Heat exchange system capable of realizing waste gas recovery

A heat exchange system and waste gas recovery technology, applied in heat exchangers, indirect heat exchangers, heat exchanger types, etc., can solve the problems of less products and low waste gas purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

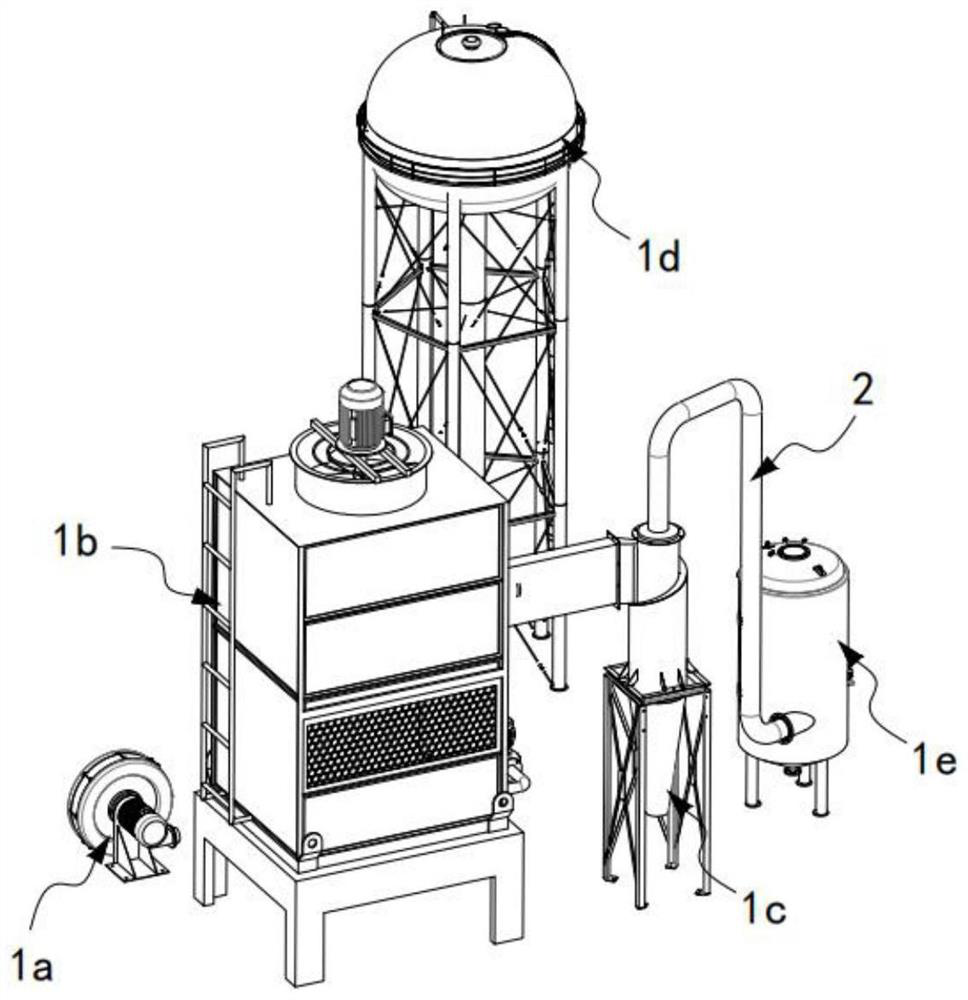

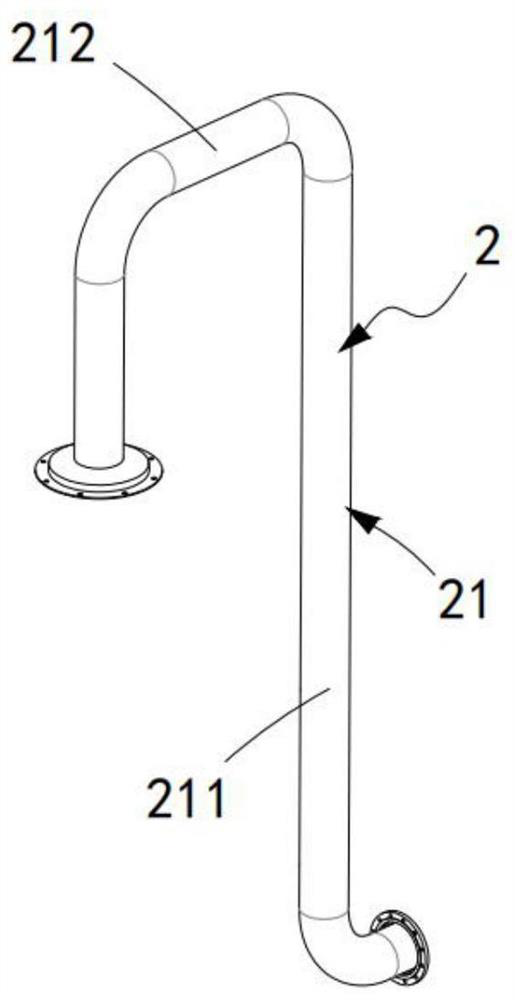

[0068] Such as figure 1 , figure 2 As shown, the exhaust gas recovery heat exchange system includes a fan 1a, a heat exchanger 1b, a rotary separator 1c, a cooling tower 1d, and a gas-liquid mixing tower 1e. The primary purification mechanism 2 arranged in communication with the tower 1e, the secondary purification mechanism 3 arranged in the gas-liquid mixing tower 1e and located at the bottom end, located in the gas-liquid mixing tower 1e and located in the secondary purification mechanism The three-stage purification mechanism 4 above the 3;

[0069] The three-stage purification mechanism 4 controls the switch of the rotary separator air inlet through the first transmission assembly 5 and controls the switching work of the rotary separator liquid outlet a101 through the second transmission assembly 6;

