Patents

Literature

150results about How to "Energy saving production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

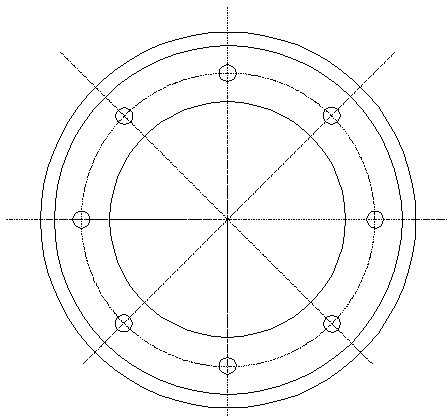

Protective box type amorphous, microcrystal or nano-crystal alloy stator core for motor and preparation method thereof

ActiveCN102361374AShort production processEnergy saving productionManufacturing stator/rotor bodiesDip-coatingNanocrystal

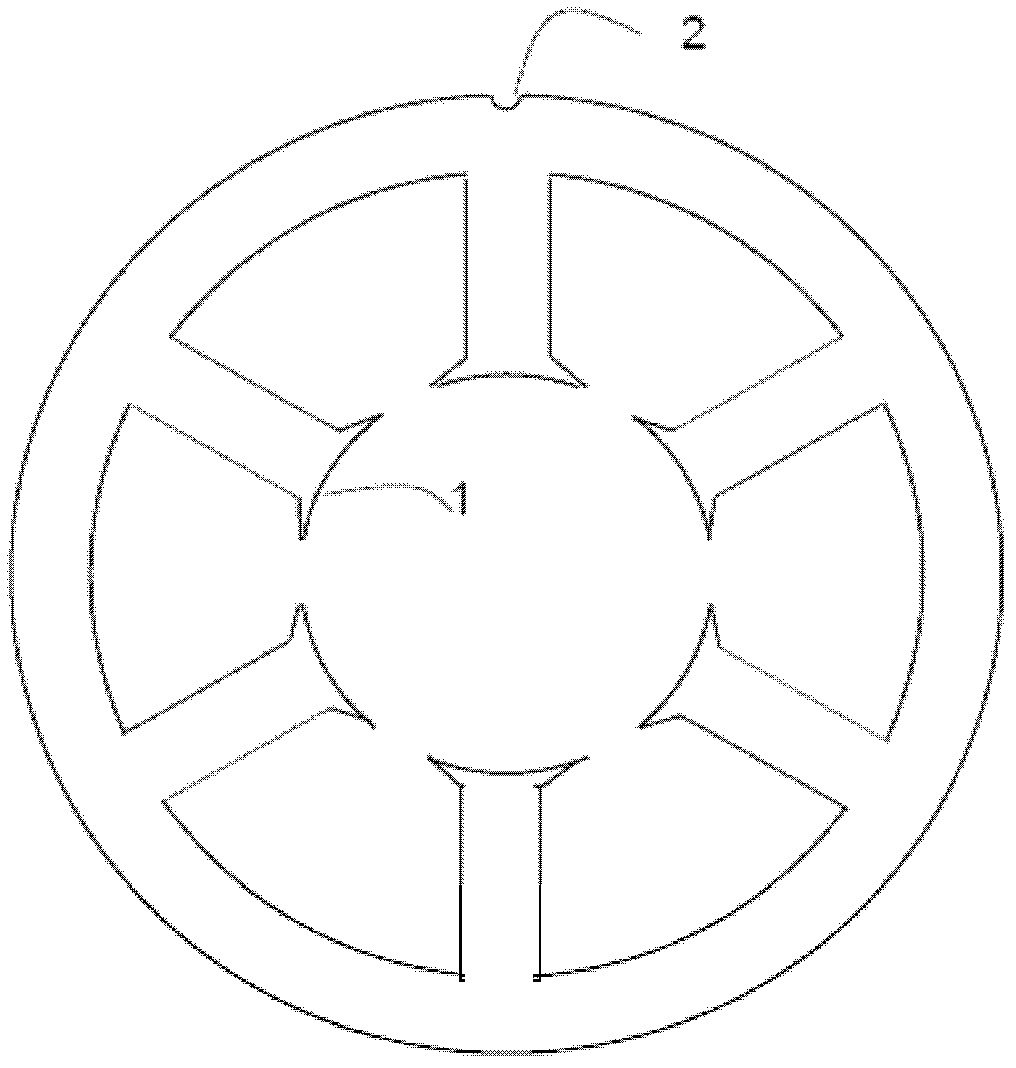

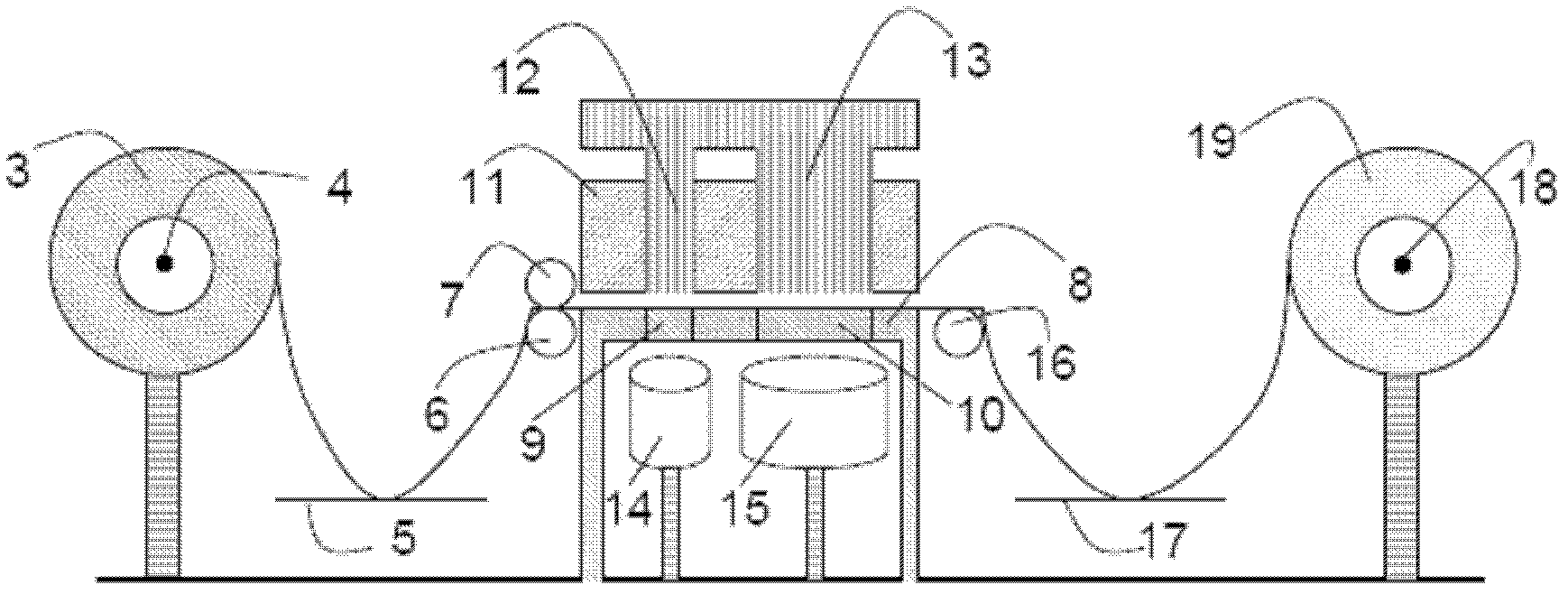

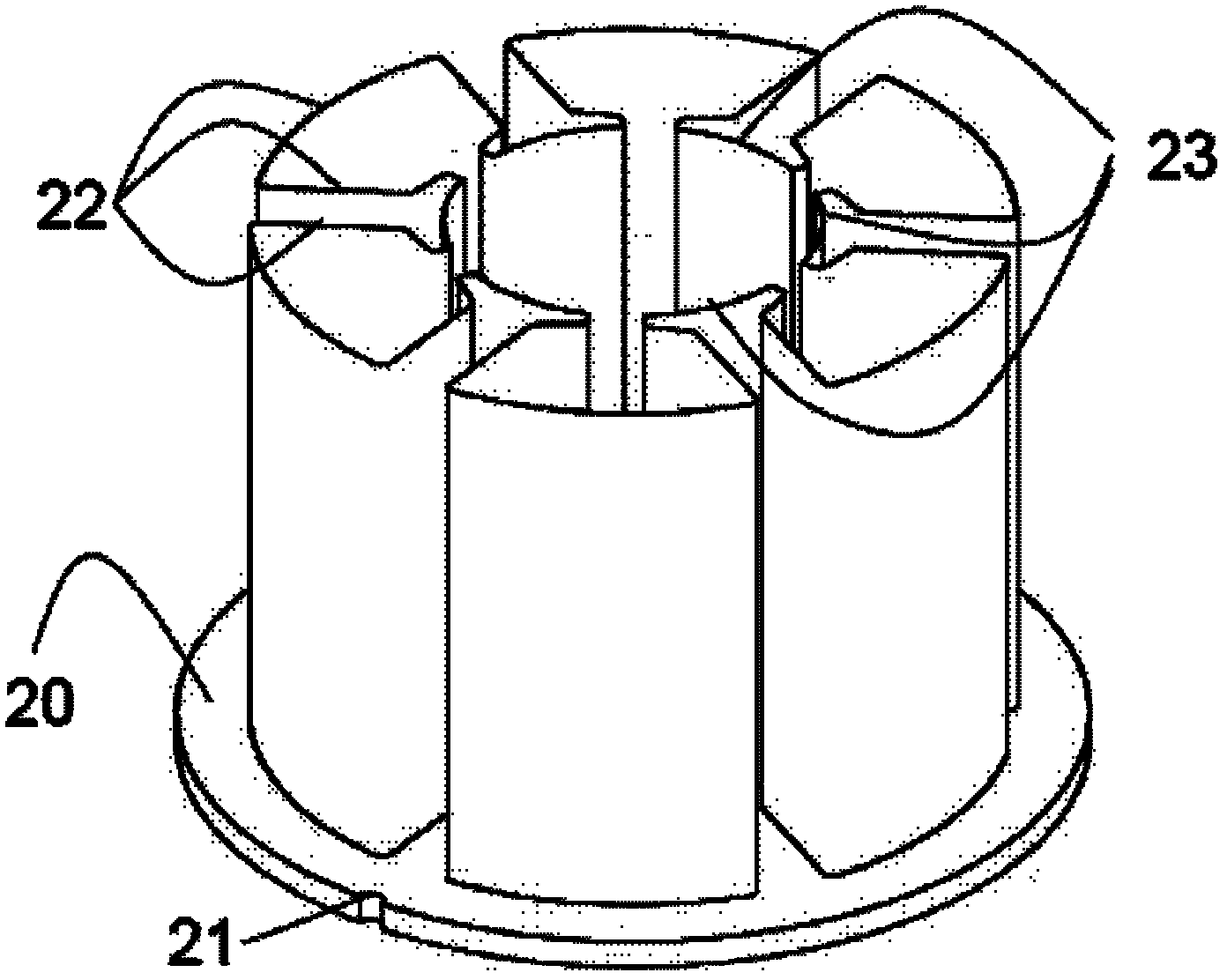

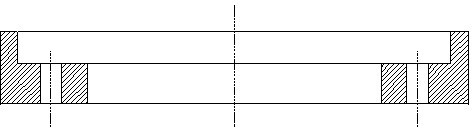

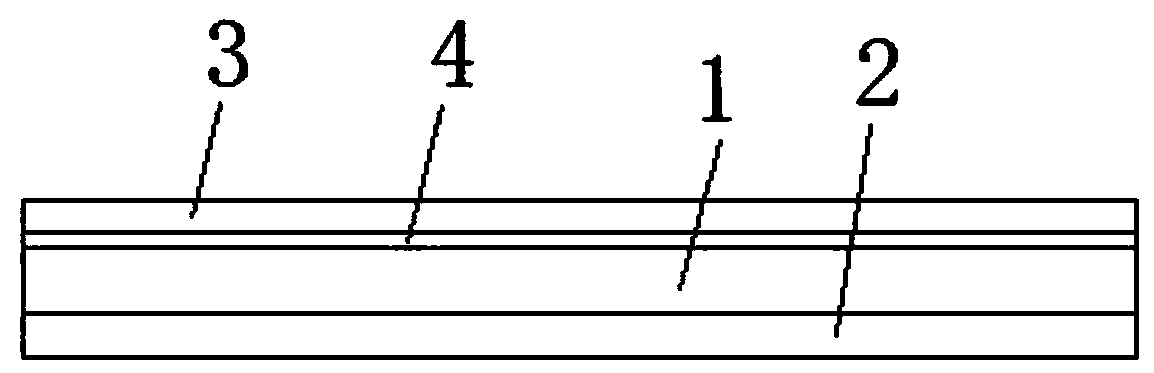

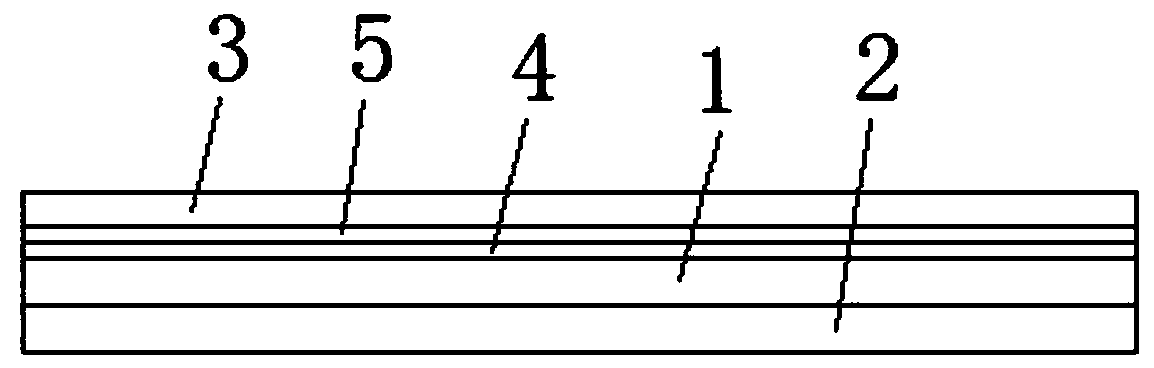

The invention belongs to the field of magnetic circuit parts of motors, and discloses a protective box type amorphous, microcrystal or nano-crystal alloy stator core for a motor and a preparation method thereof. The method comprises the following steps of: stamping a coiled alloy strip (3) to form a plurality of same annular stamped sheets, wherein the tooth ends of inner teeth (1) of the stampedsheets are positioned on the same circumference and the outer side of each stamped sheet is provided with at least one positioning groove (2); stacking the plurality of annular stamped sheets in a protective box with open upper end, putting the stamped sheets and the protective box into insulated coating solution together and performing insulated dip-coating treatment; taking out the stamped sheets and the protective box together, performing compactness treatment on the annular stamped sheets, fixing an upper end panel of the protective box and the inner center surface together, and forming the stator core; and performing integral annealing treatment on the stator core of the sealed protective box. By the method, the process problems that the stator core is easily damaged to drop residue and cracks among layers, the performance declines because the adhesive stress cannot be eliminated and the like are solved, and the performance of the stator core is greatly improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Process method for manufacturing balance weight for compressor by powder metallurgy

InactiveCN102528040AHigh dimensional accuracyNo oxidationTurbinesOther manufacturing equipments/toolsAir compressorMechanical press

The invention discloses a process method for producing a balance weight for a compressor by powder metallurgy, which comprises the steps that: (1), raw materials comprising Mn (17-25%), C (0.5-1.5%) and Fe (the rest) are uniformly blended to produce raw material powder required by production; (2), the raw material powder is put into a mechanical press (or four-column hydraulic press) for compression moulding so as to obtain a pressing compact for the balance weight; (3), the pressing compact for the balance weight is put into a continuous mesh belt furnace (or push rod furnace) for sintering to obtain a sintering compact for the balance weight; and (4), the sintering compact for the balance weight is subjected to shot blasting treatment to obtain a finished product of the high manganese steel weight balance for the air compressor. According to the production method disclosed by the invention, the stability of the sizes of workpieces is good, no impurity is generated, the quality of the surface is excellent, and the components are uniform and stable; the weight variation among products of different batches is small and can be controlled within 1%; no oxidation is generated in the production process, the internal organization of metal is excellent, the crystalline grain is finer, and the bad organizations such as coarse crystal and mixed crystal can be avoided.

