Method for Industrialized Production of High-purity Walnut Peptide Using Low-temperature Pressed Walnut Meal as Raw Material

A high-purity walnut meal technology, which is applied in plant protein processing, food ingredient functions, protein food processing, etc., can solve problems affecting product quality, lack of scientific optimization, and difficult industrial implementation, etc., to improve product color and flavor , improve the yield of walnut peptide, and be easy to achieve in industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

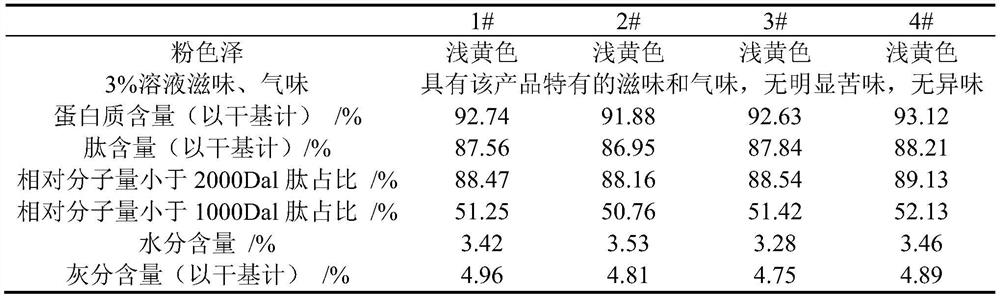

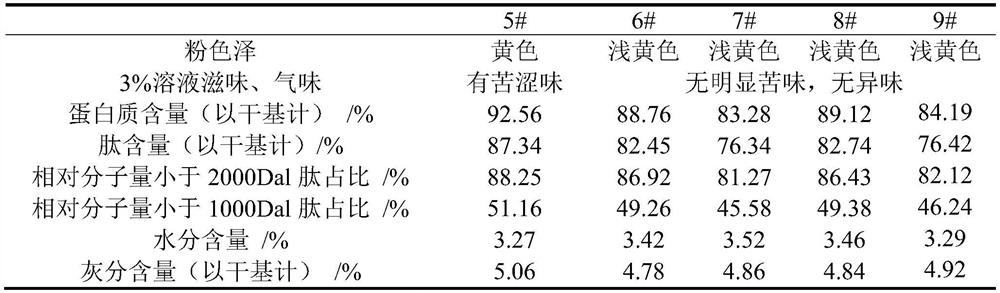

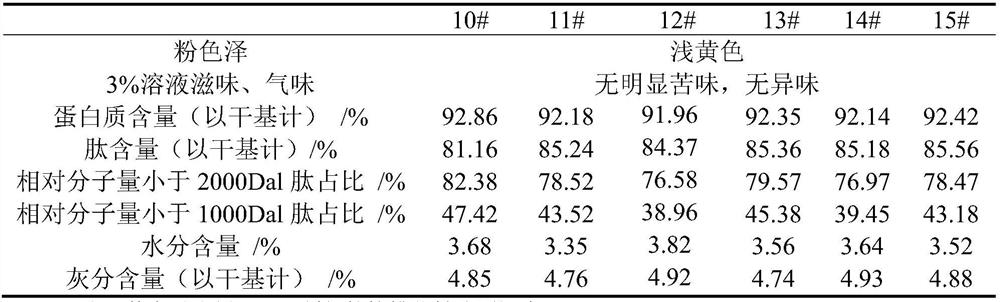

Examples

Embodiment 1

[0059] (1) Dispersion and hydration of walnut dregs: walnut dregs (on a dry basis, protein content ≥ 55% and oil content ≤ 15%) that have been degreased by low-temperature pressing with deionized water are prepared into walnut protein with a mass percentage of 10%. Solution, use a mixer to disperse and hydrate the walnut protein powder at a speed of 2000rpm for 20min;

[0060] (2) Enzymolysis with tannase, cellulase, and medium-temperature amylase: heat the dispersed and hydrated walnut protein solution to 50°C, add 0.15% tannase equivalent to the mass of walnut meal (Hunan Century Huaxing Bioengineering Co., Ltd. Company), 0.5% cellulase (neutral, Beijing Xiasheng Biotechnology Development Co., Ltd.), 1.0% medium-temperature amylase (Hunan Century Huaxing Biological Engineering Co., Ltd.), constant temperature stirring (36rpm) enzymolysis 60min;

[0061] (3) Protein denaturation, centrifugation, and water washing: pump the walnut protein solution treated in step (2) into the ...

Embodiment 2

[0066] ((1) Dispersion and hydration of walnut dregs: walnut dregs (on a dry basis, with protein content ≥ 55% and oil content ≤ 15%) that have been degreased by low-temperature pressing with deionized water are prepared into walnuts with a mass percentage of 5%. For protein solution, use a mixer to disperse and hydrate walnut protein powder at a speed of 3000 rpm for 10 minutes;

[0067] (2) Enzymolysis with tannase, cellulase, and medium-temperature amylase: heat the dispersed and hydrated walnut protein solution to 45°C, add 0.1% tannase equivalent to the mass of walnut meal (Hunan Century Huaxing Bioengineering Co., Ltd. Company), 0.1% cellulase (neutral, Beijing Xiasheng Biotechnology Development Co., Ltd.), 0.5% medium-temperature amylase (Hunan Century Huaxing Bioengineering Co., Ltd.), constant temperature stirring (18rpm) enzymolysis 90min;

[0068] (3) Protein denaturation, centrifugation, and water washing: pump the walnut protein solution treated in step (2) into t...

Embodiment 3

[0073] (1) Dispersion and hydration of walnut dregs: walnut dregs (on a dry basis, protein content ≥ 55% and oil content ≤ 15%) that are degreased by low-temperature pressing with deionized water are prepared into walnut protein with a mass percentage of 15% Solution, use a mixer to disperse and hydrate the walnut protein powder at a speed of 2000rpm for 20min;

[0074] (2) Enzymolysis with tannase, cellulase, and medium-temperature amylase: heat the dispersed and hydrated walnut protein solution to 50°C, add 0.2% tannase equivalent to the mass of walnut meal (Hunan Century Huaxing Bioengineering Co., Ltd. company), 1.0% cellulase (neutral, Beijing Xiasheng Biotechnology Development Co., Ltd.), 2.0% medium-temperature amylase (Hunan Century Huaxing Bioengineering Co., Ltd.), constant temperature stirring (25rpm) enzymolysis for 30min;

[0075] (3) Protein denaturation, centrifugation, and water washing: pump the walnut protein solution treated in step (2) into the tank, treat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com