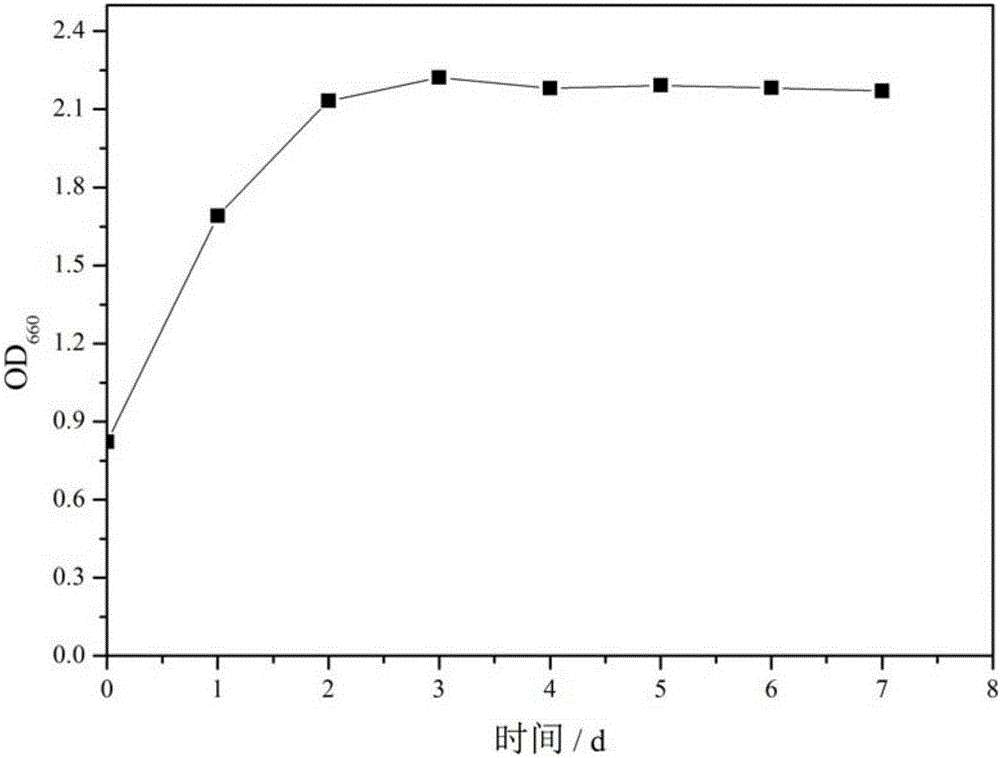

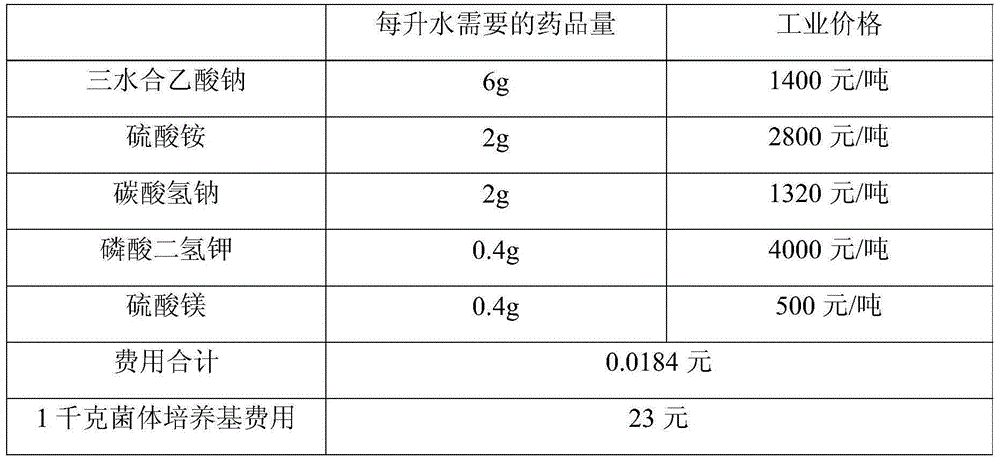

Photosynthetic bacteria culture medium and preparation method thereof

InactiveCN105199993AIncrease concentrationSimple compositionBacteriaSimple componentMonopotassium phosphate