Owner:王兴民

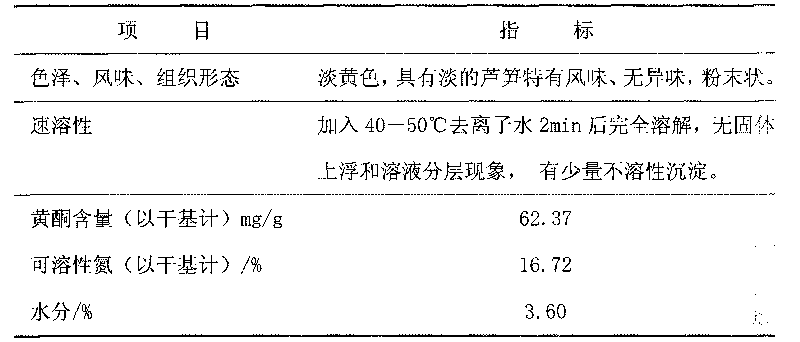

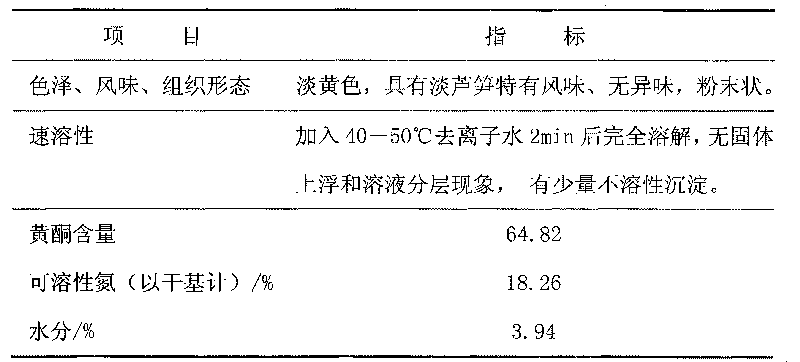

High-fiber instant asparagus ultramicro-powder beverage and preparation method thereof

InactiveCN102551168AAbundant sources of raw materialsLow costFood preparationNutrientNutritional composition

The invention provides a high-fiber instant asparagus ultramicro-powder beverage and a preparation method thereof. The asparagus ultramicro-powder beverage contains 60% to 75% of asparagus ultramicro-powders, 15% to 20% of stabilizers and 5% to 25% of flavorings. The product is prepared by the following steps: subjecting asparagus processing leftovers to vacuum freeze-drying treatment and micronization, adding stabilizers and flavorings, and mixing thoroughly; and the product is soluble in both cold and hot water. The high-fiber instant asparagus ultramicro-powder beverage is rich in dietary fiber, saponins and flavonoids and has hypolipidemic and anti-tumor functions. The method adopts the vacuum freeze-drying treatment and micronization techniques to retain the effective components of asparagus to the greatest extent and improves dissolution and digestion / absorption of nutrients of the product. The beverage and the preparation method have reasonable designs and abundant raw materials, are favorable to asparagus waste utilization, and increase the economic benefits of asparagus industry.

Owner:QINGDAO AGRI UNIV

Method for producing alumina through mineral containing aluminum

InactiveCN102718240AEnergy saving productionThe production process is environmentally friendlyChemical industryAluminium oxide/hydroxide preparationSlagAluminium hydroxide

The invention discloses a method for producing alumina through mineral containing aluminum, and relates to a method for economically and effectively recycling alumina from low-quality mineral resources containing aluminum. The method is characterized in that the production process comprises the following steps: (1), the mineral containing the aluminum are mixed with lime and sodium carbonate, and the mixture is processed into chamotte through dry-method sintering; (2), after being pulverized, the sintered chamotte is dissolved out, and the dissolved-out slurry is separated and cleansed to obtain the sodium aluminate solution and red mud slag; (3), aluminium hydroxide is decomposed and separated out after the silicon of the sodium aluminate solution is removed, the mother liquid after the decomposition returns to the dissolve-out work procedure, and the aluminum hydroxide is roasted to obtain the alumina product; (4), and the red mud slag is directly used for cement production. The method can be used for processing the low-quality mineral resources containing the aluminum, which is not in the concept scope of bauxite. The production technical flow is energy-saving and environmental-friendly, and all heat resources used in the production process are the residual heat of clinker kilns, lime kilns and calcinators. In the production flow, the red mud is used as the raw material for producing cement, no red mud slag is piled, and clean production is realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

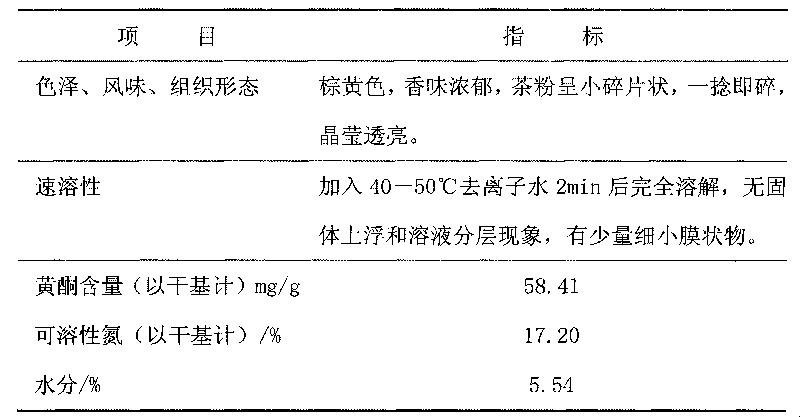

Preparation method of asparagus leaf instant tea

InactiveCN101715848AIncrease soluble nitrogen contentImprove immunityPre-extraction tea treatmentCelluloseInstant tea

The invention belongs to a preparation technology of an instant tea, relating to a preparation method of an asparagus leaf instant tea. As the prior art only picks vegetable asparagus, and loses the asparagus leaf, wherein the weight of the asparagus leaf is 70%-80% of the gross weight of plant, thereby wasting the resources; and the asparagus leaf is rotten, thereby polluting the environment. The preparation method of the asparagus leaf instant tea comprises the following four steps of: microwave inactivating enzyme of the asparagus leaf-composite formulating the leaf instant tea-hydrolyzing complex enzyme-concentrating and drying. The preparation technology has the advantages that the asparagus leaf instant tea has higher flavone content and soluble nitrogen content, and has physiological functions for enhancing human body immunity and anti-fatigue, and the like; is convenient in drinking, and can be drunken by adding water; is easy in storing and transporting; has a scientific and reasonable technology; has an energy-saving production technology, and is easy in controlling and operating; adopts an assistant extraction method with complex enzyme of cellulose and neutral protease to have mild hydrolysis condition and low ash content; and has wide raw materials source, abundant resource, low price, low cost and wide practicability.

