Patents

Literature

48results about How to "Increase the reaction concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

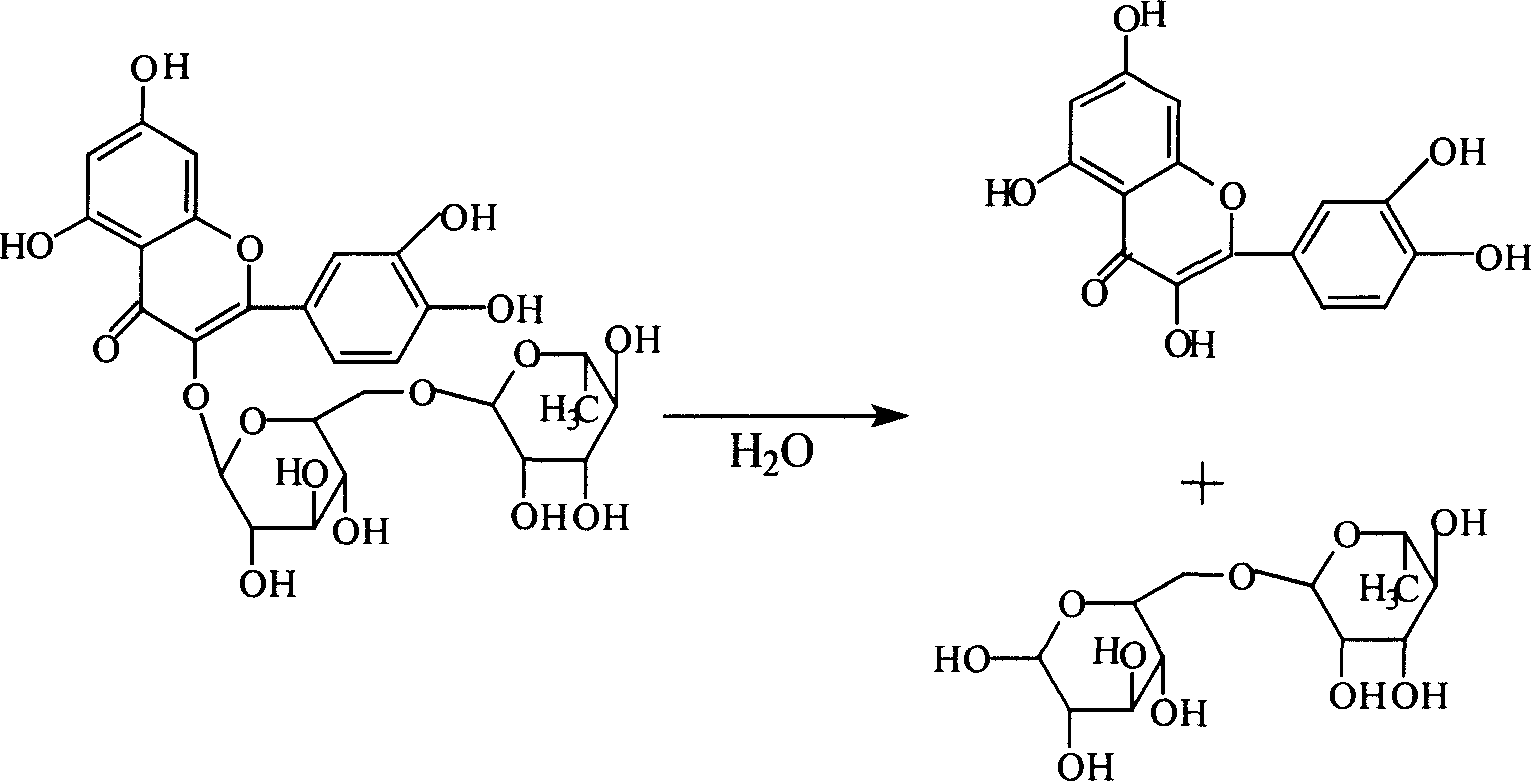

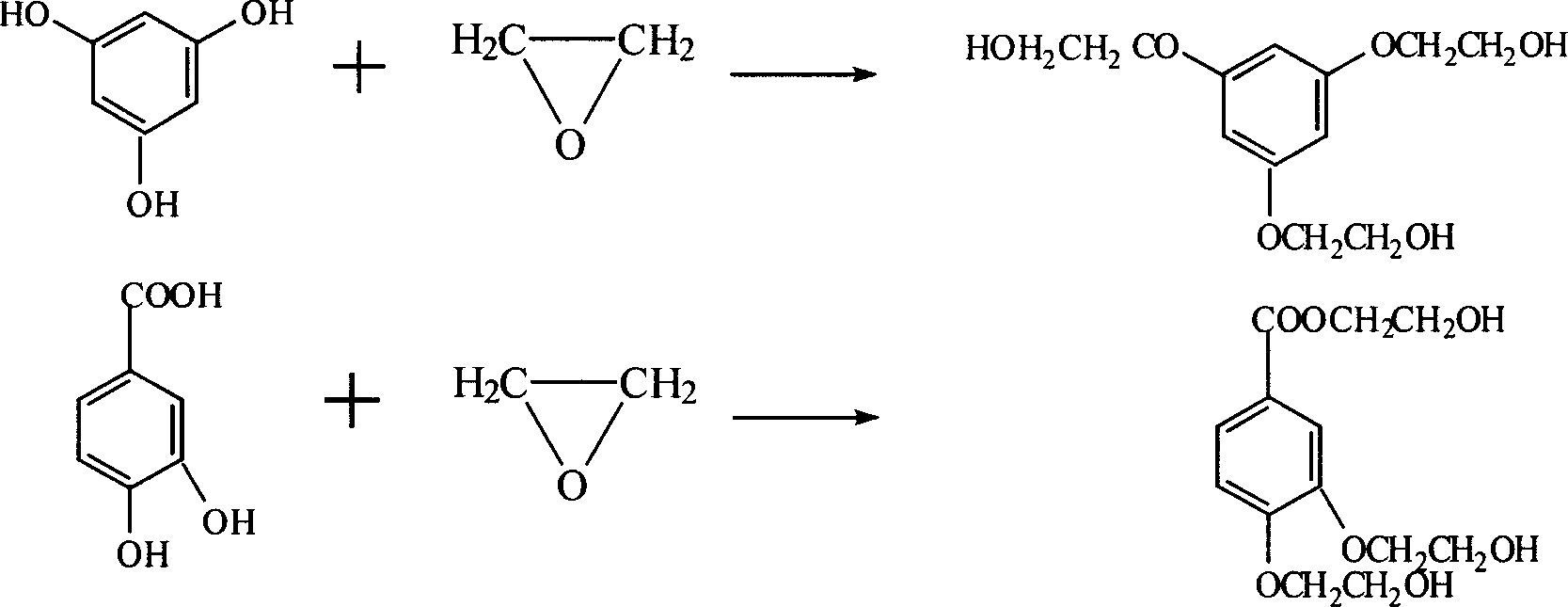

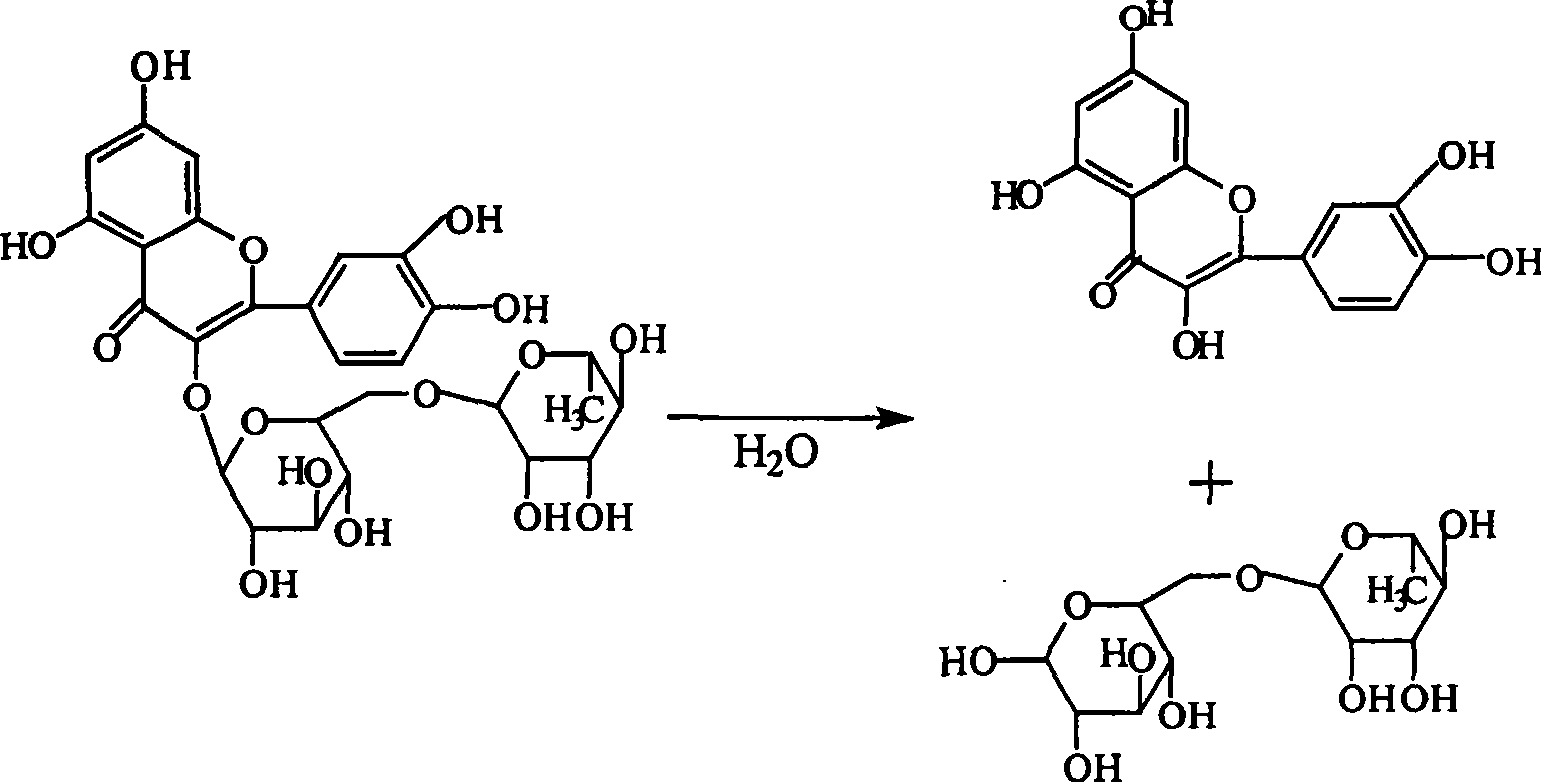

Method for preparing high-content troxerutin drug

ActiveCN1814613AHigh content and yieldReduce dosageOrganic active ingredientsSugar derivativesDrugSodium hydroxide

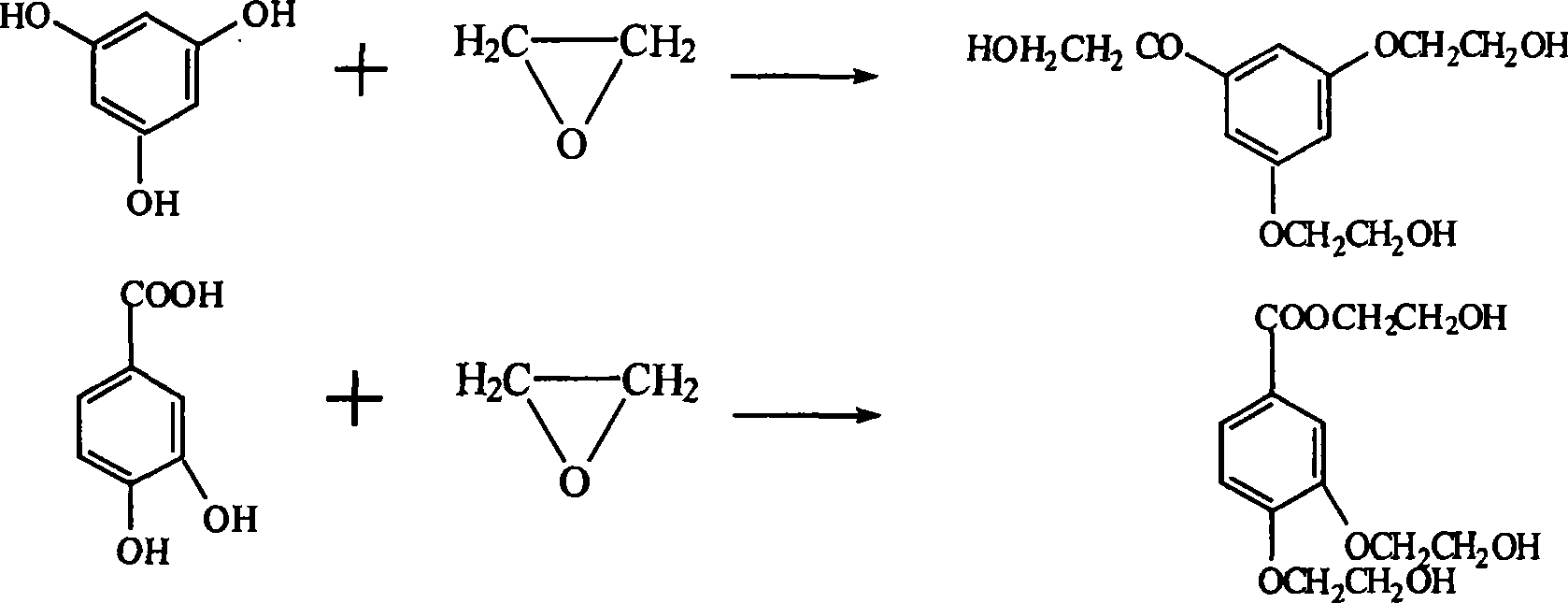

The invention offers 3', 4', 7-troxerutin synthetic method. It uses rutin and ethylene oxide to do hydroxyethylation reaction under the catalyzing of sodium hydroxide. Its features are that in the reaction, the weight ratio of rutin and water is 1:1-1:3; optimization is 1:1-1:1.5; the weight ratio of rutin and sodium hydroxide is 100:0.82-100:0.85; adding resin when the pH value of the reaction solution is 9.0-9.5 to adjust end point pH value to 9.5-10.3. The method can make high purity and high quality troxerutin. And its 3', 4', 7-troxerutin content is more than 78%; optimization is more than 80%; and the more optimization is more than 85%.

