Patents

Literature

151 results about "Troxerutin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

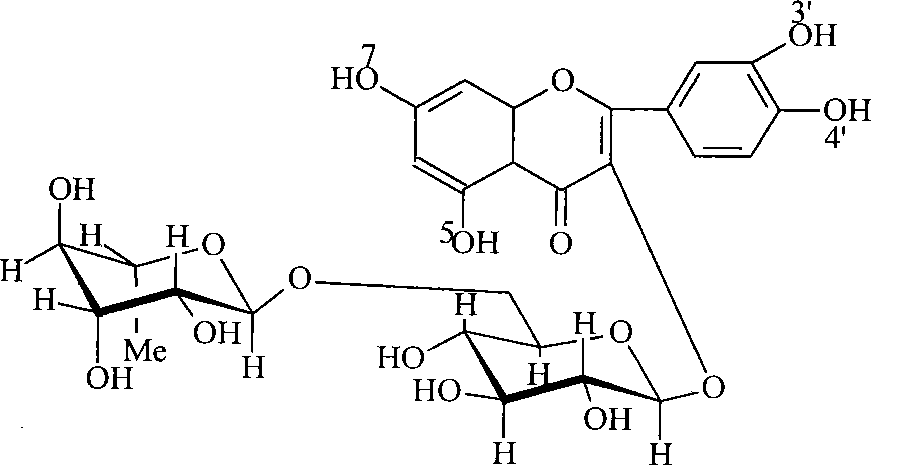

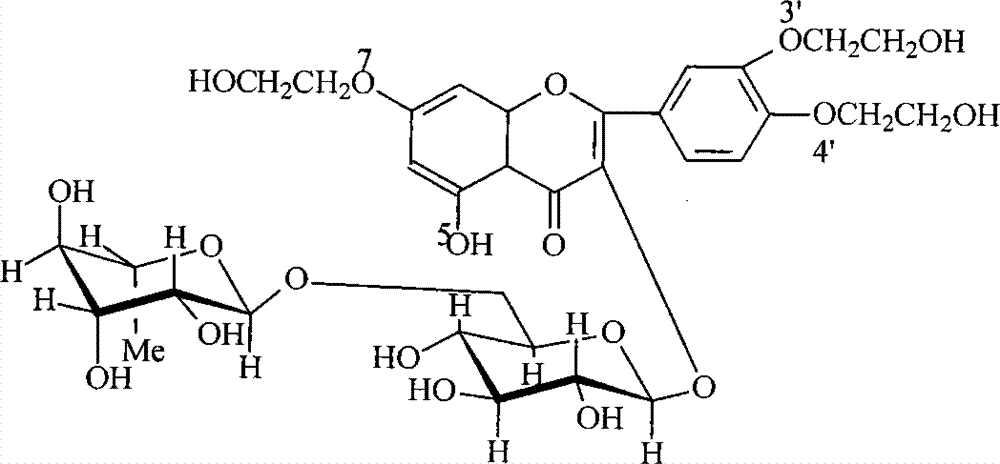

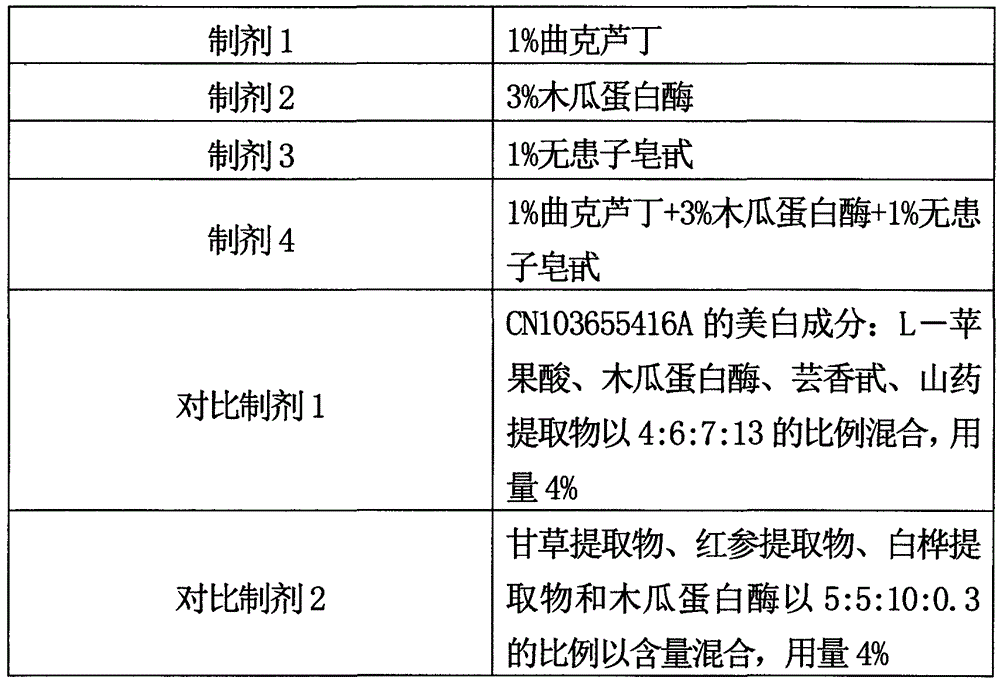

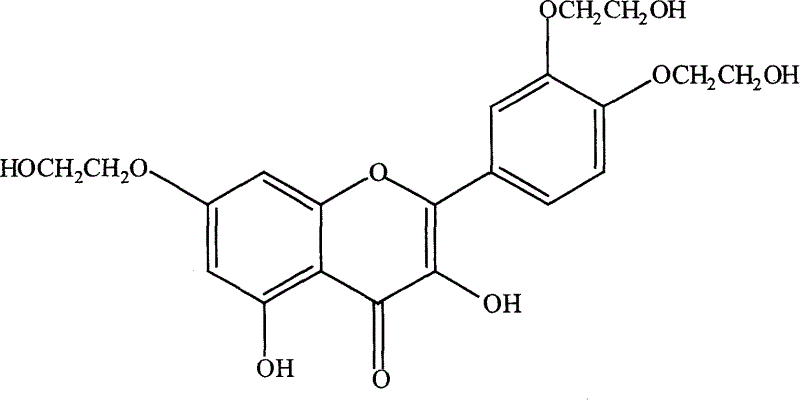

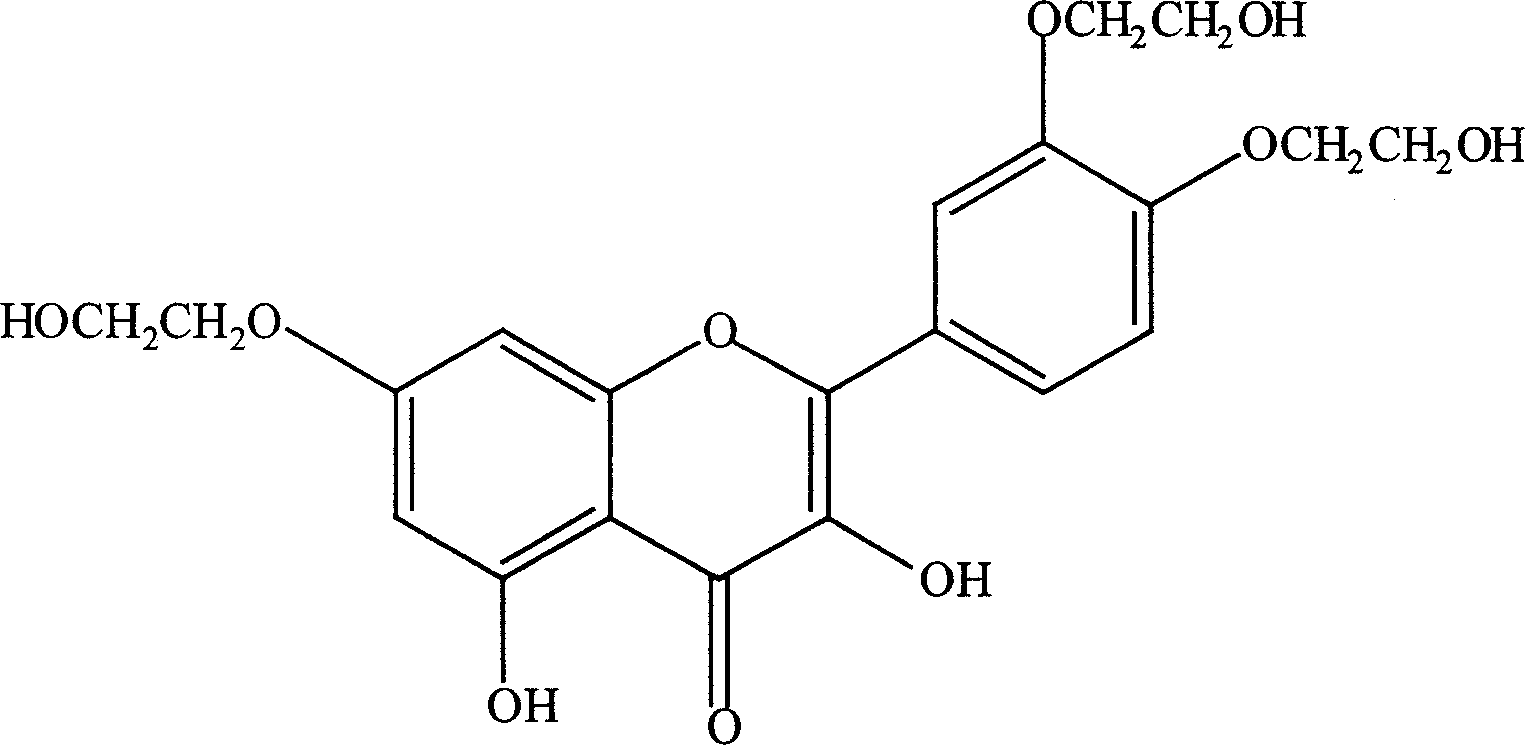

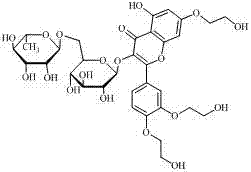

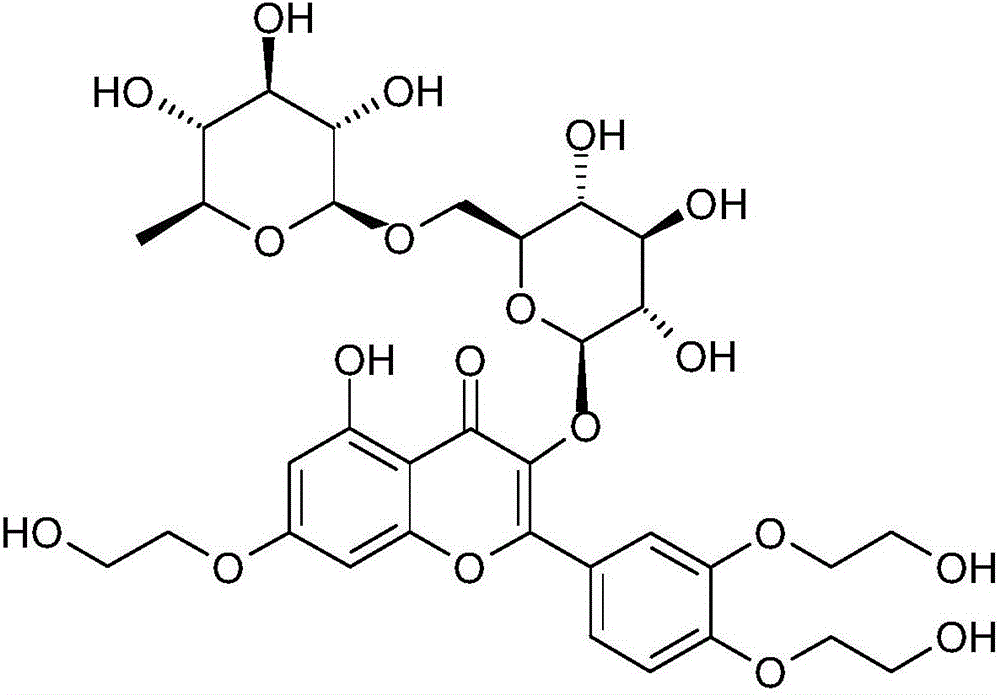

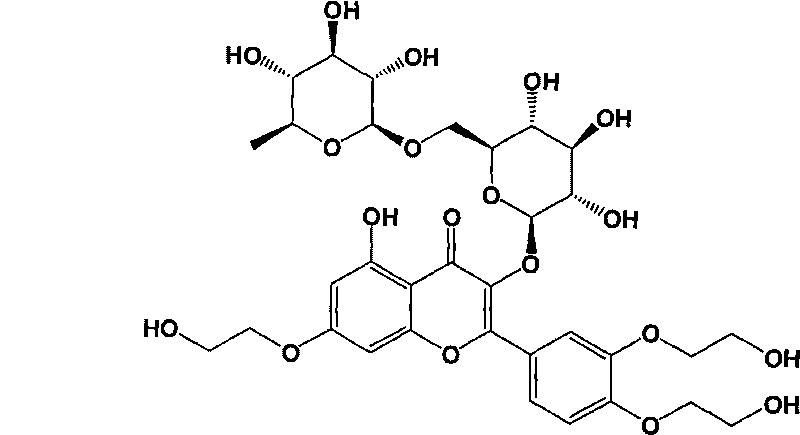

