Water-phase enzymolysis extracting method of safflower oil

A technology of safflower seed oil and extraction method, which is applied in the direction of fat oil/fat production and fat generation, can solve the problems of reduced added value of safflower seed processing, denaturation of safflower seed protein, adverse effects on human health, etc., and achieve improvement Utilization value, avoiding the oxidation of fat, and reducing the effect of denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

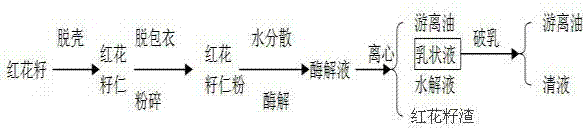

[0030] Such as figure 1 Shown:

[0031] (1) Remove the shell of safflower seeds, screen out the safflower kernels, treat the safflower kernels with hot air at 50°C for 20 minutes, and cool down with 20°C cold air under a pressure of 3kPa, rub the safflower kernels against each other to remove the coating , and then use air separation to remove the coating;

[0032] (2) Dry-crushing (crushing) the uncoated safflower kernels with a pulverizer to destroy the tissue cells of the safflower kernels to obtain safflower kernel powder with a particle size between 10 and 90 mesh;

[0033] (3) Mix and disperse 1 part of crushed safflower seed kernel powder with 5 parts of water according to the mass parts (water dispersion), adjust the pH value to 6.5 with NaOH solution, and add 0.1% of the mass of safflower seed kernel powder at 50°C neutral protease, enzymatic hydrolysis reaction for 2 hours; then lower the temperature to 30°C, adjust the pH value to 7.5 with NaOH solution, add 0.1% ...

Embodiment 2

[0040] (1) Remove the safflower seed shell, screen out the safflower kernels, treat the safflower kernels with hot air at 60°C for 30 minutes, and cool down with 25°C cold air under a pressure of 10kPa, rub the safflower kernels against each other to remove the coating , and then use air separation to remove the coating;

[0041] (2) Dry-crushing the uncoated safflower kernels with a pulverizer to obtain safflower kernel powder with a particle size between 10 and 150 meshes, and destroy the tissue cells of the safflower kernels;

[0042] (3) Mix 1 part of broken safflower seed kernel powder with 20 parts of water according to the mass parts, adjust the pH value to 7.5 with NaOH solution, add 1% neutral protease of safflower seed kernel powder at 60°C, Enzymolysis reaction for 6 hours; then lower the temperature to 40°C, adjust the pH value to 8.5 with NaOH solution, add alkaline protease with 1% mass of safflower seed kernel powder, and perform enzymolysis reaction for 6 hours...

Embodiment 3

[0045] (1) Remove the shell of safflower seeds, screen out the safflower kernels, treat the safflower kernels with hot air at 55°C for 25 minutes, and cool them with 22°C cold air under a pressure of 6kPa, rub the safflower kernels against each other to remove the coating , and then use air separation to remove the coating;

[0046] (2) Dry-crushing the uncoated safflower kernels with a pulverizer to obtain safflower kernel powder with a particle size between 10 and 60 meshes, and destroy the tissue cells of the safflower kernels;

[0047] (3) Mix 1 part of crushed safflower seed kernel powder with 10 parts of water according to the mass parts, adjust the pH value to 7 with KOH solution, add 0.4% neutral protease of safflower seed kernel powder at 52°C, Enzymolysis reaction for 3 hours; then lower the temperature to 35°C, adjust the pH value to 8 with NaOH solution, add alkaline protease with 0.4% mass of safflower seed kernel powder, and perform enzymolysis reaction for 3 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com