Owner:TOPFOND PHARMA CO LTD

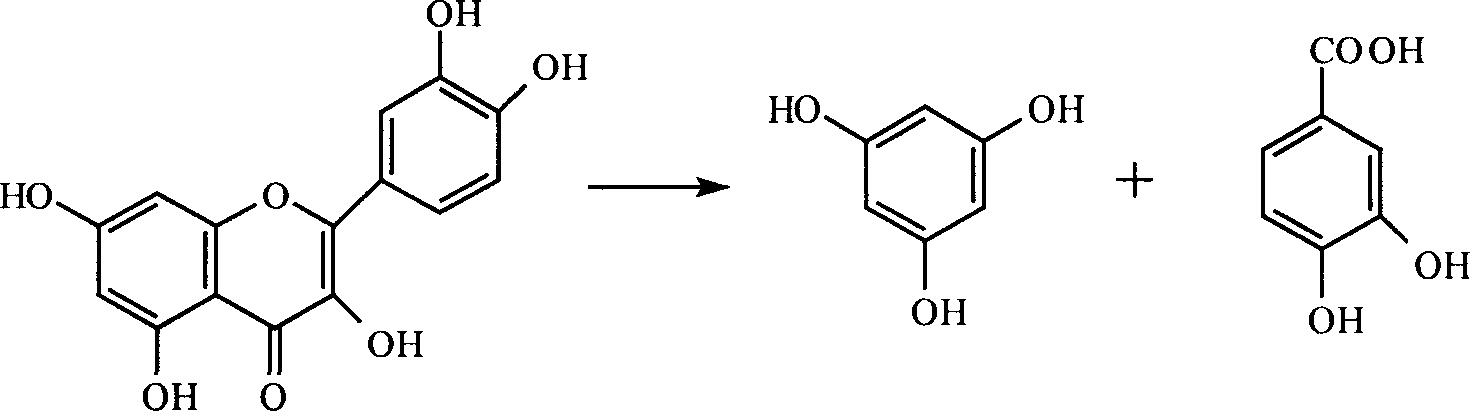

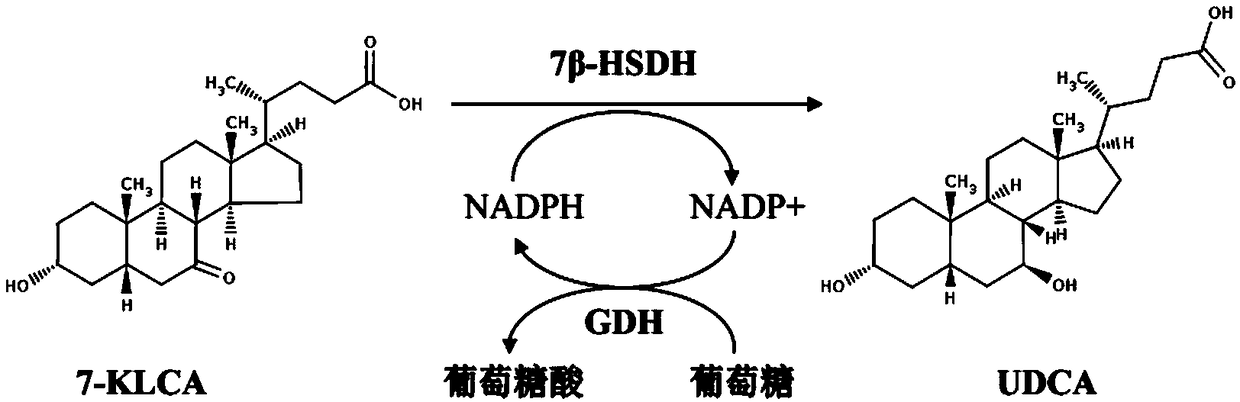

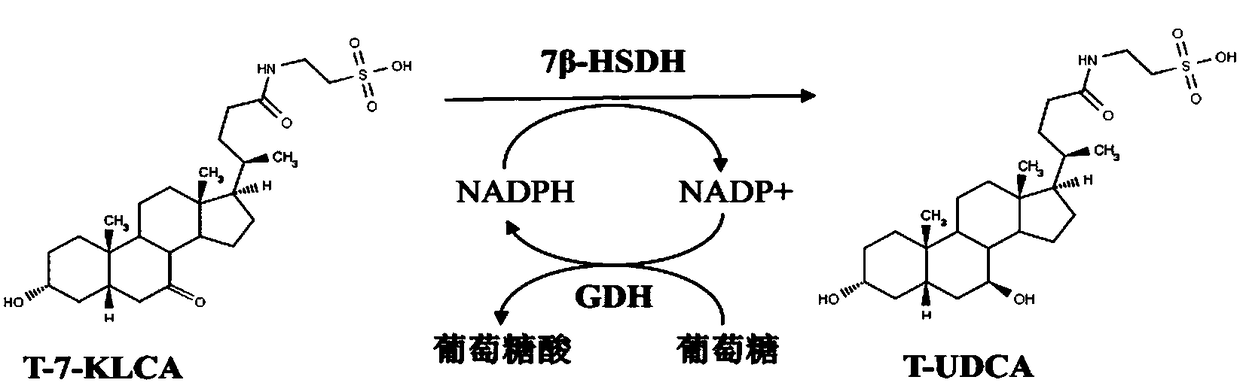

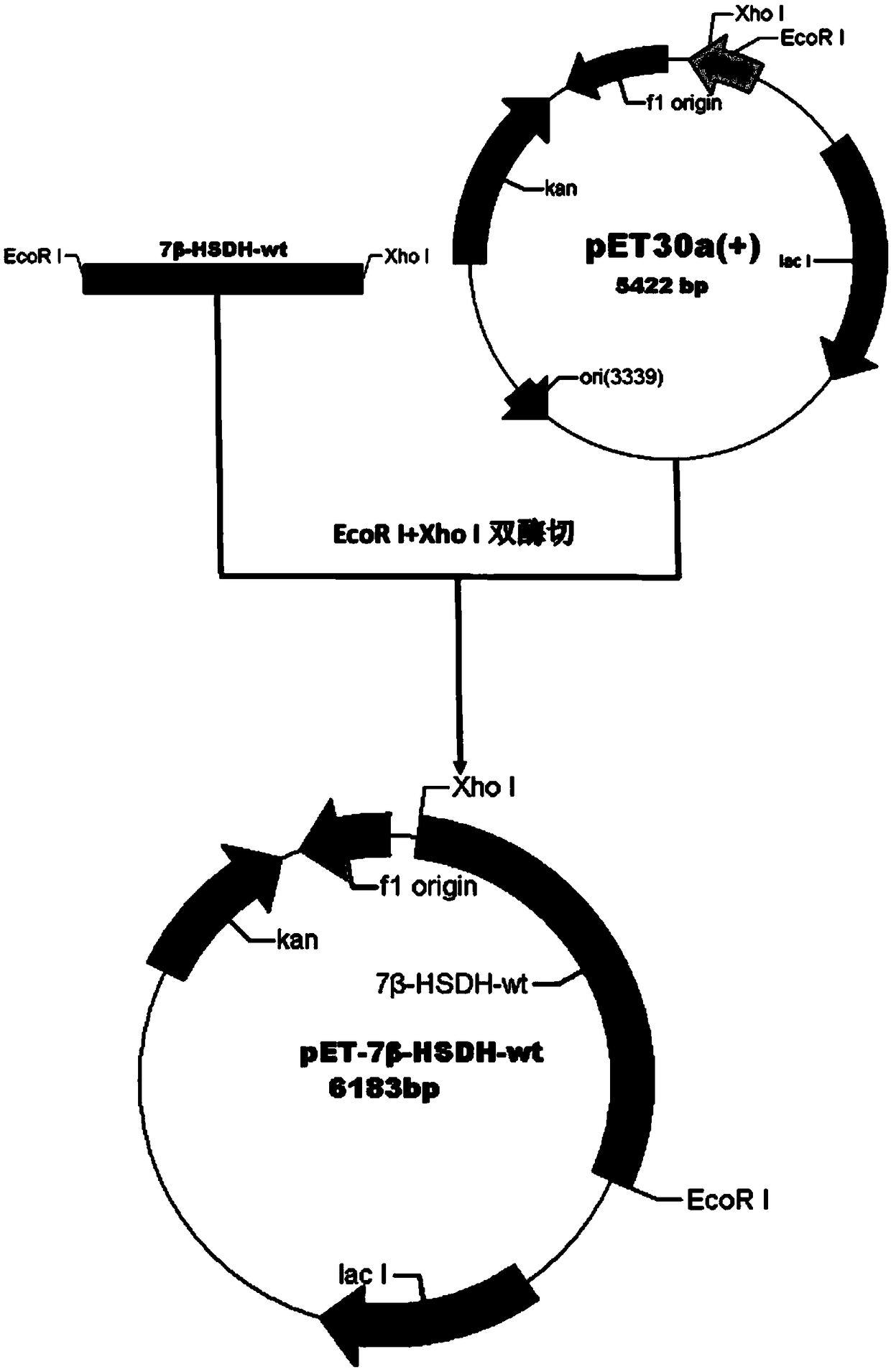

7 Beta-hydroxysteroid dehydrogenase mutant, coding sequence, recombinant expression vector, genetically engineered bacterium and application thereof

ActiveCN109182284AHigh reduction-oxidation activity ratioHigh reducing activityBacteriaMicroorganism based processesMutantGenetically engineered

The invention provides a 7 Beta-Hydroxysteroid dehydrogenase mutant, a coding sequence, a recombinant expression vector, a genetically engineered bacterium and an application thereof. Mutation is carried out on the 7Beta-hydoxy alcohol dehydrogenase from Collins aerogenes, and the reductive activity and the ratio of reducing and oxidizing activity of the obtained mutant Ca7Beta-2 are respectivelyincreased by 7.6 times and 4 times; when incubated in 100mM UDCA for 1 hour, the activity is decreased by 8.4%; at 30 DEG C and Ph 8.0, UDCA and T-UDCA are catalyzed and synthesized, and the conversion time is shortened from 24 hours to 2 hours, and the molar conversion of the substrate 7-KLCA is 100%, and the molar conversion of the substrate T-7-KLCA is 99.5% and the 7Beta-HSDH after mutation greatly reduces the production cost, improves the production efficiency, and is more suitable for industrial application.

Owner:HUNAN FLAG BIOTECHNOLOGY CO LTD

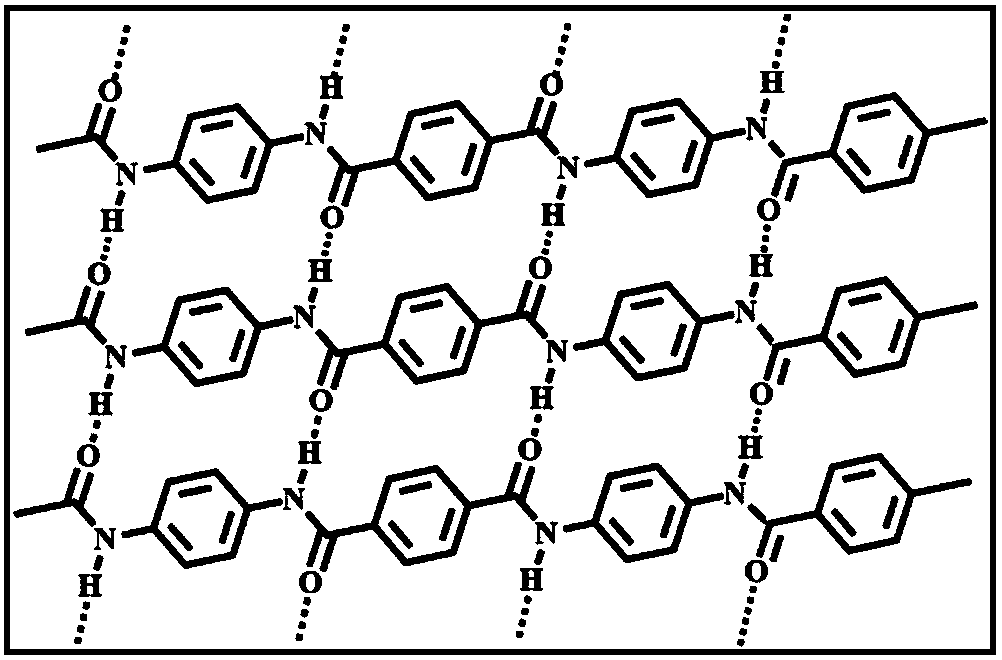

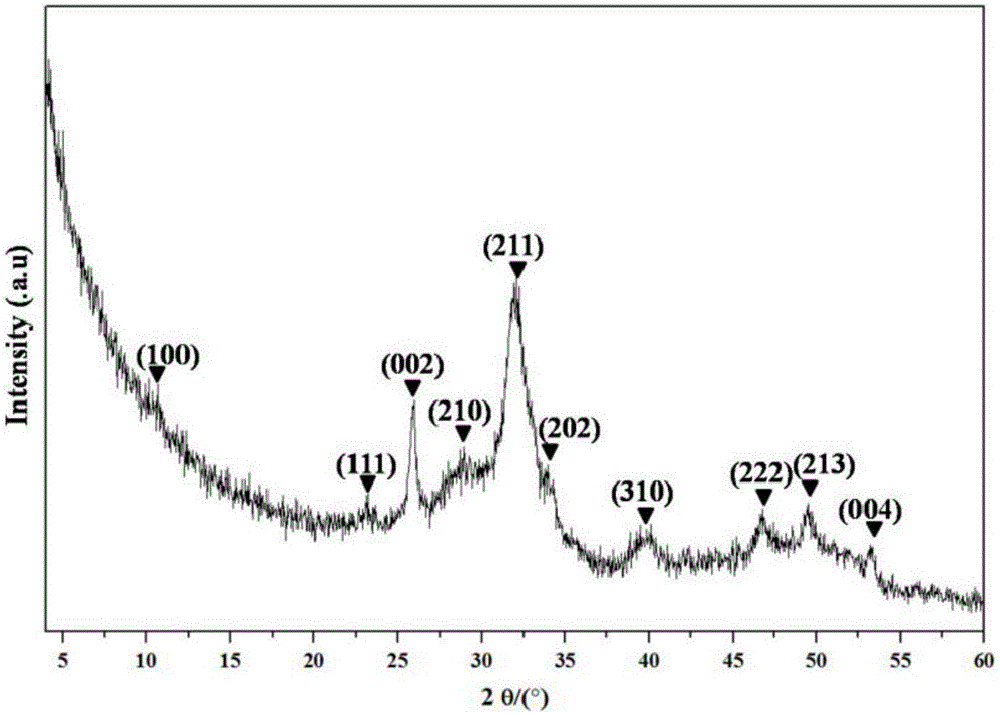

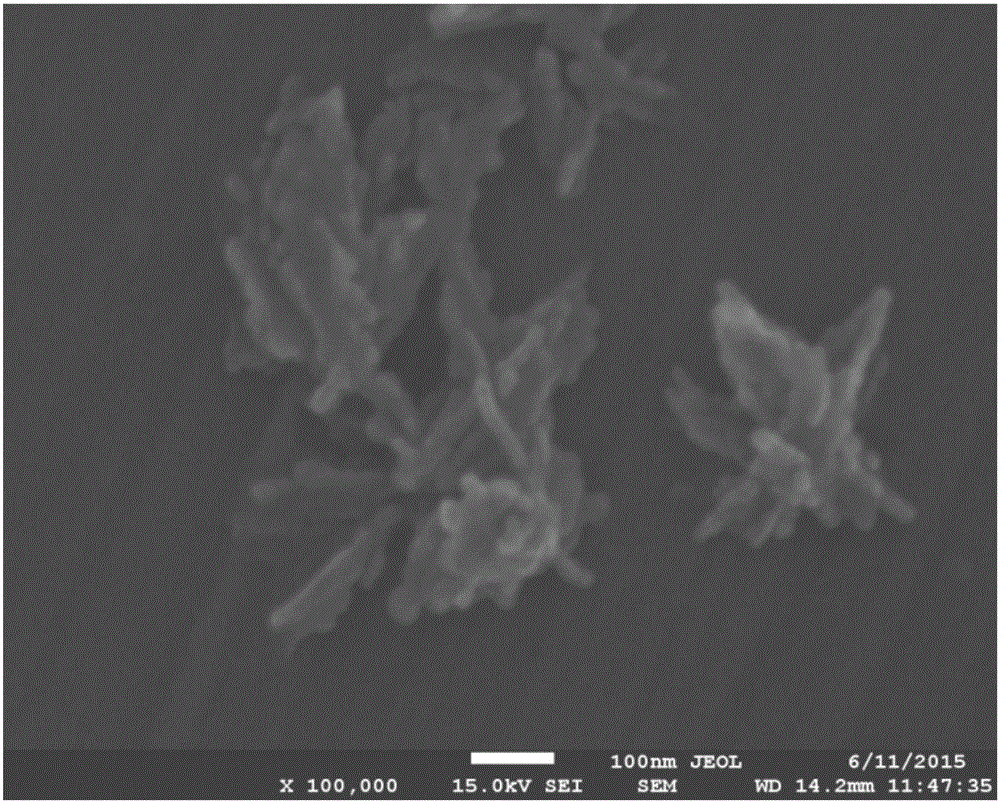

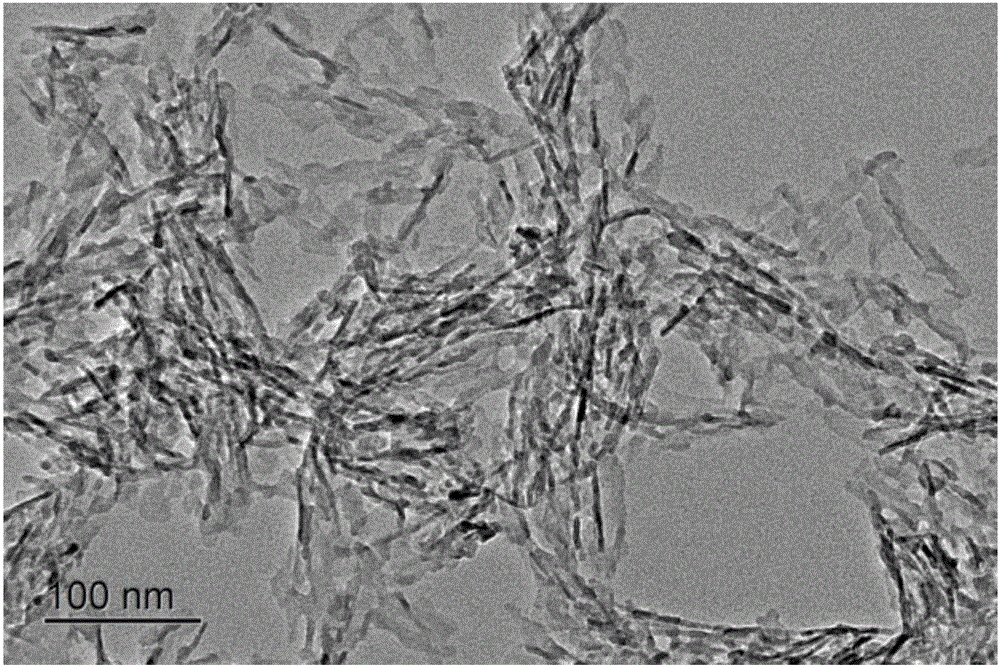

Method for preparing aramid nanofibers by using mechanical coupling chemical alkali dissolution method

ActiveCN108316039AIncrease the areaImprove surface activityCellulosic pulp after-treatmentPulping with inorganic basesProtonationDissolution

The invention discloses a method for preparing aramid nanofibers by using a mechanical coupling chemical alkali dissolution method. According to the method provided by the invention, fibrillation treatment is coupled with homogenization treatment, so that the size of aramid fibers is greatly reduced before a deprotonation reaction is performed, the specific surface area and surface activity of thearamid fibers are improved, the sub-micron-sized aramid fibers and a KOH / DMSO system are more easily subjected to a rapid deprotonation process, the reaction time is greatly shortened, the reaction concentration is increased, the reaction efficiency is significantly improved, and industrialized production is facilitated; the method has a simple preparation process, realizes short-process preparation and is easy to control; and the prepared aramid nanofibers have a small diameter, good size homogeneity, a large length-diameter ratio, high strength and excellent heat resistance, can be used asa novel construction enhancement unit of construction of macro composite materials, and has broad application prospects in the fields of composite materials, biology, medicine, electronics, energy sources and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method for C.I.112 pigment red FGR

InactiveCN101565557AInhibition of reaggregationIncrease the reaction concentrationOrganic dyesSurface-active agentsSodium nitrite

The invention relates to a preparation method for pigment red, especially for C.I.112 pigment red FGR, comprising: adding a non ionic surface active agent in water to produce a mixing liquid, adding 2.4.5-trichloroaniline in the mixing liquid, then adding hydrochloric acid, cation surface active agent, sodium nitrate to produce diazo liquid; adding aqueous alkali in water, heating, feeding rosin resin to completely dissolve, adding naphthol AS-D for standby, cooling to obtain the naphthol AS-D alkaline solution; adding non-ionic surface active agent in sulfuric acid, then adding naphthol AS-Dalkaline solution, fully stirring, obtaining AS-D coupling liquid; filtering the diazo liquid and adding into the naphthol AS-D coupling liquid for coupling reaction, fully stirring after reaction, filtering, cleaning, drying, grinding, and obtaining the finished product. The method solves the problems of environment pollution of the pigment, poor hydrophilic application of the pigment and low reaction conversion.

Owner:杭州荣彩实业有限公司

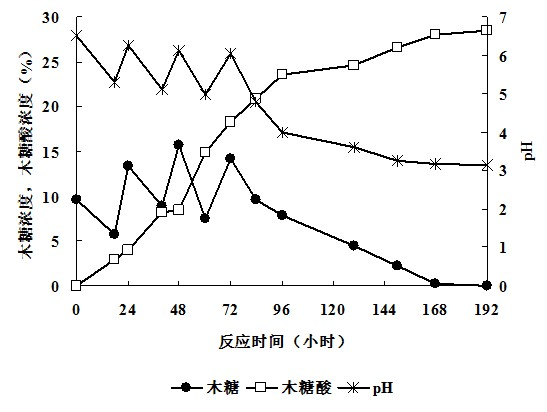

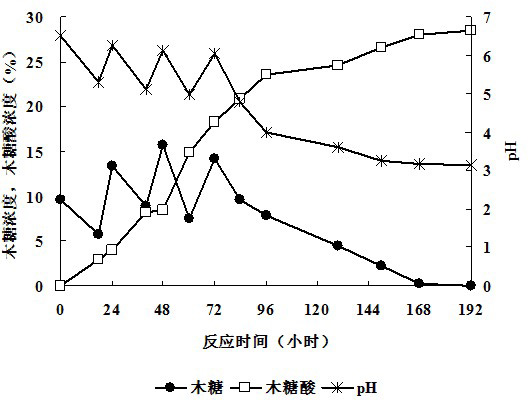

Method for preparing xylonic acid (salt) through whole-cell high-efficiency catalysis of xylose transformation

InactiveCN102676608AIncrease the reaction concentrationIncrease concentrationMicroorganism based processesFermentationGluconic acidTransformation ratio

The invention discloses a method for preparing xylonic acid (salt) through whole-cell high-efficiency catalysis of xylose transformation. The method comprises the following steps of: adding an initial reaction matrix into a liquid deep-layer ventilation reaction system; inoculating gluconabacteriumoxydonas; stirring and ventilating to continuously react; keeping dissolved oxygen concentration of the reaction system not less than 10 percent; adding xylose or xylose solution into the reaction system in a semi-continuous or continuous batch adding mode; controlling mass concentration of xylose in the reaction system to be not greater than 25 percent; synchronously adjusting and controlling the pH value to be not less than 2.8; stopping adding when the mass concentration of the xylose accumulatively added into the reaction system reaches 30 percent; and continuously performing full catalytic reaction to obtain a transformed product, i.e., the xylose acid (salt) product. According to the method, the maximum value of the accumulative concentration of the substrate xylose can reach 30 percent, the maximum utilization rate of the xylose exceeds 99 percent, the maximum concentration value of the fermentation product, i.e., the xylose acid (salt), can reach 29.8 percent, and the transformation ratio of the xylose acid (salt) can reach 100 percent.

