Insulation board and preparation method thereof

A technology of thermal insulation board and red mud, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of polluted surface and groundwater sources, secondary waste of resources, occupation of land, etc., achieving small thickness and saving The effect of energy saving of resources and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

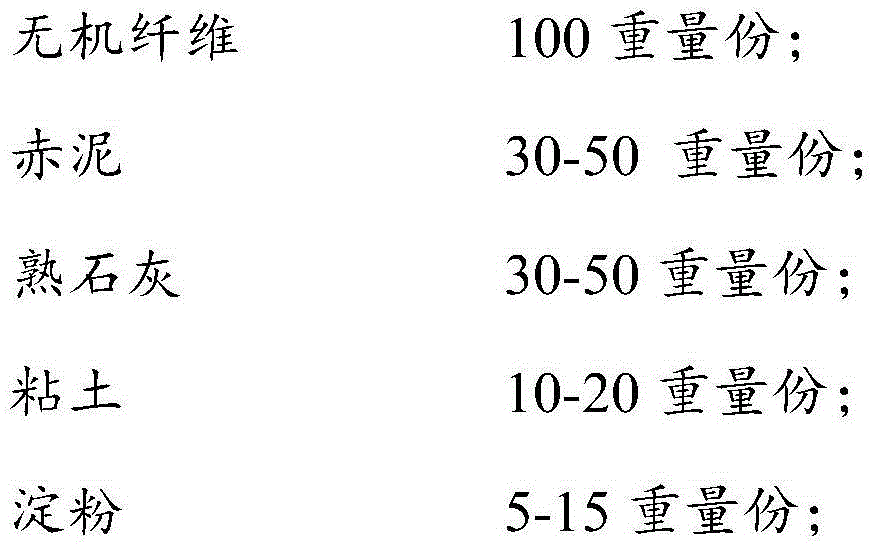

Method used

Image

Examples

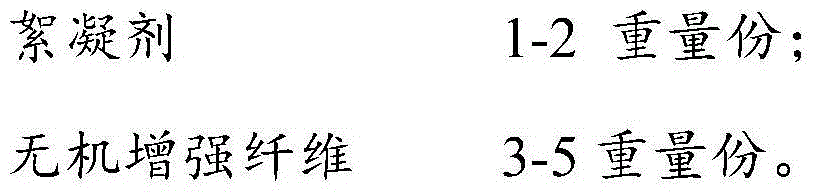

Embodiment 1

[0023] 100 grams of mineral wool fiber and 40 grams of red mud (Bayer process red mud of Shandong Aluminum Company) were dispersed in 3.0L of water, then 40 grams of slaked lime was added to stir the slurry, and then 5 grams of inorganic reinforcing fiber (wollastonite fiber) was added, 15 grams of clay, 10 grams of starch, continue to stir, and finally add 1.0 grams of aluminum sulfate, stir for 1 minute, filter, shape, and dry at 180°C for 1 hour to obtain a red mud-based insulation board with a thickness of 10mm.

Embodiment 2

[0025] Disperse 100 grams of mineral wool fiber and 30 grams of red mud (sintered red mud of Shandong Aluminum Company) in 3.0L of water, then add 30 grams of slaked lime to stir and make a slurry, then add 5 grams of inorganic reinforcing fiber (gypsum whiskers), 20 grams of clay gram, 10 grams of starch, continue to stir, and finally add 1.0 grams of polyacrylamide, stir for 1 minute, filter, shape, and dry at 180 ° C for 1 hour to obtain a red mud-based insulation board with a thickness of 10 mm.

Embodiment 3

[0027] Disperse 100 grams of mineral wool fiber and 50 grams of red mud (mixed red mud of Shanxi Aluminum Plant) in 3.0L of water, then add 50 grams of slaked lime to stir and beat, then add 5 grams of inorganic reinforcing fiber (brucite fiber), clay 10 grams, 10 grams of starch, continue to stir, and finally add 1.0 grams of aluminum sulfate, stir for 1 minute, filter, shape, and dry at 180°C for 1 hour to obtain a red mud-based insulation board with a thickness of 12mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com