Troxerutin is a flavonol, a type of flavonoid, derived from rutin. It is more accurately a hydroxyethylrutoside. It can be isolated from Sophora japonica, the Japanese pagoda tree. It is used as a vasoprotective.

High content troxerutin medicine and its preparing method

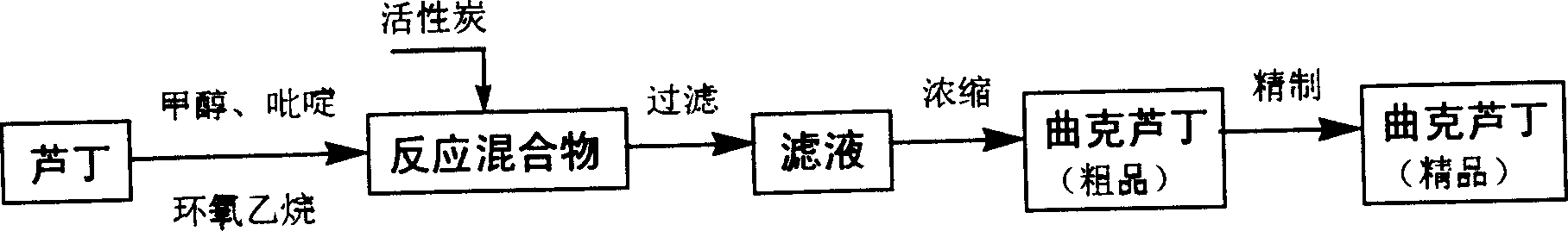

InactiveCN1554353AControl reaction endpointGuaranteed medicinal indicatorsOrganic active ingredientsBlood disorderActive matterRutin

