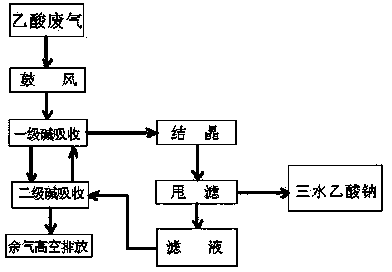

Method for preparing sodium acetate from acetic acid waste gas through alkaline absorption

A technology of alkali absorption and sodium acetate, applied in the directions of carboxylate preparation, carboxylate preparation, separation method, etc., can solve problems such as acetic acid waste gas pollution, achieve the effects of efficient production, simplified process and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0030] according to figure 1 According to the process of operation, 1000 liters of water and 200 kg of 96% sodium hydroxide are added to the first-level alkali absorption tower and the second-level alkali absorption tower respectively, heated to 55-60°C to dissolve, and the pump is circulated to absorb glucaldehyde The acetic acid waste gas transported from the lactone workshop is roughly shaken, and the alkali absorption temperature is controlled between 50-60°C. Use pH test paper to measure the pH value of the solution in the primary alkali absorption tower at any time. When the pH value is close to 10, add 96% hydrogen Sodium oxide, when the total amount of 96% sodium hydroxide added to the primary alkali absorption tower reaches 400 kg, when the pH value of the absorption liquid reaches 8-9, the absorption liquid is input into the crystallization kettle, crystallization is controlled at -5 ° C, and the filter is obtained Sodium acetate trihydrate. The crystallization filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com