Owner:SHANGHAI NORMAL UNIVERSITY

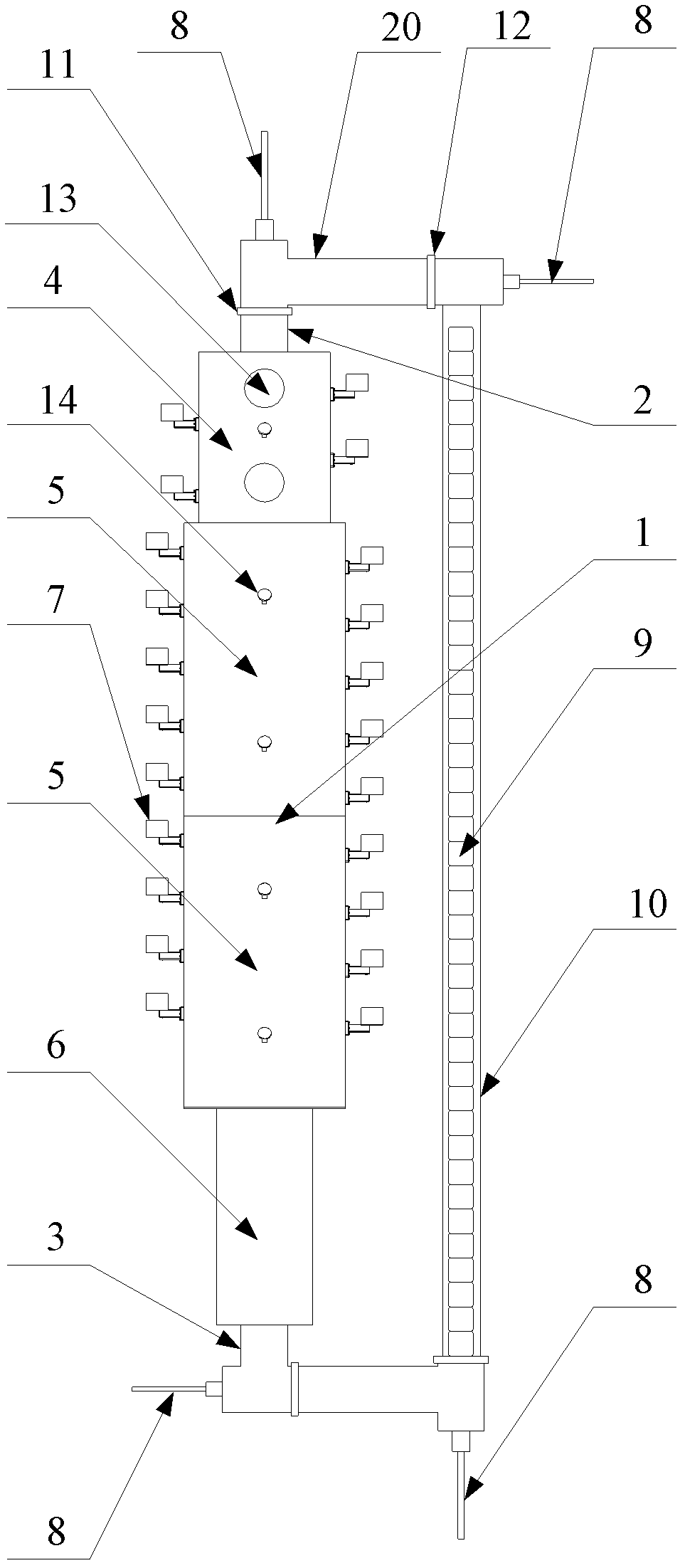

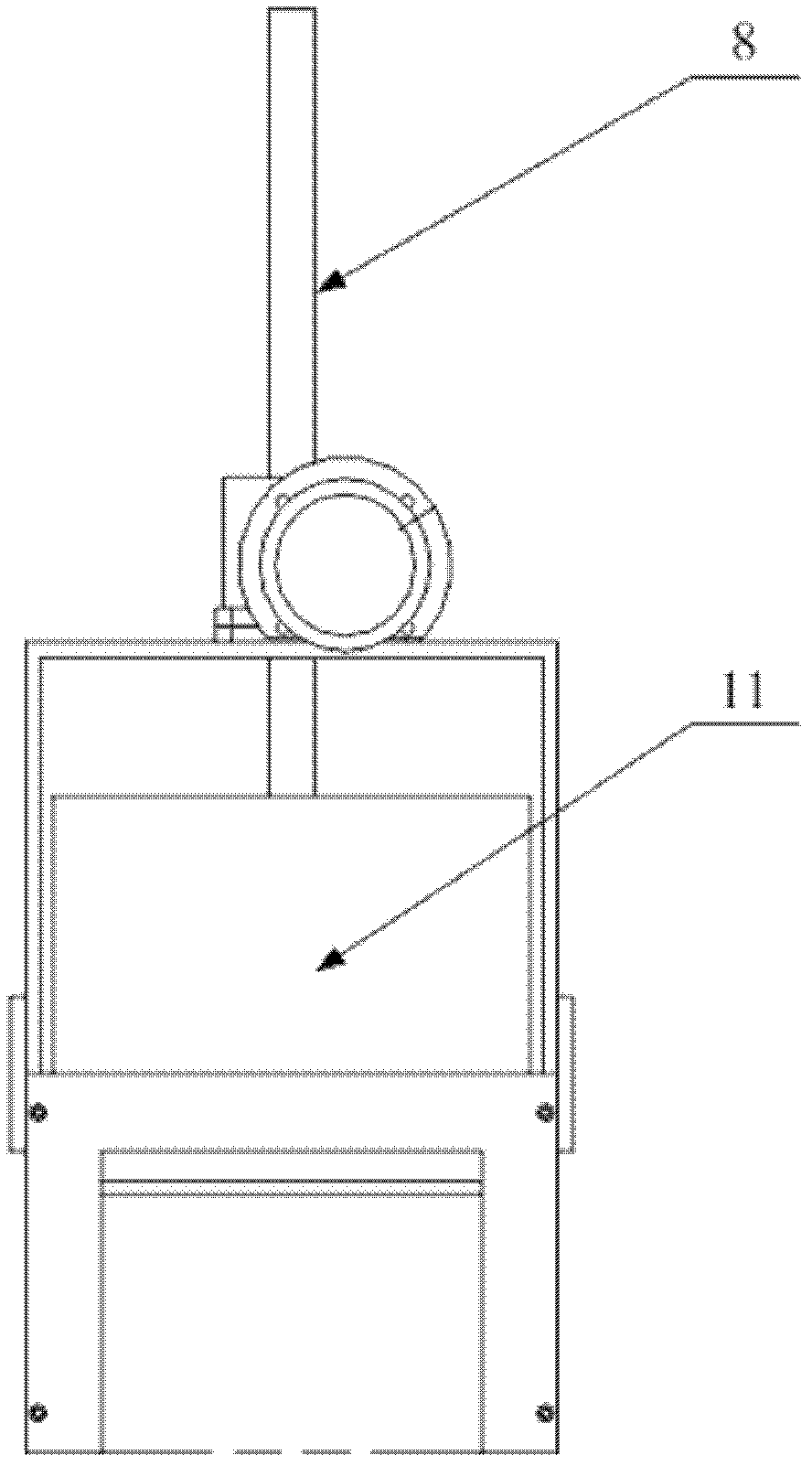

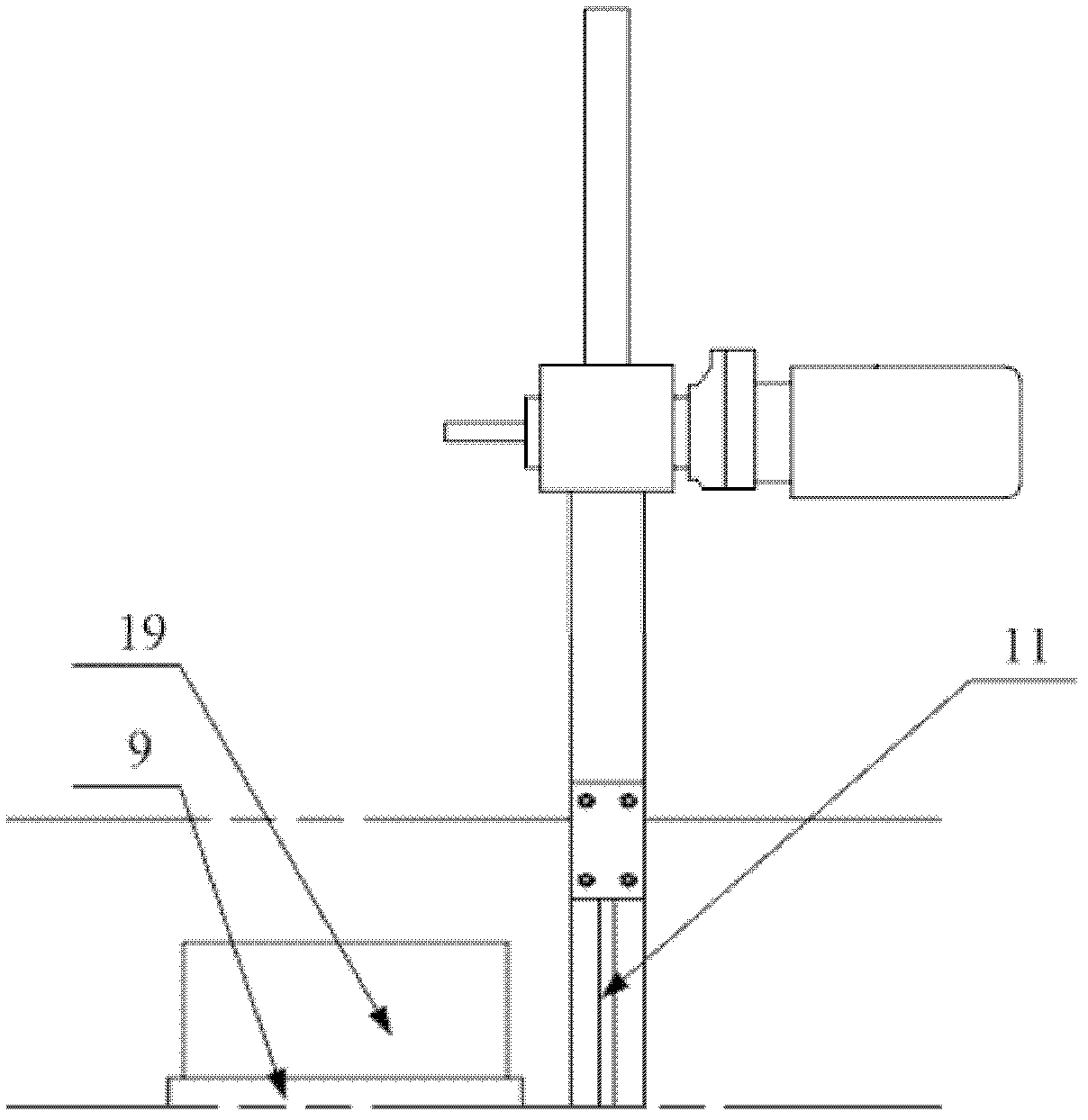

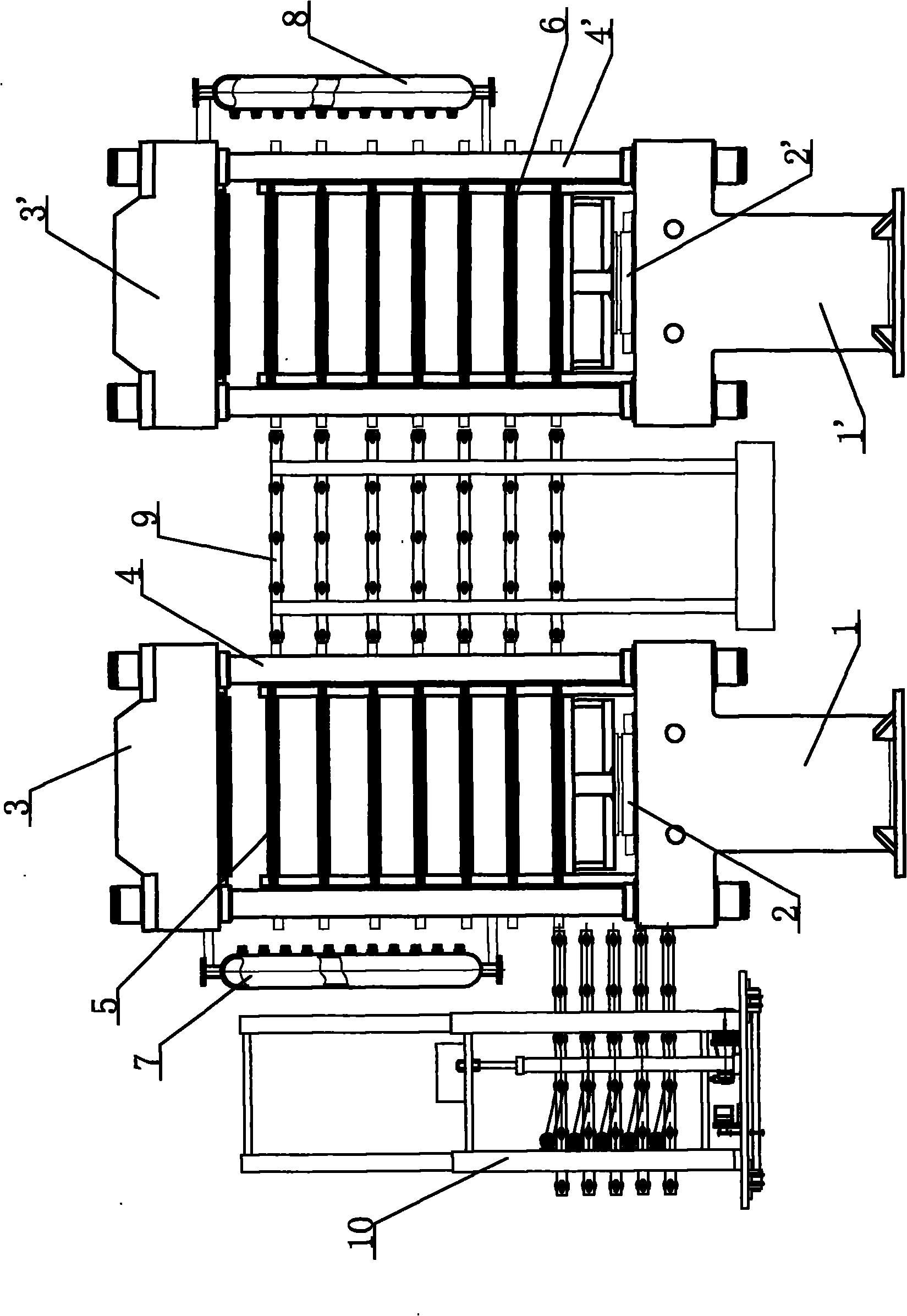

High temperature sintering kiln

The invention provides a high temperature sintering kiln, which comprises a kiln body (1), a plurality of microwave heating devices (7) arranged on the kiln body (1) and transmitting microwave to the inside of the kiln body (1), a closed type polygon track (10), a push rod (8) and a controller. The kiln body (1) is provided with a temperature rising section (4) communicated with a feeding port (2) of the kiln body (1), a high temperature section (5) communicated with the temperature rising section (4) and a cooling section (6) communicated with the high temperature section (5) and a discharging port (3) of the kiln body (1). One side of the closed type polygon track (10) penetrates through the kiln body (1), and the closed type polygon track is provided with the closed type polygon track (10) of a push plate (9) for containing vanadium nitrogen alloy materials (19). The push rod (8) is arranged at the turning position of the closed type polygon track (10) and capable of pushing the push plate (9) to move on the closed type polygon track (10). The controller controls the push rod (8) and the microwave heating device (7) to work. The high temperature sintering kiln enables the production process to be more energy-saving and higher in efficiency while achieving continuous production.

Owner:湖南阳东微波科技有限公司

Titanium alloy for manufacturing tool and preparation method thereof

The invention discloses a titanium alloy for manufacturing a tool and a preparation method thereof. The titanium alloy for manufacturing a tool consists of the following components in percentage by weight: 76.6 percent of Ti, 3 percent of Al, 4 percent of V, 5 percent of Cr, 2 percent of Fe, 7 percent of Mo, 1 percent of W, 1 percent of Zr, 0.2 percent of O and 0.2 percent of Si. The preparation method of the titanium alloy comprises the following steps of: I, mixing; II, manufacturing an electrode; III, smelting in a vacuum furnace for three times; IV, cogging; and V, rolling. The titanium alloy has the beneficial effects that the HRC (Rockwell Hardness) value of the tool produced by using the titanium alloy disclosed by the invention is over 55, and the titanium alloy is light and non-magnetic, is low in production cost, and has a wide market prospect; and the production benefit of an enterprise can be increased greatly.

Owner:陈国财

Method for treating xylose mother solution

ActiveCN101705253AReduce CODReduce processing costsSugar derivativesMicroorganism based processesYeastAlcohol

The invention relates to a method for treating xylose mother solution. The method comprises the following steps: firstly, using glucose in the alcohol yeast strain fermented xylose mother solution to prepare alcohol by distilling; and then, using xylose in the xylose yeast strain fermented mother solution to prepare xylitol by extracting, and finally extracting gum sugar. The method changes the xylose mother solution into valuable by using the two-step fermentation method, so on the one hand, the method reduces the inhibiting effect brought about by excessive glucose during producing the xylitol by fermenting, and on the other hand, improves the utilization rates of the glucose and the xylose mother solution, and greatly reduces the COD treated as wastewater at the same time; and the production process is simple, safe and energy-saving.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

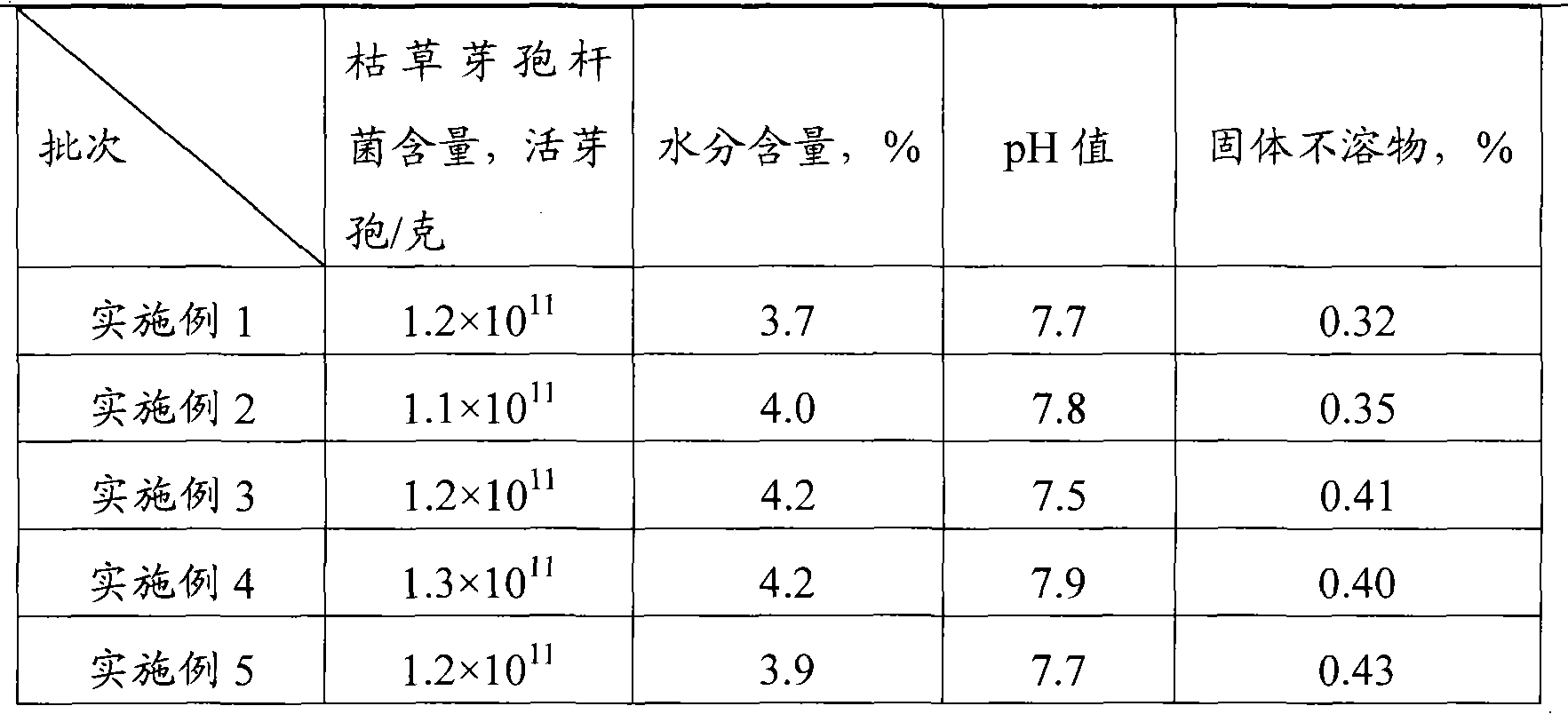

Method for preparing Bacillus subtilis

ActiveCN101654665ANot easy to polluteEasy to process and storeBacteriaMicroorganism based processesGramChemistry

The invention discloses a method for preparing Bacillus subtilis, which adopts a liquid-solid two-phase combined fermentation process, i.e. seed solution is cultured in the liquid, is inoculated to asolid culture medium after reaching proper concentration without a filtering step and insusceptible to pollution, and the concentration of the prepared Bacillus subtilis is over 1*10<11> active spore / gram. The method has simple steps, little device investment, low production cost and no three wastes. The Bacillus subtilis prepared by the method has high concentration and good control effect on plant diseases and insect pests, can be used for controlling rice blast, vegetable gray mould, powdery mildew and oidium heveae steinm and has favorable application prospect.