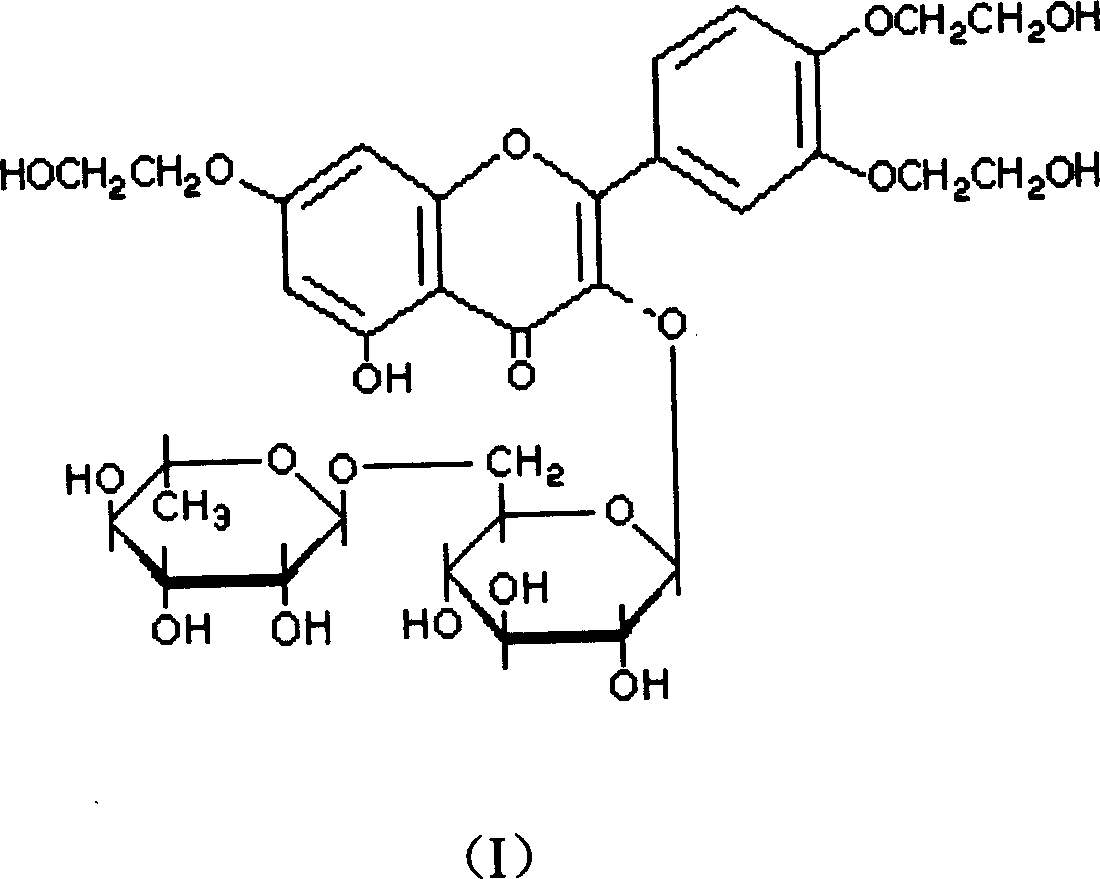

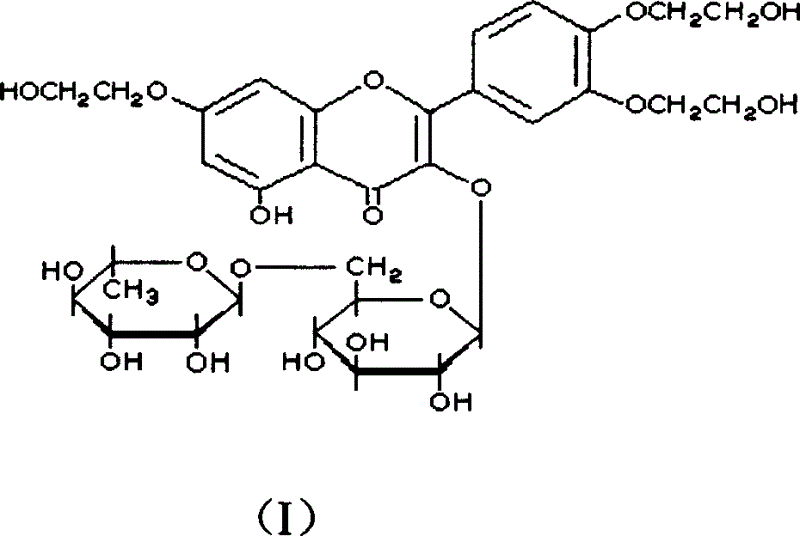

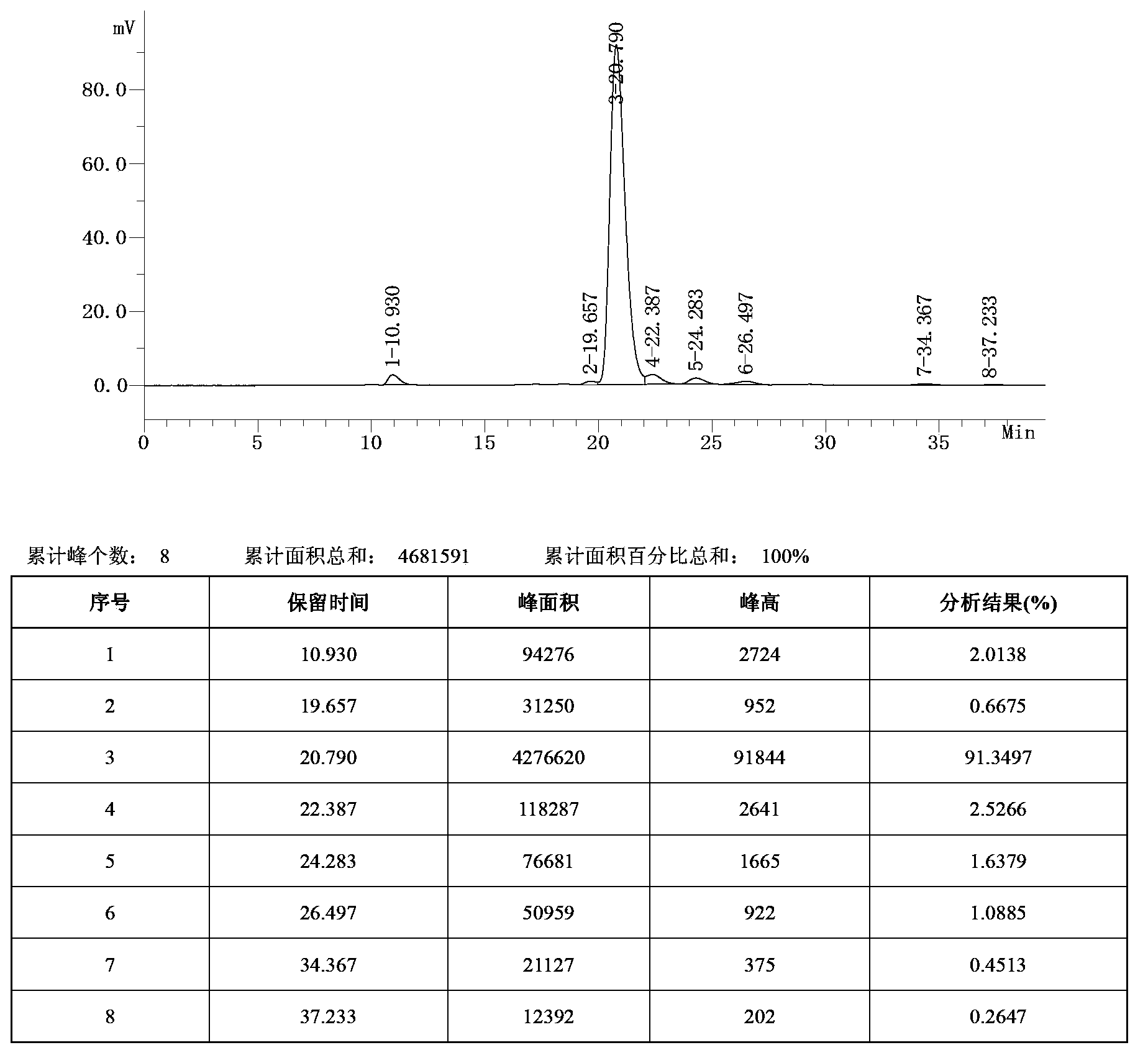

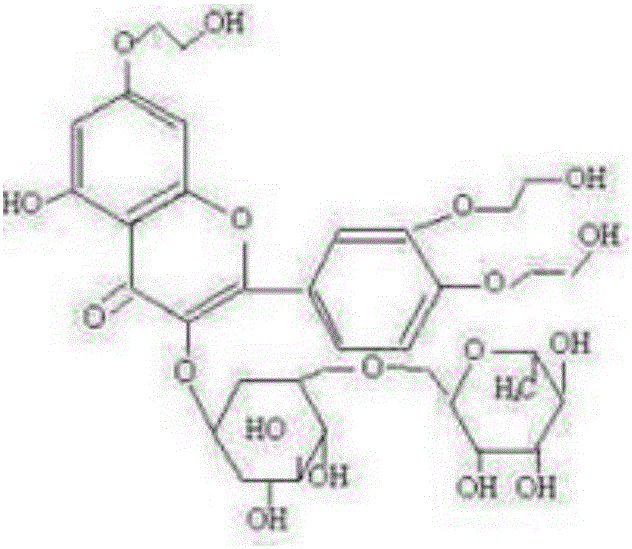

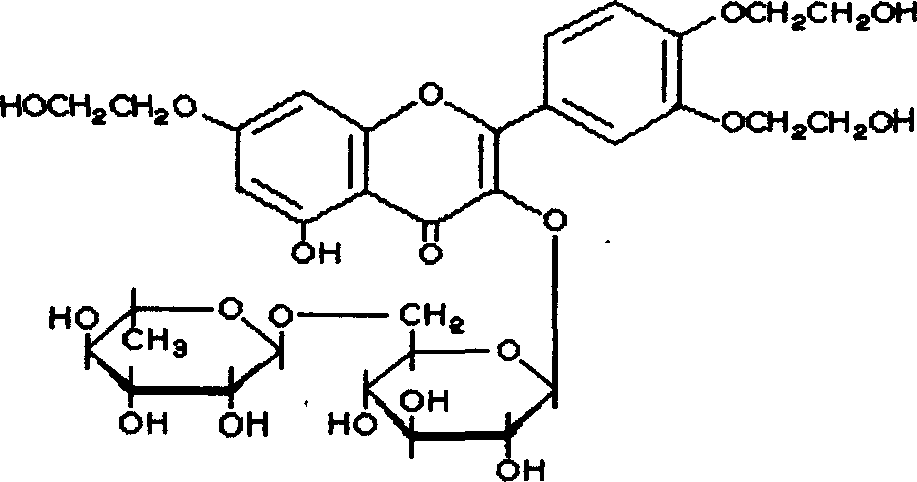

The present invention discloses a troxerutin medicine with content of active matter 3', 4', 7-trihydroxy rutin over 90%. The active matter has molecular expression of C33H42O19 and molecular weight of 742.68. The preparation process includes the reaction stage comprising hydroxyethylation reaction, hot filtering and concentration; and the refining stage comprising heating, cooling, filtering and drying. The preparation process has high yield, low cost, simple and fast operation and high product quality, and is suitable for preparation of different medicine preparation forms.

Owner:SICHUAN XIELI PHARM CO LTD

Preparation method of troxerutin

InactiveCN103113437AHigh purityEffective protectionSugar derivativesSugar derivatives preparationAlkaline waterEthylene oxide

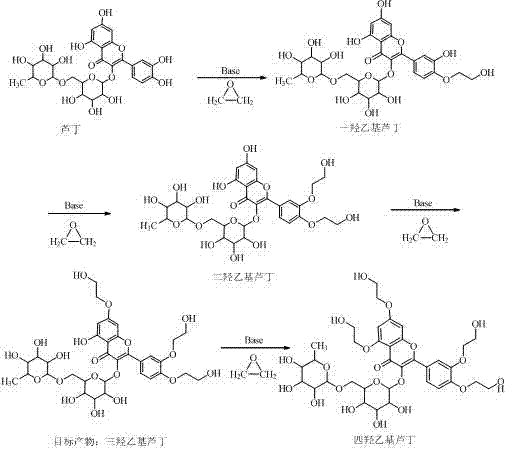

The invention relates to a method for synthesizing troxerutin with high content. According to the invention, hydroxyethyl reaction is implemented on a phenolic hydroxyl group on a rutin flavone skelecton by using ethylene oxide in alkaline water or a mixed water and ethanol solvent. The reaction is implemented through two steps: in the first step, dihydroxyethylrutin and troxerutin (namely trihydroxyethylrutin) are mainly generated, and in the second step, borax is added and serves as a coordination catalyst to protect C5-OH, so that the generation proportion of tetrahydroxyethylrutin acquired from excessive reaction is effectively reduced and the preparation of 3',4',7-tri-beta-hydroxyethylrutin is implemented, wherein the purity of the 3',4',7-tri-beta-hydroxyethylrutin after being purified can reach 90% or higher and the yield of the 3',4',7-tri-beta-hydroxyethylrutin can reach 70% or higher.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for synthesizing 3',4',7-troxerutin

InactiveCN101891784AEasy to controlHigh yieldSugar derivativesSugar derivatives preparationEpoxyEthylene oxide

The invention relates to the field of chemical pharmacy, in particular to a method for synthesizing 3',4',7-troxerutin, and solves the problems that a reaction end point has the characteristics of not easy control, low content, various impurities and the like in a conventional synthesizing method. In the method, rutin reacts with epoxy ethane by taking sodium hydroxide as a catalyst, wherein the weight ratio of the rutin to the epoxy ethane is 1:2 to 1:4; the weight ratio of the rutin to the sodium hydroxide is 100:1-100:1.5; before the pH value of reaction