The invention discloses a photosynthetic bacteria culture medium and a preparation method thereof. Each liter of the photosynthetic bacteria culture medium is prepared from the following components: 4g to 10g of sodium acetate trihydrate, 1g to 5g of ammonium sulfate, 1g to 5g of sodium hydrogen carbonate, 0.2g to 0.8g of monopotassium phosphate, 0.2g to 0.8g of magnesium sulfate and the balance of water. The pH value of the photosynthetic bacteria culture medium is 5.5 to 8.5. When the culture medium is prepared, the components are dissolved into the water, the pH value is regulated and then the volume is made to be constant. The photosynthetic bacteria culture medium provided by the invention has simple components and is only prepared from five types of common compounds; high-price substances including yeast extract, T.M storage liquid and the like in an existing culture medium are not used so that the production cost is reduced; compared with an RCVBN culture medium, the cost for producing 1kg of a bacterium culture medium can be saved by a maximum of 85%; the preparation process is simple and feasible and the operability is strong; by utilizing the culture medium to culture, the concentration of photosynthetic bacteria is high and the content of OD660 is up to 2.2.

Owner:RENMIN UNIVERSITY OF CHINA

Low-temperature phase-change heat storage material and preparation method thereof

InactiveCN102757768AAdd a small proportionSimple recipeHeat-exchange elementsWater bathsSodium carbonate anhydrous

The invention provides a low-temperature phase-change heat storage material and a preparation method thereof. The low-temperature phase-change heat storage material comprises the following components in percentage by weight: 90%-92% of sodium acetate trihydrate, 3%-5% of tetrasodium pyrophosphate decahydrate, 2%-3% of anhydrous sodium carbonate and 1%-2% of polyacrylamide. The preparation method comprises the following steps of: grinding the four components until the granularity is 30-50 meshes respectively, mixing uniformly, and heating the mixture in a water bath at the temperature of 74-79 DEG C, so as to completely melt all the components to form a colloidal liquid; after stirring uniformly, injecting the colloidal liquid into a container, wherein the injected volume is 88%-90% of the volume of the container; and after the colloidal liquid is cooled to room temperature, sealing the container. According to the invention, the adding ratio of an additive is low, the stability of the material is high, the phase-change latent heat is large, the crystallization temperature is moderate, and the supercooling degree is not more than 2 DEG C; and the phase-change heat storage material is the colloidal liquid in melting, so that the phase separation phenomenon is avoided, the preparation process is simple, the packaging is easy and the production is convenient.

Owner:路生吉

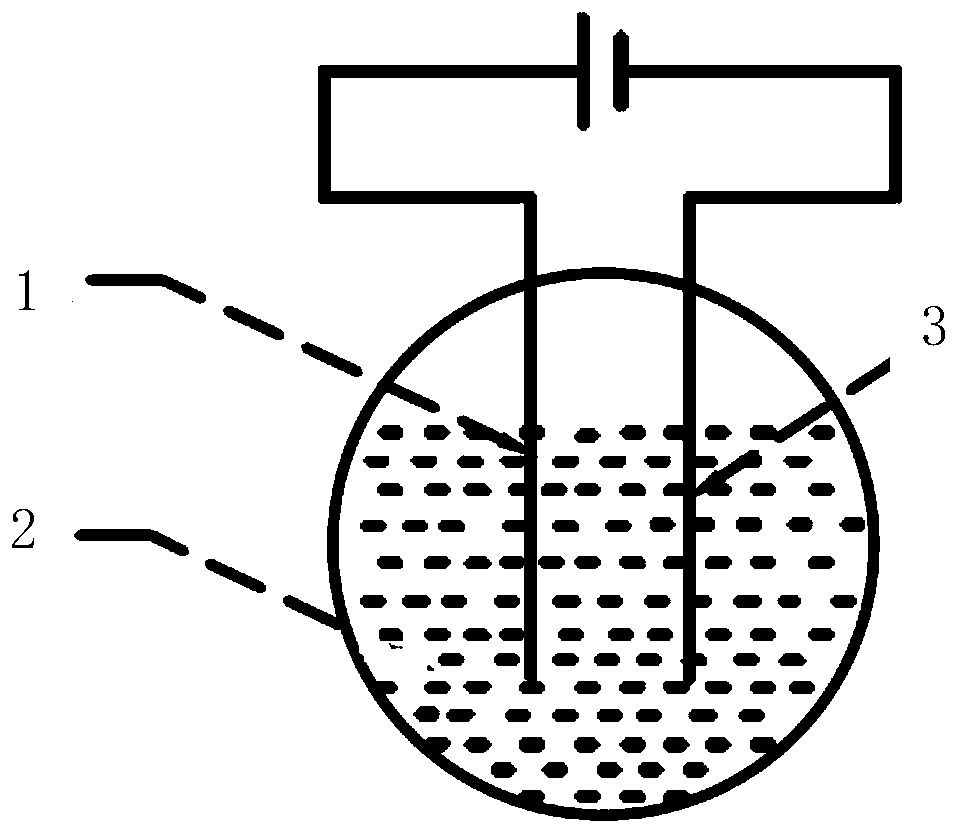

Controllable phase change material bag and preparation method and application thereof