Owner:海南利蒙特生物科技有限公司

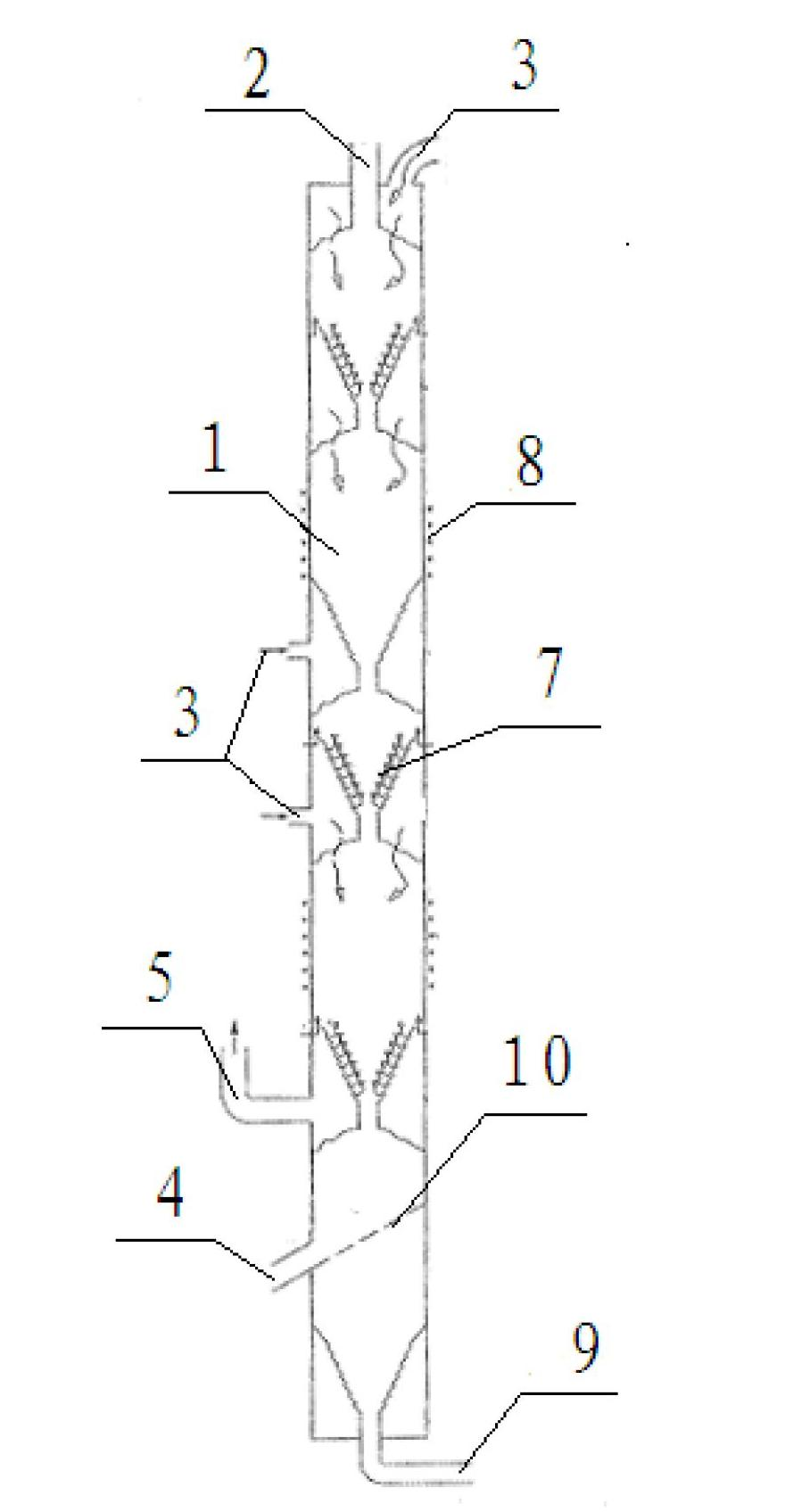

Reactor and method for producing particle materials

ActiveCN102671582AGuarantee continuous and stable operationFully contactedSiliconCarbon preparation/purificationExhaust gasNuclear engineering

The invention discloses a reactor and a method for producing particle materials. The reactor comprises a reactor cavity which is at least provided with a particle feeding hopper, a raw gas inlet, a particle product discharging port and a tail gas outlet, wherein the reactor cavity is internally provided with at least one conical distributor; the position of the tail gas outlet is higher than that of the conical distributor; the particle feeding hopper is arranged at the upper part of the reactor cavity; the particle product discharging port is arranged at the lower part of the reactor cavity; the reactor cavity also comprises an air curtain mechanism which can realize the blocking action between the reaction material and the inner wall of the reactor cavity; the reactor cavity is also provided with an internal or external mechanism for heating a reaction area; and the reactor cavity is also provided with an internal or external dynamic generation mechanism. The invention also discloses the method for producing the particle materials. According to the invention, the defects in the prior art are overcome, and the high-efficiency, energy-saving, long-term stable, safe and reliable production of the particle materials is realized.

Owner:储晞

Method for making special PVC (polyvinyl chloride) floor

The invention discloses a method for making a special PVC (polyvinyl chloride) floor, which comprises the following steps: 1. transferring heat conduction oil into a heating plate of a hot press to keep the heating plate at constant temperature; 2. automatically feeding a die, a PVC floor material and a die clamper together to a workbench; 3. lifting a master cylinder in the hot press to apply pressure; 4. repressing; 5. keeping constant pressure; 6. lowering the master cylinder in the hot press; 7. automatically feeding the die and the material together onto a workbench plate of another cold press; 8. keeping the workbench plate of the cold press at constant temperature by using a cold water machine; 9. lifting the master cylinder in the cold press to apply pressure; and 10. lowering the master cylinder in the cold press to complete the whole production process of the special PVC floor. The method for making a special PVC floor disclosed by the invention has the advantages of high efficiency, high safety, environmental protection and energy saving, and does not use a boiler.

Owner:东莞进力机械科技有限公司

Preparation method of Gamma-aminobutyric acid

ActiveCN101705261AReduce pollutionReduce manufacturing costMicroorganism based processesFermentationBiotechnologyGamma-Aminobutyric acid

The invention relates to a preparation method of Gamma-aminobutyric acid. The method includes the following steps: inoculating cultured Gamma-aminobutyric acid production bacterial strain to a fermentation culture medium in a fermentation tank for culturing, conducting combined fermentation of an aerobic section and an anaerobic section, controlling temperature in sections during the fermentationprocess and adopting a means of regulating in sections based on the demand for oxygen so that the Gamma-aminobutyric acid production bacterial strain is metabolized under an anaerobic state to produce Gamma-aminobutyric acid. The preparation method adopts ventilation in sections and high temperature fermentation, shortens the fermentation cycle, reduces the consumption of cooling water and cost and improves the yield of the Gamma-aminobutyric acid. The production process is simple, safe and energy-saving. The hydrolysis liquid of corn cob is used as fermentation raw material, thus not only changing wastes into valuables and reducing environment pollution, but also having positive significance in guaranteeing food security.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

High-thermal conductive plasticized ceramic material and preparation method and application thereof

The invention discloses a high-thermal conductive plasticized ceramic material and a preparation method and application method thereof. The ceramic material comprises micro-nano ceramic powder, an internal lubricant, an external lubricant and original plastic. The ceramic material disclosed by the invention not only retains the excellent characteristics of thermal conduction, radiation and insulation of the ceramic material, but also achieves the excellent mouldability and high-efficiency production process of a plastic material, omits the high-temperature sintering procedure of the traditional ceramic, achieves great energy conservation in a production process, is short in period, enhances the material productivity and reduces the manufacturing cost; and in addition, the ceramic material disclosed by the invention can be applied to enhancing the comprehensive property of products by manufacturing the corresponding products, has outstanding market value and development prospect and is favorable to promoting the progress of intra-industry related products and technologies.

Owner:GUANGZHOU QIANSONG TECH

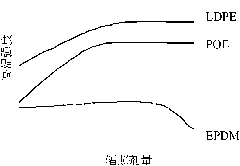

High elasticity polyolefin hose with radiation crosslinking and preparation method thereof

The invention discloses a high elasticity polyolefin hose with radiation crosslinking, wherein the high elasticity polyolefin hose is prepared by extruding a blend of polyethylene, polyolefin elastomer and rubber through a tube extruding machine and radiating by electronic rays; the blend thereof comprises the compositions in percentage by weight: 30-60 percent of the polyethylene, 20-40 percent of the polyolefin elastomer and 20-40 percent of the rubber. Through radiation crosslinking treatment, the high temperature resistance use performance of the high elasticity polyolefin hose is obviously enhanced; compared with an ordinary hose, no chemical cross-linking agent is added in the polyolefin hose production process, and a product can be completely used in a field of drinking water.

