A<2>/O oxidation ditch process operation control method

A control method and process operation technology, applied in the field of sewage treatment, can solve the problems of water quality detection lag, high design load, incomplete application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

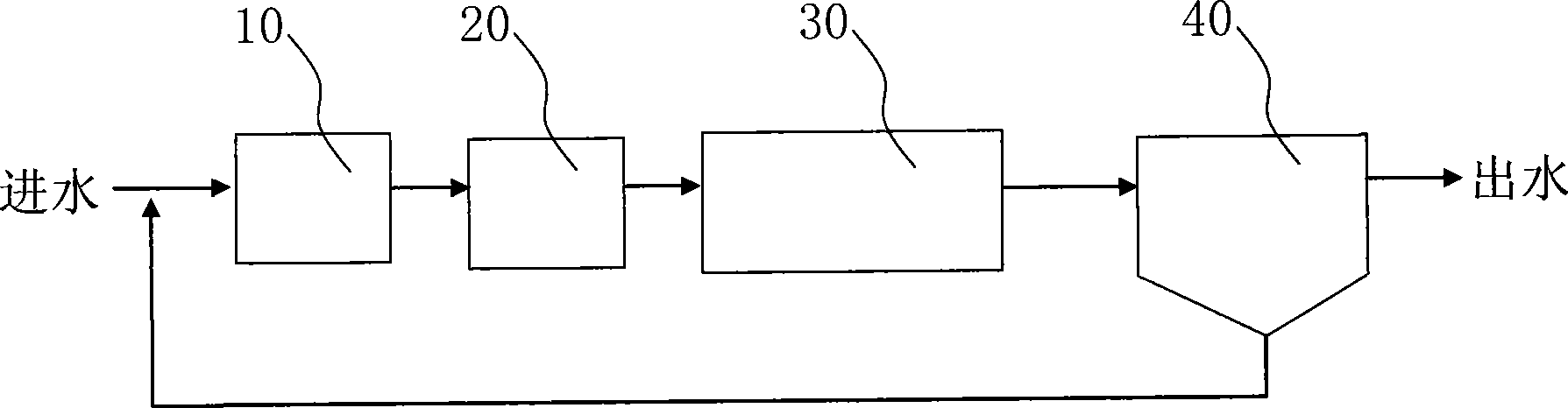

Embodiment Construction

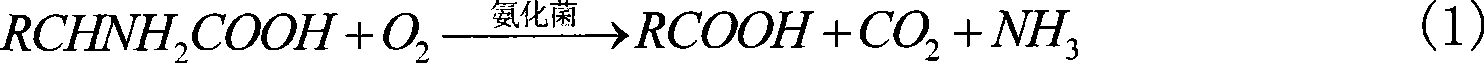

[0011] In untreated sewage, the main forms of nitrogen-containing compounds are: (1) organic nitrogen, such as protein, amino acid, urea, amine compounds and amino compounds; (2) ammoniacal nitrogen (NH 3 , NH 4 + ), generally the former is dominant.

[0012] Traditional biological denitrification is based on the conversion of organic nitrogen into ammonia nitrogen in the secondary biological treatment, through the action of nitrifying bacteria, ammonia nitrogen is converted into nitrite nitrogen and nitrate nitrogen through nitrification, and then denitrifying bacteria are used to denitrify nitrogen Nitrate nitrogen and nitrite nitrogen are converted into nitrogen and released into the atmosphere, so as to achieve the purpose of denitrification from wastewater. Therefore, biological denitrification mainly includes three reactions, namely ammonification reaction, nitrification reaction and denitrification reaction.

[0013] The three reactions are briefly described below:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com