solution reaches 9.5 to 9.6 and when the reaction temperature is between 50 and 80 DEG C, the additive amount of the epoxy ethane per hour is 4 to 5 percent based on the weight the rutin; after the pH value of the reaction solution reaches 9.5 to 9.6 and when the reaction temperature is between 40 and 70 DEG C, the additive amount of the epoxy ethane is 2.5 to 3.5 percent based on the weight of the rutin; and when the pH value of the reaction solution is 9.5 to 9.6, a weak acid salt is added. The content of the troxerutin is stabilized over 78 percent while an obtained product has very few impurities, so that national medicament standards can be reached without refining; and therefore, method improves the yield by 125 to 130 percent, reduces production cost, and is suitable for industrial production.

Owner:山西津华晖星制药有限公司

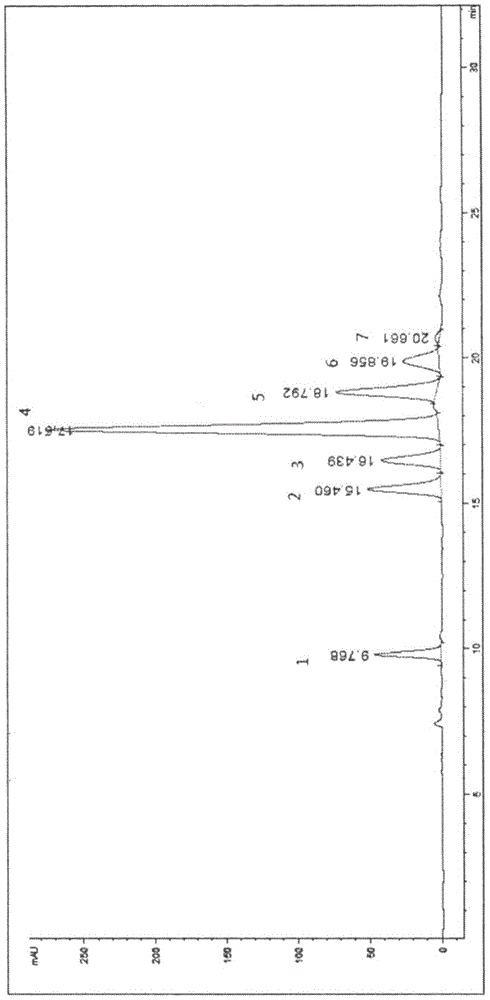

Preparation method of troxerutin

The present invention relates to a preparation method of trihydroxyethyl rutoside. In the method, rutin is firstly prepared into 7-monohydroxyethyl rutoside in a content of greater than or equal to 98% by weight, and then 7-monohydroxyethyl rutoside is hydroxyethylated continuously to obtain troxerutin having the impurity of non hydroxyethylated rutoside derivatives less than 2%. The content of 7,3',4'-trihydroxyethyl rutoside in the troxerutin is above 80% by weight. The product is further refined, and the 7,3',4'-trihydroxyethyl rutoside in a content of greater than or equal to 98% by weight could be obtained.

Owner:JINAN XINLITE TECH

Efferverscent tablets containing troxerutin and their preparation

InactiveCN1613444ADisintegrates quicklyEasy to takeOrganic active ingredientsPill deliveryEffervescent tabletDisease

An effervescent tablet for treating cerebrovascular disease is prepared from troxerutin, pharmacologically acceptable acid-base pairs, filler, adhesive, lubricant, sweetening agent and flavouring through proportional mixing, punching to become wafers, granulating, mixing and tabletting. Its advantage is quickly taking its effect.

Owner:邱学良

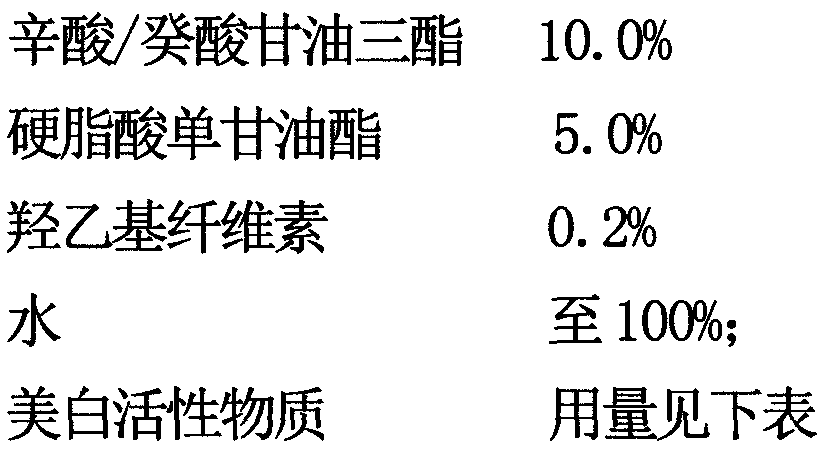

Skin whitening and fleck removing skin-care composition

The invention relates to skin whitening and fleck removing skin-care cosmetic composition. The composition can prevent excessive generation of melanin and realizes effects of skin whitening, fleck removing and skin brightening. Specifically, the skin whitening and fleck removing skin-care cosmetic composition contains troxerutin, sapindoside and papain. The composition realizes the effects of skin whitening, blackspot removal and skin brightening through synergistic effects of troxerutin, sapindoside and papain.