Owner:FSPG HI TECH

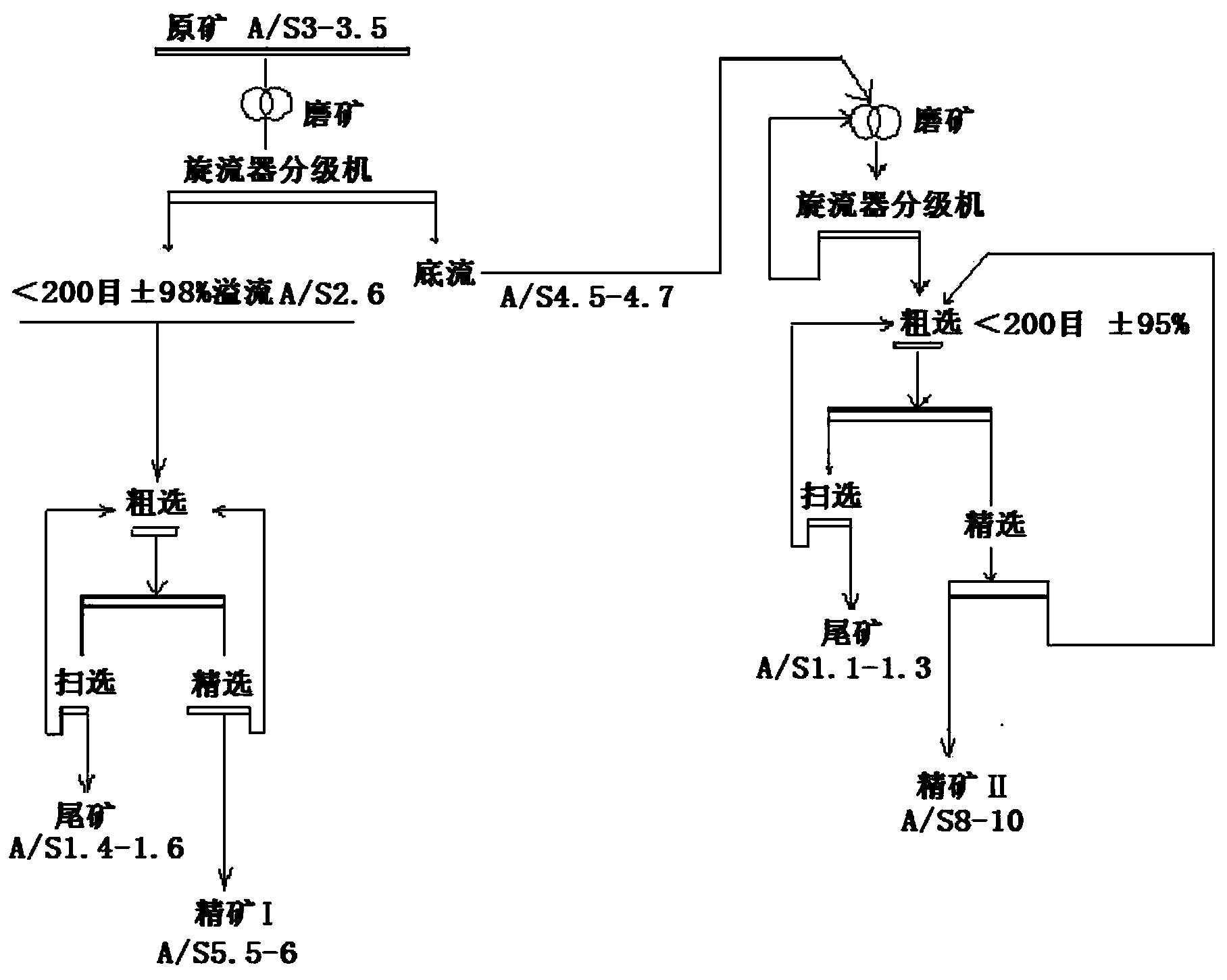

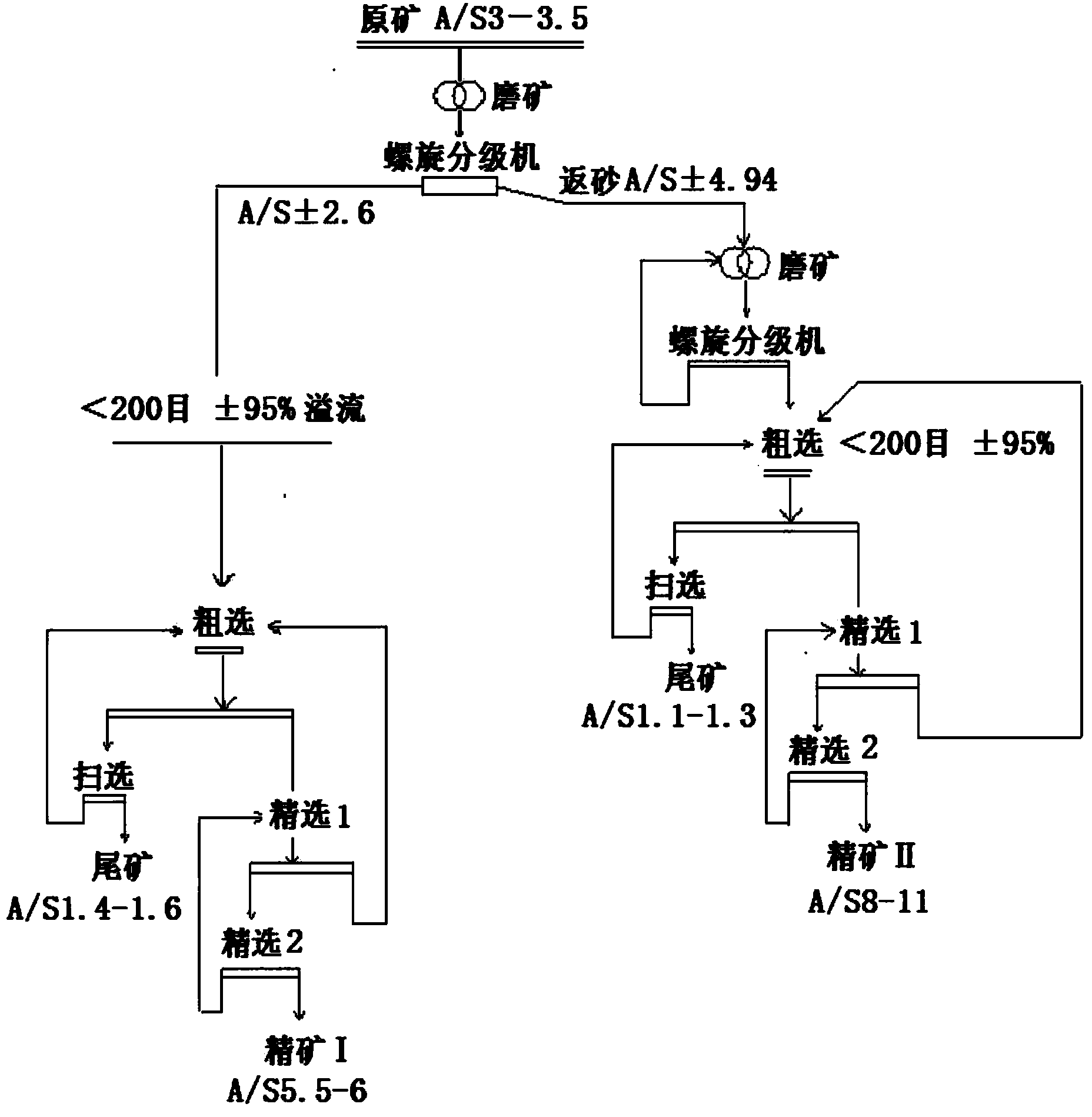

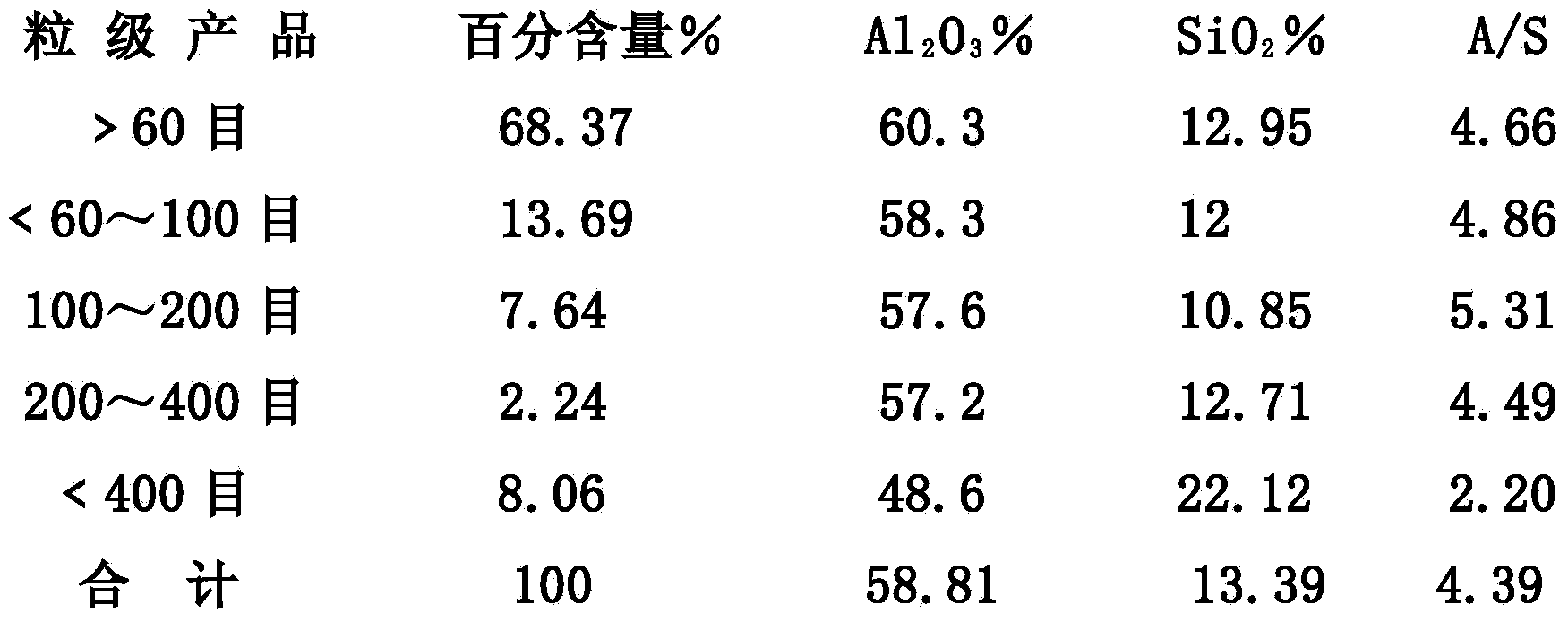

Low-quality raw bauxite ore open-grinding and dressing technology

InactiveCN103521363AHigh recovery rateLow costVortex flow apparatusMohs scale of mineral hardnessKaolinite

The invention provides a low-quality raw bauxite ore open-grinding and dressing technology. The technology comprises the following steps of roughing, scavenging and selecting so as to obtain concentrate with A / S of 5.6-6; feeding the bottom flow or return sand discharged by a classifying machine into another grinding machine for grinding and then classifying by another classifying machine, wherein the A / S of the bottom flow or return sand achieves the middle-quality bauxite standard, and the ore granularity is less than 60 meshes; roughing, scavenging and selecting overflow in which the ore with granularity less than 200 meshes accounts for + / -95% so as to obtain concentrate with A / S of 8-11. By fully utilizing the difference in Mohs hardness of diaspore and kaolinite, the technology improves A / S of bauxite concentrate to 8 above, can improve the production of alumina, and is high in Al2O3 recovery rate, energy-saving, low in cost and low in alkaline consumption; for ore dressing enterprises, the technology can increase the yield, save energy and reduce the cost, has favorable quality and price, and generates great benefit; the technology can also be used for producing in high-aluminum clay ore dressing enterprises; the technology can be used for dressing middle-grade bauxite, and the A / S of the concentrate can be stabilized at 11-12.

Owner:李耀吾

Manufacturing method of high-intensity environmental-friendly board

ActiveCN104760113AIncrease added valueHigh technology contentSolid waste managementLaminationRadioactive contaminationHigh intensity

Owner:河北宜美康环保科技股份有限公司

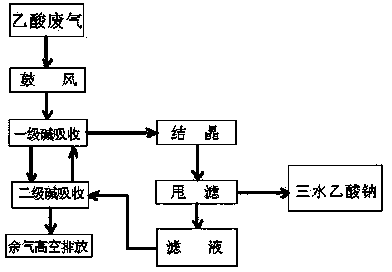

Method for preparing sodium acetate from acetic acid waste gas through alkaline absorption

ActiveCN103664573AIncrease the reaction concentrationReduce consumptionOrganic compound preparationChemical industrySodium acetateChemical industry

The invention relates to a method for preparing sodium acetate from acetic acid waste gas through alkaline absorption. The method comprises the following steps: 1, inputting acetic acid waste gas to an alkaline absorption tower through an induced draft fan to carry out multistage circulated alkaline absorption, and emptying the absorbed air, wherein the acetic acid waste gas is generated in a chemical industry or drug production process; 2, controlling the alkaline absorption liquid temperature between 30 DEG C and 80 DEG C, and adding solid sodium hydroxide or sodium carbonate when the pH value is less than or equal to 10; 3, stopping adding alkaline when the concentration of the added sodium hydroxide or sodium carbonate is up to 25-50%, and inputting alkaline absorption liquid to a crystallization kettle when the pH value of the alkaline absorption liquid is up to 8-9; 4, cooling the alkaline absorption liquid to 10 DEG C below zero to 30 DEG C, and carrying out centrifugal swing filtration to obtain sodium acetate trihydrate, or drying at the temperature of 120-150 DEG C to prepare anhydrous sodium acetate; and 5, adding centrifuged mother liquid into the alkaline absorption tower to be recycled, adding a hydrogen dioxide solution or potassium permanganate solution to decolor after the mother liquid turns yellow, wherein the mother liquid can be recycled. No new waste water, waste gas and waste residue are generated, and the production process is clean, environment-friendly, energy-saving and efficient.

Owner:HUBEI YITAI PHARMA

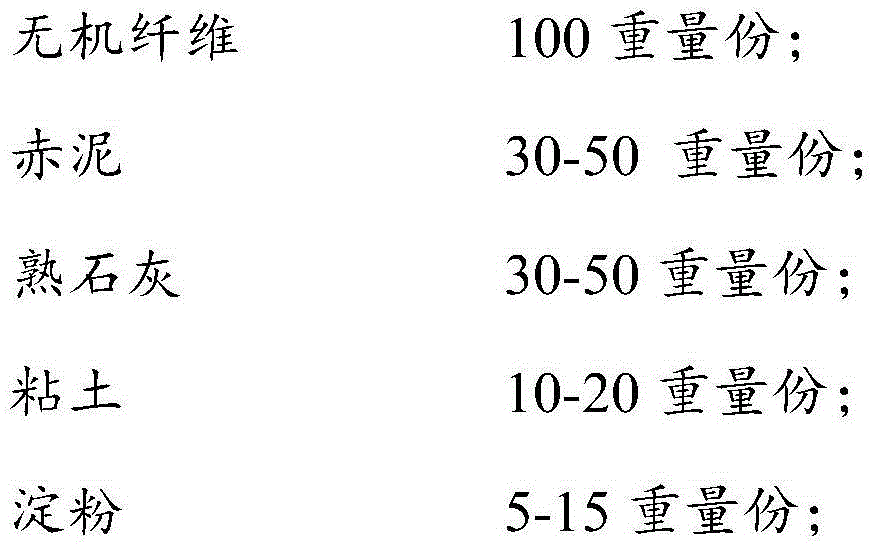

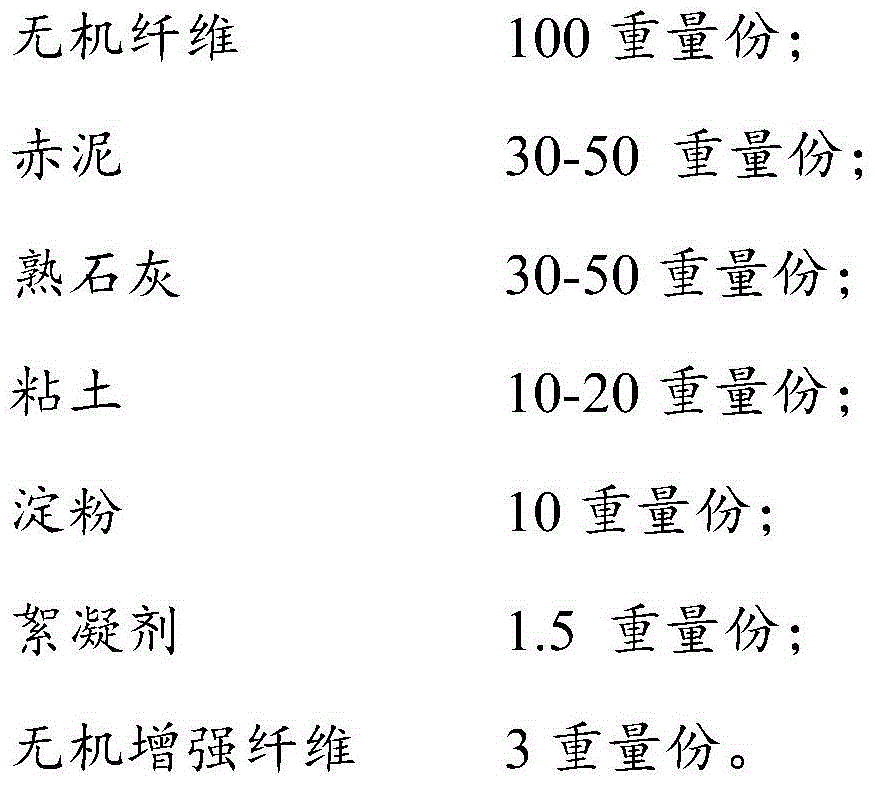

Insulation board and preparation method thereof

InactiveCN104944876AHigh value-added comprehensive utilizationSave resourcesSolid waste managementFiberRed mud

The invention provides an insulation board comprising the following raw material components in parts by weight: 100 parts of inorganic fibers, 30-50 parts of red mud, 30-50 parts of slaked lime, 3-5 parts of inorganic reinforced fibers, 10-20 parts of clay, 5-15 parts of starch and 1-2 parts of a flocculating agent. The insulation board provided by the invention is produced by using a lot of stacked waste materials namely red mud produced during production of aluminum oxide as a main material to realize high-added-value comprehensive utilization of the red mud. The preparation of the insulation board does not need calcination and sintering, so that the production process is energy-saving. The prepared board is nontoxic and non-inflammable, and is an environment-friendly material. The insulation board prepared by the method provided by the invention has higher mechanical strength than that of an existing mineral wool board, and has lower thermal conductivity.

Owner:BEIJING NEW BUILDING MATERIALS PLC

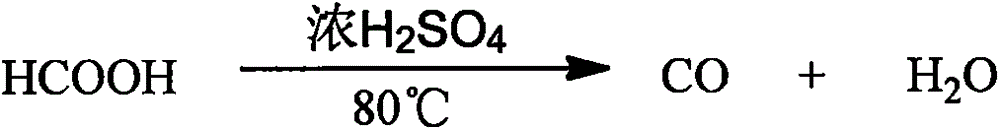

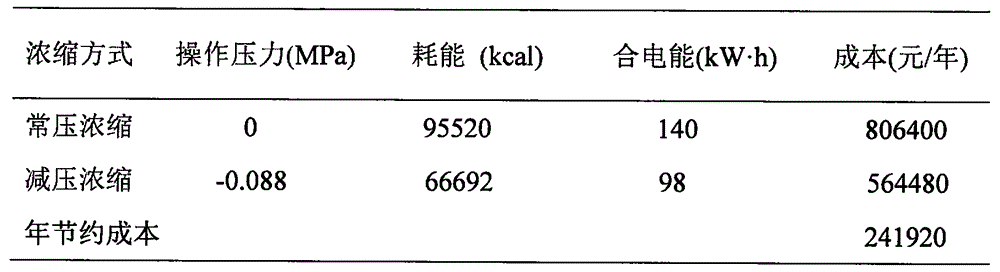

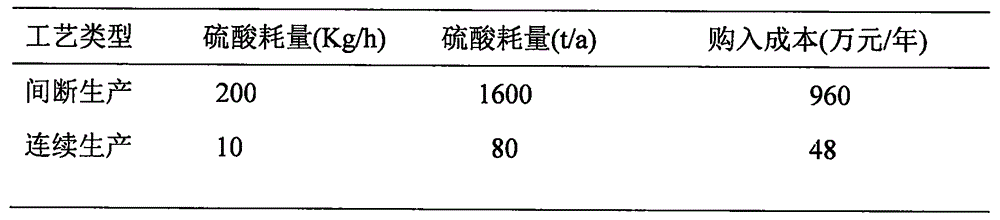

Method for industrially preparing high-purity carbon monoxide through formic acid dehydration

The invention relates to a method for industrially preparing high-purity carbon monoxide through formic acid dehydration. The method includes the steps that (1) formic acid is dehydrated into carbon monoxide under the concentrated sulfuric acid co-heating condition; (2) the generated carbon monoxide is purified to obtain the carbon monoxide with the purity being 99.999%; (3) dilute sulfuric acid generated by dehydration reaction is subjected to vacuum concentration, so that the dilute sulfuric acid continues participating in the reaction and being recycled, and acidic waste water generated in the reaction serves as a cooling medium and continues being recycled after being neutralized. The method achieves continuous feeding, continuous discharging, vacuum concentration of the dilute sulfuric acid and recycling of the sulfuric acid and the waste water. An advanced PLC control system is arranged, and production can be converted into industrial continuous production. Investment intensity is low, production cost is low, operation is safe, stable and reliable, and the technology saves energy and is environmentally friendly.

