Method for producing citric acid through continuous batch feeding fermentation

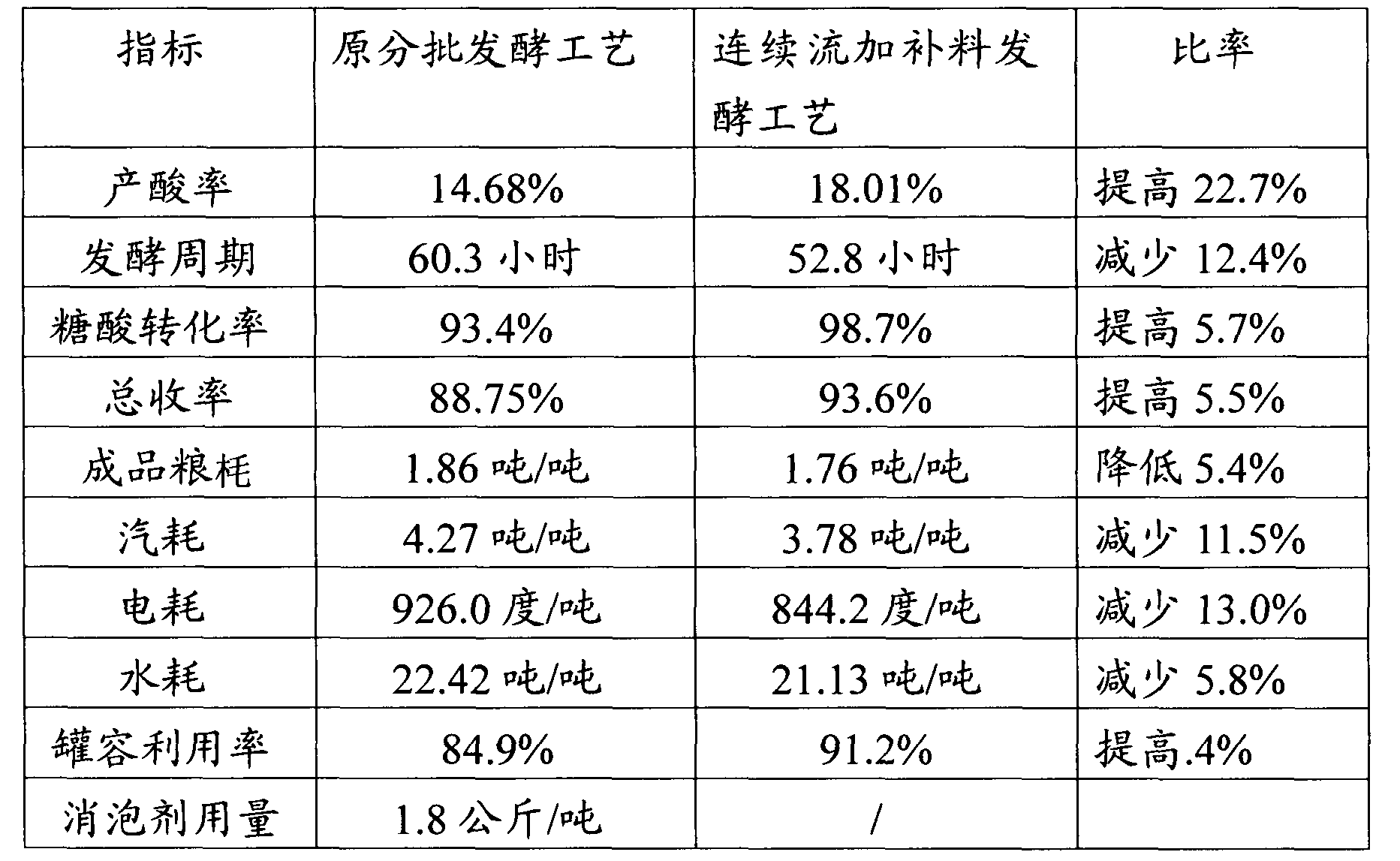

A technology of fed-feed fermentation and citric acid, applied in the field of citric acid production and biological process engineering, can solve the problems of low acid production rate and conversion rate, poor product quality, long fermentation period, etc., to improve the quality and increase the filling coefficient. , the effect of low residual sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

