Water-repellent semiconducting metal-shielded flame-retardant braided strap and processing technology thereof

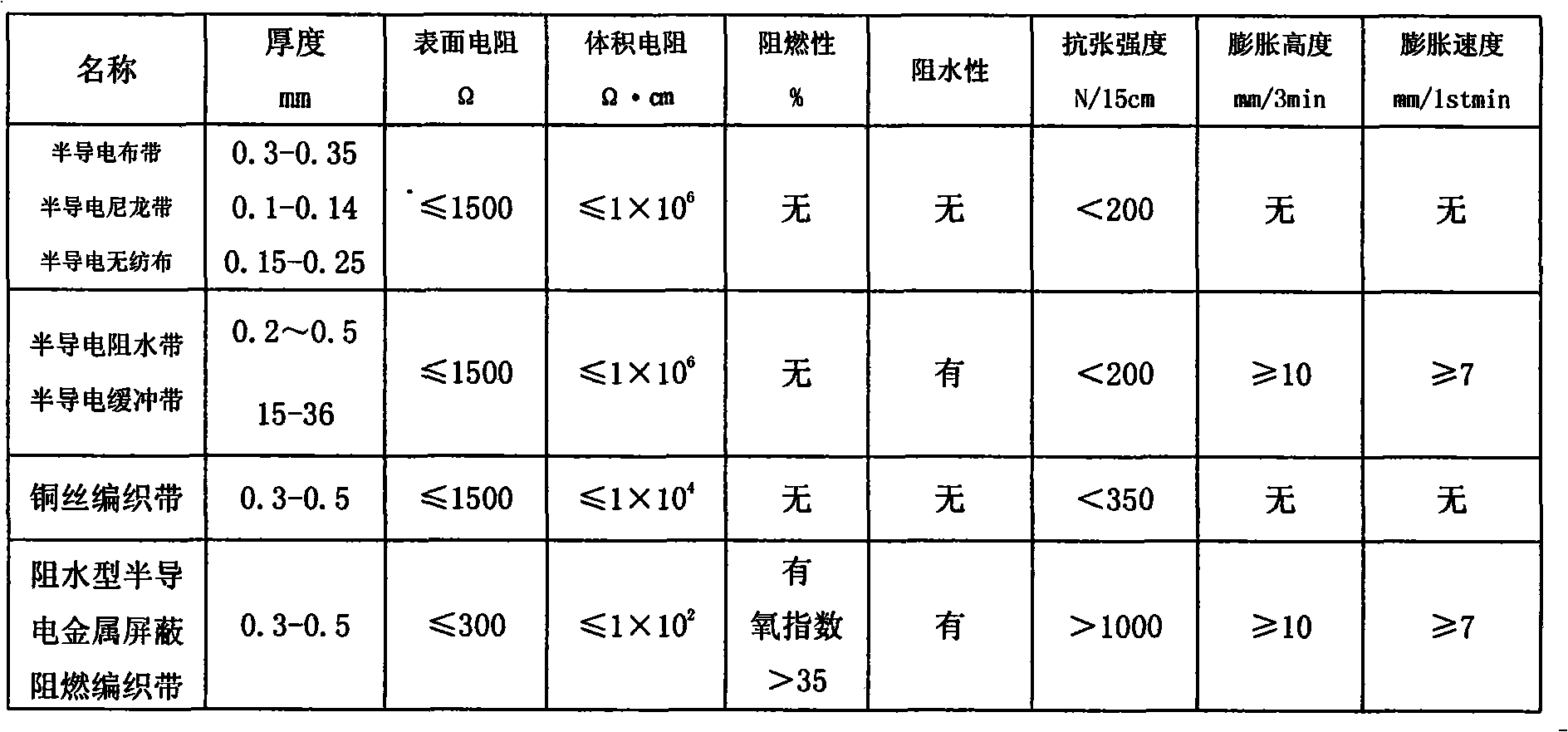

A technology of metal shielding and processing technology, which is applied in the direction of power cables, conductors, circuits, etc. with shielding layer/conductive layer, and can solve problems such as surface resistance, large volume resistance, poor tensile strength, insufficient expansion height, and insufficient expansion speed , to achieve the effect of reducing surface resistance and volume resistance, high temperature resistance level, and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

