Technique for purifying calcium carbide furnace gas

A calcium carbide furnace and furnace gas technology, which is applied in the chemical industry, can solve the problems of not realizing comprehensive utilization, polluting the atmospheric environment, and the limitation of comprehensive utilization processes such as calcium carbide furnace gas purification and deep processing, achieving high added value comprehensive utilization and improving enterprise economy. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

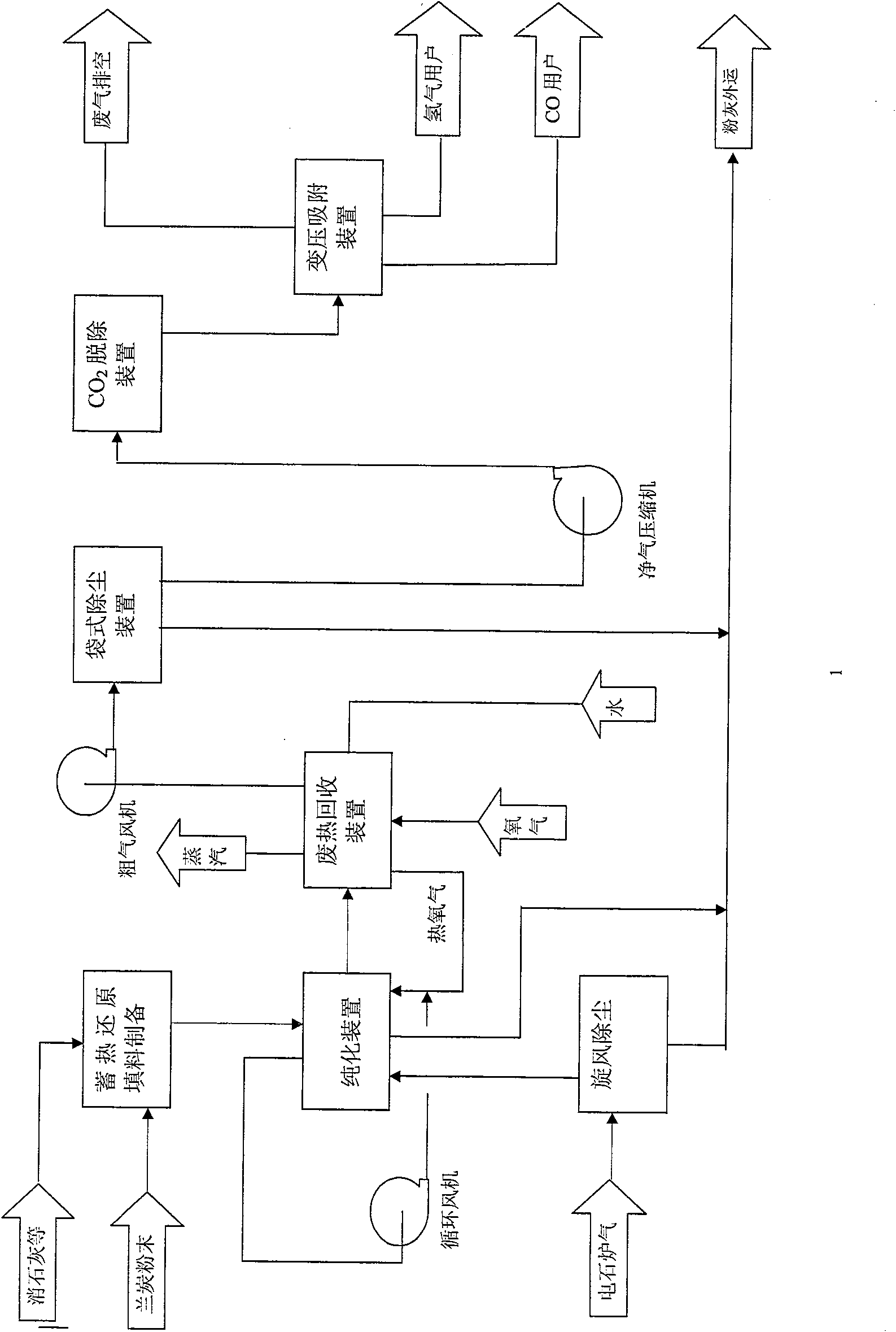

[0013] Concrete technological process of the present invention is:

[0014] 1. Preparation of regenerative reduction filler:

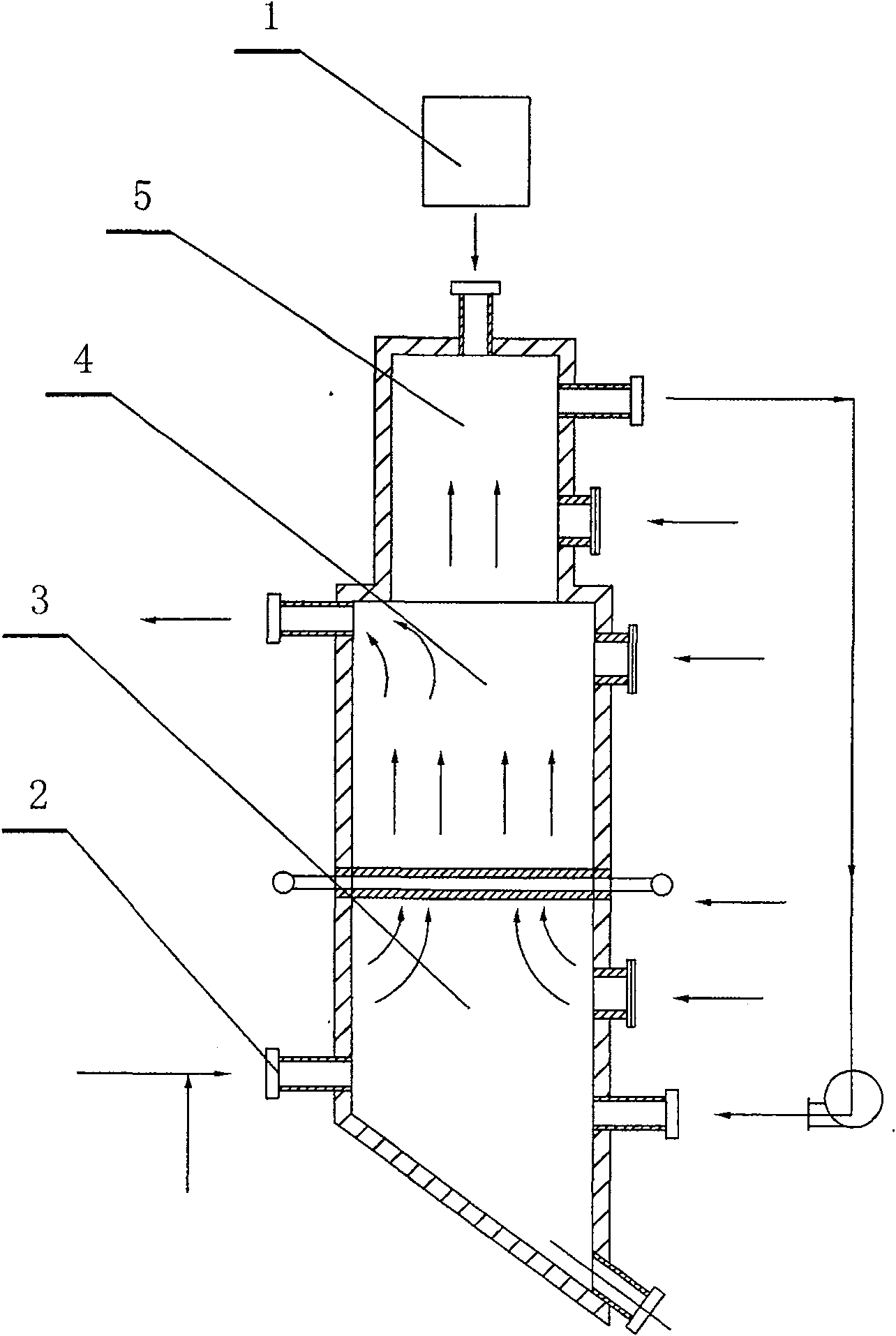

[0015] The semi-coke powder, slaked lime powder and coal tar produced in the production of calcium carbide furnace are mixed according to the ratio of (60%-75%): (10%-25%): 15%-20% (processing with semi-coke powder can achieve The effect of using waste to make waste), and press it into a spherical filler with a diameter of 25-75mm in a ball briquetting machine, and the strength requirements: cold strength ≥ 60kg / piece, hot strength ≥ 25kg / piece. The semi-coke is made into a spherical shape because the surface of the sphere is relatively smooth, which is not conducive to the deposition of dust entrained in the furnace gas on its surface, and can prevent bridging at the same time. Then this spherical filler is fed into the purification tower through the feeding system 1 at the top of the purification tower, which can be fed continuously or intermittentl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com