Owner:BEIJING HUANYU JINGHUI CITY GAS TECH CO LTD

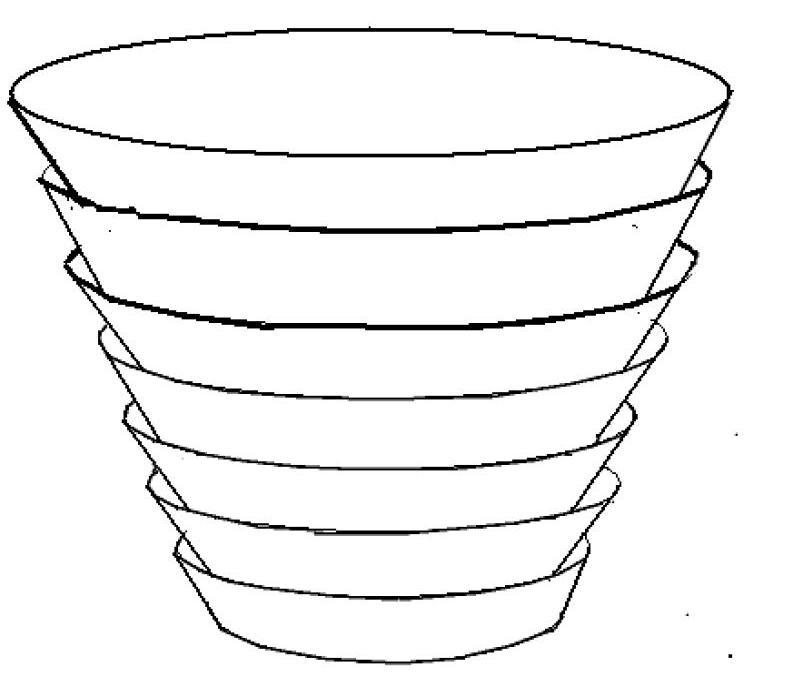

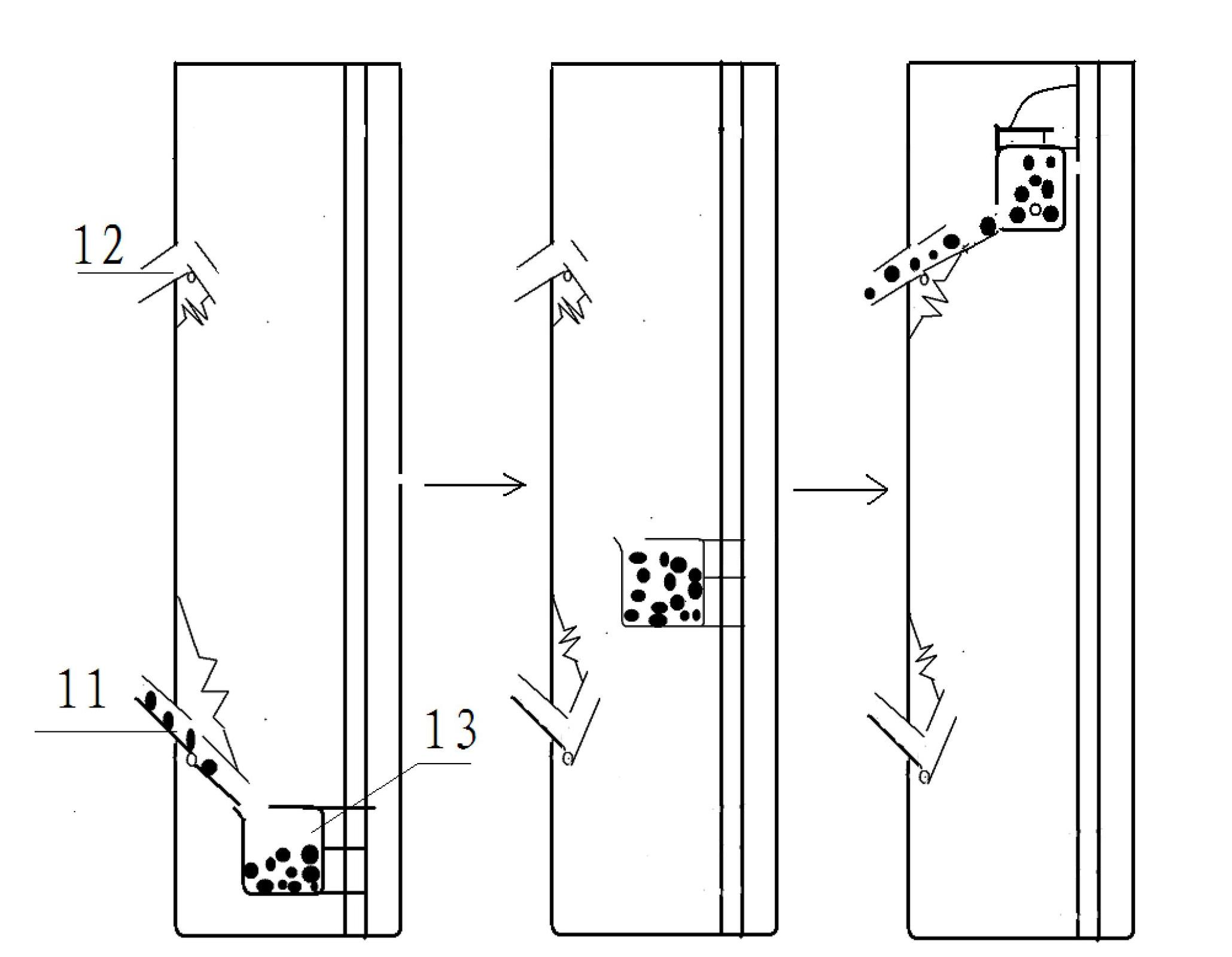

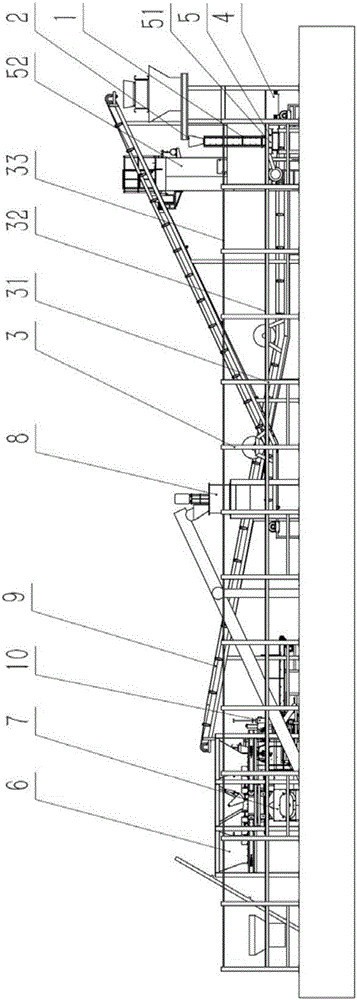

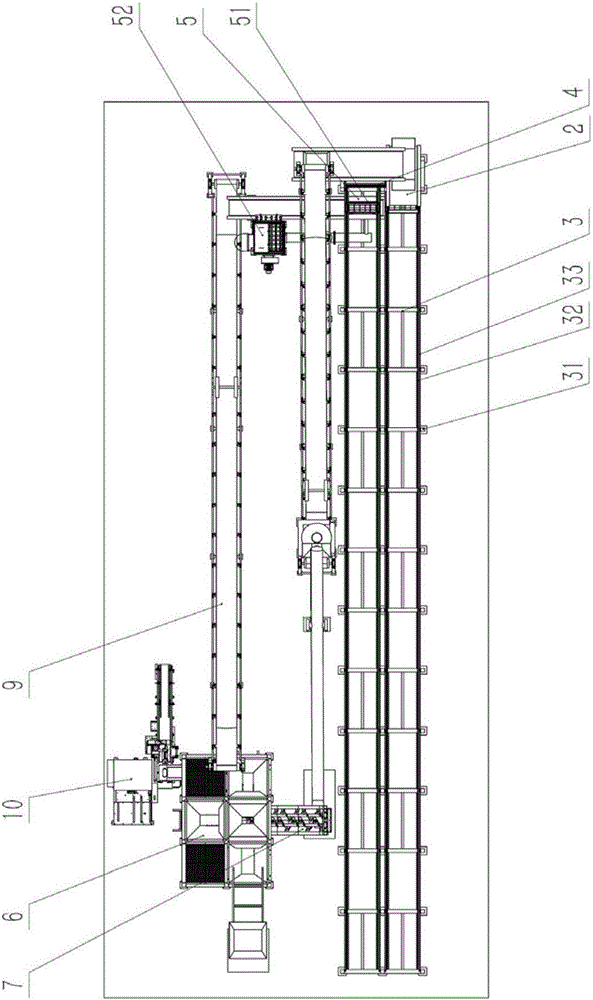

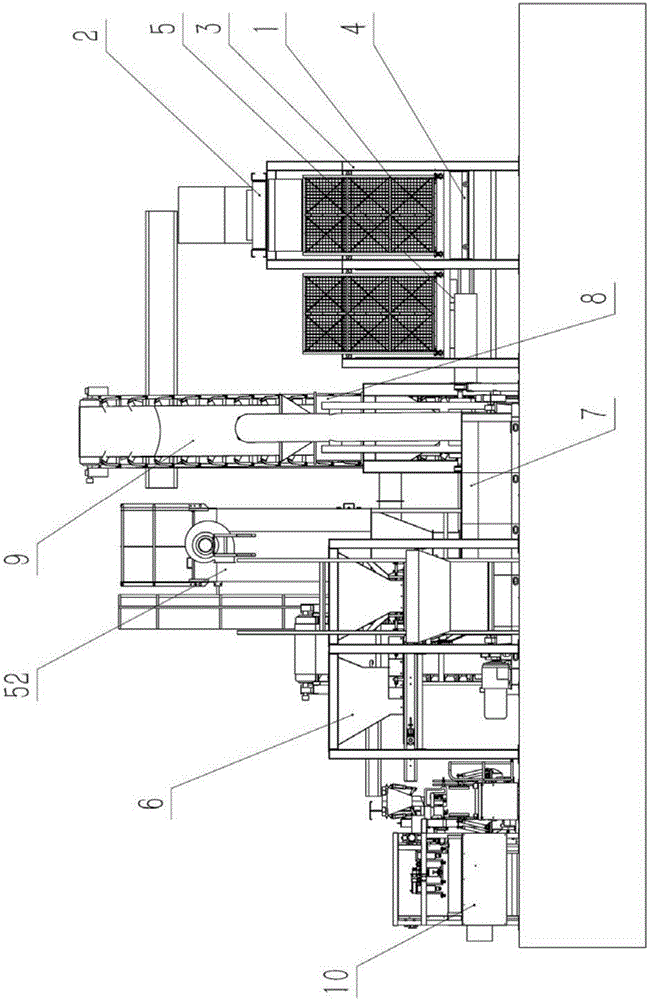

Vertical tray fermentation system and fermentation method

ActiveCN106673742AIncrease heightReduce manufacturing costBio-organic fraction processingOrganic fertiliser preparationEngineeringFermentation system

The invention discloses a vertical tray fermentation system. The vertical tray fermentation system comprises a vertical fermentation tray, a tray loading machine, a tray sliding device and a tray rail replacing device; the vertical fermentation tray is born and slid on the tray sliding device and a tray rail replacing device, the tray loading machine is arranged above the vertical fermentation tray and the end part of the tray sliding device; the tray rail replacing device is arranged and mounted at the end part of the tray sliding device; a fermentation method of the vertical tray fermentation system comprises the following steps: S1, preparing the system, S2, mixing materials, S3, stirring the materials, S4, crushing the materials, S5, loading the materials into the tray, S6, sliding the tray and fermenting the materials, S7, discharging the materials from the tray, S8, replacing rails for the tray and making the tray circularly charge the materials. The technical problems to be solved by the vertical tray fermentation system are to lower manufacturing and processing difficulties and manufacturing and using costs of the vertical tray fermentation system, avoid operation processes of stacking, unstacking, tray dumping, material pouring and the like, and facilitate long-distance transportation.

Owner:GUANGXI LIYUANBAO SCI & TECH

Method for extracting purple corn pigment

InactiveCN102229753AHigh purityEnergy saving productionChemical industryNatural dyesFiltration membraneCeramic composite

The invention relates to a method for extracting purple corn pigment. The purple corn pigment according with the conventional international standards is extracted by eleven steps, namely sorting and crushing, extraction with acid water, rough filtration and cooling, filtration of kieselguhr, filtration with a ceramic composite membrane, adsorption and desorption, concentration with a nano-filtration membrane, evaporation concentration, separation, spray drying, and obtaining of a finished product; the raw materials and the extraction equipment used in the extraction method are conventional materials and equipment, so the method is suitable for large-batch production; the extracted purple corn pigment has unique physiological functions of resisting oxidation, softening blood vessels, preventing and killing colon cancer cells and the like, and can be applied in the fields of food, health-care products and medicine; and the production mode is energy-saving and environment-friendly.