Owner:GUANGZHOU GAOZI COSMETICS CO LTD

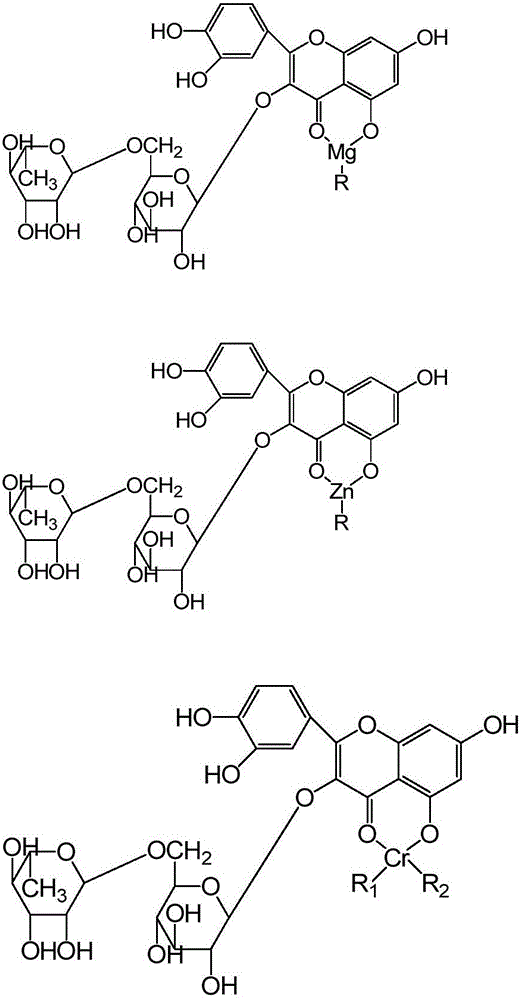

Compound for treating cardiocerebral vascular disease and its preparing method and its use in pharmaceutical field

The compound for treating cardiac and cerebral vascular diseases is triethoxyl quercetin. The preparation process includes the following steps: A. hydrolyzing Troxerutin as material with beteroside hydrolase through stirring at 30-70 deg c for 3-5 days; and B. filtering, water washing the precipitate and drying. Triethoxyl quercetin has pharmacological activity obviously superior to Troxerutin. Different forms of medicine may be prepared with the compound as active component for preventing and treating cardiac and cerebral vascular diseases and cerebral apoplexy.

Owner:车庆明

Medicinal composition, its preparation method and its use

ActiveCN1589811ARegulate and improve brain metabolismGood clinical effectPharmaceutical delivery mechanismUnknown materialsDiseaseThrombus

