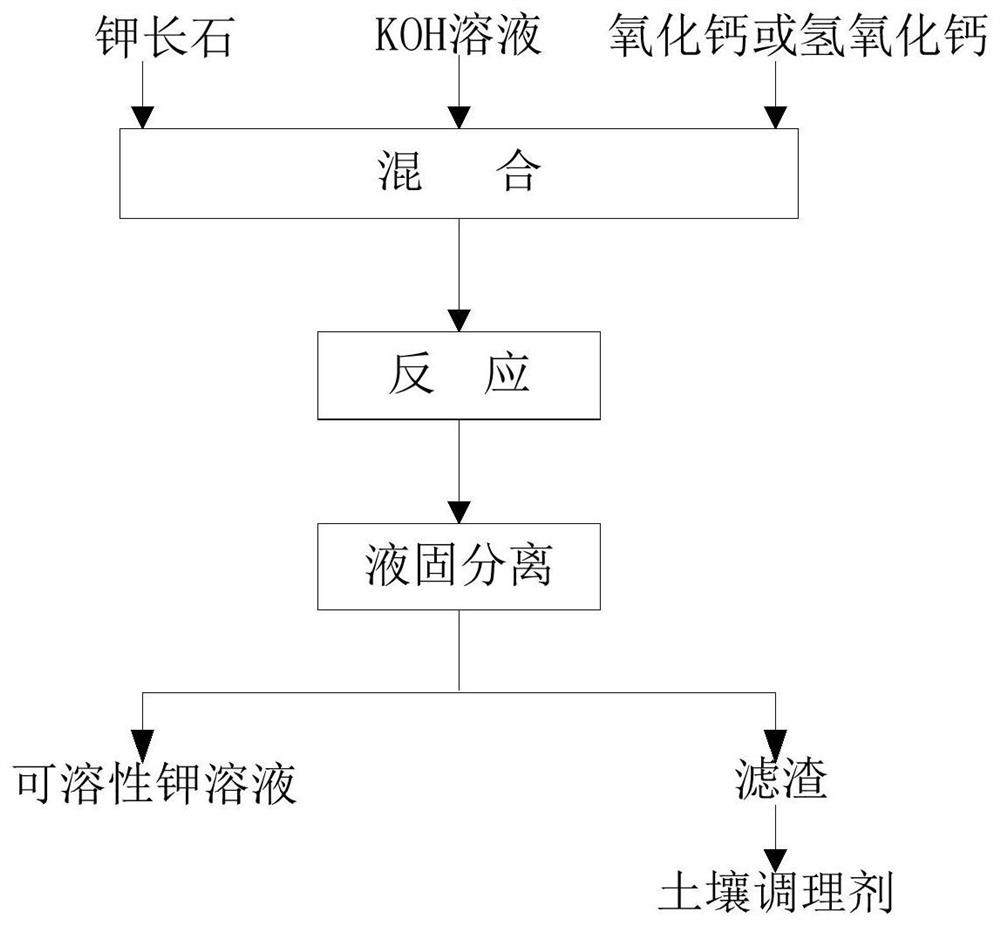

A kind of method that alkali activates potassium feldspar to prepare soluble potassium and calcium silicate soil conditioner

A technology for activating potassium feldspar and soil conditioner, which is applied in the field of comprehensive utilization of resources, can solve the problems of low potassium extraction rate, serious pollution, and high energy consumption, and achieve the effects of less environmental pollution, low reaction temperature, and less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add the prepared potassium hydroxide solution with a mass concentration of 1g / L into the reaction kettle with a cooling device, and add the oxidized Potassium content is 13.94%, silicon dioxide content is the potassium feldspar powder of 66.41% (passes through 100 mesh sieves after being pulverized), and calcium hydroxide is added to adjust the Ca / Si molar ratio in the mixture to be 0.9, and after mixing evenly, react at 190° C. for 6 hours, Stir well, and after the reaction is completed, cool down to below 100°C, and the filtrate obtained after suction filtration of the reaction product is a soluble potassium solution; wash the filter residue slurry twice, and dry the filter residue at 100°C after suction filtration. After testing, K in the filter residue 2 The content of O is 1.6%, and K is calculated 2 The dissolution rate of O was 92.78%; the content of citrate-soluble silica in the filter residue was 26.88%, the content of calcium oxide was 32.01%, and the water c...

Embodiment 2

[0029] The configured potassium hydroxide solution with a mass concentration of 50g / L is added to the reaction kettle with a cooling device, and the oxidation Potassium content is 12.04%, silicon dioxide content is 65.01% potassium feldspar powder (passes through 50 mesh sieves after crushing), and calcium oxide is added to adjust the Ca / Si molar ratio in the mixture to be 0.3, after mixing evenly, react at 210°C for 1h, fully Stir and cool down to below 100°C after finishing the reaction. The filtrate obtained after liquid-solid separation of the reaction product is a soluble potassium solution; wash the filter residue slurry 3 times, and dry the filter residue at 30°C after suction filtration. After testing, K in the filter residue 2 The content of O is 1.75%, calculated K 2 The dissolution rate of O was 91.17%; the content of citrate-soluble silica in the filter residue was 23.06%, the content of calcium oxide was 8.80%, and the moisture content of the filter residue was 3...

Embodiment 3

[0031] The configured potassium hydroxide solution with a mass concentration of 30g / L is added to the reaction kettle with a cooling device, and the oxidation Potassium feldspar powder with a potassium content of 10.21% and a silicon dioxide content of 68.02% (passed through a 80-mesh sieve after crushing), adding calcium hydroxide to adjust the Ca / Si molar ratio in the mixture to 1.5, and reacting at 160°C for 4.5 hours after mixing evenly , fully stirred, after the reaction was completed, the temperature was lowered to below 100°C, and the filtrate after suction filtration of the reaction product was a soluble potassium solution; the filter residue slurry was washed 4 times, and the filter residue was dried at 120°C after suction filtration. After testing, K in the filter residue 2 The content of O is 1.13%, it is calculated that K 2 The dissolution rate of O is 90.00%, the content of citrate-soluble silicon dioxide in the filter residue is 24.06%, the content of calcium ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com