Protective box type amorphous, microcrystal or nano-crystal alloy stator core for motor and preparation method thereof

A nanocrystalline alloy and stator iron core technology is applied in high frequency motors, microcrystalline or nanocrystalline alloy stator iron cores and their preparations, and in the field of motor casing type amorphous, which can solve the corresponding problem of soft magnetic properties of amorphous alloy materials. Force sensitivity, amorphous stator core saturation flux density, magnetic permeability and core loss and other performance degradation problems, to achieve the effect of shortening production process, production energy saving, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

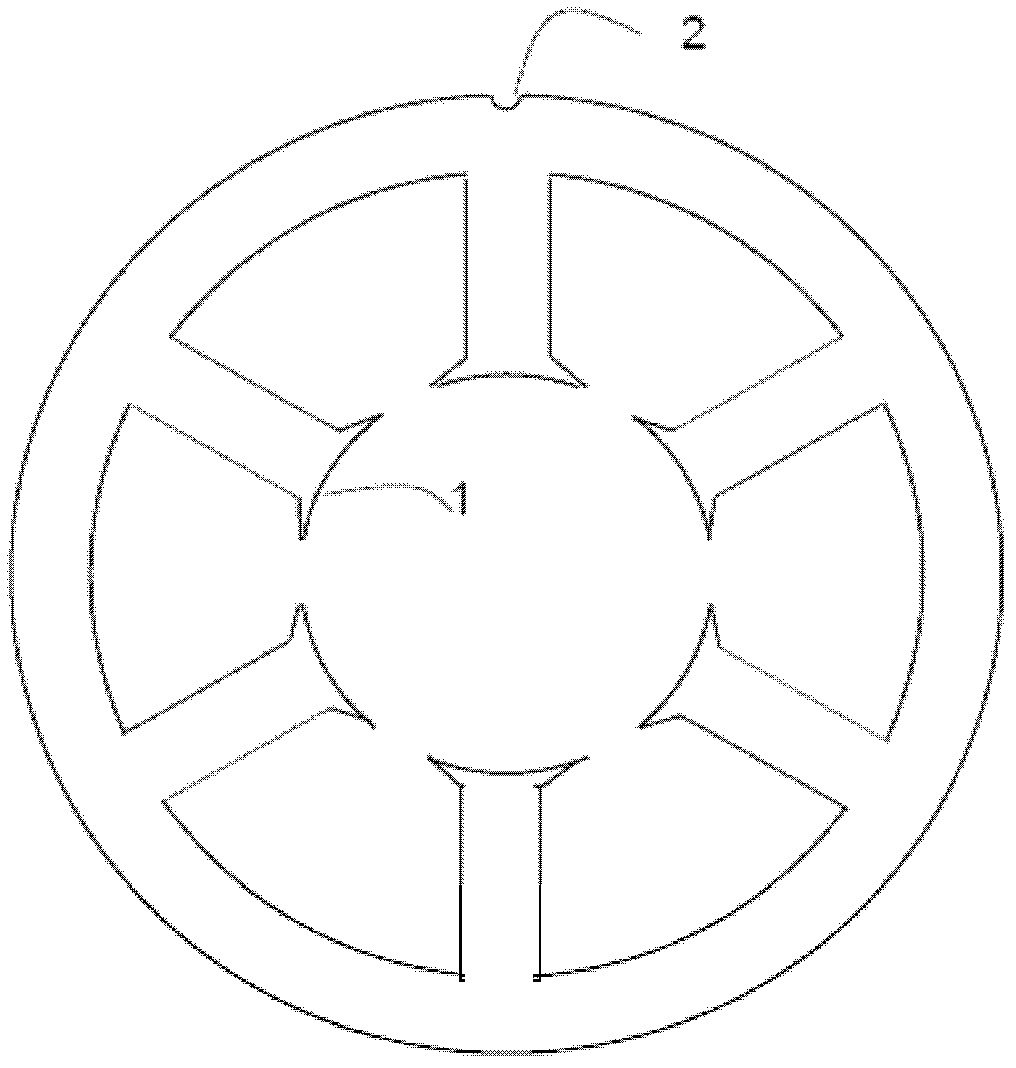

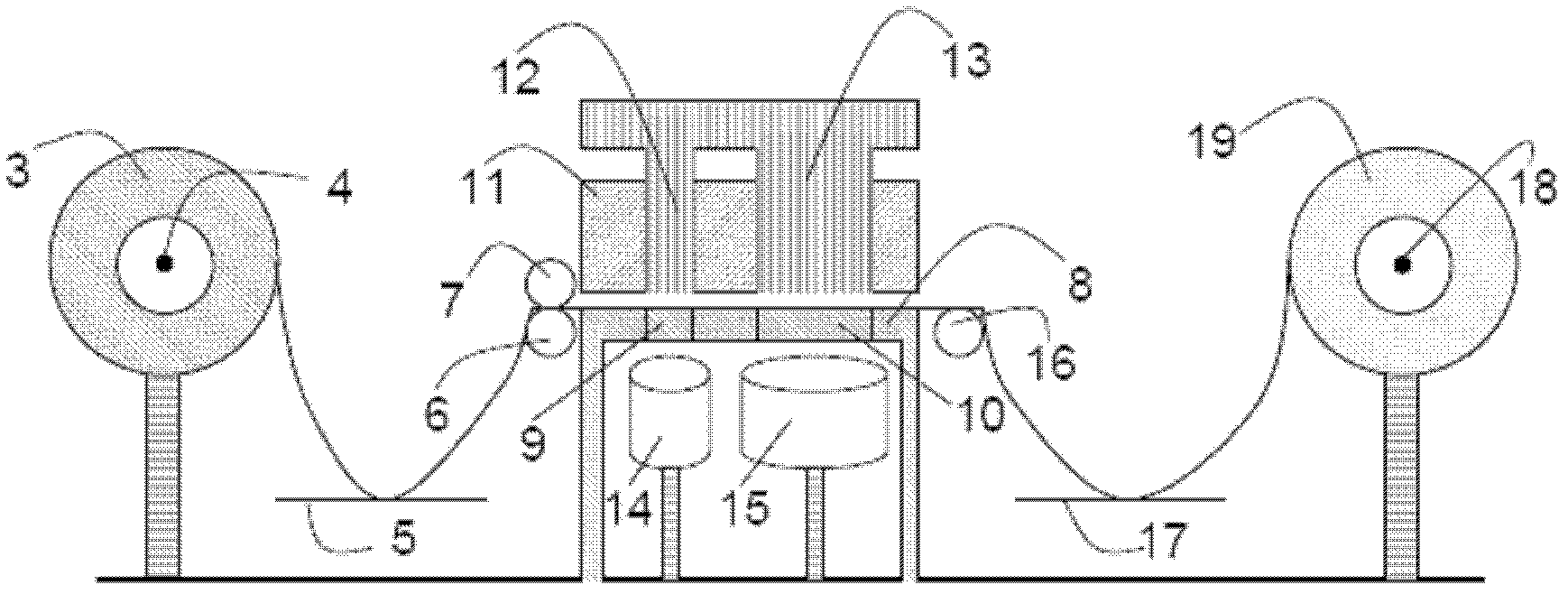

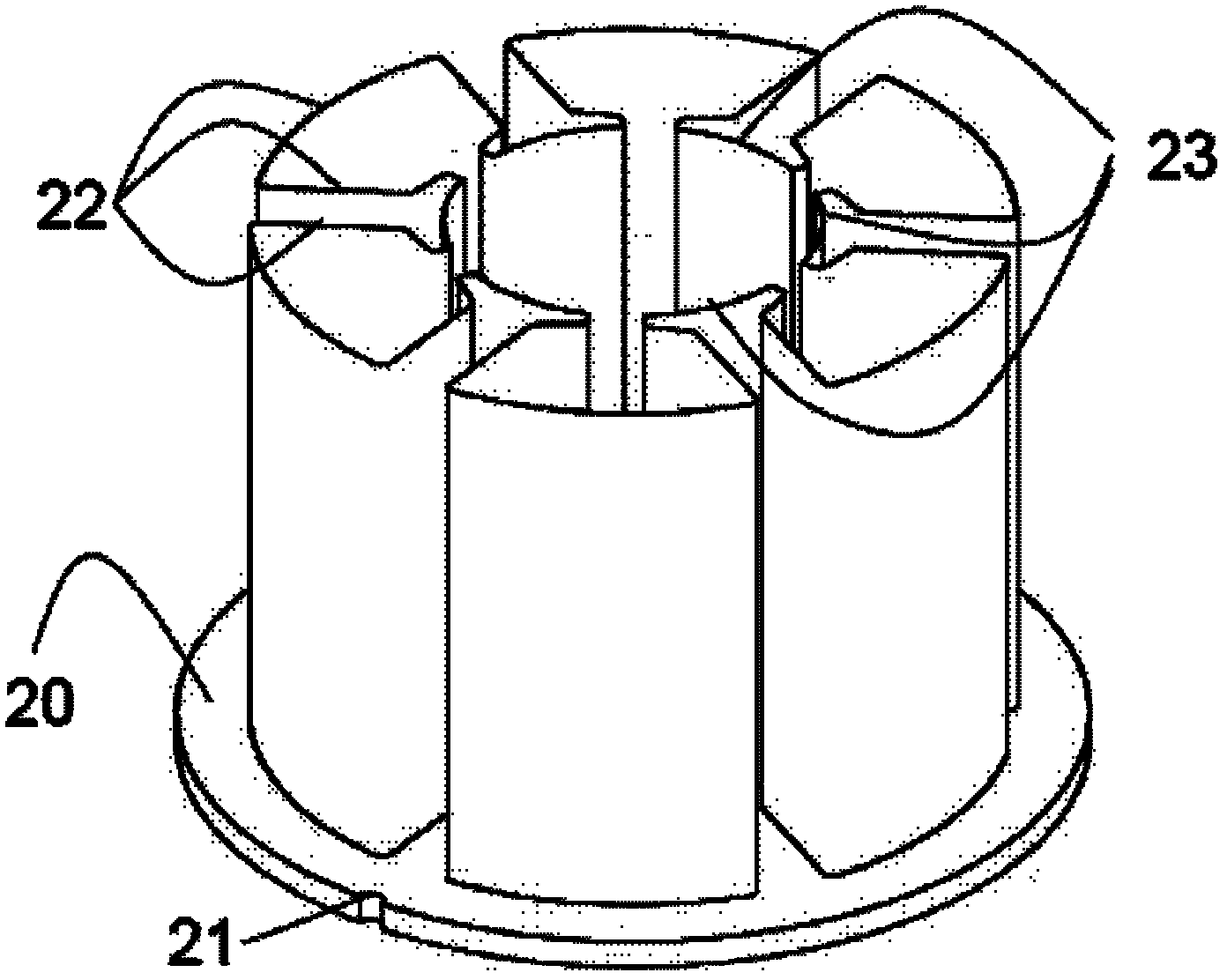

[0069] Since the method for preparing the box-type amorphous, microcrystalline or nanocrystalline alloy stator core for motors using the preparation method of the present invention is the same, only the corresponding materials need to be replaced, and different materials can be selected according to the performance of different materials. process parameters, the alloy stator core of different materials such as amorphous, microcrystalline or nanocrystalline can be prepared. Therefore, the preparation of the amorphous alloy stator core is only taken as an example below, in conjunction with the accompanying drawings and embodiments, for the present invention The specific embodiment will be described in further detail.

[0070] In this embodiment, the nominal composition of the amorphous alloy strip material used to make the amorphous stator alloy iron core for the motor is Fe 80 Si 9 B 11 (at.%), the thickness of the strip is 30±1μm, the width is 140mm, and the surface is flat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com