Production method and device of 3-(ethylthio)butyraldehyde

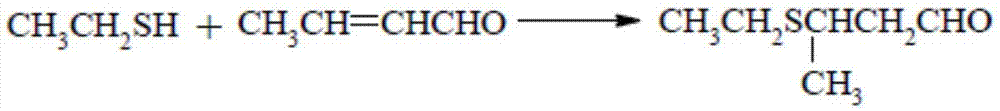

A technology of ethylthiobutyraldehyde and a production method, which is applied in the methods of chemically changing substances by atmospheric pressure, chemical instruments and methods, preparation of sulfides, etc., can solve the problems of large space occupation, low production efficiency, poor sealing, etc. The problem is to prevent the concentrated heat release of the reaction, stabilize the output, and reduce the difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

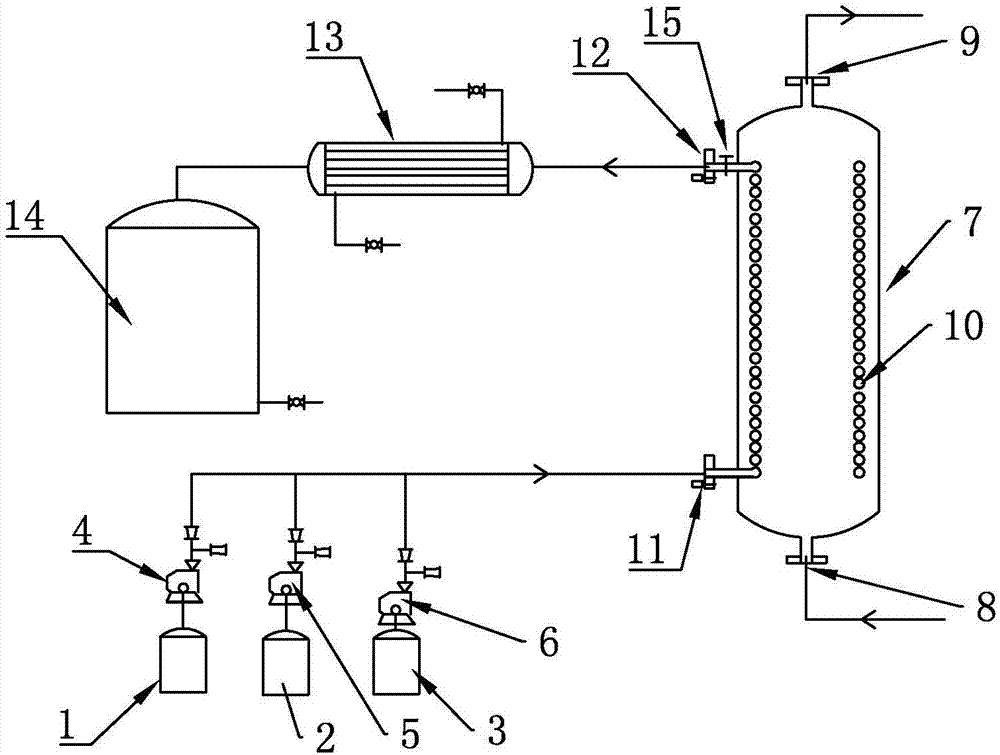

[0039] Embodiment one Production equipment involved in the production of the present invention

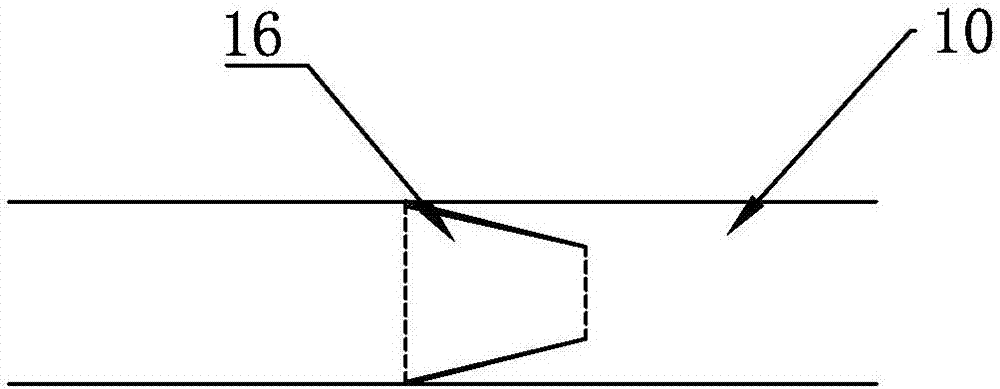

[0040] Such as figure 1 and figure 2 Shown, the production equipment of 3-ethylthiobutyraldehyde comprises ethanethiol storage tank 1, crotonaldehyde storage tank 2 and catalyst storage tank 3; The catalyst metering pump 6 transports the material to the coil reactor 7 for reaction; the heat transfer oil is used for heating during the reaction, and the heat transfer oil enters through the heat transfer oil inlet 8 at the bottom of the coil reactor 7; The heat-conducting oil outlet 9 leads out; the heat-conducting oil is used to heat the material in the coil 10, and the material enters from the material inlet 11 at the bottom of the coil reactor 7, and passes through the material outlet 12 located at the upper part of the coil reactor 7 after reaction Output; after being condensed by the condenser 13, it can be transported to the finished product storage tank 14 for storage; in ...

Embodiment 2

[0042]Crotonaldehyde is passed through crotonaldehyde metering pump 5 with the flow of 87.5 kilograms per hour, and triethylamine is passed through catalyst metering pump 6 with the flow of 2.5 kilograms per hour, and ethanethiol is passed through ethanethiol metering pump 4 with the flow of 77.7 kilograms per hour, Enter the coil reactor 7 and mix evenly, keep the reaction temperature at 30°C, and the residence time in the coil reactor 7 is 25 minutes. The material passes through the back pressure valve 15 on the material outlet 12 to control the reaction pressure of 20 kg. After the reaction, the material passes through The pipeline enters the product storage tank 14 . The content of the finished product reaches 94%, which is directly used for the next reaction. Because the reaction temperature is controlled at 30° C., the reaction speed is slowed down at a lower temperature, the reaction is incomplete, and condensation through the condenser 13 is not required.

Embodiment 3

[0044] Crotonaldehyde is passed through crotonaldehyde metering pump 5 with the flow of 87.5 kilograms per hour, and triethylamine is passed through catalyst metering pump 6 with the flow of 2.5 kilograms per hour, and ethanethiol is passed through ethanethiol metering pump 4 with the flow of 77.7 kilograms per hour, Enter the coil reactor 7 and mix evenly, keep the reaction temperature at 50°C, and stay in the coil reactor 7 for 20 minutes. The material passes through the back pressure valve 15 on the material outlet 12 to control the reaction pressure of 20 kg. After the reaction, the material passes through After the condenser 13 condenses to 30°C, it enters the finished product storage tank 14 . The content of the finished product reaches 95.4%, which is directly used for the next reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com