PendingCN110173907AAchieve controlled releaseEasy to prepareSolar heating energyHeat recovery systemsWater bathsSodium acetate

The invention discloses a controllable phase change material bag and a preparation method and an application thereof. The preparation method comprises the following steps of (1) performing surface treatment on a metal plate or bar so as to form the metal plate or bar with a rough surface, embedding seed crystal powder which is used for inducing phase change materials into a nucleus into the surface, then putting in a sodium acetate solution, putting the sodium acetate solution in a water bath, and insulating so as to obtain a controllable trigger metal electrode; (2) mixing sodium acetate trihydrate crystal, water and a thickening agent, heating in the water bath and mixing so as to completely dissolve, so that a supersaturated phase transition heat storage solution is obtained, pouring the solution into a stainless steel metal ball, inserting into the controllable trigger metal electrode in the step (1) and a conducting electrode, then packaging, finally, putting in the water bath, and insulating so as to obtain the controllable phase change material bag. According to the controllable phase change material bag, the inherent supercooling defect of inorganic phase change materials is used, so that the controllable heat storage / release of supercooling phase change materials is realized, and the controllable phase change material bag has the advantages of simple preparation process, low equipment cost, short recycling period, stability in heat release and the like.

Owner:SOUTH CHINA UNIV OF TECH

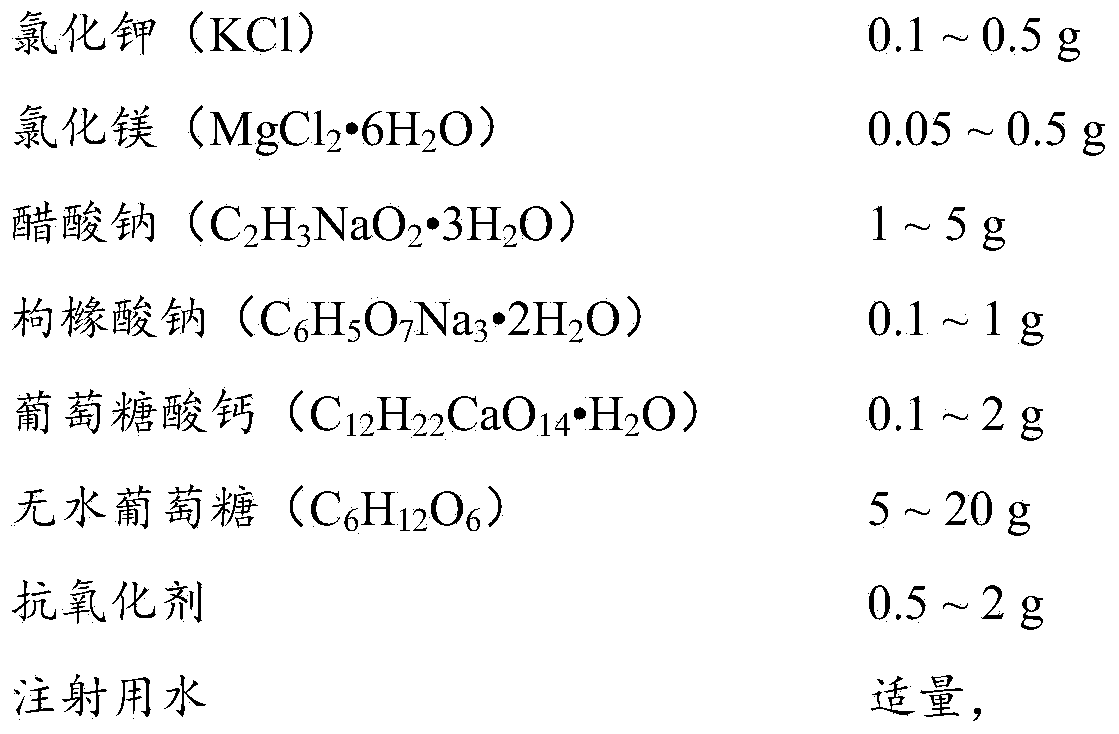

Injection containing sodium, potassium, magnesium, calcium and glucose injection and preparation method of injection

