Brine for marinated eggs and marinating method thereof

A production method and a technology for marinated eggs, which are applied in the application, food heat treatment, food ingredients as taste improvers, etc., can solve the problems of large-scale food production impact, the inability of brine to fully enter, and the inability of marinated eggs to taste evenly, so as to save money. Consume, reduce hardness, not easy to evaporate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

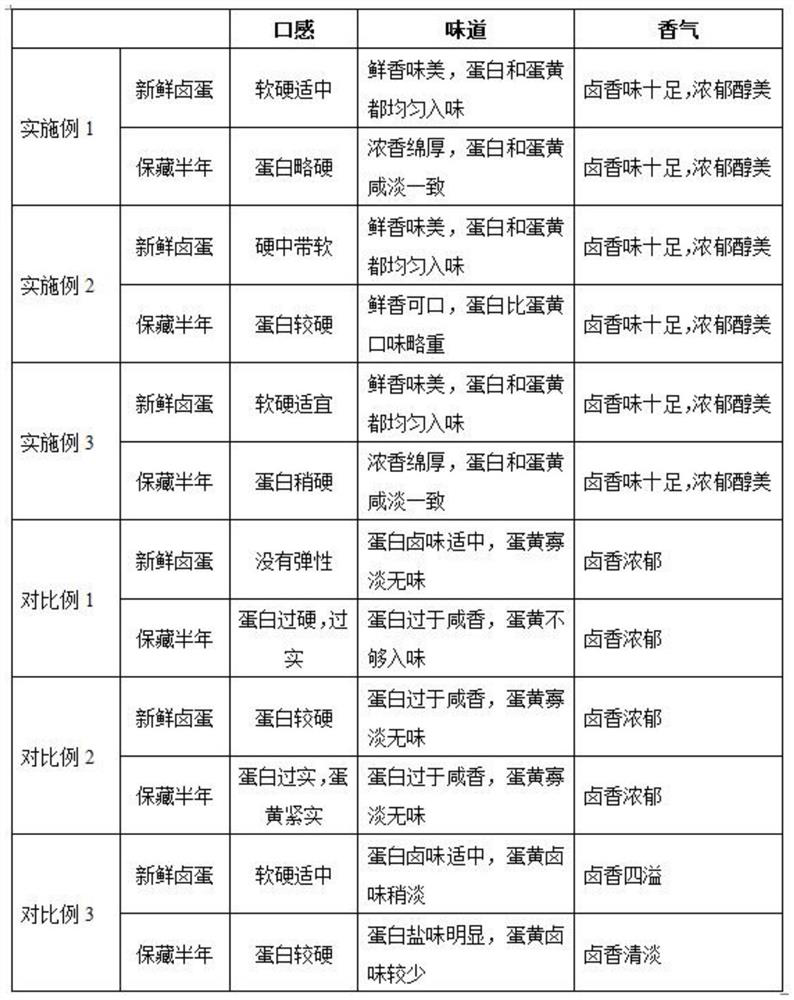

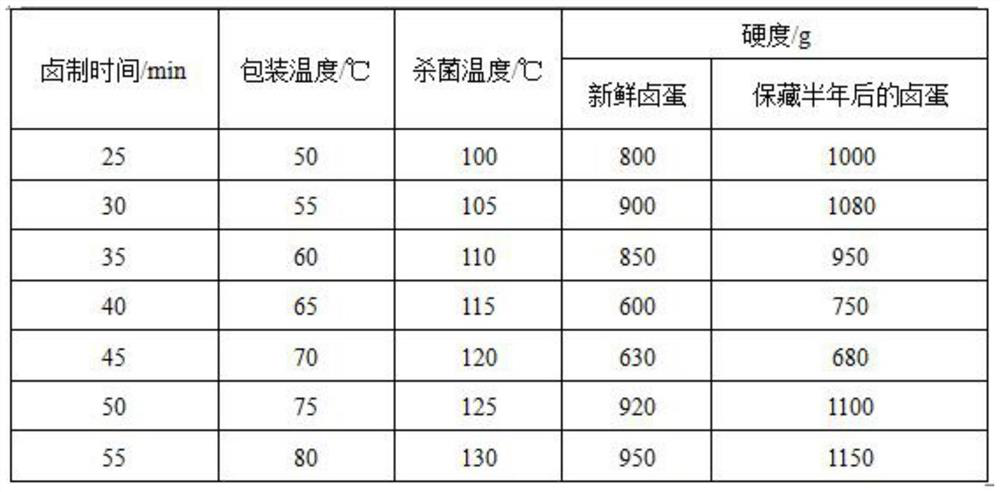

Examples

Embodiment 1

[0026] A brine for marinated eggs, the raw material formula of which is calculated in parts by weight: 23 parts of rice wine, 4 parts of star anise, 3 parts of cinnamon, 0.5 parts of cloves, 6 parts of Chinese pepper, 3 parts of licorice, 8 parts of Begonia fimbristipula Hance, 15 parts of chili Parts, 1.5 parts wort, 6 parts dried ginger, 7 parts eucommia ulmoides, 0.3 parts Amomum villosum, 2 parts nutmeg, 10 parts agarwood, 2 parts salt, and 200 parts water; the preparation method of the wort is: crushing the malt Obtain the malt powder that has passed a 40-mesh sieve, then mix the malt powder and water in a weight ratio of 1:6, and saccharify at a constant temperature of 70°C until the reaction with the iodine solution does not show blue color, then boil and then stand still Overnight, the filtrate was filtered the next day, and the bacteria were removed by pasteurization to obtain wort.

[0027] A marinating method of marinated eggs, including the following steps:

[0028] St...

Embodiment 2

[0035] A brine for marinated eggs, the raw material formula of which is calculated in parts by weight: 25 parts of rice wine, 2 parts of star anise, 1 part of cinnamon, 1 part of clove, 8 parts of Chinese pepper, 5 parts of licorice, 4 parts of Begonia fimbristipula hance and 10 parts of chili Parts, 5 parts of wort, 9 parts of dried ginger, 3 parts of Eucommia ulmoides, 0.5 parts of Amomum villosum, 5 parts of nutmeg, 5 parts of agarwood, 6 parts of salt, and 300 parts of water; the preparation method of the wort is: crushing malt Obtain the malt powder that has passed a 50-mesh sieve, then mix the malt powder and water at a weight ratio of 1:5, and saccharify at a constant temperature of 68°C until the reaction with the iodine solution does not show blue color, then boil and then stand still Overnight, the filtrate was filtered the next day, and the bacteria were removed by pasteurization to obtain wort.

[0036] A marinating method of marinated eggs, including the following st...

Embodiment 3

[0044] A kind of brine for marinated eggs, the raw material formula of which is calculated in parts by weight: 24 parts of rice wine, 5 parts of star anise, 2 parts of cinnamon, 0.6 parts of cloves, 7 parts of Chinese pepper, 4 parts of licorice, 7 parts of Begonia fimbristipula hance and 12 parts by weight Parts, 3 parts of wort, 8 parts of dried ginger, 5 parts of Eucommia ulmoides, 0.4 parts of Amomum villosum, 3 parts of nutmeg, 8 parts of agarwood, 4 parts of salt, and 250 parts of water; the preparation method of the wort is: crushing the malt Obtain the malt powder that has passed through a 45 mesh sieve, then mix the malt powder and water in a weight ratio of 1:6, and saccharify at a constant temperature of 69°C until the reaction with iodine solution does not show blue color, then boil and then stand still Overnight, the filtrate was filtered the next day, and the bacteria were removed by pasteurization to obtain wort.

[0045] A marinating method of marinated eggs, incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com