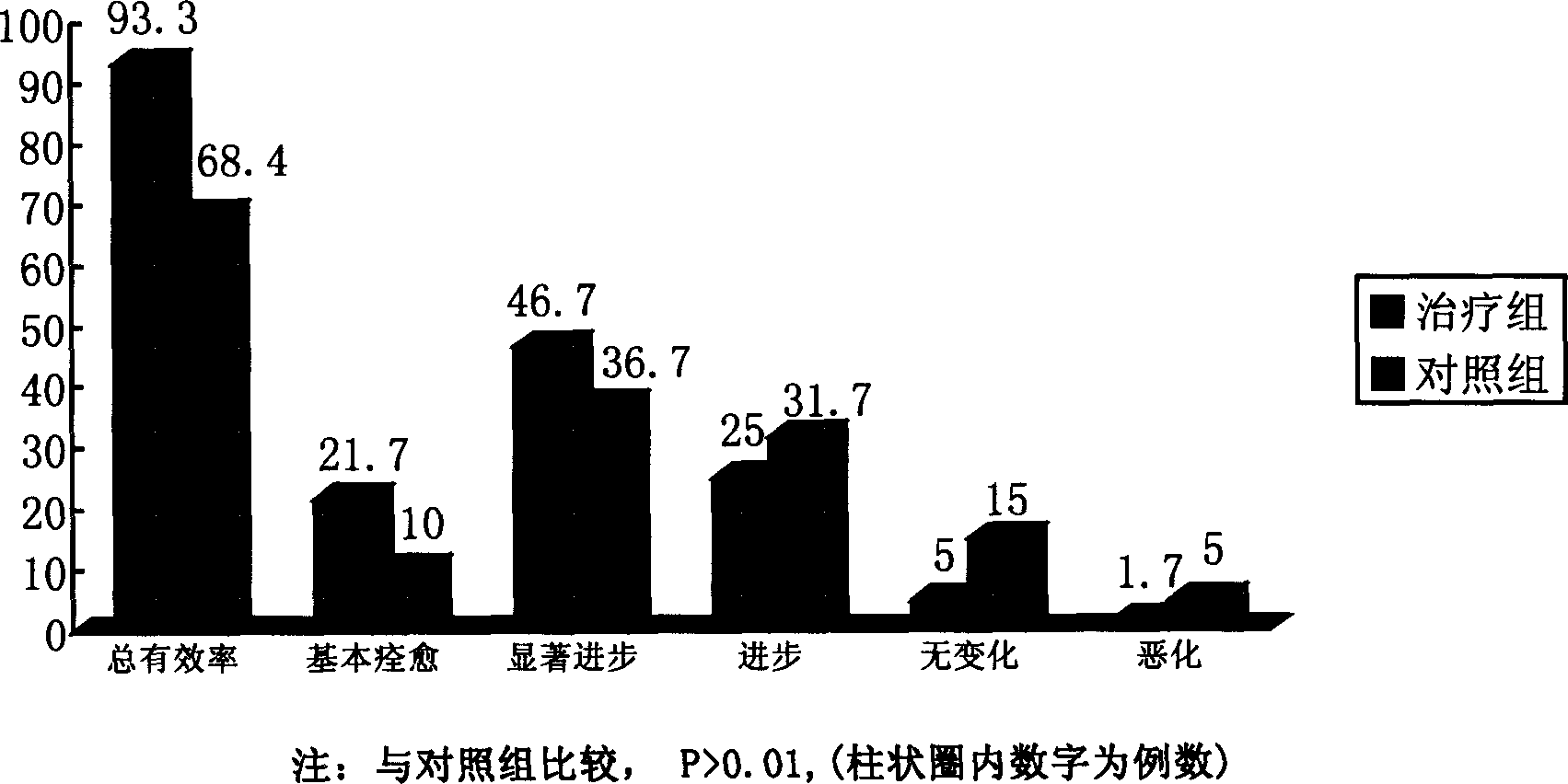

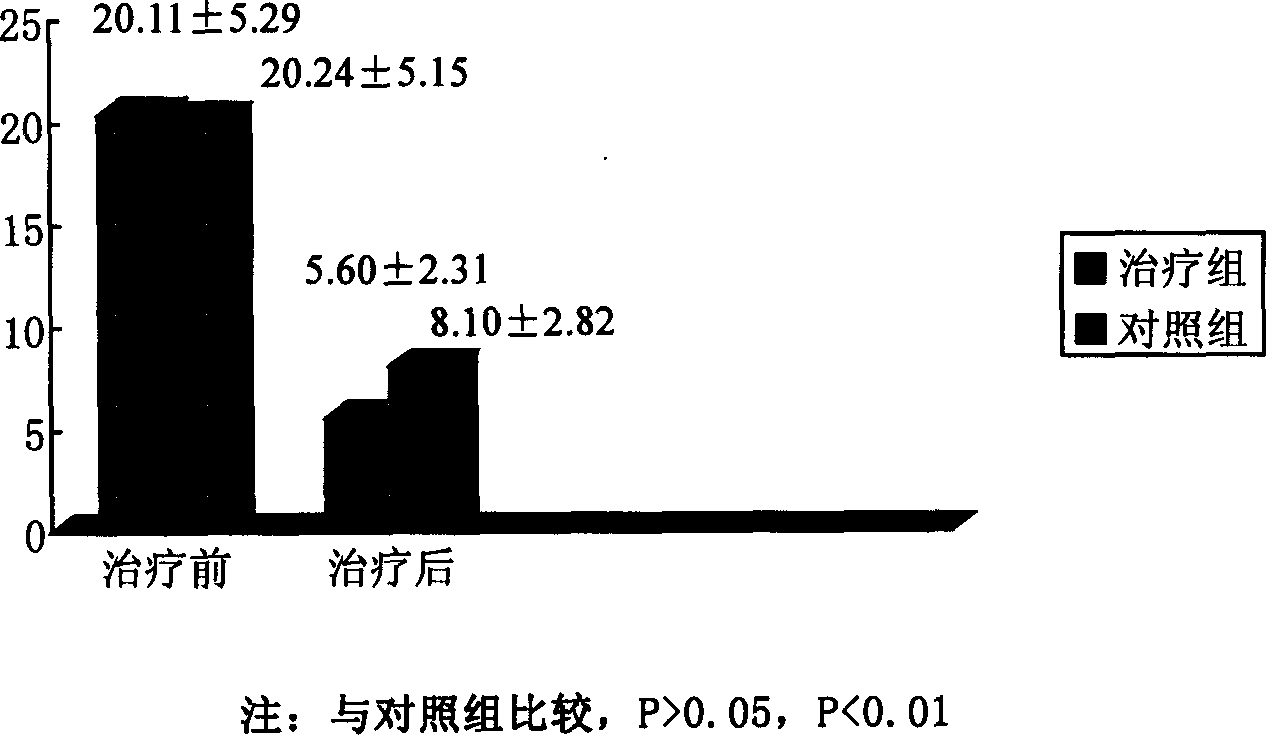

The invention discloses a medicinal composition containing weinaolutong (7, 3', 4'-troxerutin) obtained by hydroxyethylating eldrin and brain extract which is extracted form brain tissue of mammalian except human. The medicinal composition contains 1 to 1000 parts of weinaolutong, by weight, and the weight of the weinaolutong in the medicinal composition is 0.1 to 200 times bigger than total nitrogen content in the brain extract. The invention also discloses preparation method and use of the medicinal composition. The medicinal composition can restrain platelet agglutination thereby preventing thrombosis, and can regulate and improve brain supersession, and is used for treating acute and chronic cerebrovascular disease and sequela such as brain dysfunctional caused by craniocerebral trauma and cerebrovascular disease; and can also be used for treating occlusive syndrome, arteriosclerosis, thrombosis phlebitis, capillary bleeding and dropsy caused by elevation of vascular permeability.

