High elasticity polyolefin hose with radiation crosslinking and preparation method thereof

A technology of radiation cross-linking and polyolefin, applied in the direction of hoses, pipes, mechanical equipment, etc., to achieve the effects of improved high temperature resistance, short service life, and energy saving in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

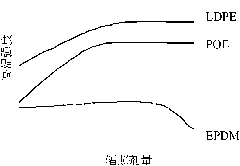

[0044] LDPE, POE, and EPDM are used for blending and granulation, wherein, in terms of weight percentage, LDPE is 40%, POE is 30%, and EDPM is 30%. The blend is extruded by a single screw to make a hose with a wall thickness of 1.5mm and an outer diameter of 11mm, and the hose is irradiated under a certain dose (6-12M) to obtain the high-elastic irradiation of the present invention. Cross-linked tube. Wherein, after measurement, the mechanical properties of the ternary blend are:

[0045] Maximum load (N): 222.35

[0046] Tensile strength (MPa): 15.78

[0047] Elastic modulus (MPa): 0.75

[0048] Yield strength (MPa): 5.3

[0049] Elongation at break (%): 883.4

[0050] Breaking strength (MPa): 15.78

[0051] The maximum stress that the irradiated hose of this embodiment can bear is 1.2 MPa as measured by the hydraulic instantaneous burst test (GB / T 5563-1994).

[0052] The gel rate of the irradiated hose of this example was 84.2%.

Embodiment 2

[0054] Experimental method is the same as Example 1, but when adopting LDPE, POE, EPDM to carry out blending granulation, by weight percentage, the component of LDPE is 30%, the component of POE is 40%, the component of EDPM is 30%.

Embodiment 3

[0056] Experimental method is the same as Example 1, but when adopting LDPE, POE, EPDM to carry out blending granulation, by weight percentage, the component of LDPE is 50%, the component of POE is 30%, the component of EDPM is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com