Method of producing fresh sweet potato

A manufacturing method and technology of sweet potato chips, applied in food preparation, cocoa, confectionery, etc., can solve the problems of poor taste, sticky syrup, thick color and other problems of snack foods, and achieve uniform texture and taste, crispy taste, and moderate sweetness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

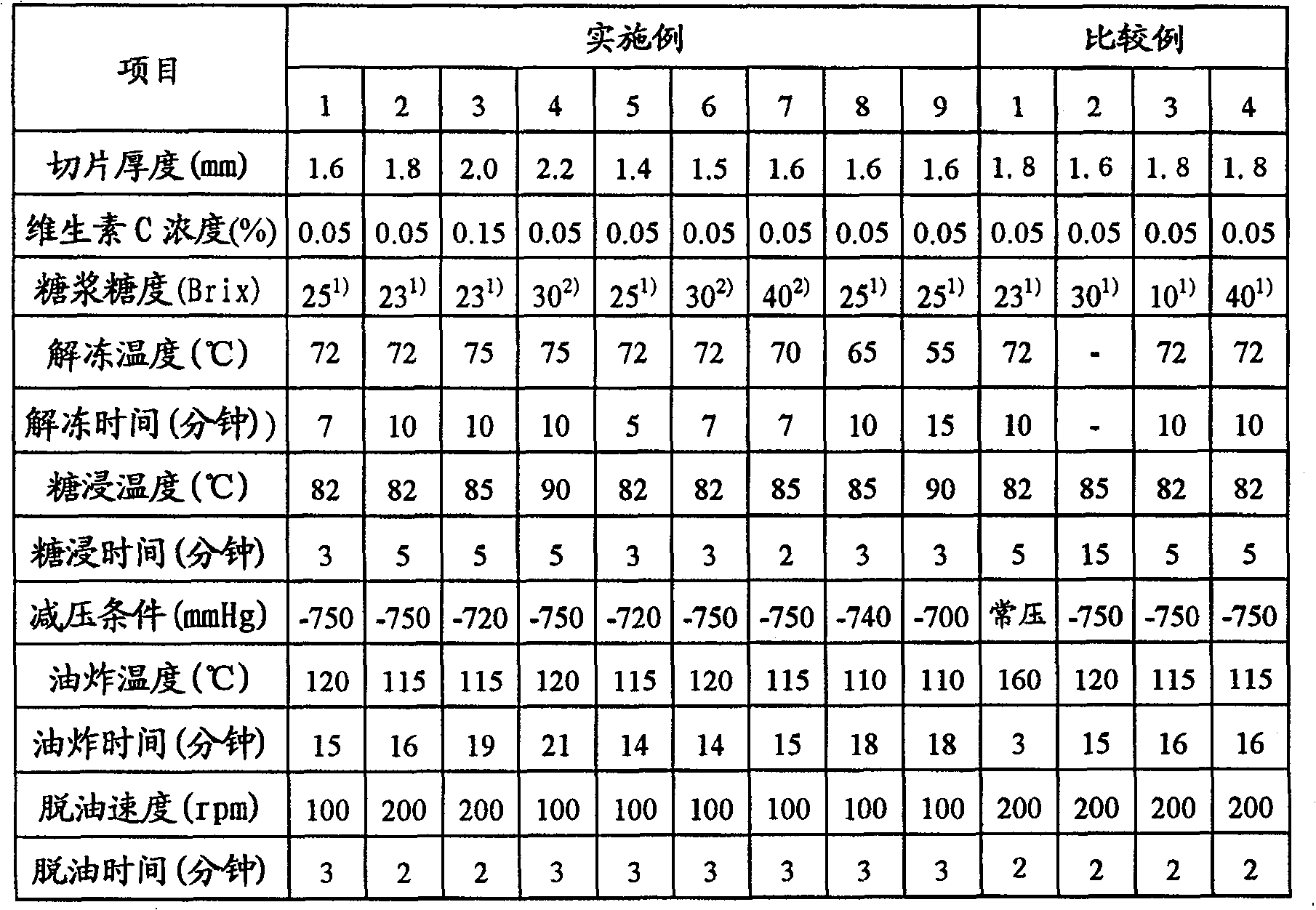

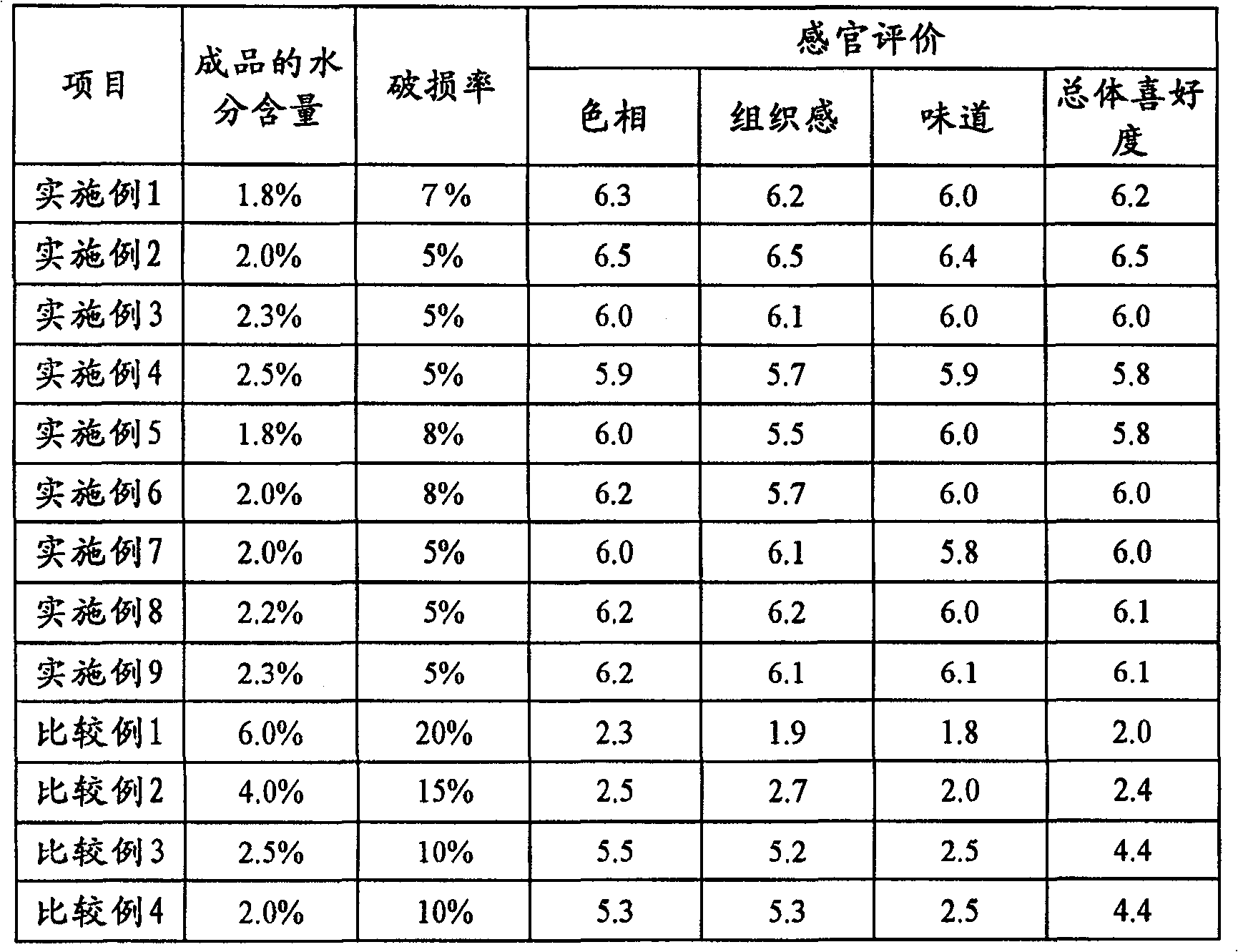

[0035] The sweet potato is washed with clean washing water, peeled, and then immersed in a vitamin C solution for 10 minutes, then cut into slices, then dipped in the vitamin C solution, and then dehydrated naturally. The above-mentioned naturally dehydrated sweet potato slices are placed in a quick-freezer at -24°C, frozen for 24 hours or more, then immersed in syrup for thawing and sugar soaking, and deep-fried under reduced pressure. The fried sweet slices are de-oiled, then cooled and packaged. The following table 1 briefly lists the conditions used to manufacture fresh sweet potato chips.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com