Owner:NANJING FORESTRY UNIV

Controlled capsule type sodium borohydride hydrogen generating agent

InactiveCN101112969AImprove storage and transportationImprove preservationHydrogen productionAmylaseCellulose acetate

The invention discloses a controllable capsule borohydride sodium hydrogen propellant. The controllable capsule borohydride sodium hydrogen propellant is the borohydride sodium or 100 weight borohydride sodium and the stabilizer, activator, or the mixture of the stabilizer and the activator with the weight proportion ranging from 1 to 100 are wrapped in the capsule; the material of the capsule is the aluminum foil, glutin, glycerin, amylases, copolymerization polypeptides, maize papers, cellulose acetate, aromatic polyamide, polysulfone, polyethylene, and polypropylene. The catalyst is the transition metal salt and the hydrate, the transition metal powder, transition metal / carrier, and the framework-typed catalyst formed by the fore-driving body alloy. The stabilizer is the sodium hydroxide. The invention has the beneficial effects of 1) improving the safety and convenience of the series of links such as the transportation, storage and the application, etc. of the sodium borohydride; 2) improving the controllability of the hydrolyze reaction and the invariableness of the reaction speed; 3) improving the highest reaction consistence of the sodium borohydride and reaching high hydrogen production density.

Owner:ZHEJIANG UNIV

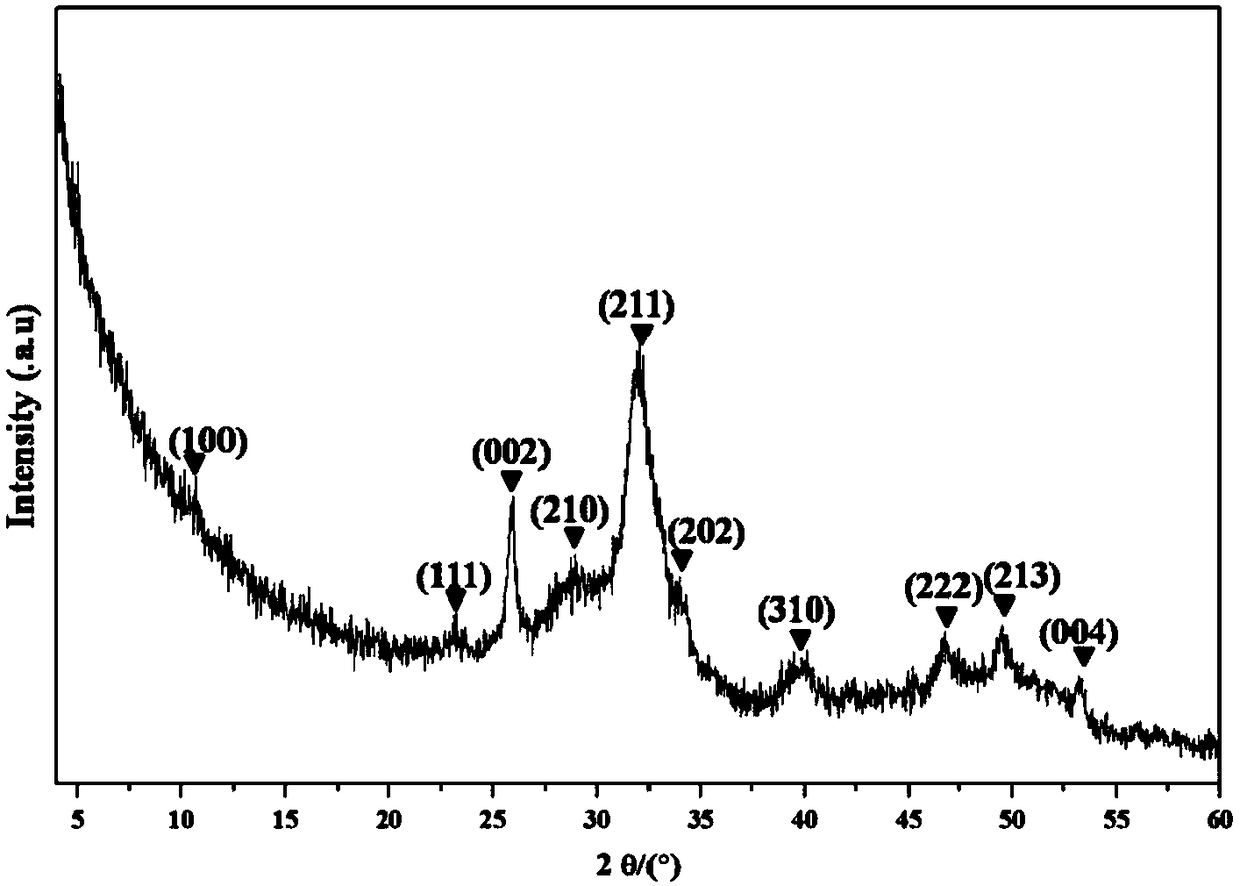

Simple and efficient preparation method of nano calcium phosphate

A simple and efficient preparation method of nano calcium phosphate comprises steps as follows: A, a calcium salt solution and a phosphate solution are prepared; B, diphosphonate is dissolved in the calcium salt solution, the phosphate solution is dropwise added to the calcium salt solution at the temperature of 37 DEG C, a reaction system is formed, and the pH value of the reaction system is adjusted to 7.0-11.0; the mole ratio of calcium to diphosphonate to phosphorus in the reaction system is (0.50-1.67): (0.01-0.02):1; after titration is completed, the reaction system is continuously stirred for 1-120 min, and the pH value of the reaction system is adjusted to 7.0-11.0; centrifugal washing and filtration are performed, precipitates are re-suspended in absolute ethyl alcohol, and a turbid liquid is obtained; C, a diphosphonate chemical is added to the turbid liquid, nano calcium phosphate slurry is obtained, and the mole ratio of diphosphonate to phosphorus in the nano calcium phosphate slurry is (0.01-0.02):1; the nano calcium phosphate slurry is subjected to ball milling treatment at the rotating speed of 300-600 r / min for 4-12 h and finally dried, and nano calcium phosphate powder is obtained.

Owner:SOUTHWEST JIAOTONG UNIV

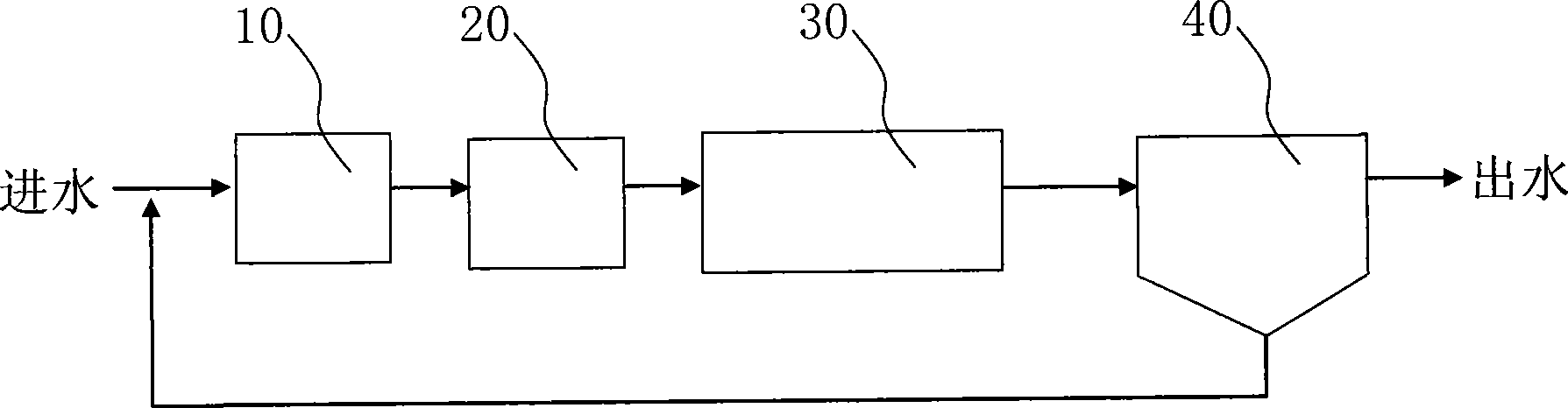

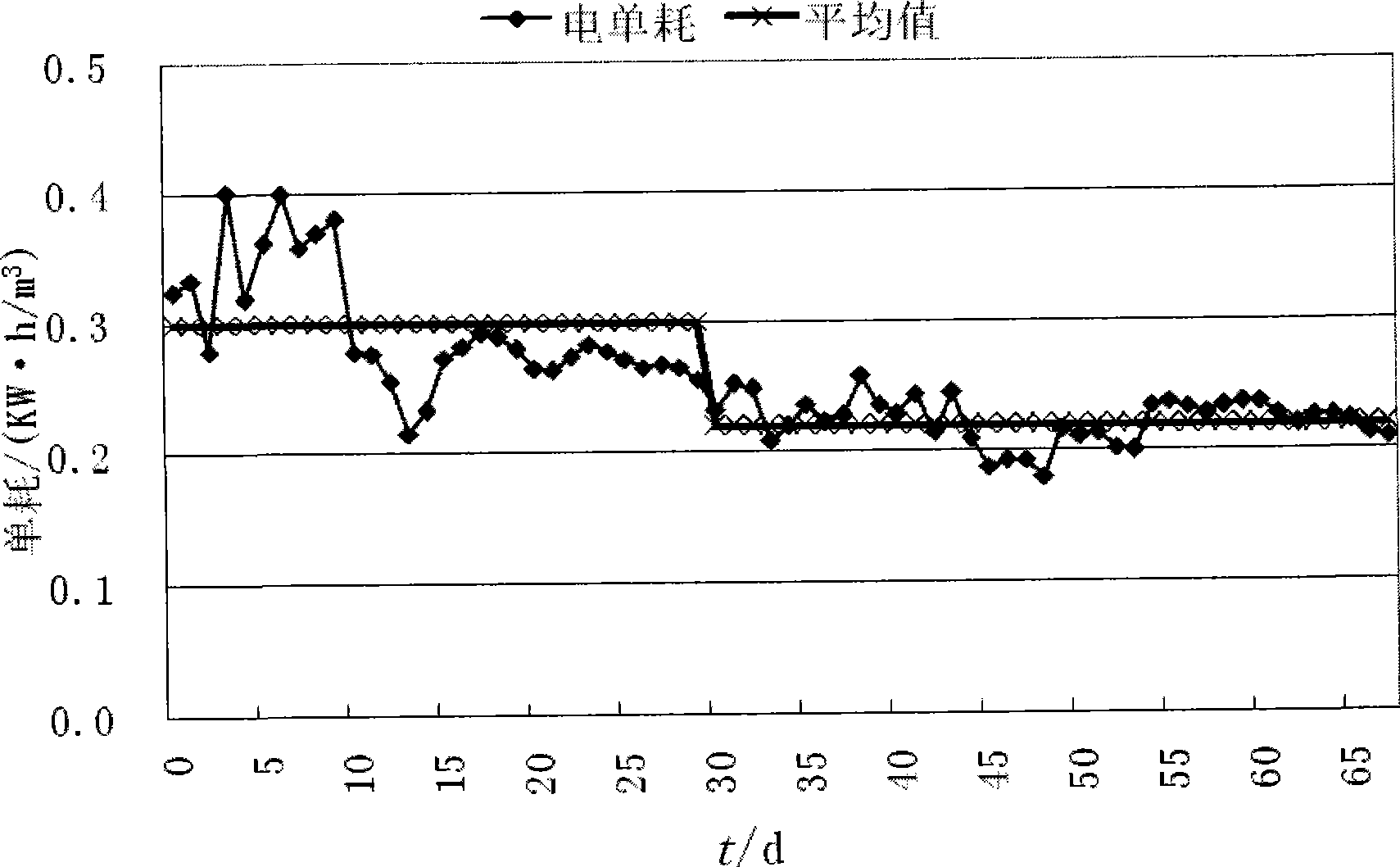

A<2>/O oxidation ditch process operation control method

InactiveCN101456626AImprove reaction efficiencyIncrease the reaction concentrationTreatment with aerobic and anaerobic processesSubstrate concentrationOxidation ditch

The invention belongs to the technical field of sewage treatment, and particularly relates to a method for operating and controlling an A<2> / O oxidation ditch process. The method comprises: the sewage orderly flows through an anaerobic tank, an anoxic tank and an oxidation ditch aeration tank and finally enters a secondary sedimentation tank, and supernatant fluid is discharged by sludge-water separation; and the oxidation ditch aeration tank adopts an intermittent aeration mode. The prior oxidation ditch aeration tank adopts the continuous aeration mode, and the water flow state in the oxidation ditch is the perfect mixing mode, so that the reaction efficiency of the prior oxidation ditch aeration tank is relatively low. According to the technical proposal, because the oxidation ditch aeration tank of the invention adopts the intermittent aeration mode, the reaction is easily controlled, and the reaction efficiency and the substrate concentration in the oxidation ditch are greatly improved, thereby improving the nitrification efficiency and oxygen utilization efficiency at the nitrifying stage, improving the denitrification efficiency, simultaneously lowering oxygen consumption, and greatly lowering energy consumption of the oxidation ditch.

Owner:中节能国祯环保科技股份有限公司

Novel adsorption catalyst for nitrogen removal of sewage and preparation method thereof

ActiveCN103041856AImprove adsorption capacityLong-term useOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsNitrogen removalFreeze-drying

The invention discloses a novel adsorption catalyst for nitrogen removal of sewage and a preparation method thereof. The preparation method comprises the following steps of: firstly, mixing FeC13 solution with tannin solution according to a certain proportion, and regulating pH of the mixed solution to 7.0 by adding NaHCO3; then carrying out centrifuging, distilled water washing and recentrifuging on the neutral mixed solution; and carrying out freeze drying on solid matters obtained by centrifugal separation so as to obtain a novel ferric tannate adsorption catalysis material. The novel adsorption catalyst for the nitrogen removal of the sewage and the preparation method thereof have the advantages of simplicity in operation, economy, applicability and the like; due to a prepared ferric tannate adsorption catalyst, NH4<+>- and NO2<->-N in water can be simultaneously absorbed and converted into N2; and the adsorption catalyst has the advantages of rich pore structures, high stability, good adsorption and nitrogen removal catalyzing effects and wide applicable range and can be widely applied to the nitrogen removal of the sewage.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

