Production method of EDTA

A production method and technology of ethylenediamine, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as high equipment requirements, pollution sources, and potential safety hazards, reduce side reactions, and increase reaction concentration. , the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

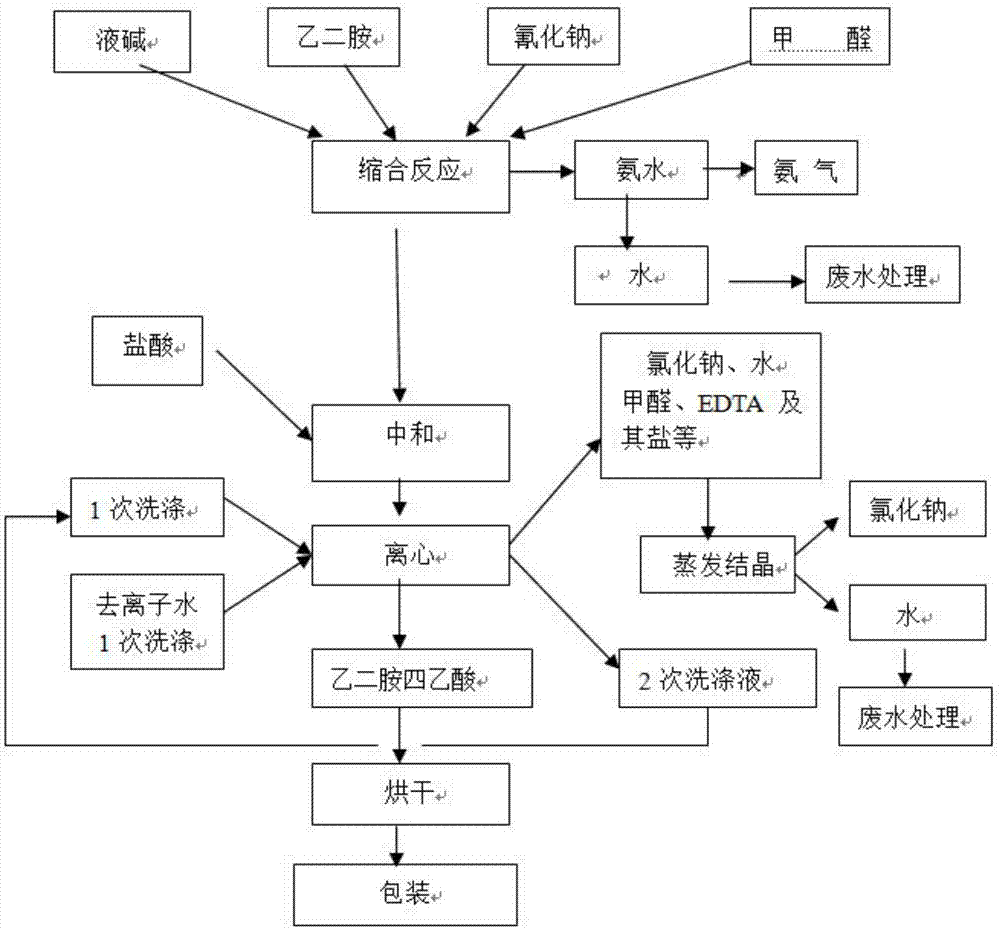

[0019] see figure 1 , a kind of EDTA production method, adopts sodium cyanide, ethylenediamine, formaldehyde and liquid caustic soda to prepare ethylenediaminetetraacetic acid as raw material, comprises the following steps:

[0020] 1) Condensation reaction

[0021] 1.1 Heating condensation reaction

[0022] When feeding for the first time, you must first open the condensation condenser E-9201A-C inlet and return valves, open the water ring vacuum pump P-9203, and open the ammonia gas recovery device. Then start to put ethylenediamine, caustic soda, and sodium cyanide solution into the reaction kettle, start stirring after putting in the specified amount of materials, turn on the material circulation pump P-9208A-C, and then turn on the steam regulating valve FV9206 to increase the temperature, and the amount of steam introduced It is controlled by the temperature of the reactor TIC9201 (the temperature of the reactor increases, the opening of the regulating valve FV9206 dec...

Embodiment 2

[0041] Substantially the same as Example 1, the difference is that in step 1) when the material in the kettle reaches a certain temperature of 88°C, start to add formaldehyde and remaining sodium cyanide solution and step 2) the temperature of centrifugation is 85°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com