Owner:JILIN SIHUAN PHARM CO LTD

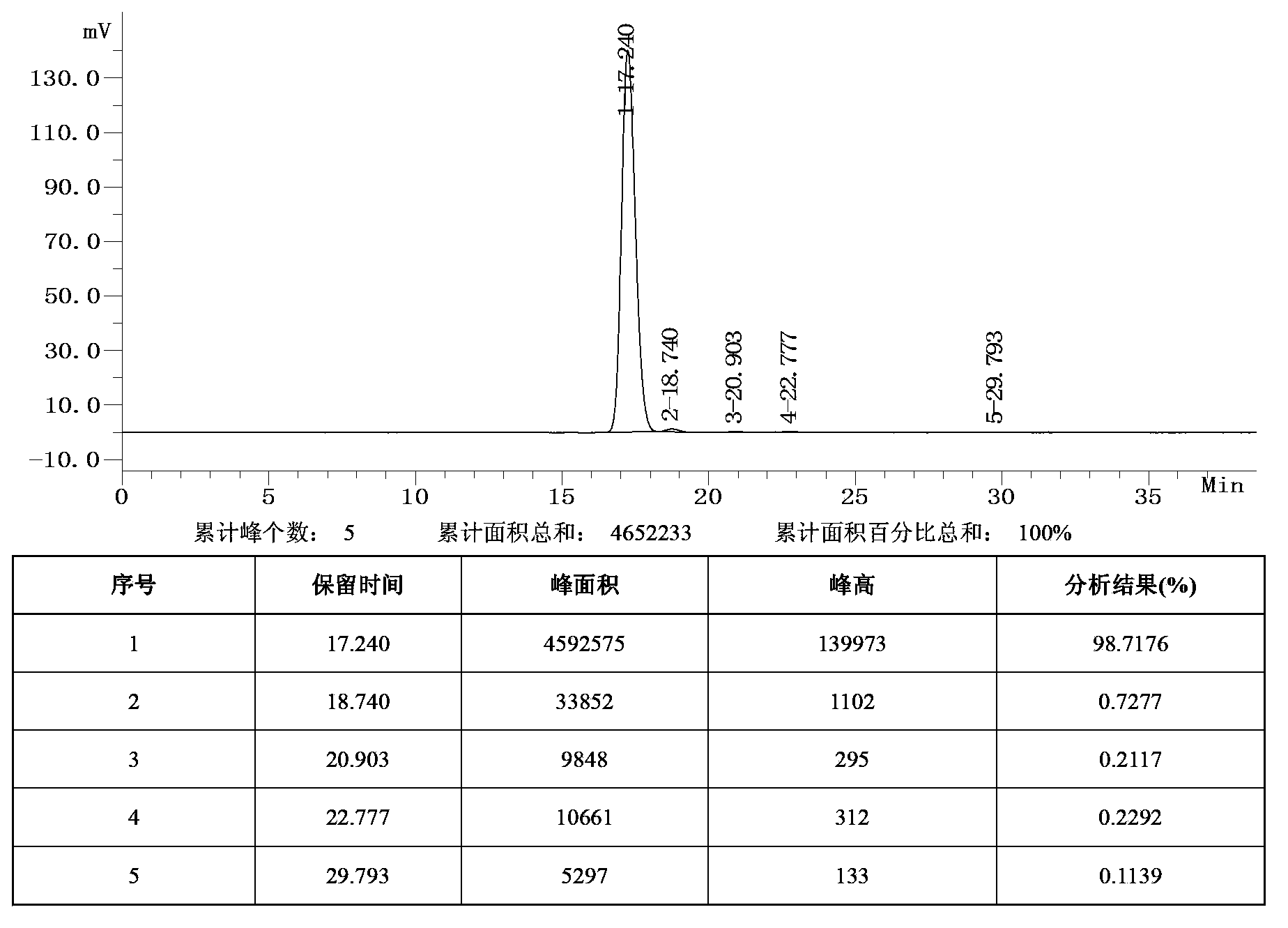

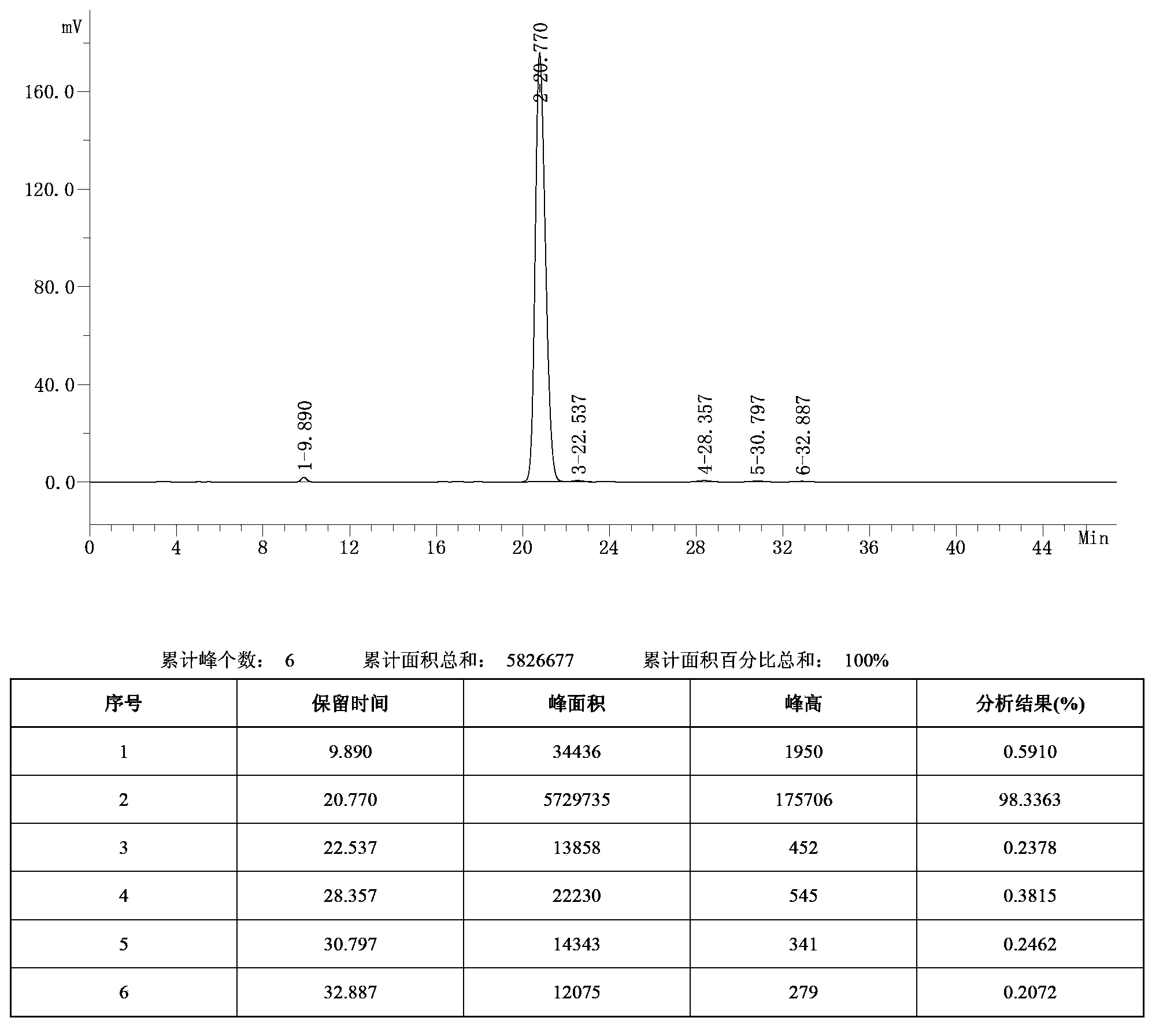

Preparation method of high-content troxerutin

ActiveCN106892950ANo toxicityImprove responseSugar derivativesSugar derivatives preparationSolventRutin

The invention discloses a preparation method of high-content troxerutin and belongs to the technical field of medicinal chemistry. According to the technical scheme, the preparation method of the high-content troxerutin comprises the specific steps that a coarse raw material product rutin is purified and refined to obtain high-content rutin higher than 99.0%; the high-content rutin reacts under the catalytic action of a catalyst natural polymer sodium alginate to prepare troxerutin; the troxerutin is purified to obtain the high-content troxerutin with the content higher than 98.0%. The preparation method refines the raw material rutin, water is adopted as a solvent in the refining process, the method is green and environmentally friendly, and the purity of the obtained rutin can be up to 99.0% or above. In addition, during troxerutin preparation, the natural polymer sodium alginate and appropriate reaction condition are adopted to make reaction reach the best level, and the high-content troxerutin crude drug with content higher than 98.0% can be obtained only by simply purifying the obtained product.

Owner:HENAN NORMAL UNIV

Troxerutin powder injection

InactiveCN1586467AImprove stabilityQuality assurancePowder deliveryOrganic active ingredientsHydrolysateFreeze-drying

The troxerutin powder for injection includes troxerutin 2-100 wt% and excipient 0-98 wt%, and the excipient is one of mannitol, lactose, glycine, sorbic alcohol, low molecular weight dextran, glucose, cane sugar and hydrolysate gel. It is bacteria-free powder or bacteria-free freeze dried produce. The present invention is used in treating ischemic cerebral vascular diseases, central retinitis, arteriosclerosis, thrombotic phlebitis, varicosity, etc. and has the advantages of stability, fast dissolution in water and high safety.

Owner:广东阳江制药厂有限公司

Medicinal composition, and its preparing method and use

ActiveCN1813797AActivate and promote synthesisTo promote metabolismNervous disorderUnknown materialsNervous systemThrombus

The present invention discloses a medicine composition. Said medicine composition contains troxerutin obtained by making rutin undergo the process of hydroxyethylation, brain extract extracted from brain tissue of mammal except for human being and ganglioside extracted from brain tissue of mammal except for human being. Said invention also provides the concrete mixing ratio of the above-mentioned three components, and provides its preparation process and application.

Owner:吉林天成制药有限公司

Troxerutin for injection and method for preparing the same

InactiveCN1524521AGood water solubilityImprove bioavailabilityPowder deliveryOrganic active ingredientsFreeze-dryingBiomedical engineering

Troxerutin for injection and method for preparation, wherein troxerutin (injection level) powder as a medicinal raw material is dissolved in a definite quantity of water for injection to obtain sterility solution, the freeze dried injection is finally prepared through cryodesiccation, or the prepared sterility solution can be condensed, dried (or not) to obtain the freeze dried injection through nano techniques.

Owner:崔彬

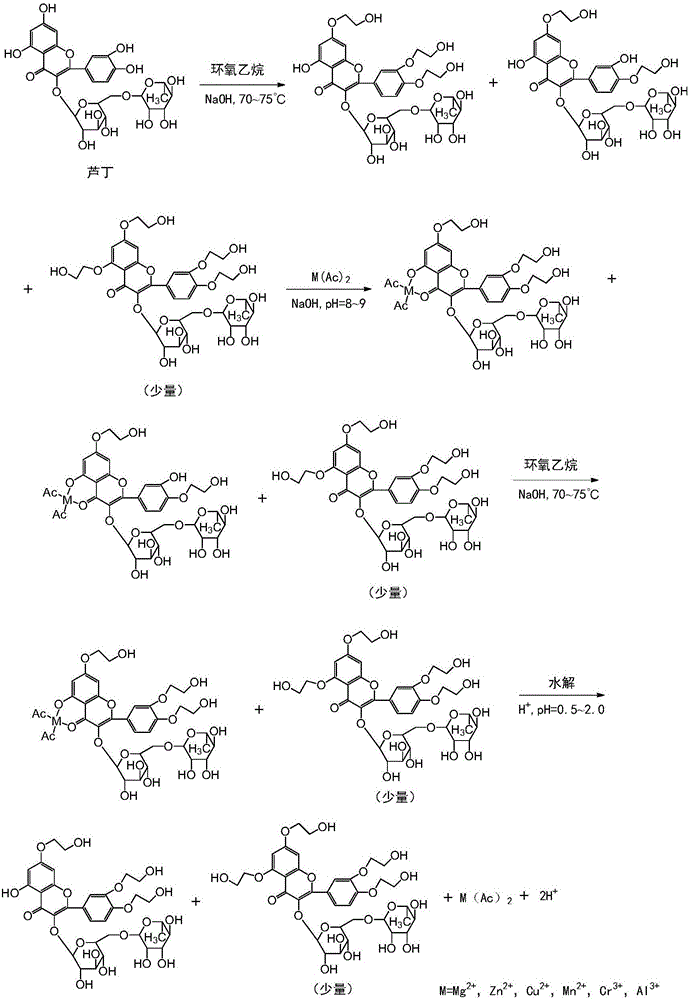

High-purity troxerutin and preparation method thereof

ActiveCN106632548AHigh purityMaximize your conversion rateSugar derivativesSugar derivatives preparationOrganic synthesisOrganic chemistry

The invention provides high-purity troxerutin and a preparation method thereof, and relates to the technical field of medicinal chemistry and organic synthetic chemistry. The preparation method comprises a front etherification step, a complexation step, a post etherification step and a post-treatment step. The preparation method of the high-purity troxerutin is relatively low in cost, the high-purity troxerutin can be prepared and the method is suitable for industrial production.

Owner:HEFEI LIFEON PHARMA

Troxerutin injection and its preparation method

InactiveCN1520812AOrganic active ingredientsPharmaceutical delivery mechanismOsmotic pressureVascular disease

The present invention is one kind of transfused Troxerutin fluid and its preparation process. The transfused Troxerutin fluid includes Troxerutin and non-sodium chloride and non-glucose osmotic pressure regulator of sorbic alcohol, fructose, mannitol or lactose. The transfused Troxerutin fluid preparation accords with the clinical requirement for cerebral vascular disease in limiting sugar and salt intaking amount, and has the osmotic pressure regulating effect the same as that of transfused fluid containing glucose in 5 % or sodium chloride in 0.9 %.