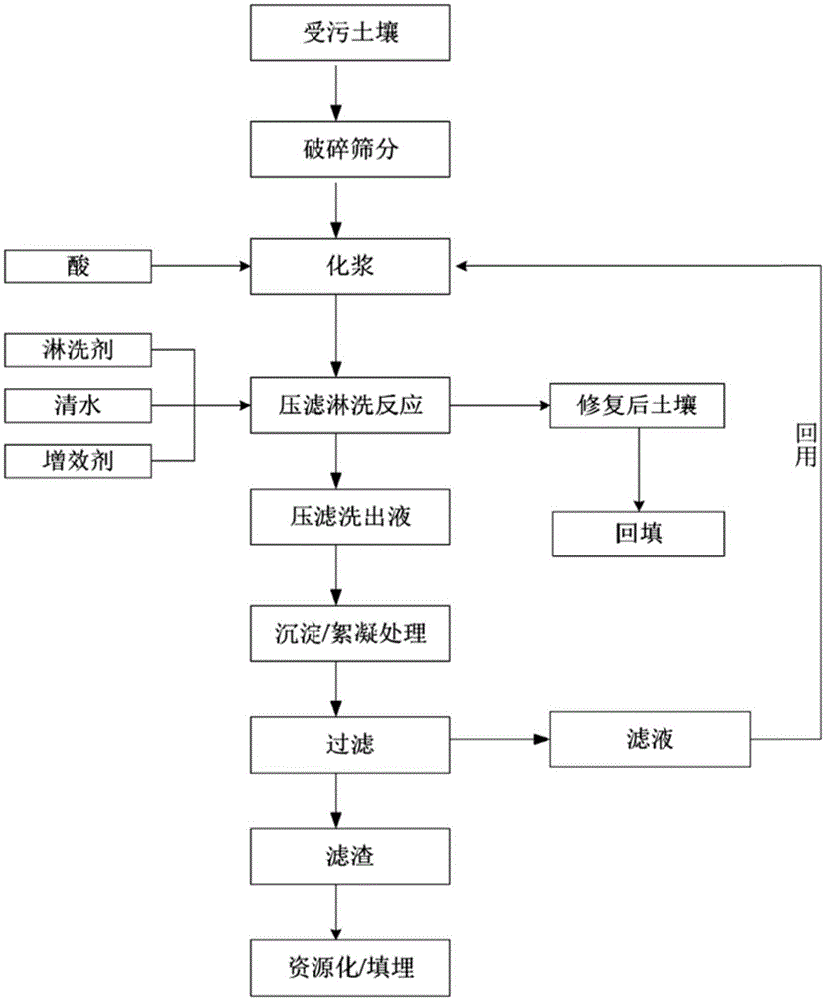

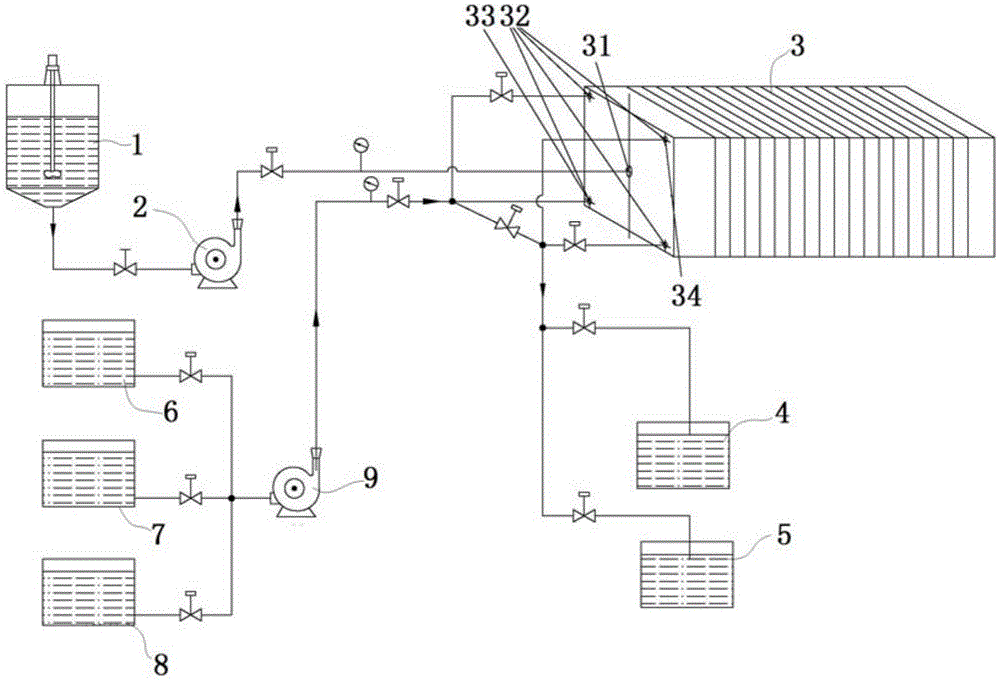

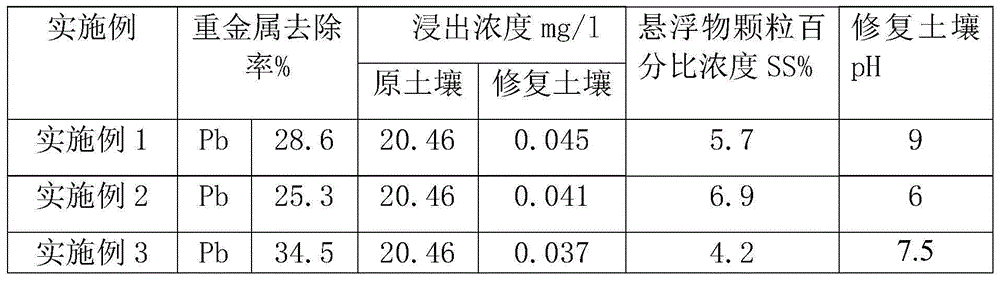

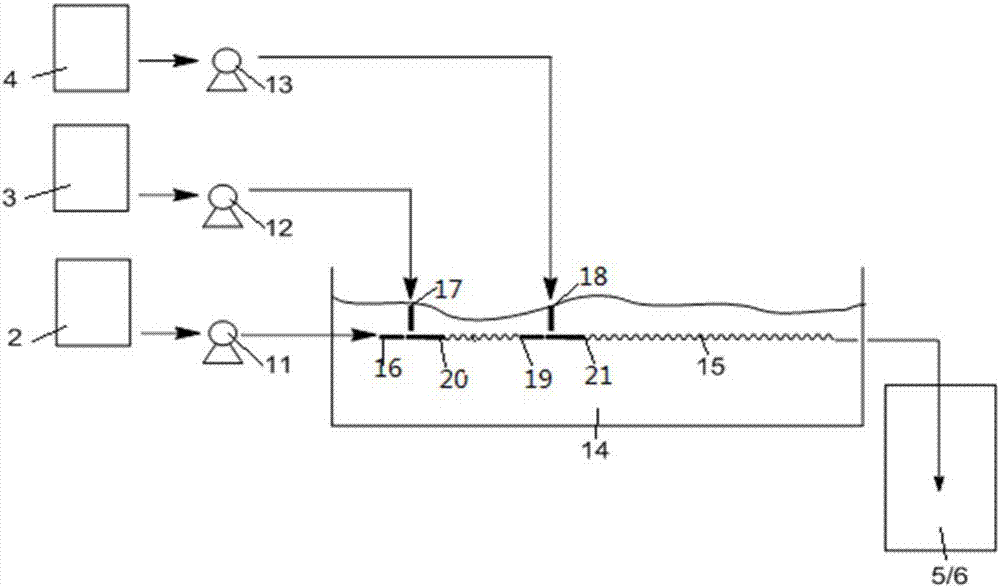

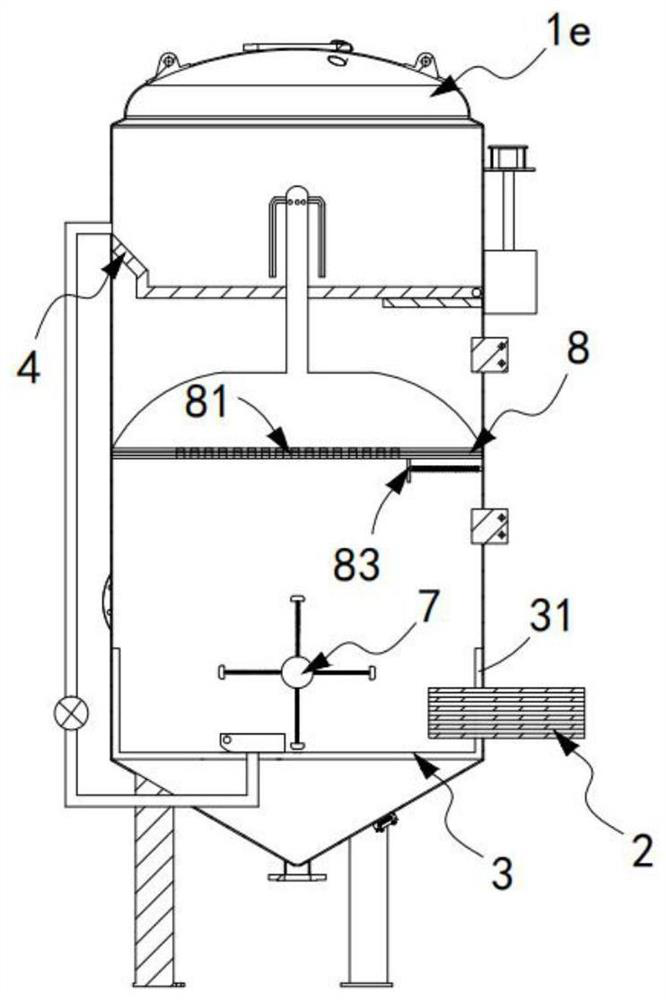

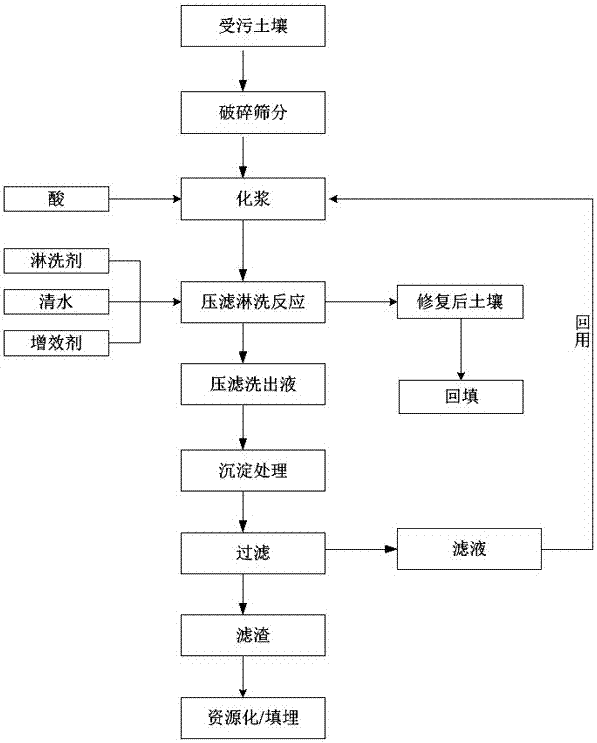

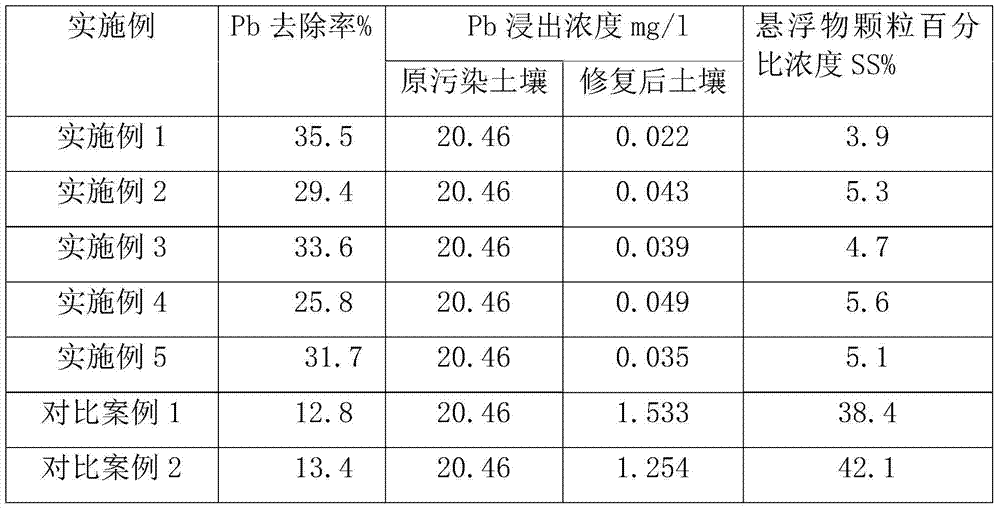

Method and system for efficient filter pressing and drip washing of contaminated soil and control method

InactiveCN105032921AReduce the amount requiredReduce the liquid-solid ratioContaminated soil reclamationVulcanizationPollution soil

The invention discloses a method and system for efficient filter pressing and drip washing of contaminated soil and a control method. The method for repairing heavy metal contaminated soil comprises the following steps that firstly, the pulp smelting and acidification reaction is carried out; secondly, a sizing agent obtained after the sufficient reaction is filtered to obtain a soil filter cake and filter liquor; thirdly, pre-drip washing is carried out, heavy metal left in capillary holes in the filter cake is replaced and washed out; fourthly, after pre-drip washing is carried out, an eluting agent is injected in a washing reaction type membrane press filter step by step to carry out the multi-stage drip washing reaction; fifthly, after the drip washing reaction is carried out, dissociative heavy metal left in the soil filter cake can be stabilized, tiny heavy metal particles formed in the stabilization process are moved out of the soil, the input pressure ranges from 0.22 MPa to 0.35 MPa, and the vulcanization drip washing amount accounts for 50-80% of the total water content of the soil; and sixthly, the soil is stabilized. The problem that in the drip washing process in the prior art, leacheate is left in the soil, and consequently the soil leaching toxicity heavy metal index exceeds the standard is solved.

Owner:HUNAN MUKUN ENVIRONMENTAL PROTECTION

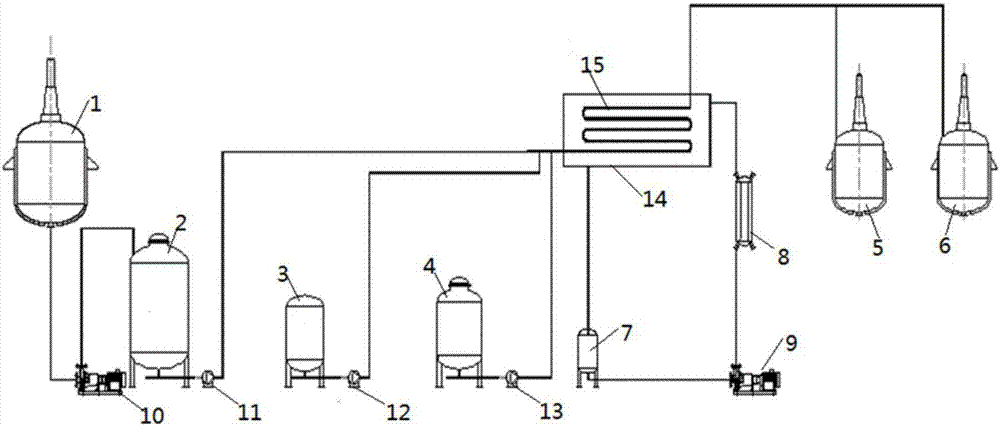

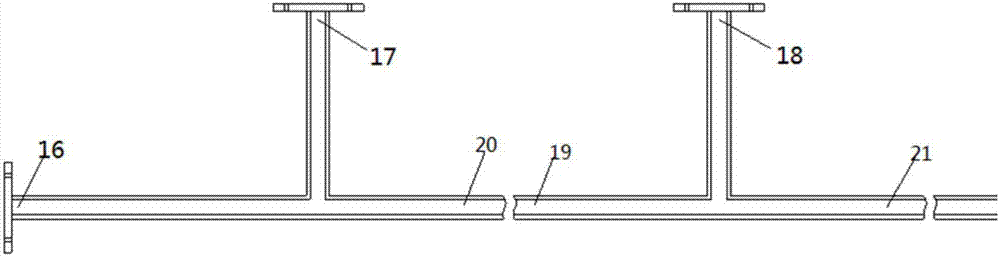

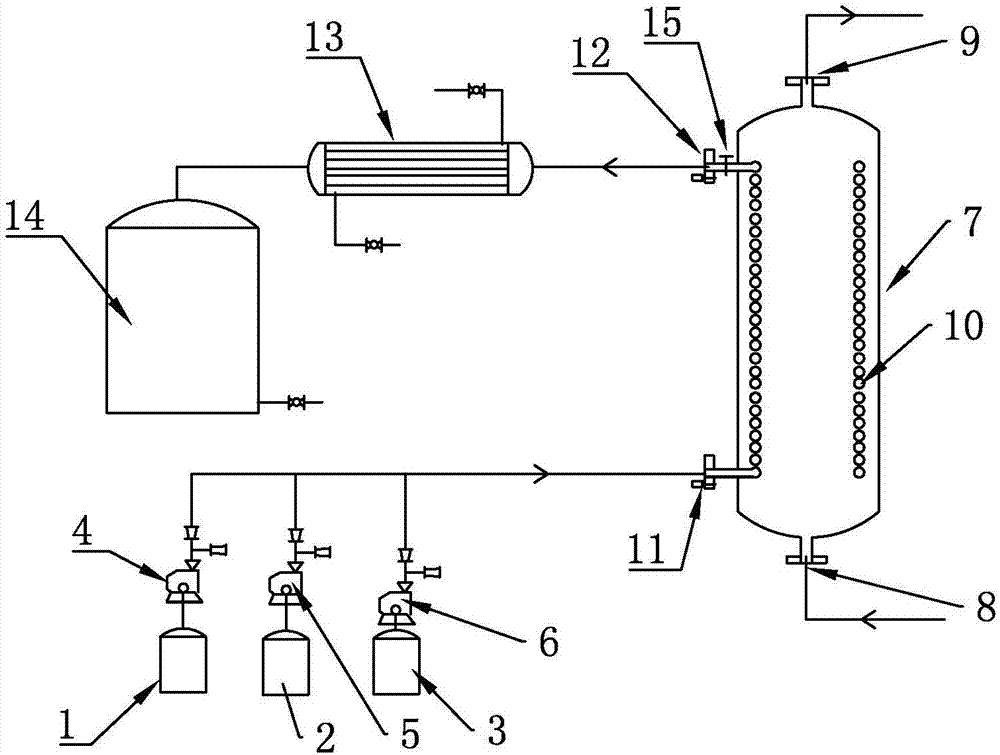

Preparation method and device of aromatic chloride

ActiveCN107021889ASimple structureReduce dosageCarbamic acid derivatives preparationOrganic compound preparationHydrogen chlorideContinuous production

The invention discloses a preparation method and a device of aromatic chloride. The preparation method comprises the following step: performing chlorination on a mixed solution of a solution of a compound A, a hydrogen peroxide solution and a hydrogen chloride solution in a tubular reactor so as to obtain a compound B, wherein the mole ratio of the compound A to hydrogen peroxide and hydrogen chloride in the mixed solution is 1:(1-4):(1-4), and the retention time of the mixed solution in the tubular reactor is 30-600s. The invention further discloses a tubular reaction device. The preparation method disclosed by the invention is very short in reaction time, precise in reaction condition control, high in security, good in continuous production, high in product yield, high in purity and applicable to large-scale industrial production.

Owner:LIANHE CHEM TECH TAIZHOU +1

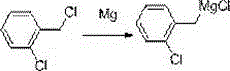

Synthetic method of o-chlorobenzylmagnesium chloride

InactiveCN106279216AImprove hydrophobicityHigh boiling pointMagnesium organic compoundsChlorideSolvent

The invention relates to a synthetic method of o-chlorobenzylmagnesium chloride. A reaction is carried out by using a specific solvent at the molar ratio of o-chlorobenzyl chloride to magnesium chips being 1: 1.1-1:3.0, preferably 1:1.5. Especially, a reaction trigger step exists in specific process. Especially after reaction triggering, temperature rises to 35-80 DEG C, preferably 35-45 DEG C. By the synthetic method, the purposes of easy industrialization, reaction safety, high yield, less side reaction and green synthesis can be achieved.

Owner:HAIZHENG CHEM NANTONG CO LTD

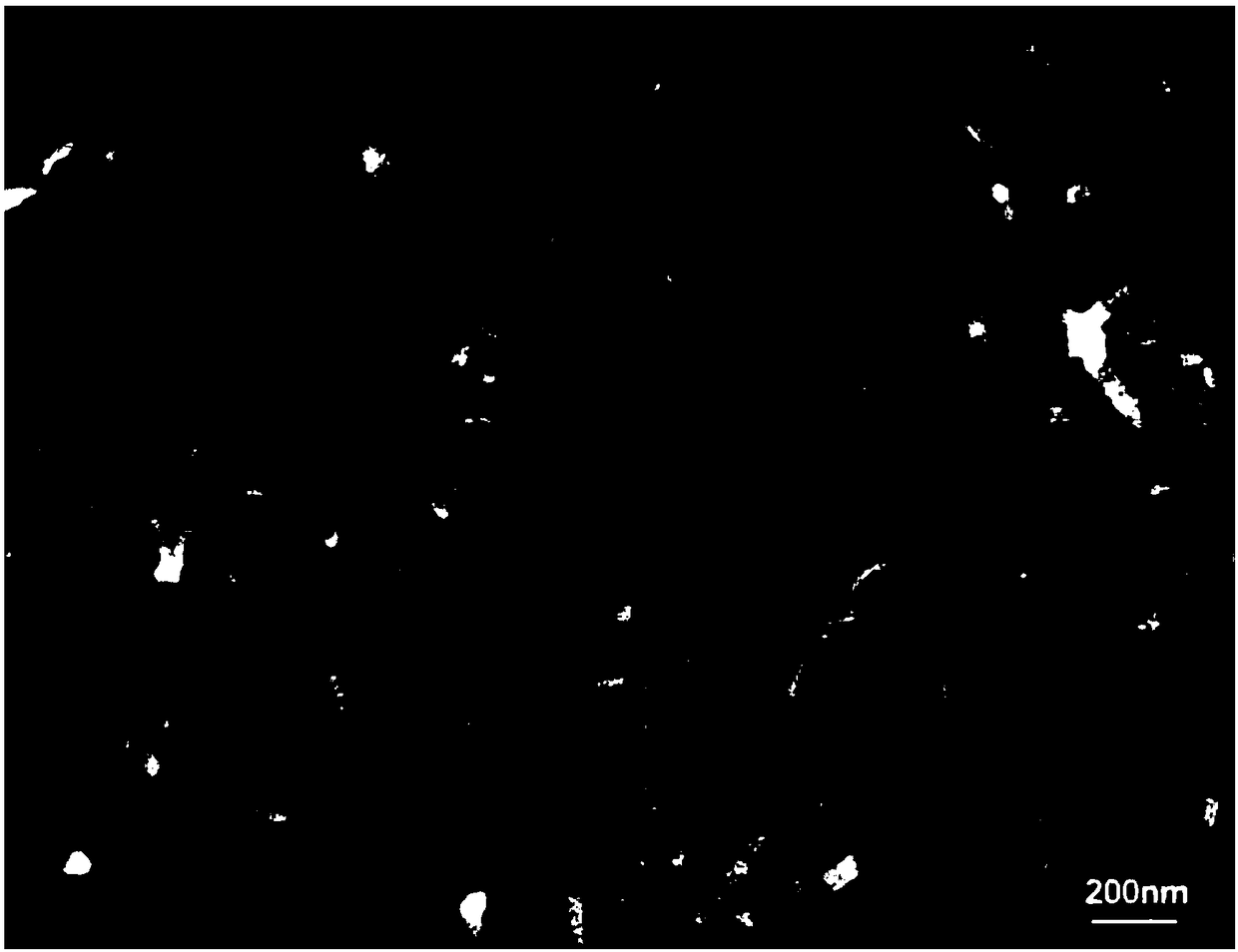

Preparation method of oil soluble high dispersion nano-metal copper

The invention discloses a preparation method of oil soluble high dispersion nano-metal copper. The preparation method includes steps of dissolving Cu2+ soluble inorganic salt into water solution to react with complex sodium oleate, forming Cu coordination compound provided with a protective layer, then adding reducing agents to restore, and obtaining materials of the oil soluble high dispersion nano-metal copper through centrifugal separation and vacuum drying. The preparation method has the advantages that the preparation method is simple, condition is moderate, a water solution system is adopted, and the preparation method is environment-friendly, and facilitates large-scale production.