Owner:HUAIBEI PUHAO BIOLOGICAL TECH

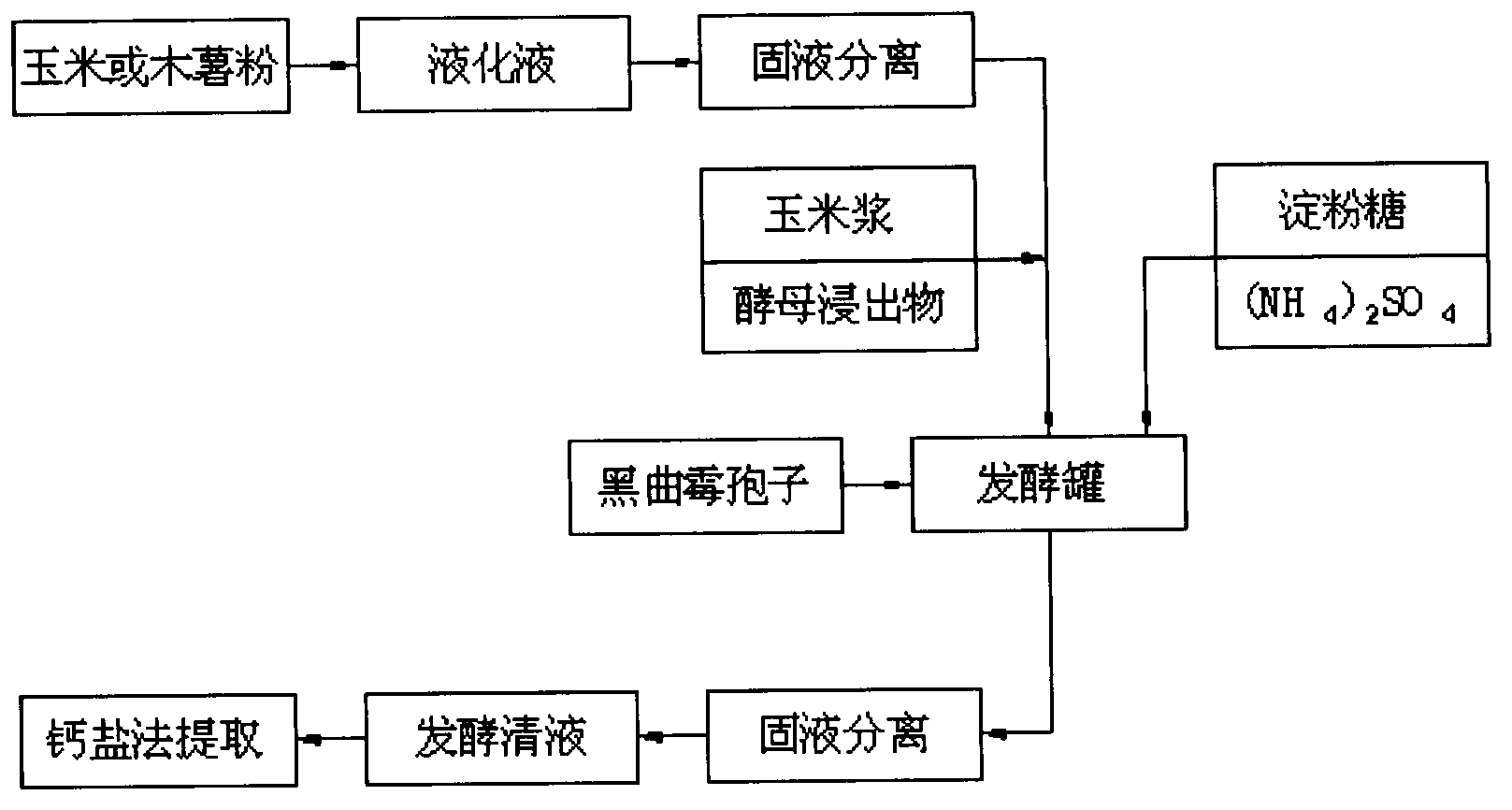

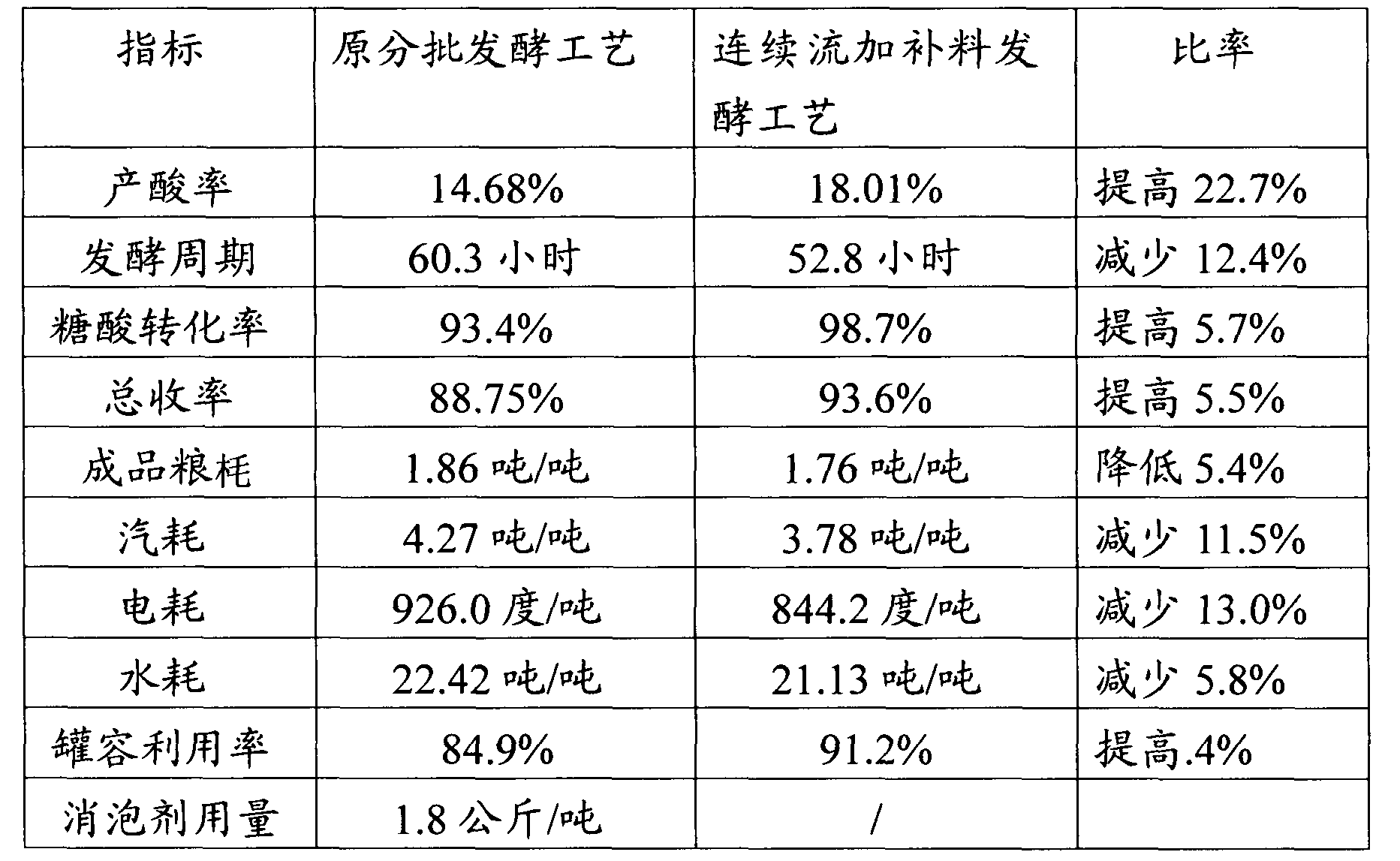

Method for producing citric acid through continuous batch feeding fermentation

ActiveCN103290070AHigh densityAdjustable viscosityMicroorganism based processesFermentationAlpha-amylaseSlurry

A method for producing citric acid through continuous batch feeding fermentation is characterized in that the method comprises the following steps: 1, crushing a starch-containing raw material, adding water, mixing to obtain a starch slurry, adding high-temperature alpha-amylase to form a mixed slurry, liquefying through adopting a continuous injection liquefying technology to obtain a liquefied liquid, and carrying out solid-liquid separation of the liquefied to obtain a liquefied clear liquid; 2, adding the liquefied clear liquid to a fermentation tank, adding a nitrogen source to prepare a basic culture medium, carrying out heating disinfection of the basic culture medium, cooling to 38-40DEG C (room temperature), inoculating Aspergillus niger strains, carrying out ventilated culture of the Aspergillus niger strains for 20-36h, feeding the culture medium in batch for 16-22h, and continuously fermenting the Aspergillus niger strains until the residual sugar content is below 1.0% to prepare a fermentation liquid; and 3, heating the fermentation liquid to 75-85DEG C, terminating the fermentation, filtering to obtain a citric acid fermentation clear liquid, and extracting to obtain citric acid. The method mainly solves the prominent problems of large fermentation energy consumption, high cost and bad product quality caused by long fermentation period, low citric acid yield, low conversion rate in the fermentation production of citric acid.

Owner:NANTONG KAISAI BIOCHEM ENG EQUIP

Method for manufacturing nanometer hydrated alumina fluid dispersion for numerical code color spraying image paper

InactiveCN101280536AEnergy saving productionIncrease brightnessPaper/cardboardNanoparticles dispersionParticle-size distribution

The invention discloses a manufacture method of nanometer hydrated alumina dispersion liquid for digital color inkjet printing image paper, which adopts the following process: 1) aluminum Isopropoxide is hydrolyzed by isopropyl alcohol and water; 2) the hydrolyzed liquid is distilled to obtain the isopropyl alcohol; 3) the isopropyl alcohol is condensed, adjusted in acidity and alkalinity, and added with secondary particle size distribution regulator for treatment; 4) finally, the hydrated alumina dispersion liquid is added with an acid solution stabilizer by the means of drop, so as to obtain the stable nanometer hydrated alumina dispersion liquid for digital color inkjet printing image paper, thereby solving the difficulty of drying need, being easy for accumulation, uneven nanometer particle dispersion, and dust pollution during production and use when manufacturing nanometer hydrated alumina material in the prior digital color inkjet printing image paper. The nanometer hydrated alumina dispersion liquid has the advantages of high efficiency, energy saving, and environmental protection, so that the surface layer of paper has light transmission, anti-crack, good ink absorption, high brightness, bright color and strong solid feeling. The nanometer hydrated alumina dispersion liquid is suitable for manufacturing digital color inkjet printing image paper as one-time coated cloth.

Owner:许炯

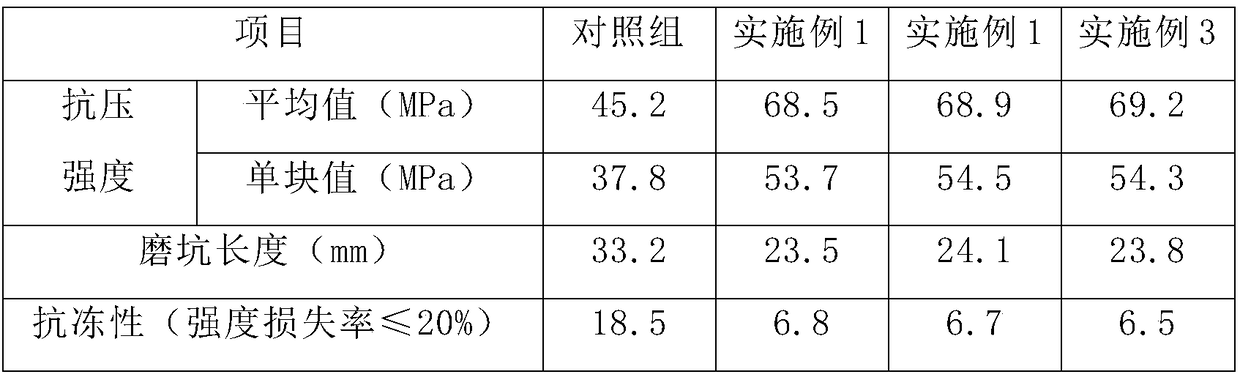

Baking-free pavement brick added with hydrophobic modified glass fibers

The invention relates to the technical field of building materials and particularly relates to a baking-free pavement brick added with hydrophobic modified glass fibers. The pavement brick contains the following components: steel slag coarse aggregates, granite aggregates, cement, quartz sand, red mud, coal gangue powder, potassium feldspar powder, hydrophobic modified glass fibers, a sealing curing agent, a water reducing agent and water, wherein the hydrophobic modified glass fibers are glass fibers which are subjected to surface hydrophobic modification, the particle sizes of the steel slagcoarse aggregates are 2mm-4mm, the particle sizes of the granite aggregates are 1mm-2mm, and the fineness of quartz sand is 100-150 meshes; the cement is Portland cement, aluminate cement or magnesium oxychloride cement; and the water reducing agent is a polycarboxylic acid water reducing agent or a naphthalene water reducing agent. A manufacturing process of the pavement brick is energy-saving,environment-friendly and low in cost, and a brick body is high in rigidity and compression strength and unlikely to crack.

Owner:合肥协耀玻璃制品有限公司

Self-adhesive functional composite film and preparation method thereof

ActiveCN111378399AAvoid inconvenienceEasy to useNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesive cementPolymer science

The invention discloses a self-adhesive functional composite film. The self-adhesive functional composite film comprises a plastic base film, one side of the plastic base film is coated with a solvent-free adhesive and forms a self-adhesive layer in a radiation curing mode, a release layer is arranged on the other side of the plastic base film, the release layer is a transparent release layer withlow surface energy, and the stripping force of the release layer to a standard adhesive tape is smaller than 0.5 N / 25 mm. The invention provides the self-adhesive functional composite film. The self-adhesive layer is formed by using the solvent-free adhesive, the preparation process of coating and radiation curing is adopted, and meanwhile, the transparent release layer with low surface energy isadopted, so that timely coating and curing can be realized, the procedures of placing and drying are omitted, no solvent volatilizes in the preparation process, the production is easy, simple and efficient, and the technical effects of energy conservation, environmental protection and high efficiency are achieved.

Owner:成都彭州立源高分子材料有限公司

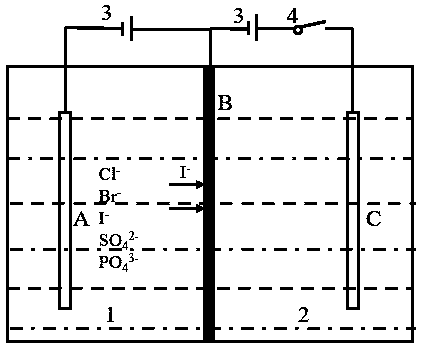

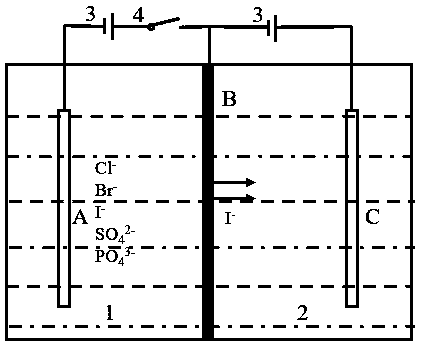

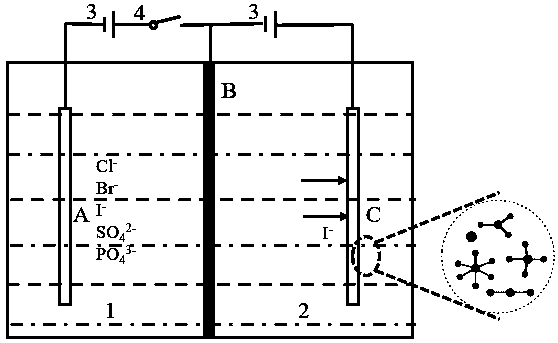

Method for producing iodine product through electronic control ionic membrane extraction coupling electrolysis process

ActiveCN108441881AEliminate secondary pollutionImprove adsorption and desorption efficiencyOrganic diaphragmsElectrode shape/formsElectrode potentialElectrolysis

The invention discloses a method for producing an iodine product through an electronic control ionic membrane extraction coupling electrolysis process. The method comprises the steps of putting a polypyrrole functional membrane material with adsorption selectivity into a raw material liquid containing iodide ions, applying a corresponding oxidation potential to the membrane material, and adsorbingthe iodide ions in a water phase into the membrane material, so that the iodide ions are enriched; after the enrichment reaches saturation, applying an opposite potential, and desorbing the iodide ions adsorbed in the membrane into a corresponding salt solution under an electric field auxiliary action, so that the membrane material is regenerated; and carrying out specific oxidation reaction on acounter electrode, and generating the corresponding iodine product. According to the method provided by the invention, electrode potential oxidoreduction is adopted as the main driving force, so thatthe secondary pollution caused by a chemical regenerating agent is eliminated; by adopting electrode potential oxidoreduction as the driving force, the adsorption and desorption efficiency of the ions is greatly improved, and the iodide ions in the low-concentration raw material liquid containing iodine can be extracted; and the functional membrane material can be recycled.