InactiveCN104224829AImprove securityReduce contentMetabolism disorderPharmaceutical delivery mechanismAntioxidantPotassium

The invention discloses an injection containing sodium, potassium, magnesium, calcium and glucose and a preparation method of the injection. Every 1000 ml of injection contains 5-10 g of sodium chloride, 0.1-0.5 g of potassium chloride, 0.05-0.5 g of magnesium chloride hexahydrate, 1-5 g of sodium acetate trihydrate, 0.1-1 g of sodium citrate dehydrate, 0.1-2 g of calcium gluconate monohydrate, 5-20 g of anhydrous glucose, 0.5-2 g of antioxidant and appropriate water for injection, and a pH regulator solution is used for regulating the pH to be 4.5-6.0. The injection containing sodium, potassium, magnesium, calcium and glucose has the advantages that as appropriate antioxidant is added, the content of 5-hydroxymethyl furfural in the sterilized sodium, potassium, magnesium, calcium and glucose injection is effectively reduced; the sterilization time and injection preparation temperature are optimized, so that glucose being converted into 5-hydroxymethyl furfural at excess temperature is avoided, and the content of 5-hydroxymethyl furfural in the injection containing potassium, calcium and glucose is also effectively reduced; the preparation method is simple and reliable and is suitable for industrial production.