Owner:CHINA NAT ACAD NANOTECH & ENG

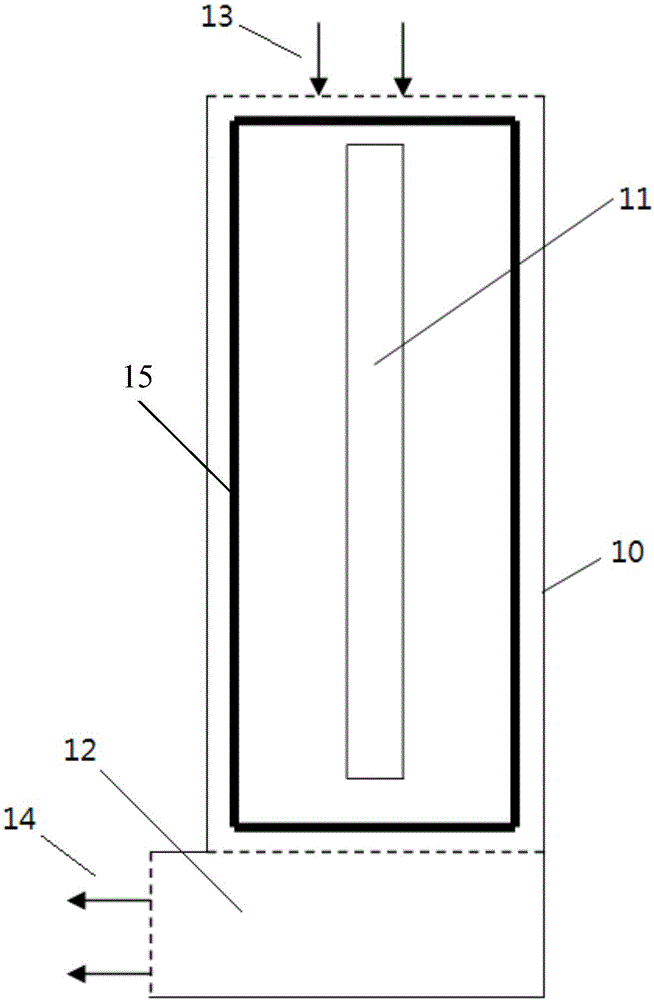

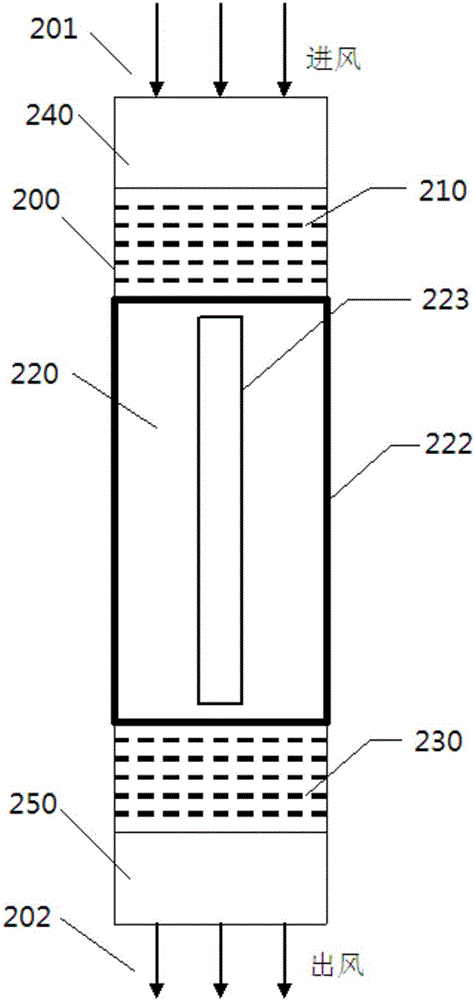

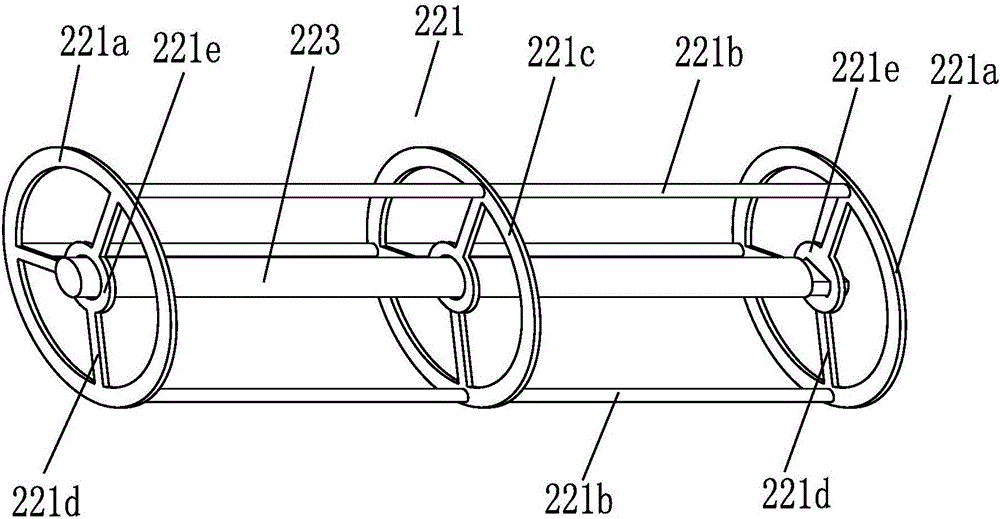

Air purification device for removing low concentration formaldehyde and benzene series

InactiveCN106466553AQuick clearEfficient removalGas treatmentDispersed particle separationBenzenePhysical chemistry

The invention provides an air purification device for removing low concentration formaldehyde and benzene series. The device comprises a casing provided with an air inlet and an air outlet communicating with a space to be purified, a pretreatment bin arranged in the casing and located behind the air inlet, Wherein a physical adsorption layer for adsorbing formaldehyde in air and benzene series molecular particles in air is arranged in the pretreatment bin, a photocatalyst reaction bin arranged in the casing and behind the pretreatment bin, and an exhaust gas recovery bin which is arranged in the casing, behind the photocatalyst reaction bin and in front of the air outlet and is used for recovering and trapping trace amounts of formaldehyde and benzene molecular particles undecomposed catalytically by the photocatalyst reaction bin. The air purification device utilizes a pretreatment bin-photocatalyst reaction bin-exhaust gas recovery bin three-grade composite bin structure to solve the technical problem that the existing photocatalyst technology can not clear the low concentration of formaldehyde and benzene series particles in the air.

Owner:湖北尼帕莱尔环保科技有限公司

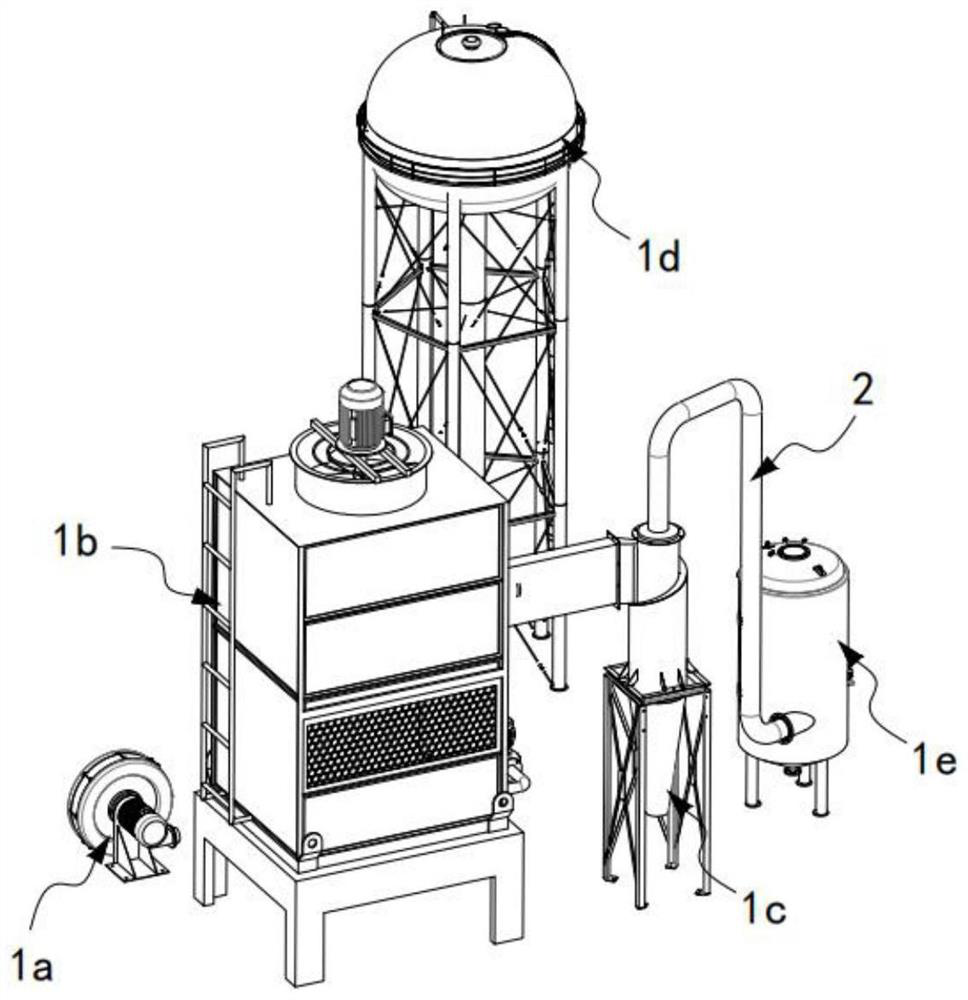

Heat exchange system capable of realizing waste gas recovery

PendingCN113324428AIncrease profitImprove reaction efficiencyGas treatmentRecuperative heat exchangersLiquid storage tankProcess engineering

The invention relates to a heat exchange system capable of realizing waste gas recovery. The heat exchange system comprises a fan, a heat exchanger, a rotary separator, a cold water tower and a gas-liquid mixing tower and further comprises a first-stage purification mechanism, a second-stage purification mechanism and a third-stage purification mechanism; the third-stage purification mechanism controls opening and closing of an air inlet of the heat exchanger through a first transmission assembly and controls switching work of a liquid outlet a of the rotary separator through a second transmission assembly; a purification liquid storage tank is arranged outside the gas-liquid mixing tower, and a purification liquid in the purification liquid storage tank is continuously introduced into the first-stage purification mechanism; an output mechanism is arranged in the second-stage purification mechanism, and the output mechanism quantitatively and intermittently conveys the purification liquid into the third-stage purification mechanism; a separation mechanism is arranged below the third-stage purification mechanism. The technical problem that the waste gas purification effect is low due to the fact that products are fewer and fewer due to the fact that reactants of the purification liquid are fewer and fewer after the purification liquid of the gas-liquid mixing tower is subjected to multiple times of reactions is solved.

Owner:福建亿一智控有限公司

Method for preparing high-content troxerutin drug

ActiveCN100503627CReduce dosageReduce generationOrganic active ingredientsSugar derivativesPtru catalystEthylene oxide

The invention provides a method for synthesizing 3', 4', 7-trihydroxyethyl rutin, which uses rutin and ethylene oxide to carry out hydroxyethylation reaction under the condition of sodium hydroxide as a catalyst, It is characterized in that, in the hydroxyethylation reaction, the weight ratio of rutin to water is 1:1 to 1:3, preferably 1:1 to 1:1.5; the weight ratio of rutin to sodium hydroxide is 100:0.82 ~100: 0.85; Another feature of the present invention is that when the pH value of the reaction solution is 9.0~9.5, add resin; adjust the pH value of the end point of the reaction solution by using the resin to be 9.5~10.3. The method of the present invention can prepare high-purity and high-quality troxerutin products, and the 3', 4', and 7-trihydroxyethylrutin content in the troxerutin crude product prepared by the method of the present invention can be obtained by using The HPLC test is greater than 78%, preferably greater than 80%, more preferably greater than 85%.

Owner:TOPFOND PHARMA CO LTD

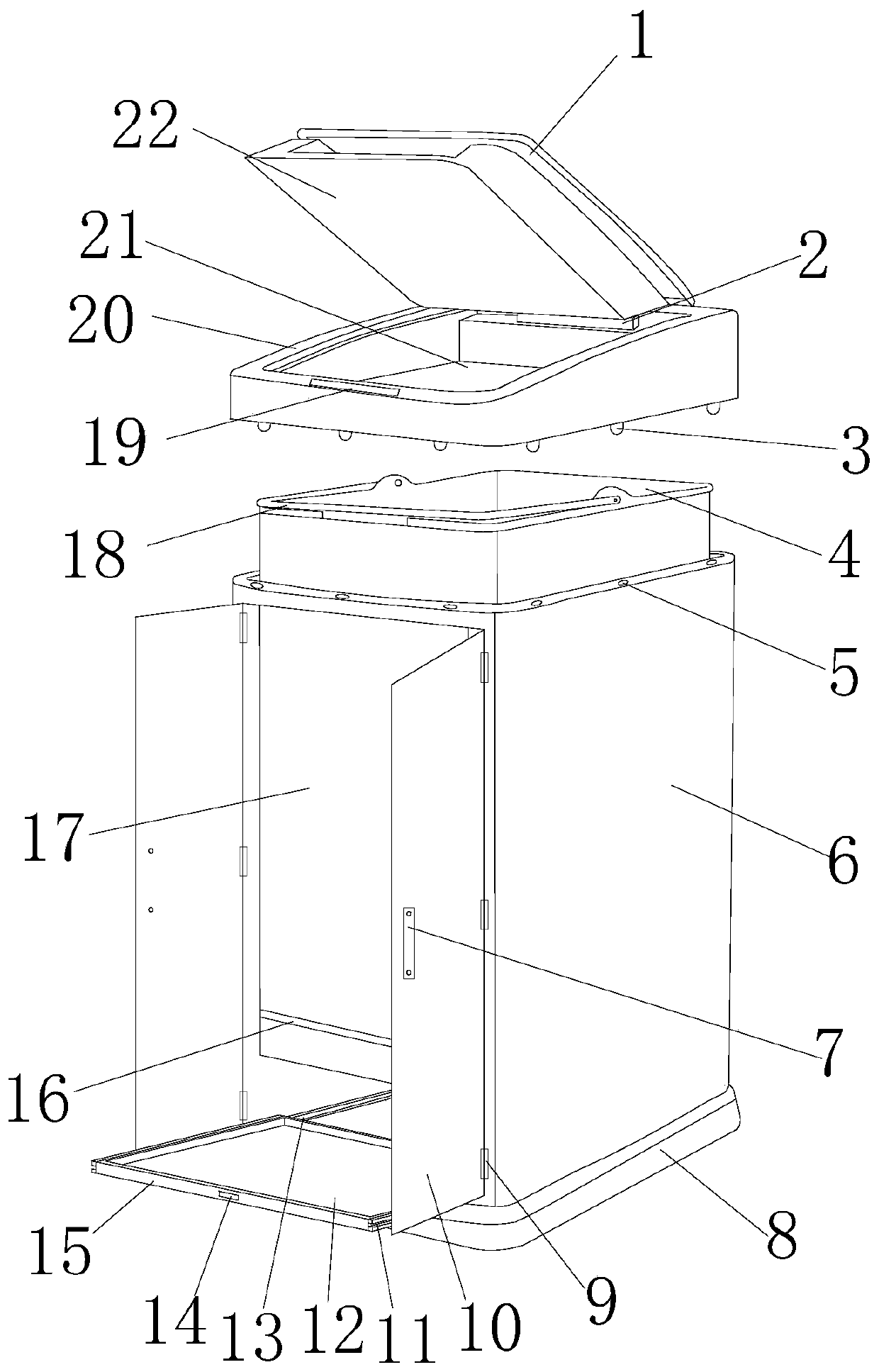

Intelligent garbage recycling equipment for home automation

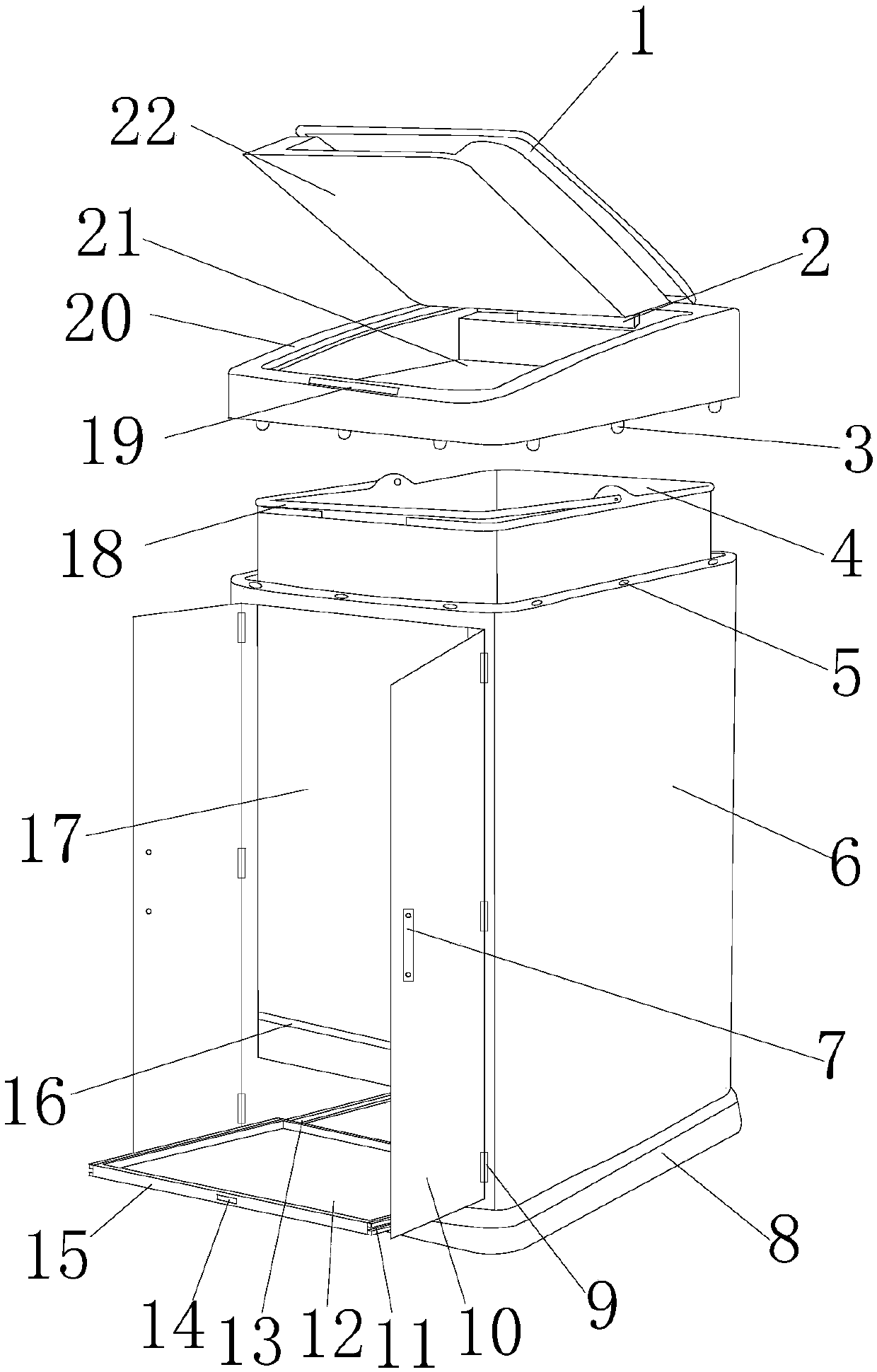

The invention discloses intelligent garbage recycling equipment for home automation. The intelligent garbage recycling equipment structurally comprises an infrared induction cover, a hinge base, positioning columns, an inner cavity, positioning holes, a base body, U-shaped handles, an antiskid base, symmetric hinges, door planks, sliding grooves, a groove, rails, a handle, a pulling plate, a catalytic activated carbon layer, an inner garbage can, a lifting handle, a liquid crystal operation panel, a cover body, a garbage throwing port and a compression device, wherein the bottom of the base body is fixedly connected with the top of the antiskid base; the positioning holes with equal intervals are uniformly formed in the top surface of the base body; and the positioning holes and the base body are of an integrated structure. The intelligent garbage recycling equipment is provided with the compression device and has the function of compressing the garbage, the volume of the garbage is reduced through physical compression, the density of organic matters is increased so that the reaction concentration can be increased and the biochemical effect can be accelerated, and therefore the decomposition of the organic matters in the garbage can be accelerated, gaps can be generated, the occupied space of the garbage can be reduced, and more garbage can be contained.