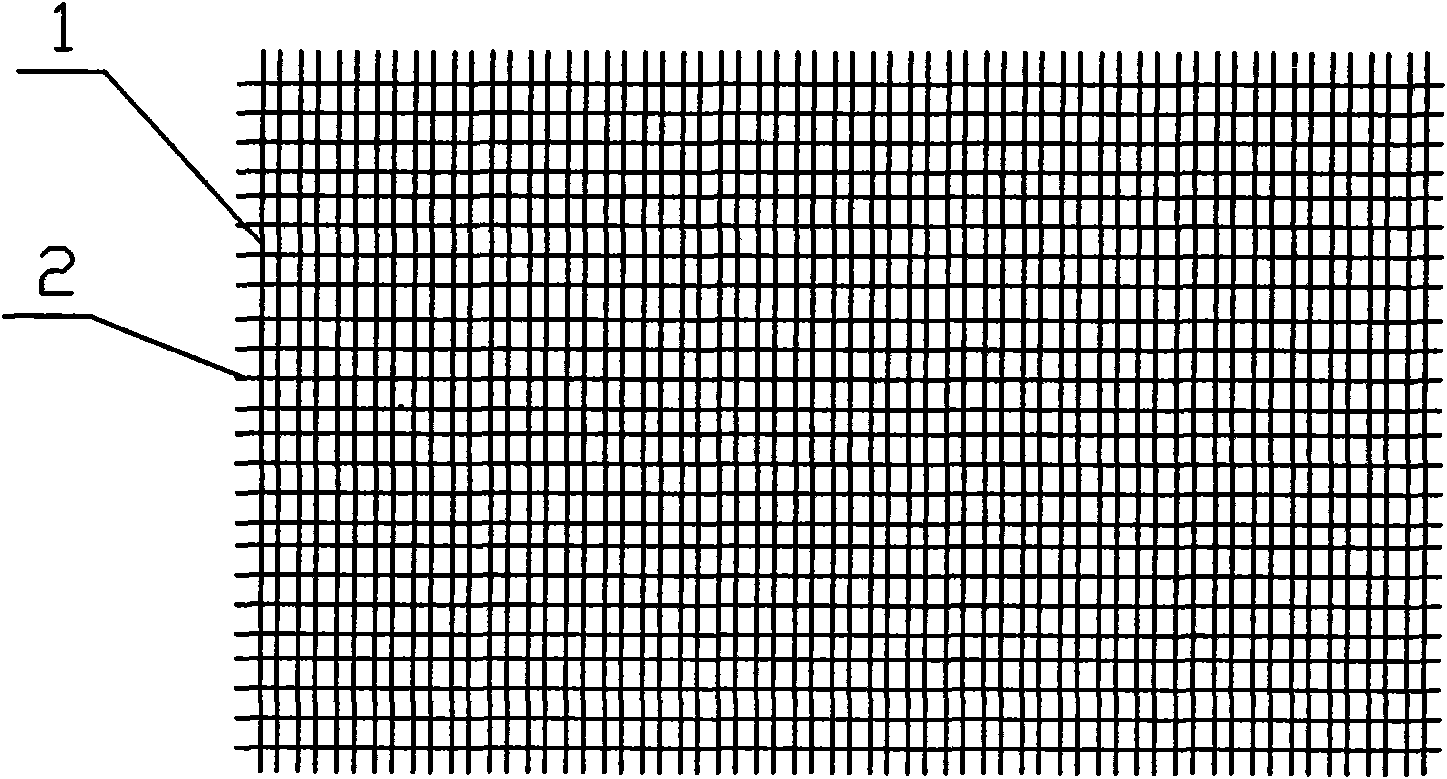

[0023] The present invention includes a base cloth and conductive liquid and flame retardant liquid attached to the base cloth. The base cloth is woven from warp 1 and weft 2. Warp 1: each unit consists of a 30-45 double-strand non-alkali glass fiber The yarn and a φ0.2mm tinned copper wire are arranged in parallel, and the weft yarn 2: 30-45 single-strand glass fiber yarns.