Owner:SICHUAN KELUN PHARMA CO LTD

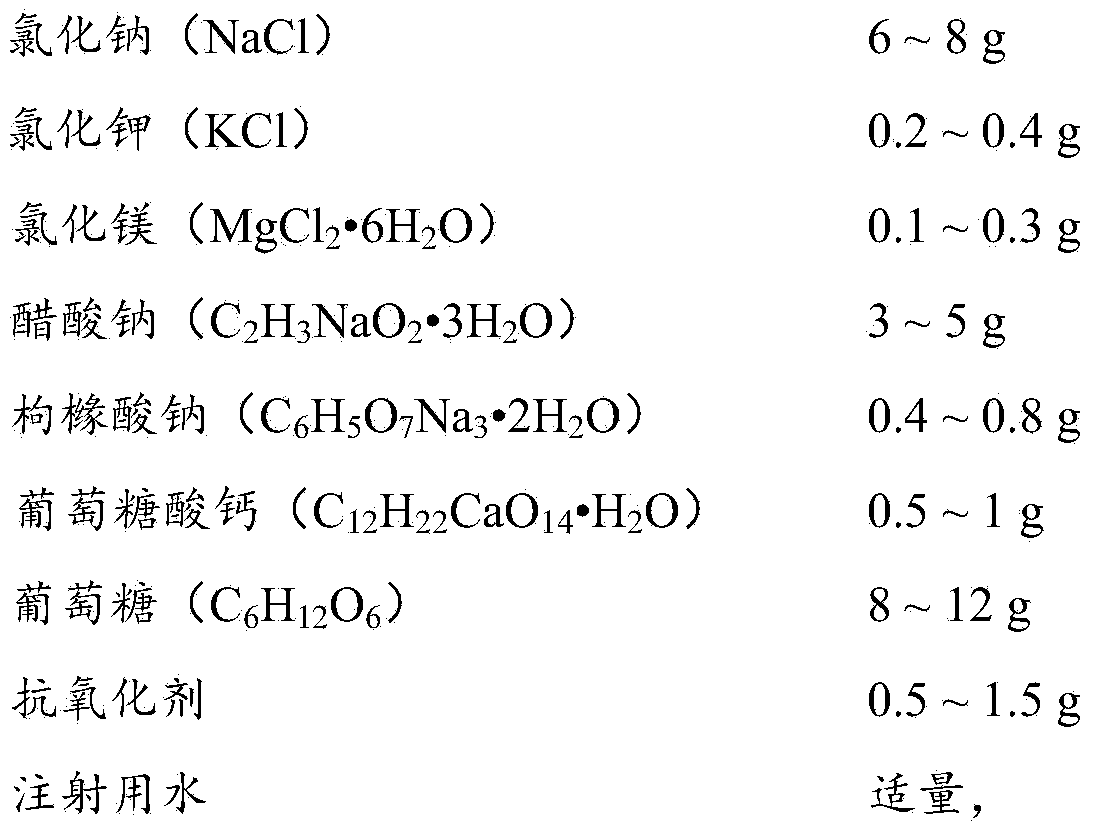

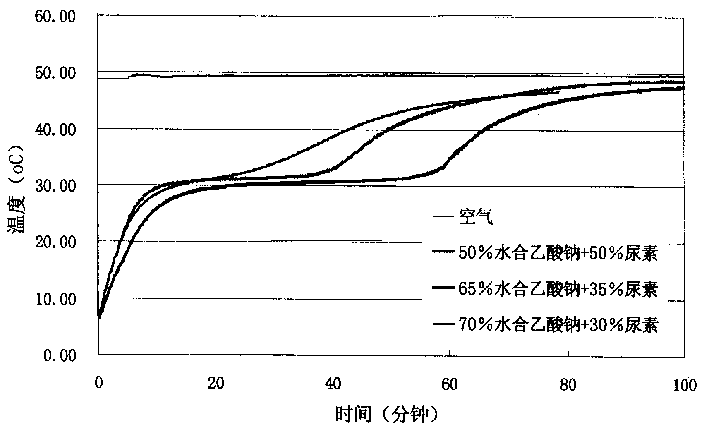

Phase change material

InactiveCN1460702ANot corrosiveThe phase transition process is reversibleHeat-exchange elementsWater bathsSodium acetate

The present invention relates to a phase transition material, it contains trihydrated sodium acetate whose mass ratio is 50-70% and urea with mass ratio of 30-50%. The above-mentioned two materials are uniformly mixed, heated in constant temperature water bath 65-80 deg.c and continuously stirred until the mixture is changed into the transparent liquor. Said phase transition material is nno-toxic and has no corrosion, and its phase transition process is reversible, and can be used for several times, and its phase transition temp. is 26-33 deg.c and its phase transition latent heat is greater than 100 kJ / kg.

Owner:TSINGHUA UNIV

Water softening and detergent compositions

InactiveUS6093688AEasy to handle and dispense into washloadMore compactInorganic/elemental detergent compounding agentsAnionic surface-active compoundsWater softeningAcetic acid

The speed of disintegration of tablets containing a water-softening agent, especially water-insoluble, water-softening agent intended as detergency builder for fabric washing is enhanced by incorporating sodium acetate trihydrate, potassium acetate or a mixture thereof. To inhibit caking and facilitate handling during manufacture, smaller particles of another substance are preferably provided at the surface of the crystals of the acetate or citrate.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

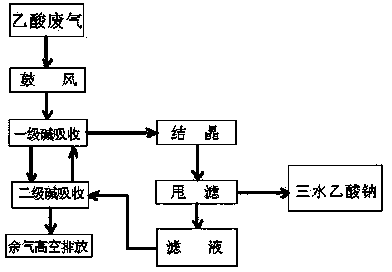

Method for preparing sodium acetate from acetic acid waste gas through alkaline absorption

ActiveCN103664573AIncrease the reaction concentrationReduce consumptionOrganic compound preparationChemical industrySodium acetateChemical industry

The invention relates to a method for preparing sodium acetate from acetic acid waste gas through alkaline absorption. The method comprises the following steps: 1, inputting acetic acid waste gas to an alkaline absorption tower through an induced draft fan to carry out multistage circulated alkaline absorption, and emptying the absorbed air, wherein the acetic acid waste gas is generated in a chemical industry or drug production process; 2, controlling the alkaline absorption liquid temperature between 30 DEG C and 80 DEG C, and adding solid sodium hydroxide or sodium carbonate when the pH value is less than or equal to 10; 3, stopping adding alkaline when the concentration of the added sodium hydroxide or sodium carbonate is up to 25-50%, and inputting alkaline absorption liquid to a crystallization kettle when the pH value of the alkaline absorption liquid is up to 8-9; 4, cooling the alkaline absorption liquid to 10 DEG C below zero to 30 DEG C, and carrying out centrifugal swing filtration to obtain sodium acetate trihydrate, or drying at the temperature of 120-150 DEG C to prepare anhydrous sodium acetate; and 5, adding centrifuged mother liquid into the alkaline absorption tower to be recycled, adding a hydrogen dioxide solution or potassium permanganate solution to decolor after the mother liquid turns yellow, wherein the mother liquid can be recycled. No new waste water, waste gas and waste residue are generated, and the production process is clean, environment-friendly, energy-saving and efficient.

Owner:HUBEI YITAI PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com