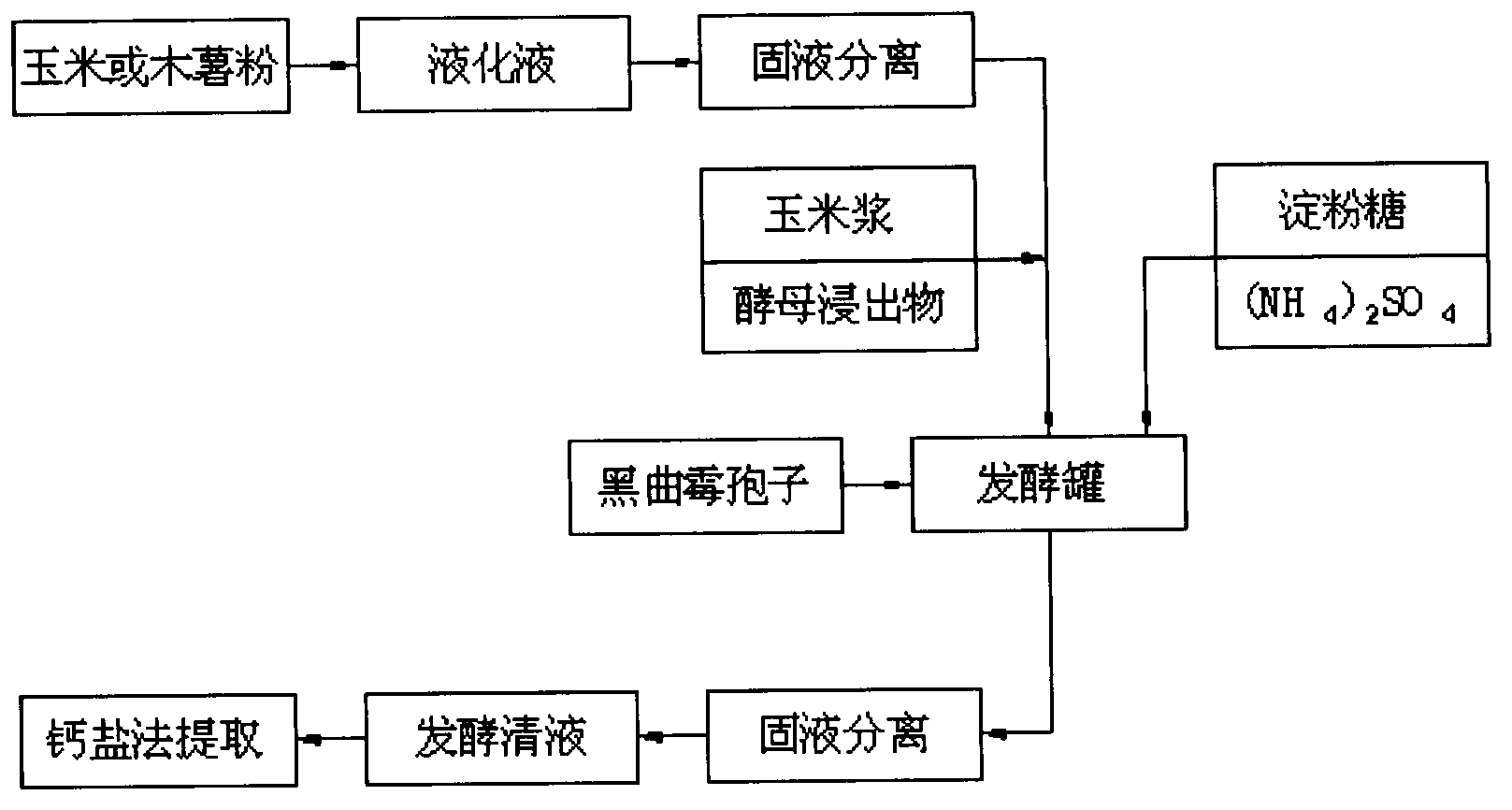

[0038] A method for producing citric acid by continuous fed-batch fermentation is characterized in that it comprises the following processing steps:

[0039] Step 1. After pulverizing the raw material containing starch, adding water to make starch slurry, adding high-temperature α-amylase to the starch slurry, and then adopting continuous jet liquefaction process for liquefaction to obtain liquefied liquid, and performing solid-liquid separation on the liquefied liquid. Prepare liquefied supernatant;

[0040] Wherein, the starch-containing raw material is selected from corn, cassava and potato;

[0041] The pH value of the starch slurry is 5.0 to 7.0;

[0042] The added amount of the high-temperature α-amylase is calculated by adding 5 to 15 enzyme activity units of high-temperature α-amylase per gram of the starch-containing raw material;

[0043]Step 2. Put the liquefied clear liquid obtained in step 1 into a fermenter, add a nitrogen source to prepare a basal medium; heat...

Embodiment 2

[0061] (1) Take the corn raw material, grind it into a fineness of 40 mesh corn flour, add water to adjust the slurry, the concentration after the slurry adjustment is 182.4g / L; adjust the pH value of the slurry to 5.5; add 8 per gram of corn flour Add high-temperature α-amylase in the amount of 1 enzyme activity unit, adopt continuous jet liquefaction process to liquefy, and obtain liquefied liquid; adopt plate and frame filter to carry out solid-liquid separation, and make liquefied supernatant liquid.

[0062] (2) Put the liquefied clear liquid into a 50m fermenter, and the total sugar concentration is 9.6%. Add 1.0% corn steep liquor to prepare a basal medium, the volume of which is 69.3% of the volume of the fermenter. Heat the medium to 110°C to sterilize, keep it for 25 minutes and then quickly cool down to 39°C±1, inoculate directly with Aspergillus niger spores, the spore concentration is 2×10 6 pieces / ml. Turn on the stirring and the first stage of the 3D jet air d...

Embodiment 3

[0066] (1) Weigh the corn raw material, pulverize it into a fineness of 40 mesh corn flour, add water to adjust the slurry, the concentration after the slurry adjustment is 162.8g / L; adjust the pH value of the slurry to 5.5; add 5 Add high-temperature α-amylase in the amount of 1 enzyme activity unit, adopt continuous jet liquefaction process to liquefy, and obtain liquefied liquid; adopt plate and frame filter to carry out solid-liquid separation, and make liquefied supernatant liquid.

[0067] (2) Put the liquefied supernatant into 300m 3 In the fermenter, the total sugar concentration was 8.6%. Add 0.8% corn steep liquor to prepare a basal medium, the volume of which is 62.7% of the volume of the fermenter. Heat the medium to 105°C to sterilize, maintain it for 25 minutes and then quickly cool down to 38°C±1, inoculate directly with Aspergillus niger spores, the spore concentration is 2×10 6 pieces / ml. Turn on the stirring and the first stage of the 3D jet air distributo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com