[0024] The preferred method of the present invention: warp yarn 1: each unit is composed of a 45 double-ply non-alkali glass fiber yarn and a φ0.2mm tinned copper wire, and weft yarn 2: 30 single-ply glass fiber yarn.

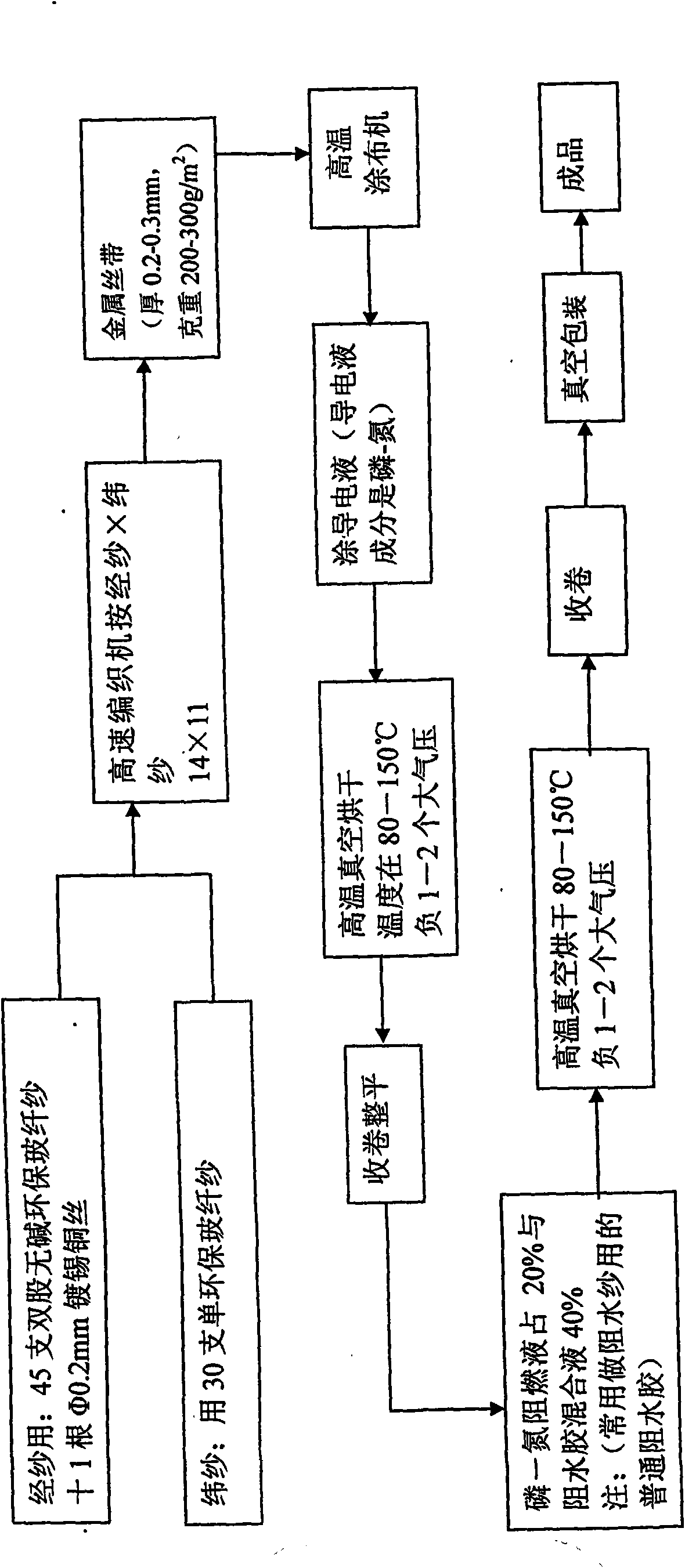

[0025] The present invention carries out according to the following processing steps:

[0026] 1) Material selection: warp yarn 1: each unit is composed of a 30-45 double-strand non-alkali glass fiber yarn and a φ0.2mm tinned copper wire arranged in parallel, weft yarn 2: 30-45 single-strand glass fiber yarn;

[0027] 2) Weaving, sending warp yarn 1 and weft yarn 2 to a high-speed knitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com