Owner:四川携网网络科技有限公司

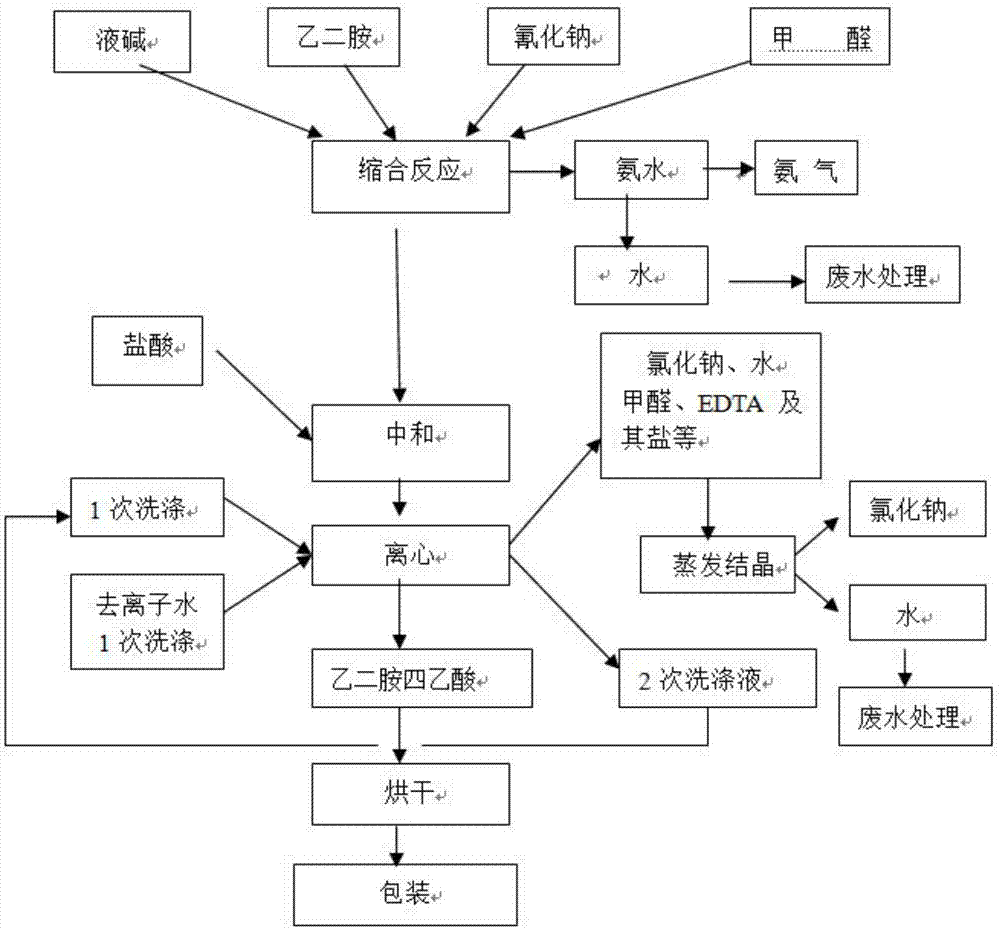

Production method of EDTA

InactiveCN107501111AEasy to removeLess side effectsOrganic compound preparationAmino-carboxyl compound preparationEthylenediamineSodium cyanide

The invention discloses a production method of EDTA (ethylenediaminetetreacetic acid). The production method is characterized by preparing EDTA by taking sodium cyanide, ethanediamine, formaldehyde and liquid caustic soda as raw materials and comprises the following steps: (1) condensation reaction: adding part of a sodium cyanide solution, a liquid caustic soda solution and ethanediamine into a condensation reaction kettle, then starting stirring, then switching on a steam regulating valve, then increasing the temperature to 88-95 DEG C, dropwise adding formaldehyde and the remaining sodium cyanide solution, condensing the tail gas generated in the reaction process and absorbing the tail gas under negative pressure, adding hydrogen peroxide after the reaction is ended, and decolorizing to obtain a condensed material; (2) acidification reaction: adding the condensed material into an acidification reaction kettle, starting stirring, opening an acidification condenser, adding return water into the acidification condenser, adding hydrochloric acid into a reaction kettle till the pH of the reaction kettle is 2.1-4, carrying out centrifugal separation on the precipitated crystal to obtain an EDTA wet material, then carrying out airflow drying to obtain EDTA. Through the production method, the occurrence of side reactions is reduced; the purity of EDTA is improved; the conditions are provided for directly preparing sodium salt; the process steps are simplified.

Owner:潍坊滨海石油化工有限公司

High-purity ammonium aluminum carbonate hydroxide as precursor of high-purity easy-sintering aluminum oxide ceramic powder and preparation process thereof

InactiveCN101870482BReduce volumeLess investmentAluminium compoundsAluminum ammonium sulfateAmmonium Hydrogen Carbonate

The invention belongs to the technical field of preparation, moulding and processing of an inorganic nonmetallic material, namely superfine nano powder, in particular to a preparation process of a high-purity ammonium aluminum carbonate hydroxide as a precursor of high-purity easy-sintering aluminum oxide ceramic powder. The high-purity ammonium aluminum carbonate hydroxide as the precursor of the high-purity easy-sintering aluminum oxide ceramic powder is prepared by the following steps of: carrying out chemical reaction synthesis on 41.68-42.85 percent by weight of crystalline solid ammonium hydrogen carbonate and 57.15-58.32 percent by weight of crystalline solid aluminum ammonium sulfate which are adopted as raw materials; and then forming the high-purity ammonium aluminum carbonate hydroxide as the precursor, wherein 0.2-0.3 percent by weight of crystalline alpha-Al2O3 is used as an additive; a mixture of 0.1-0.15 percent by weight of citric acid and 0.35-0.5 percent by weight of glycol is used as a dispersing agent; and an ammonium sulfate solution of 0.2 times of the weight sum of the solid ammonium hydrogen carbonate and the solid aluminum ammonium sulfate is used as a mineralizing agent. The invention has the advantages of energy saving, environmental protection and cleanness.

Owner:JIAZUO HONGCHENG ADVANCED CERAMIC TECH

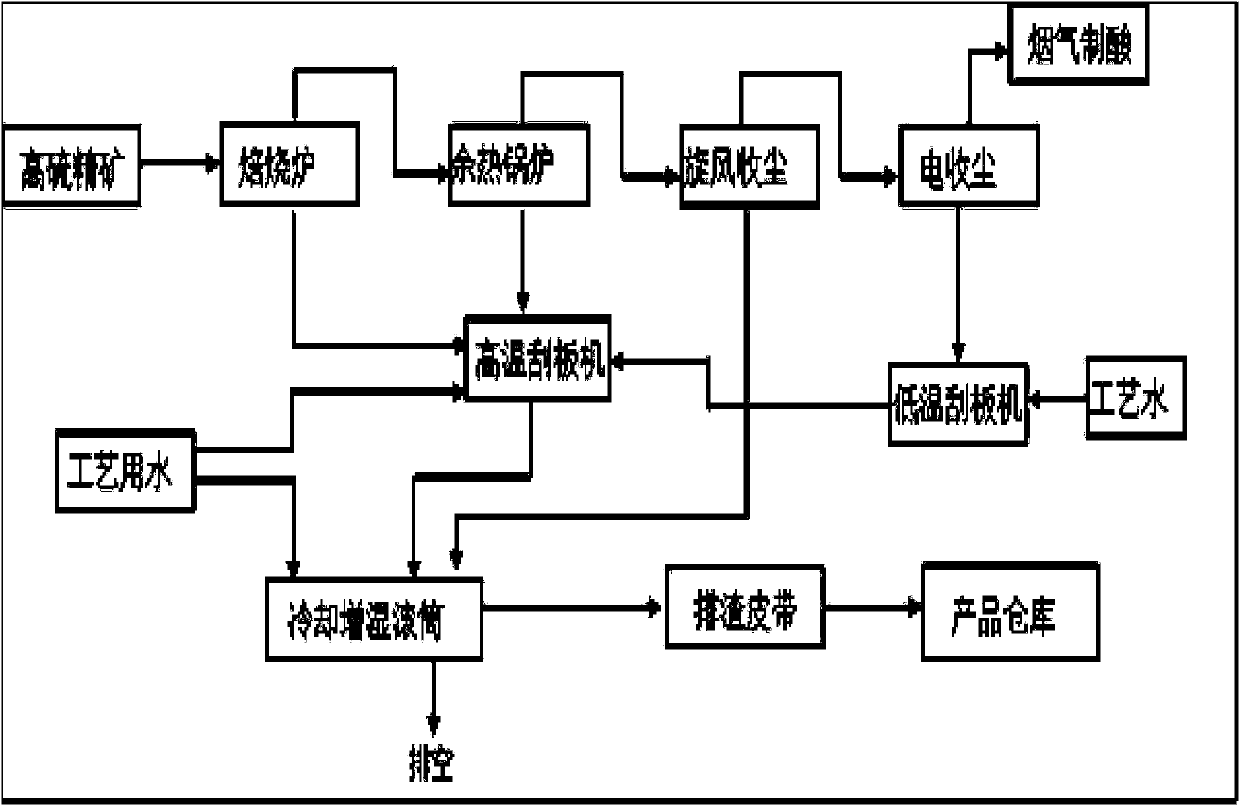

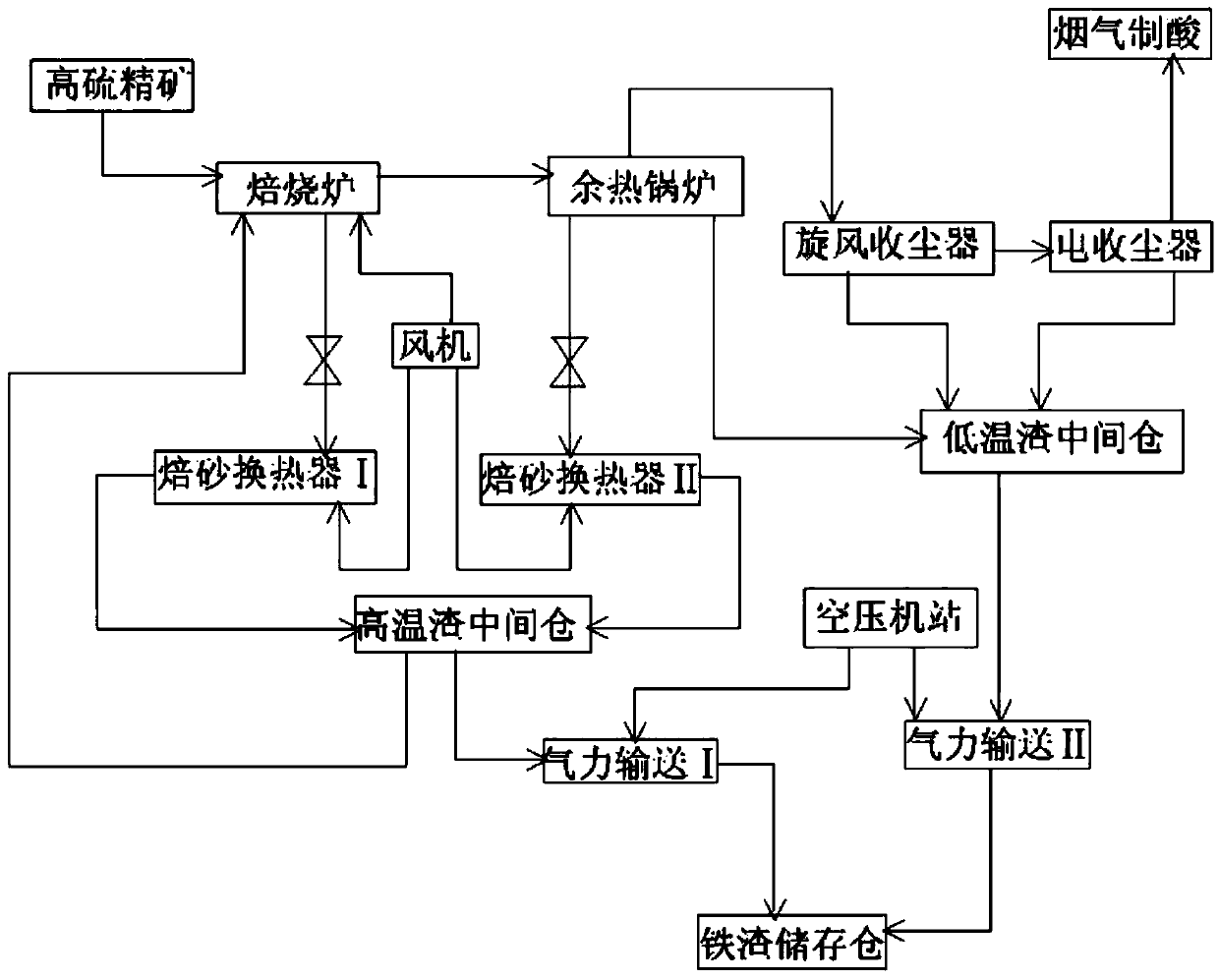

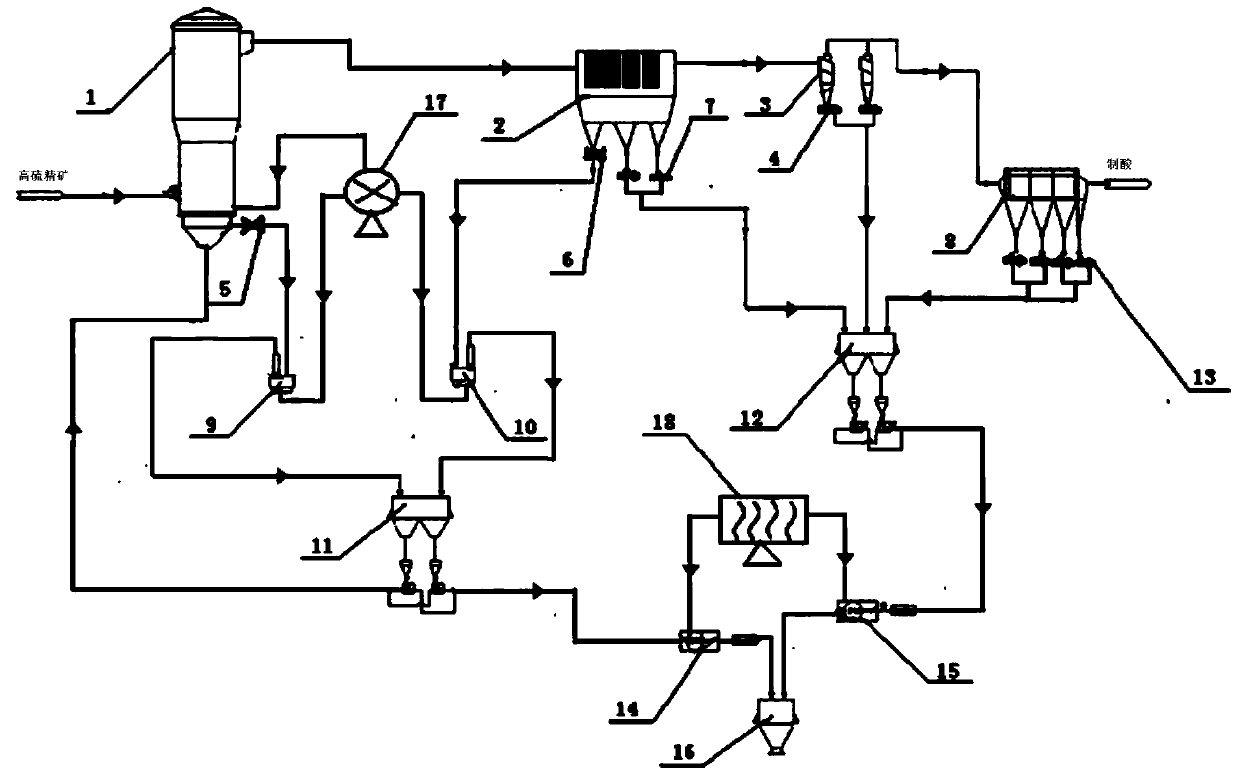

Recovery system and method of magnetized cinder of high-Fe sulfuric acid

ActiveCN103789535AAchieve instant cooling effectReduce pollutionSulfur compoundsEnergy inputRecovery methodSulfur

The invention belongs to the technical field of cinder recovery, and particularly relates to a recovery system and method of magnetized cinder of high-Fe sulfuric acid. The recovery system comprises a sulfur concentrate acid preparing system, a cooling system and a cinder conveying system, wherein the magnetized cinder obtained after sulfur concentrate is processed in a roasting furnace is respectively treated by a waste heat boiler, a cyclone dust collector, an electric dust collector, a cinder heat exchanger, pneumatic transmission and the like, and high temperature cinder is cooled and recovered. The magnetized cinder provided by the invention is conveyed in a pneumatic manner, thereby not only thoroughly eliminating the environmental pollution caused by the conventional cooling and humidifying process, but also saving a lot of water resources and water treatment investment. The obtained magnetized cinder does not need to be dried, thereby effectively avoiding energy consumption for oxidization and subsequent drying of the magnetized cinder.