[0070] A purification liquid storage tank is arranged outside the gas-liquid mixing tower 1e, and the purification liquid in the purification liquid storage tank is conti...

Embodiment 2

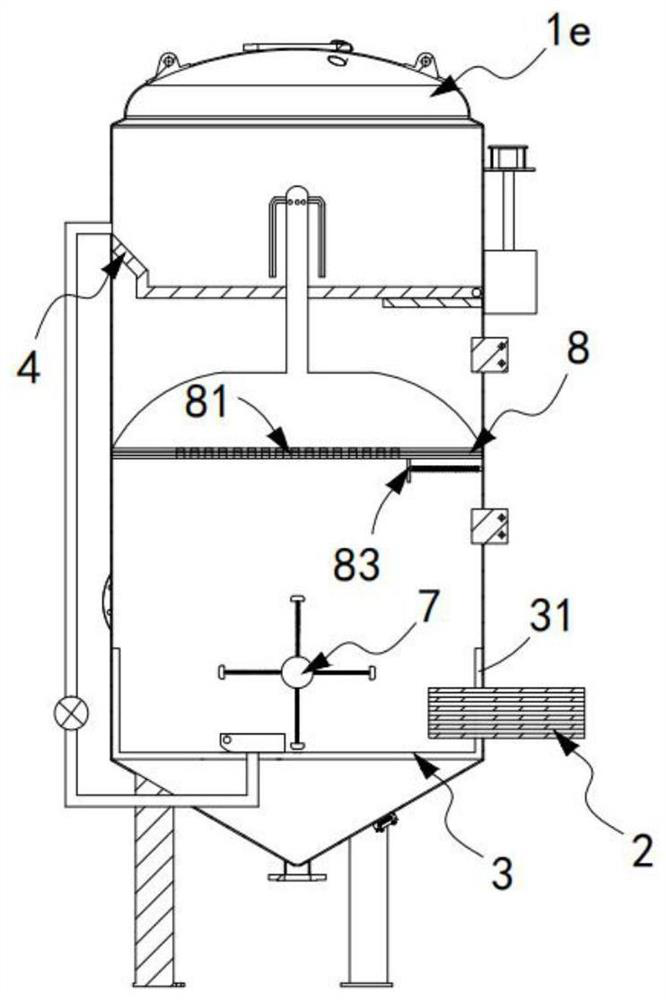

[0099] Such as Figure 7 to Figure 12 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0100] further, such as Figure 7 to Figure 9 As shown, the filter assembly 81 includes:

[0101] A filter plate 811, the filter plate 811 is fixedly arranged on the inner wall of the gas-liquid mixing tower 1e and two groups are arranged up and down;

[0102] A hole blocking plate 812, the hole blocking plate 812 is rotatably arranged between two adjacent filter plates 811;

[0103] A shroud 813, the shroud 813 is fixed above the filter plate 811 and is a hollow structure; and

[0104] A hose 814 , one end of the hose 814 communicates and is fixedly connected with the upper end of the cage 813 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com