Owner:TAIYUAN UNIV OF TECH

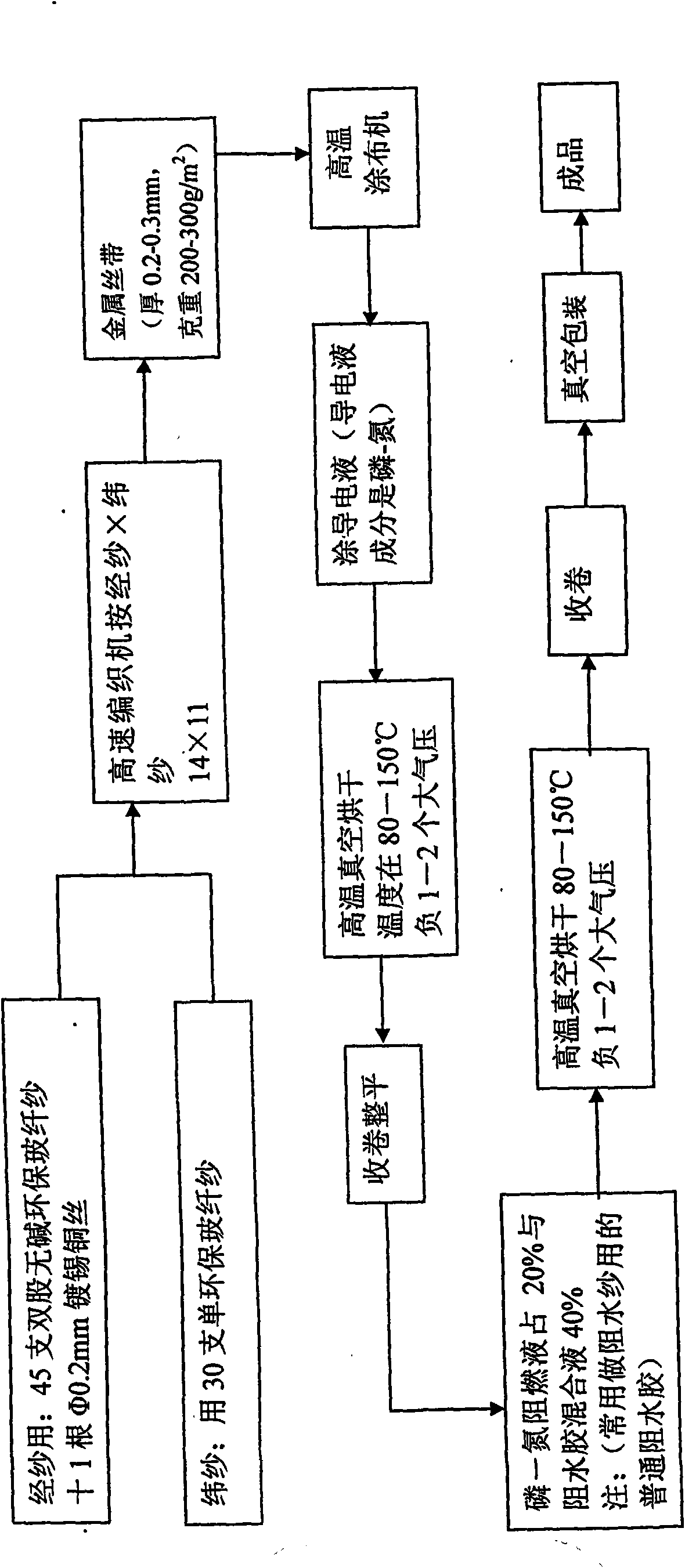

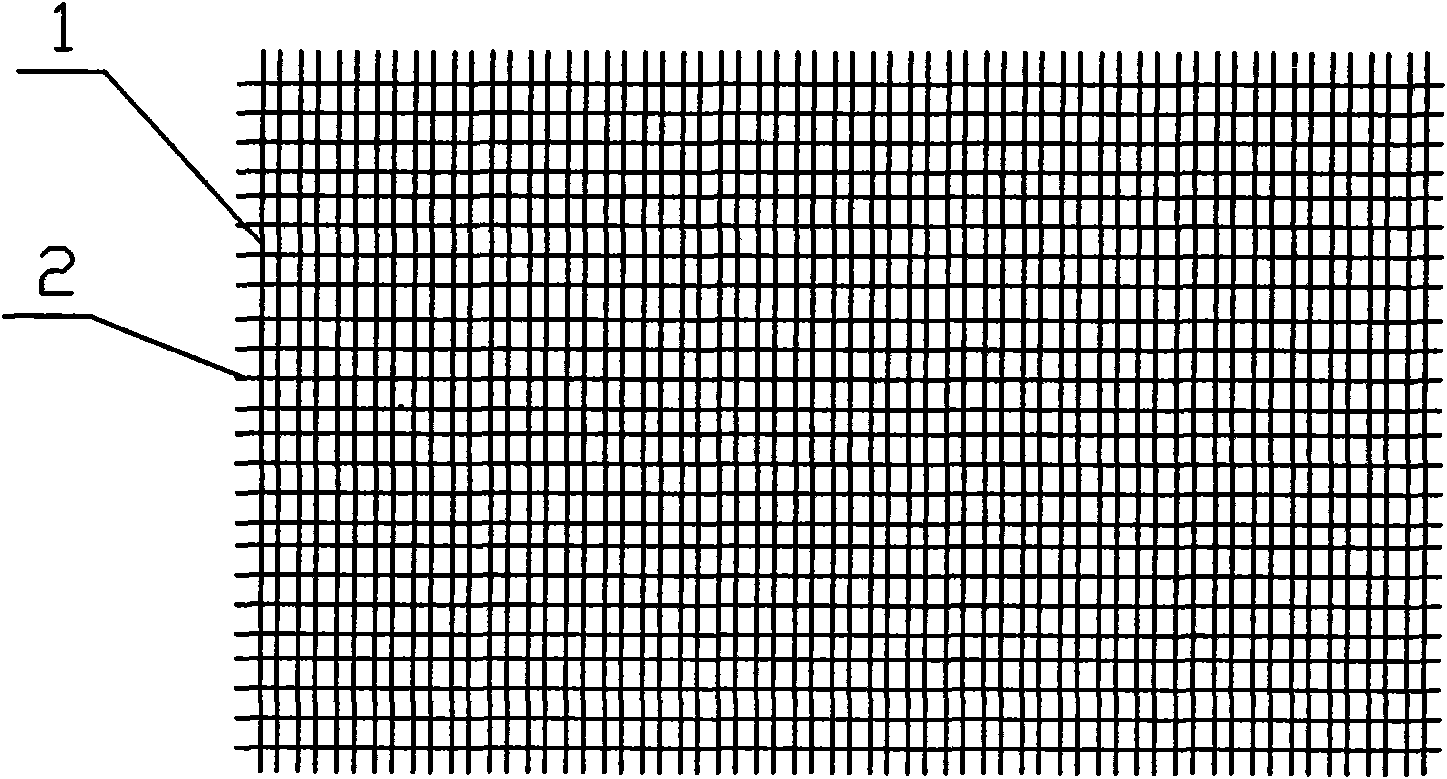

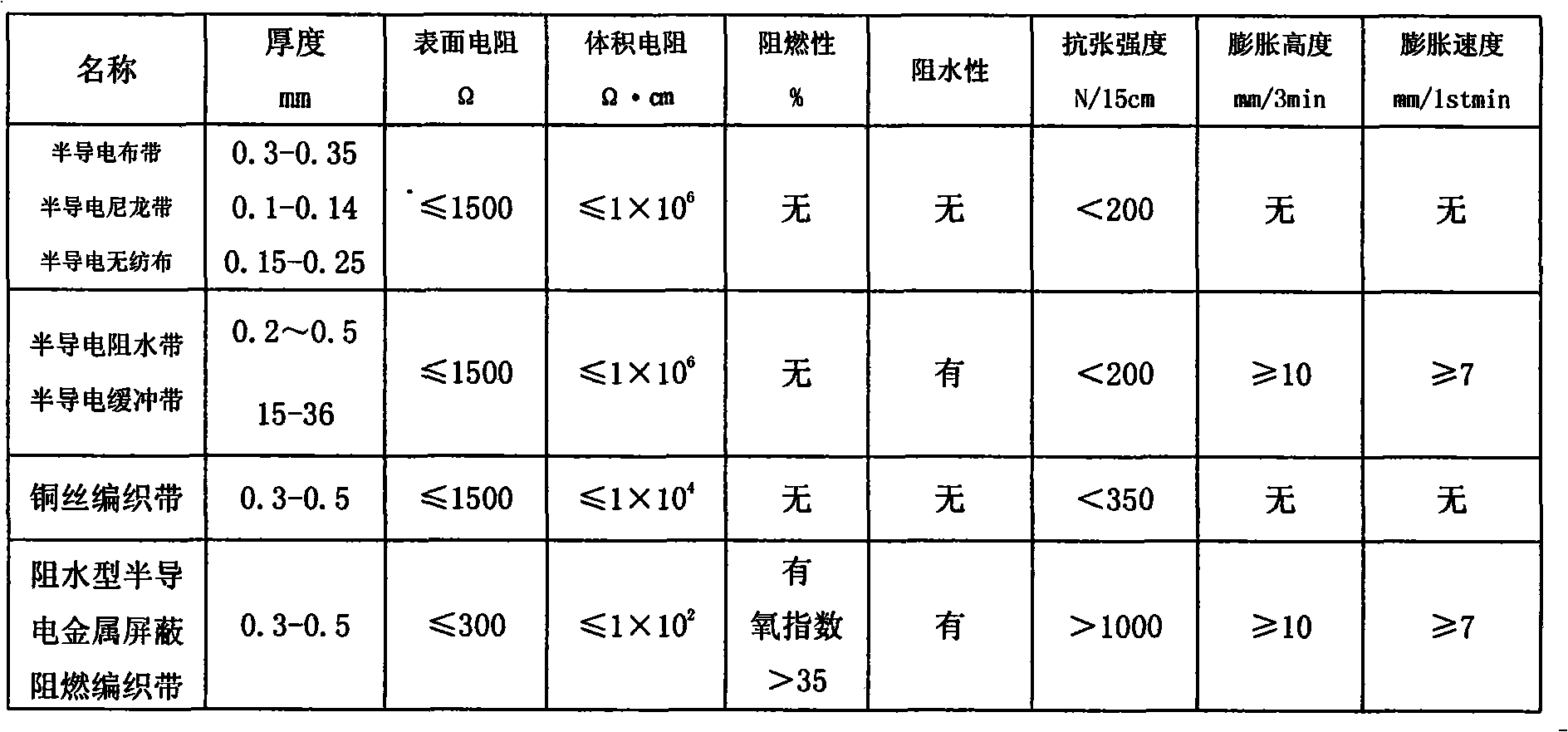

Water-repellent semiconducting metal-shielded flame-retardant braided strap and processing technology thereof

InactiveCN101908390AFull immersionSemi-conductiveClimate change adaptationPower cables with screens/conductive layersSemiconductionAdhesive

The invention discloses a water-repellent semiconducting metal-shielded flame-retardant braided strap. The water-repellent semiconducting metal-shielded flame-retardant braided strap comprises a base fabric, and conductive liquid, flame-retardant liquid and a water-repellent adhesive attached to the base fabric; and the base fabric is formed by braiding wraps and wefts. The processing technology comprises the following technological steps of: 1) sorting: sorting the wraps and the wefts; 2) braiding: braiding the wraps and wefts by using a high-speed braiding machine; 3) coating the conductive liquid: coating the conductive liquid on the base fabric in a liquid-immersing groove; 4) drying: drying the base fabric, rolling and leveling; 5) coating the flame-retardant liquid: coating the flame-retardant liquid on the treated base fabric in the liquid-immersing groove; 6) drying: drying the base fabric, rolling and leveling; and 7) packaging: performing vacuum packaging on the braided strap to form a finished product. The water-repellent semiconducting metal-shielded flame-retardant braided strap has the advantages of semiconduction, water-repellent and flame-retardant property, high heat resistance grade, high tensile strength, and energy conservation, consumption reduction and environmental protection in the production process.

Owner:YANG ZHOU TENGFEI ELECTRIC CABLE & APPLIANCE MATERIALS CO LTD

Intelligent ecological resource utilization production method of light-weight calcium carbonate

InactiveCN107902686AEnergy saving productionProduction environmental protectionCalcium/strontium/barium carbonatesFood processingFlue gasCarbonization

The invention discloses an intelligent ecological resource utilization production method of light-weight calcium carbonate. By a carbonization production method, limestone and other raw materials arecalcined to produce lime and carbon dioxide, then water is added for slaking the lime to produce lime milk, and then the carbon dioxide is inflated for carbonizing the lime milk to produce a calcium carbonate precipitate, and finally the calcium carbonate precipitate is dehydrated, dried and pulverized to obtain the light-weight calcium carbonate; the intelligent ecological resource utilization production method is characterized in that in the calcining production process, materials are automatically fed into a calcining furnace in an elevator way, and the materials are discharged from the lower part of the calcining furnace in a swinging way; in the dehydrating and drying process, a rice husk combusting furnace is used for producing hot air for drying, comprehensive utilization of afterheat of the hot air is achieved in a multi-layer circulating way, and flue gas produced by combustion of rice husk is settled for pollution-free discharge so as to achieve intelligent ecological resource utilization production of the light-weight calcium carbonate.

Owner:湖南恒旺碳酸钙有限公司

Ointment for treating coronary disease and its production process

InactiveCN1813912AImprove ischemic stateGood curative effectOrganic active ingredientsAerosol deliveryCoronary artery diseaseMyrrh

The present invention discloses a Guanxin adhesive plaster and its production process. It is made up by using the Chinese medicinal materials of salvia root, ligusticum root, Chinese angelica root, carthamus flower, myrrh, clove, frankincense, dalbergia wood, camphor, xylene musk, menthanol, diphenhydramine hydrochloride, borneol and medical carrier rubber plaster matrix through a certain preparation process. Besides, said invention also provides the concrete steps of said preparation process.

Owner:李秀花

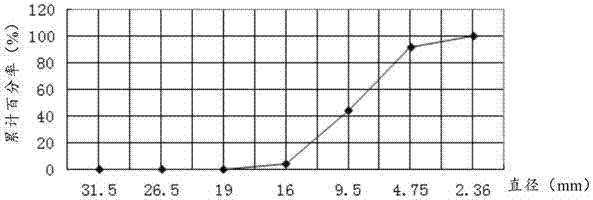

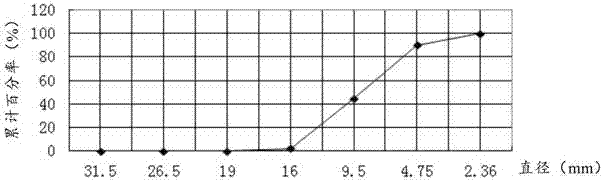

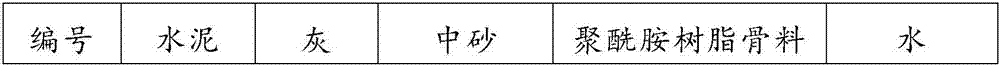

Concrete aggregate used for replacing crushed stone aggregate and related concrete

InactiveCN107129171AProduction environmental protectionEnergy saving productionCrushed stoneCompressive strength

The invention provides a concrete aggregate used for replacing crushed stone aggregate. The concrete aggregate is a resin aggregate; and preferably, the resin aggregate is a circular-grain resin aggregate. The grain composition of the resin aggregate meets requirements as prescribed in table 3.2.1-2 in Standards for Quality and Inspection Methods of Sand and Stone Applied to Common Concrete JGJ52-2006. The mud content and clay lump content of the resin aggregate are both 0 wt%; the content of elongated and flaky particles in the resin aggregate is 0 wt%; and the resin aggregate has comprehensive strength of 100 MPa. The resin aggregate is polyamide resin aggregate. The invention also provides concrete containing the above replacing aggregate instead of crushed stone aggregate. The replacing aggregate for concrete provided by the invention can replace crushed stone aggregate in preparation of concrete; and the aggregate is environment-friendly and energy-saving to prepare, realizes recycling of resources, is stable in quality, has the characteristics of light weight and cuttability and is suitable for large-scale promotion and application.

Owner:SHANGHAI TUNNEL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com