Owner:ZHAOYUAN ZHAOJIN JINHE TECH

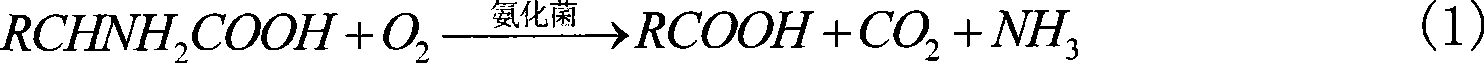

Biological enzyme deinking method for waste paper

InactiveCN1240900CIncrease the reaction concentrationHigh catalytic efficiencyFats/resins/pitch/waxes removal in pulpPaper recyclingFiltrationSewage

Provided is a biological enzyme deinking method for waste paper, in which flotation applies polyoxyethylene alkyl ether as flotation auxiliary, deinking process applies compound enzyme as deinking agent. The method improves the white content of the regenerated pulp by chemistry method, which is enhanced to 5-8% higher, and the COD value of the discharged sewage reduced more than 60%. The paper pulp filtration performance is further increased and the strength is similar, thus it can meet requirement of making different papers.

Owner:ENZYME ENG INST SHAANXI PROVINCE ACAD OF SCI

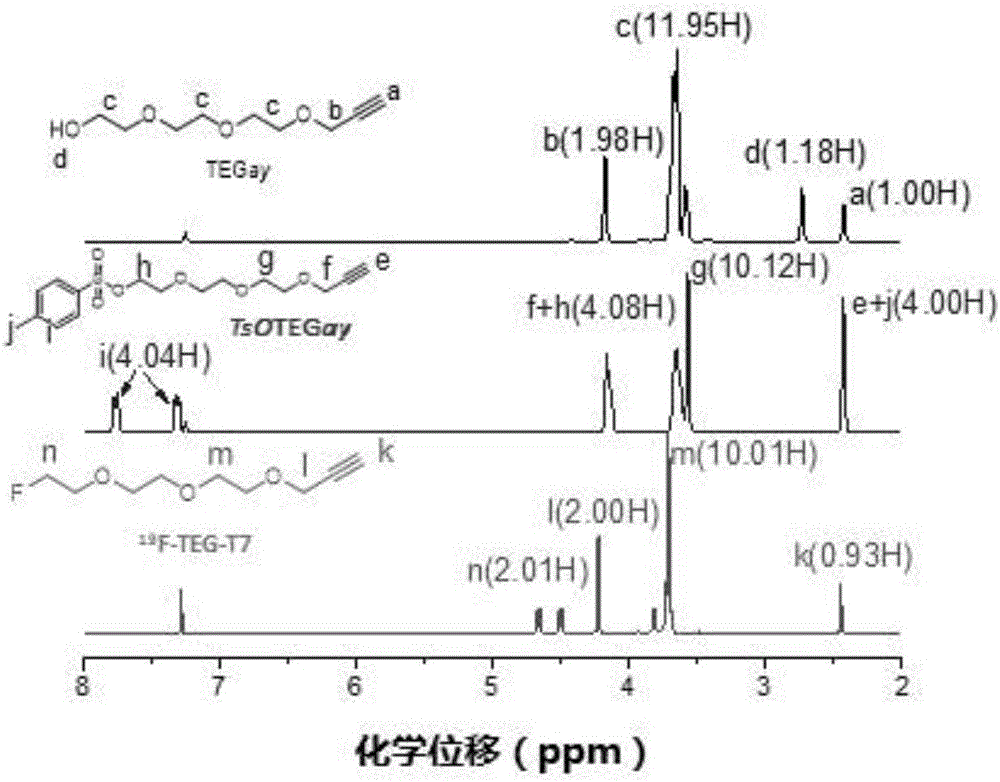

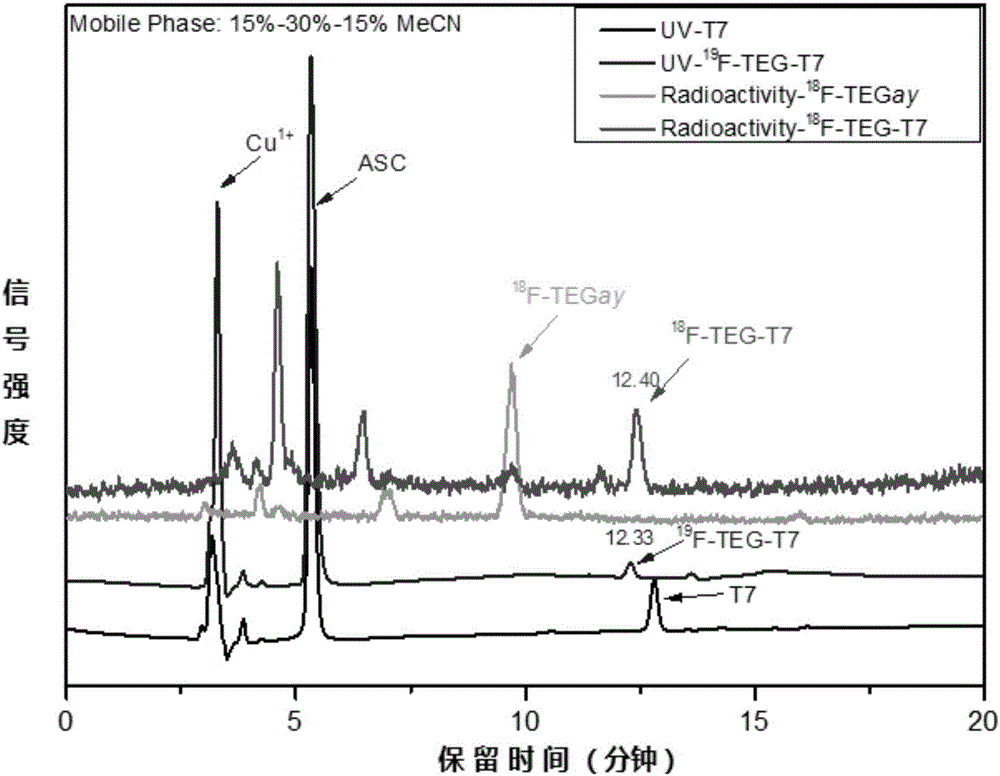

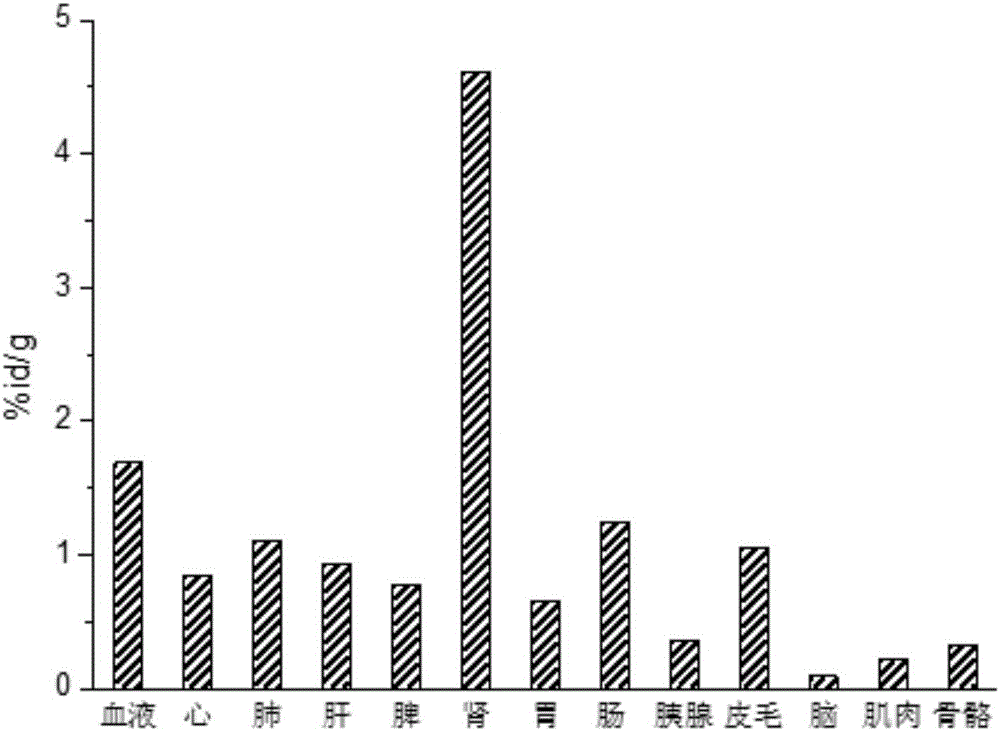

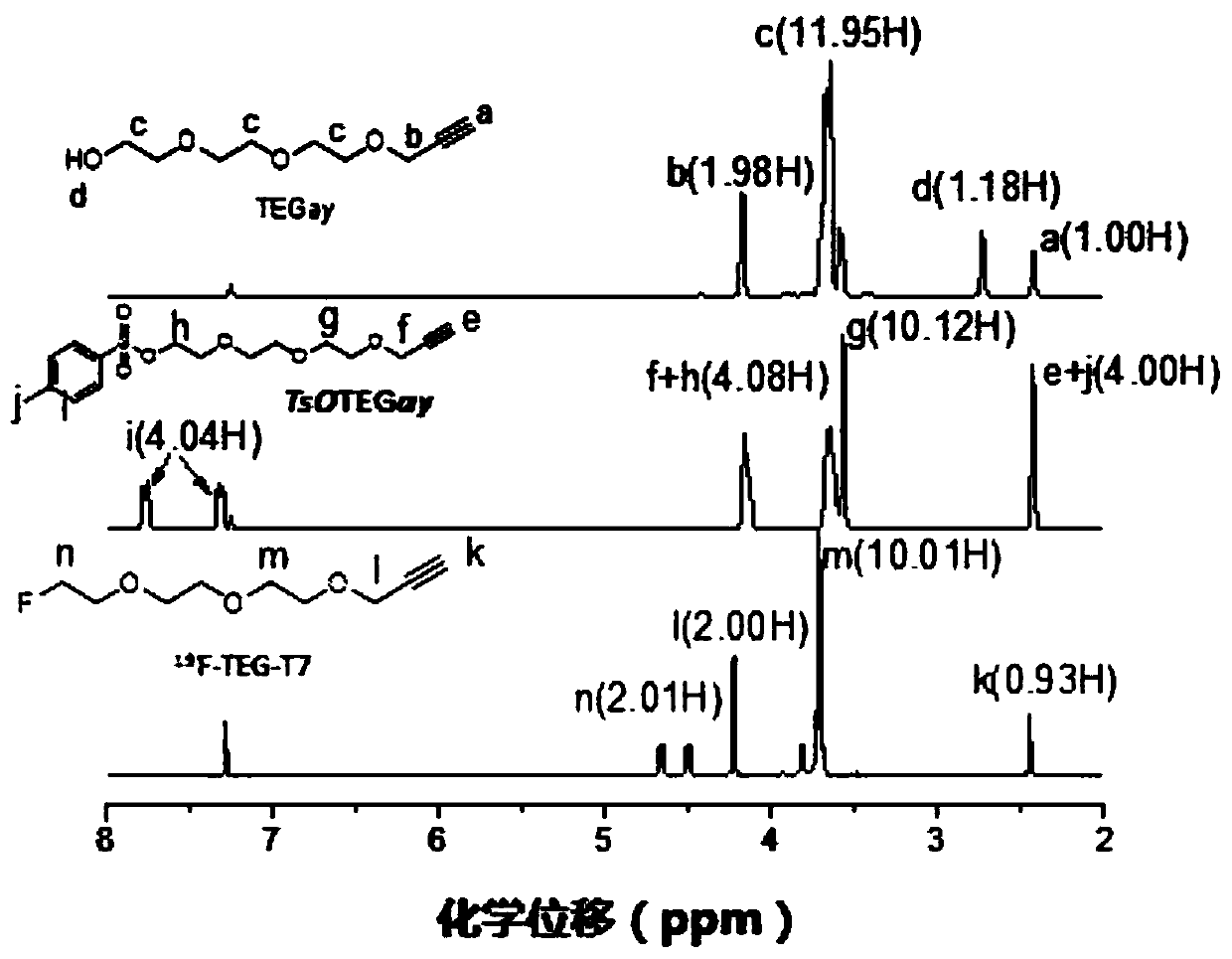

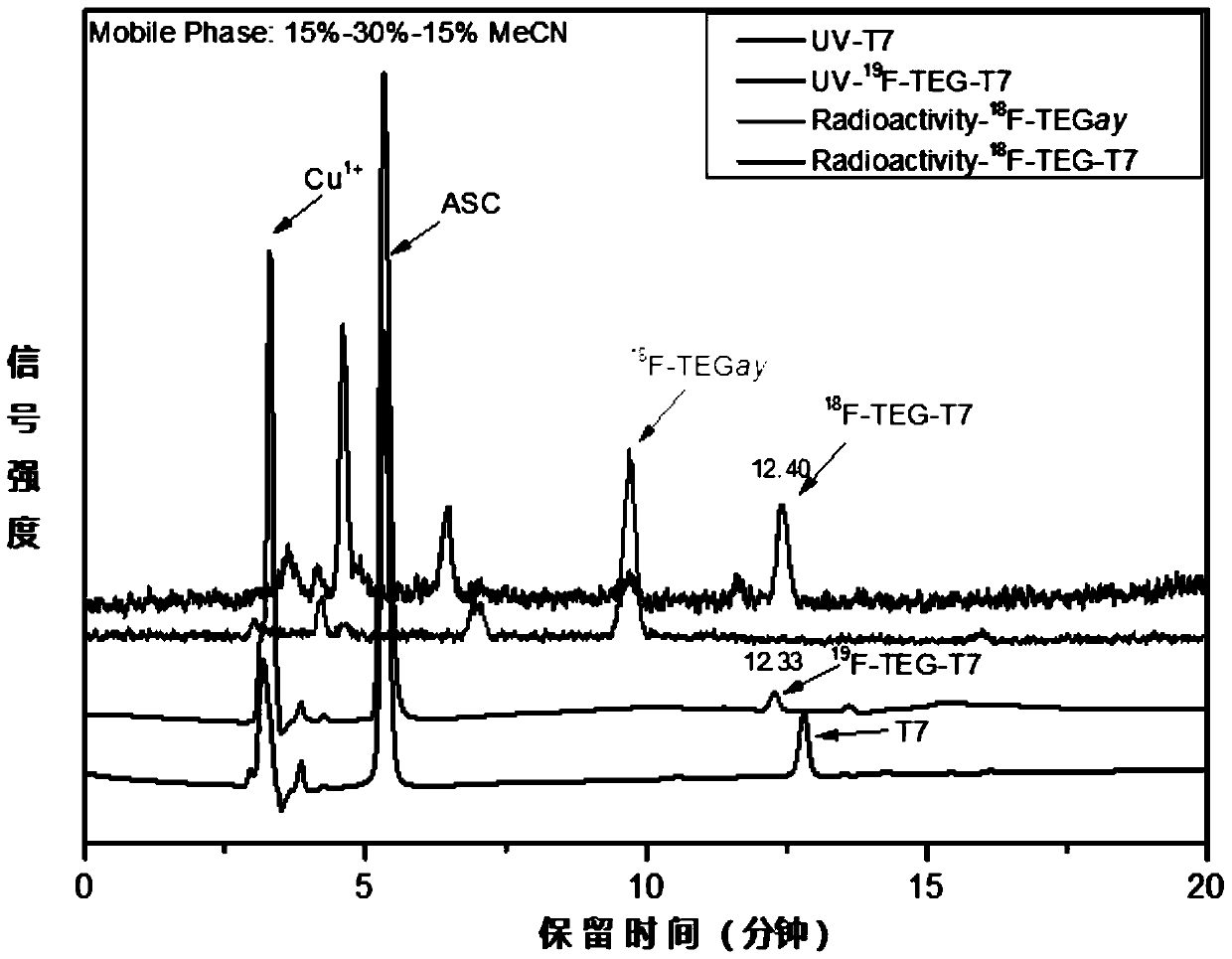

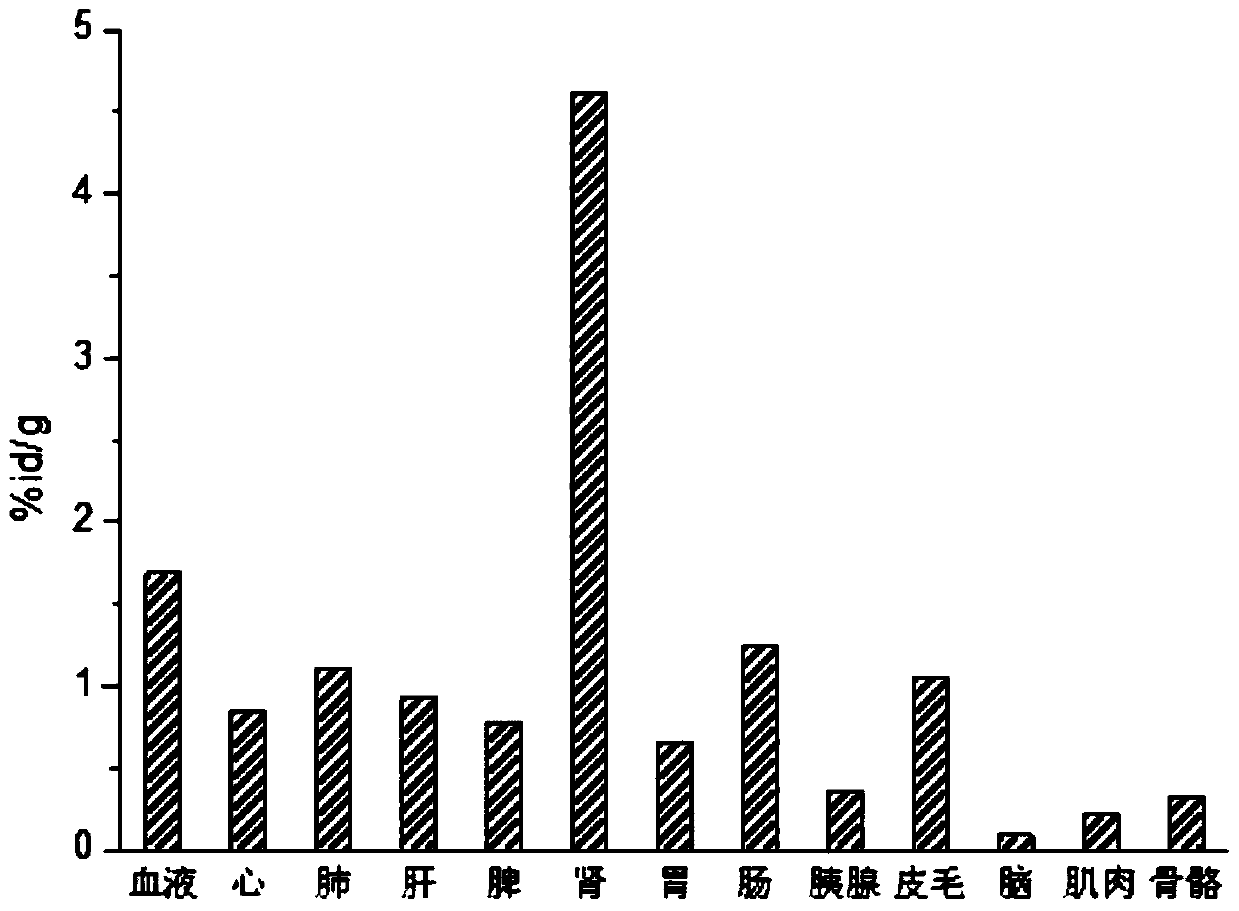

18F click labelling transferrin receptor targeting polypeptide T7 as well as preparation method and application thereof

ActiveCN106084004ADoes not cause defluorinationHigh radiochemical yieldRadioactive preparation carriersX-ray constrast preparationsTumor targetClick chemistry

The invention discloses 18F click labelling transferrin receptor targeting polypeptide T7 as well as a preparation method and application thereof. According to the preparation method, synthesis steps of click chemistry are improved, addition amount of a prosthetic group TsOTEGay is reduced, the addition amount of polypeptide T7 is appropriately increased, feeding ratio of the prosthetic group to the polypeptide T7 is adjusted to be 1:(1-2); after 18F-TEGay is synthesized through reaction, a polypeptide precursor is directly added for carrying out click reaction without carrying out HPLC purification, a 'one-pot two-step' process is adopted for synthesizing 18F-TEG-T7, and finally HPLC purification is carried out; and one purification process is reduced, the whole synthesis and purification time is greatly reduced and can be controlled to be within 120 minutes, radiochemical yield is about 28.26 minus and plus 7.43% (n=3). The optimized 'two-step one-pot' click reaction can be applied to research of 18F labelling polypeptide, and a novel tumor targeted probe can be prepared.

Owner:GUANGZHOU GENERAL HOSPITAL OF GUANGZHOU MILITARY COMMAND

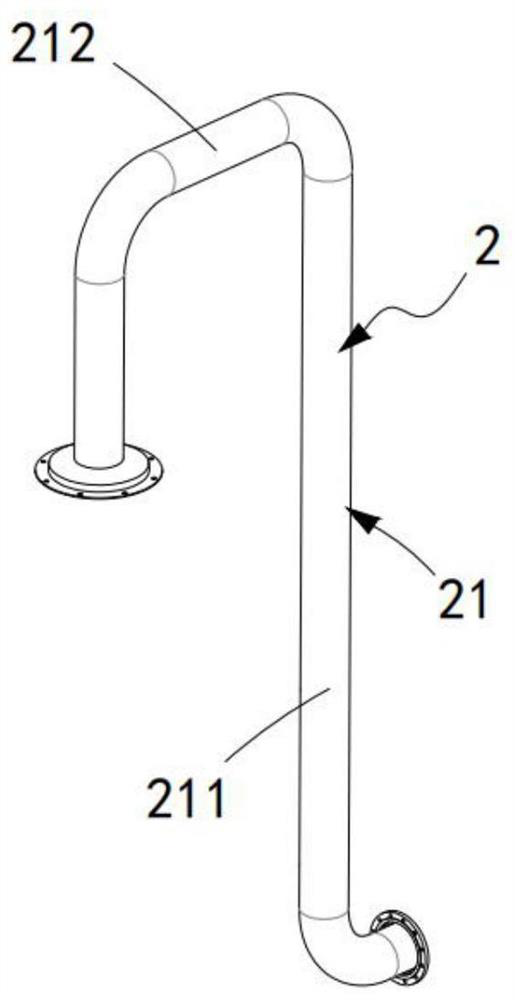

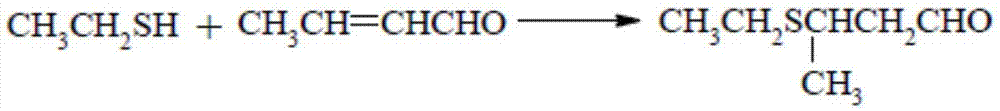

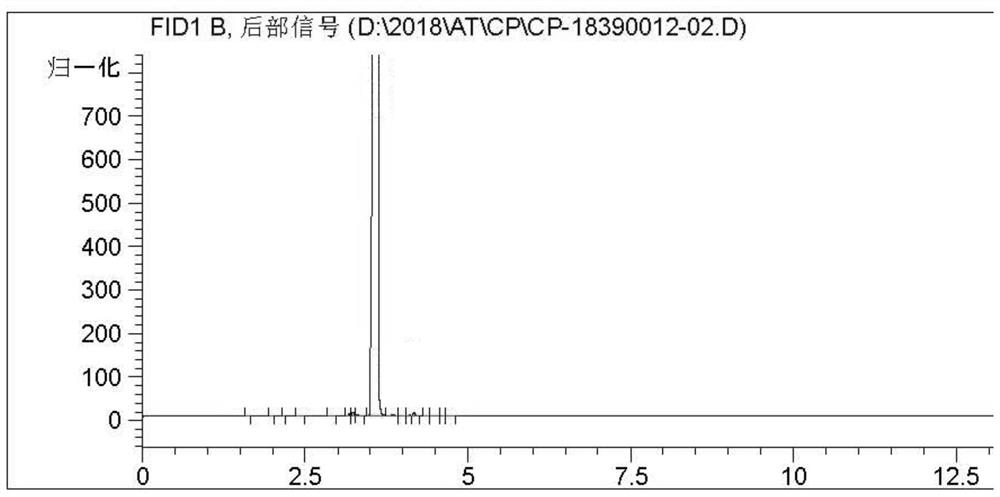

Production method and device of 3-(ethylthio)butyraldehyde

PendingCN107029636AReduce volatilityReduce difficultySulfide preparationPressure vessels for chemical processCrotonaldehydeProcess engineering

The invention discloses a production method and device of 3-(ethylthio)butyraldehyde. Crotonaldehyde, ethanethiol and a catalyst are pumped into a coil tube reactor according to the mole ratio of (0.9-1.1) to 1 to (0.01-0.03), the temperature is kept to 20-200 DEG C, the pressure is kept to 5-50 kg / m<2>, the time is 5-25 minutes, then the mixture is delivered to a finished product storage tank after cooling, and a finished product is obtained. The raw materials are introduced into the airtight tube reaction, the ethanethiol small volatilization is decreased through pressurized reaction, and the aftertreatment difficult is reduced. The production method and device has the advantages of being simple in reaction process, short in reaction time, good in impermeability, better in safety, high in product content and stable in yield.

Owner:WEIFANG CYNDA CHEM +1

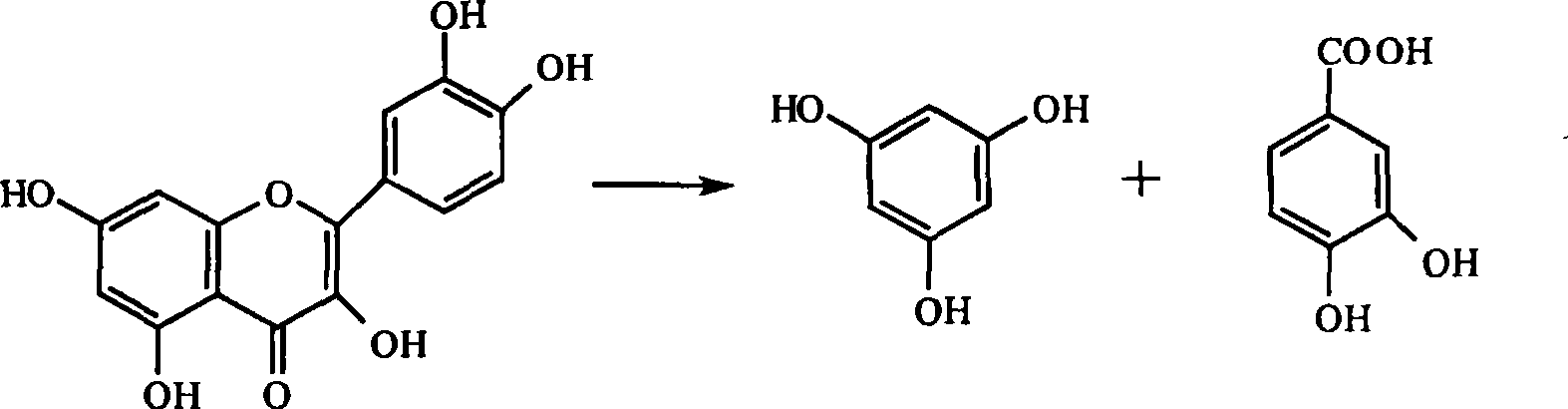

A kind of method adopting biological enzyme to catalyze the stereoselective resolution of loxoprofen enantiomer

This patent introduces a chiral resolution method for obtaining (RR)- and (SR)-loxoprofen enantiomers, that is, an enzymatic stereoselective esterification method for splitting loxoprofen partial enantiomers The invention belongs to the technical field of splitting chiral compounds by biological methods. Choose Novozym from Rhizomucor miehei ® 40086 lipase is used as a biocatalyst, and the lipase has the characteristics of high selectivity and high catalytic efficiency in the catalytic esterification of loxoprofen, and can obtain (RR)-loxoprofen and (SR) with high optical purity ‑Loxoprofen. After enzyme-catalyzed stereoselective esterification resolution, the enantiomeric excess value of the target product reached 98.64%, the yield was 72.70%, and the overall conversion rate of the substrate was 63.40%. Compared with other methods, the method has high reaction concentration, fast reaction rate, high optical purity of the product, simple operation and post-treatment, low cost, and green and environment-friendly production process, and is an efficient resolution method for loxoprofen.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

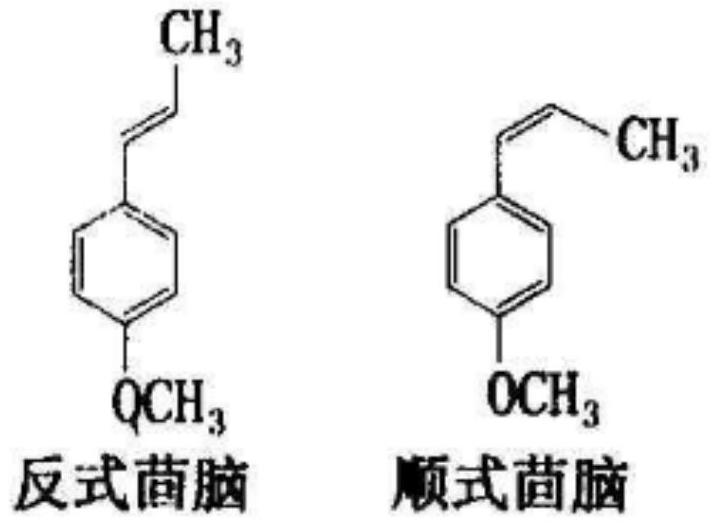

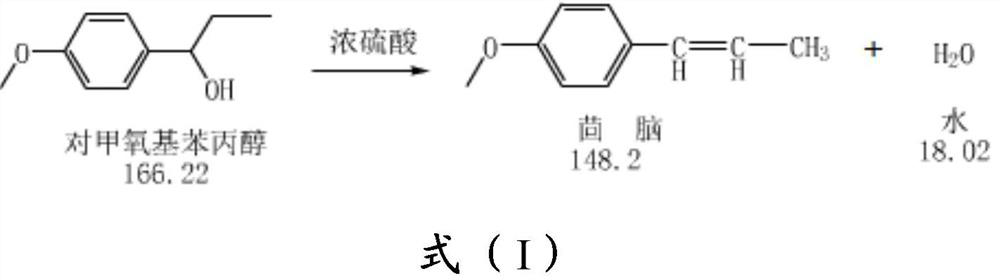

A production process for preparing anethole by catalyzing the dehydration of p-methoxyphenylpropanol

ActiveCN108440257BReduce generationHigh selectivityMolecular sieve catalystsOrganic compound preparationPropanolReaction rate

The invention discloses a production process for preparing anethole by catalyzing the dehydration of p-methoxyphenylpropanol. Dehydration of methoxyphenylpropanol produces anethole. In the production process of the present invention, no waste gas is generated in the reaction process, the reaction rate is fast, the yield is high, the polymerization impurities of anethole are few, and it has high economic value, and the reaction does not require post-processing and solvent participation, and has low requirements for equipment. Easy to industrialize.

Owner:SUQIAN COSMOS CHEM

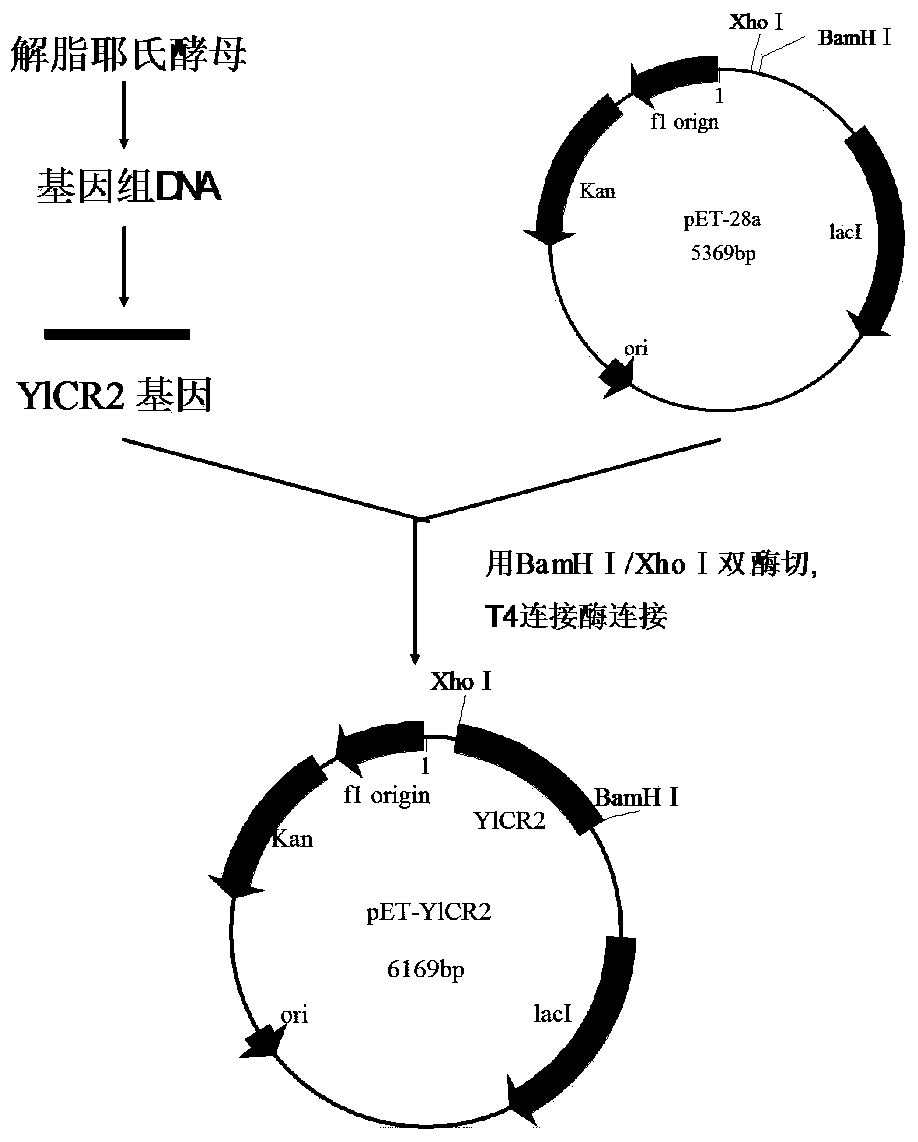

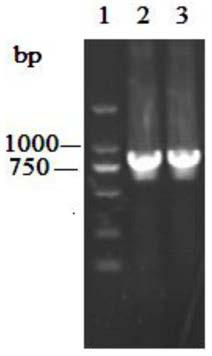

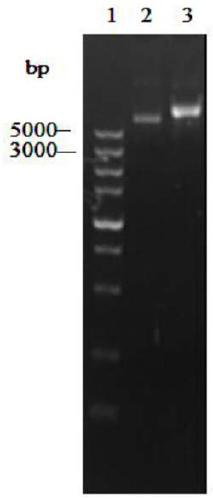

Application of carbonyl reductase gene, engineering bacteria containing the gene and method for catalyzing reduction reaction

ActiveCN105062986BImprove catalytic performanceHas the effect of carbonyl reductionBacteriaMicroorganism based processesHydroxybutyric acidAlcohol

Owner:NANJING TECH UNIV

A method for repairing heavy metal polluted soil by pressure filtration and leaching

InactiveCN104984992BReduce the amount requiredReduce the solid-to-liquid ratioContaminated soil reclamationSlurryFilter press

The invention discloses a method for repairing heavy metal polluted soil by pressure filtration and leaching. The restoration method includes the following steps: S1, crushing and screening the heavy metal-contaminated soil; S2, pulping the crushed and screened soil, and adding acid to fully react with acid-soluble heavy metals in the soil; S3 The above-mentioned fully reacted slurry is subjected to pressure filtration, and the residual acid solution in the capillary pores of the soil filter cake is replaced and diluted by clear water; Heavy metals are fully reacted; S5 puts synergists into the filter press reactor to stabilize the free heavy metals remaining in the soil, and at the same time migrates the tiny heavy metal particles formed during the stabilization process out of the soil, and the filter cake is passed through clean water Rinse, so that the heavy metal ions or compounds or complexes remaining in the filter cake can be further fully washed out with the water flow, and the repaired soil can be obtained. The invention solves the problem in the prior art that the leaching solution remains in the soil during the leaching process and the index of toxic heavy metals leached from the soil exceeds the standard.

Owner:HUNAN MUKUN ENVIRONMENTAL PROTECTION

A simple and efficient method for preparing nano-calcium phosphate

Owner:SOUTHWEST JIAOTONG UNIV

18 f click-mark transferrin receptor targeting polypeptide t7 and its preparation method and application

ActiveCN106084004BThe synthesis steps are simpleIncrease volumeRadioactive preparation carriersX-ray constrast preparationsTumor targetTumor targeting

Owner:GUANGZHOU GENERAL HOSPITAL OF GUANGZHOU MILITARY COMMAND

A smart garbage recycling device for smart home

ActiveCN107600830BAvoid scratchesReduce coefficient of frictionRefuse receptaclesActivated carbonStructural engineering

The invention discloses intelligent garbage recycling equipment for home automation. The intelligent garbage recycling equipment structurally comprises an infrared induction cover, a hinge base, positioning columns, an inner cavity, positioning holes, a base body, U-shaped handles, an antiskid base, symmetric hinges, door planks, sliding grooves, a groove, rails, a handle, a pulling plate, a catalytic activated carbon layer, an inner garbage can, a lifting handle, a liquid crystal operation panel, a cover body, a garbage throwing port and a compression device, wherein the bottom of the base body is fixedly connected with the top of the antiskid base; the positioning holes with equal intervals are uniformly formed in the top surface of the base body; and the positioning holes and the base body are of an integrated structure. The intelligent garbage recycling equipment is provided with the compression device and has the function of compressing the garbage, the volume of the garbage is reduced through physical compression, the density of organic matters is increased so that the reaction concentration can be increased and the biochemical effect can be accelerated, and therefore the decomposition of the organic matters in the garbage can be accelerated, gaps can be generated, the occupied space of the garbage can be reduced, and more garbage can be contained.

Owner:四川携网网络科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com