Owner:四川中方制药有限公司

Compound coenzyme Q10 medicine prepn and its prepn process and application

InactiveCN101019854AGood lookingQuality improvementOrganic active ingredientsPeptide/protein ingredientsCoenzyme A biosynthesisHeart disease

The present invention is one kind of compound coenzyme Q10 medicine preparation and its preparation process and application. The compound coenzyme Q10 medicine preparation is prepared with coenzyme Q10 and one or two of troxerutin, inosine, ATP, glyceryl fructose, coenzyme A, amino acid, nicholin and vitamins. It is used mainly for improving energy metabolism, assisting treatment of cardiac and cerebral vascular diseases, such as ischemic heart disease, senile myocardial sclerosis, etc, and promoting the synthesis of ATP.

Owner:BEIJING QI YUAN YI DE PHARMA RESEARCH CENTER

Method for preparing troxerutin by adopting self-suction type stirred autoclave

ActiveCN104478972ASimplify dosing stepsFully contactedSugar derivativesSugar derivatives preparationFiltrationSolvent

The invention discloses a method for preparing troxerutin by adopting a self-suction type stirred autoclave. The method comprises the following steps: adding raw materials namely rutin, ethylene oxide, a solvent namely methanol and a catalyst namely natural weakly-alkaline high-molecular compound chitosan into a self-suction type stirred autoclave, starting a digital control instrument, setting a temperature to be 70-90 DEG C, regulating a voltage to be 100V, setting a rotating speed to be 1000r / min, stirring and heating to reach a set temperature, and reacting for 3-6 hours; and stopping stirring after reaction is ended, rapidly cooling by using cold water, shutting down the digital control instrument, opening a reaction kettle, pouring out reaction liquid, adjusting a pH value of the poured reaction liquid to be 5-6 by using hydrochloric acid, performing suction filtration, adding a crystal seed into the reaction liquid subjected to suction filtration, standing for later crystallization, and filtering to obtain a product namely troxerutin. According to the method disclosed by the invention, the reaction raw materials are integrally added into the self-suction type stirred autoclave, so that material feeding steps can be simplified; and the adopted catalyst is natural weakly-alkaline high-molecular compound chitosan, so that the raw material is wide in source, and is natural, non-toxic and weakly-alkaline, and side reactions such as hydrolysis, oxidation and the like caused by strong alkaline catalysis can be avoided.

Owner:HENAN NORMAL UNIV

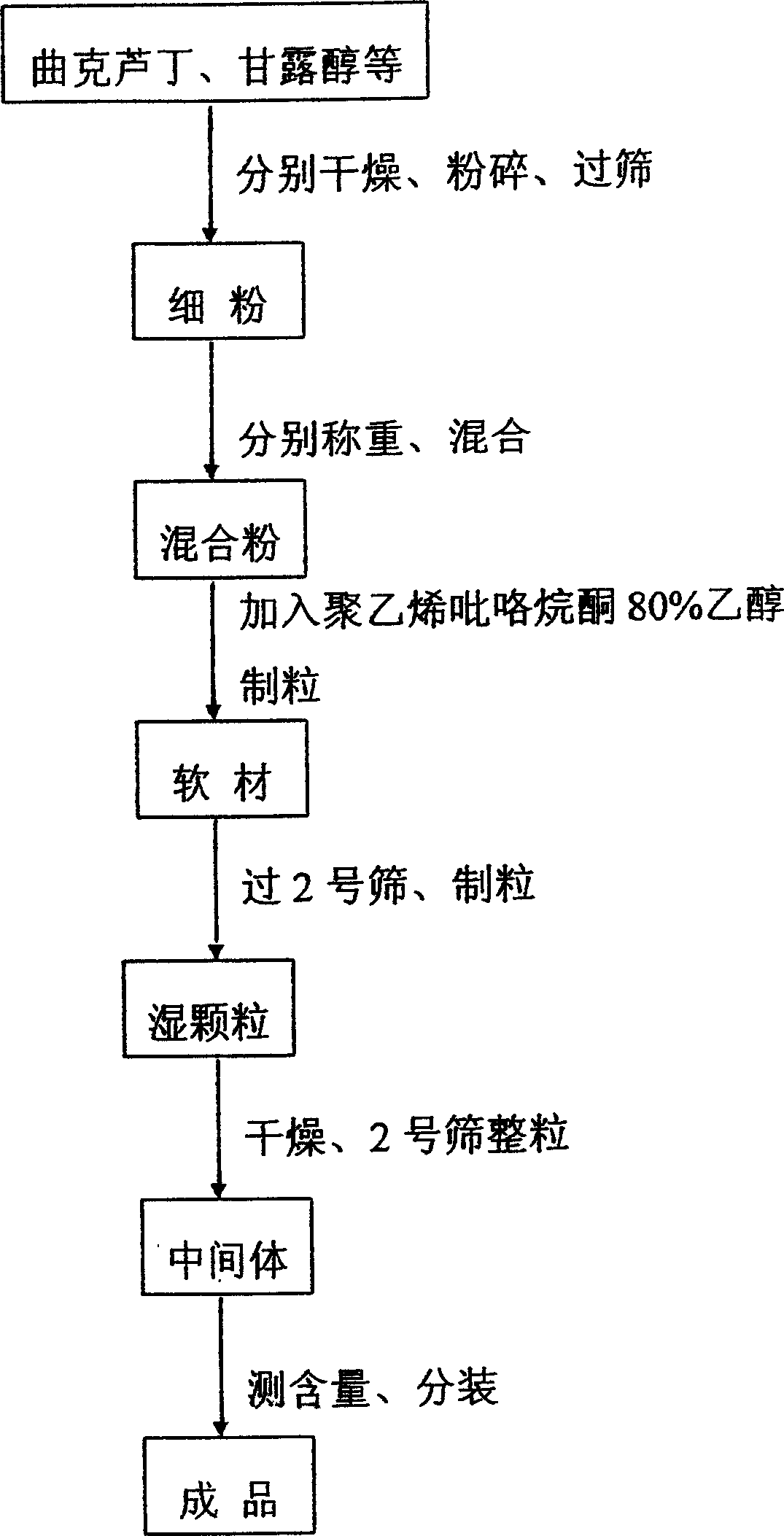

Quke rutin granule agent and its preparation method

InactiveCN1555792AEasy to takeFast absorptionOrganic active ingredientsGranular deliveryMANNITOL/SORBITOLMedicine

A granular troxerutin for improving microcirculation and treating venous insufficiency and pile is prepared from troxerutin, sweetening agent, mannitol and polyvinyl pyrrolidone through drying, pulverizing, sieving, proportionally mixing, and granulating. Its advantage is high curative effect.

Owner:SICHUAN XIELI PHARM CO LTD

Method for purifying troxerutin from troxerutin industrial decoction dreg

InactiveCN105669802AMeet specificationsSimple and fast operationSugar derivativesSugar derivatives preparationChromatographic columnTroxerutin

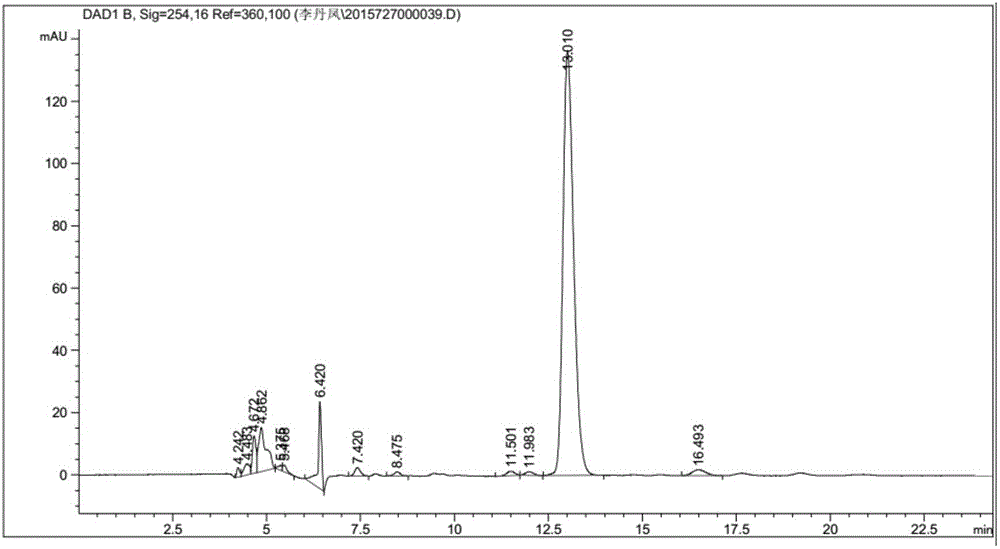

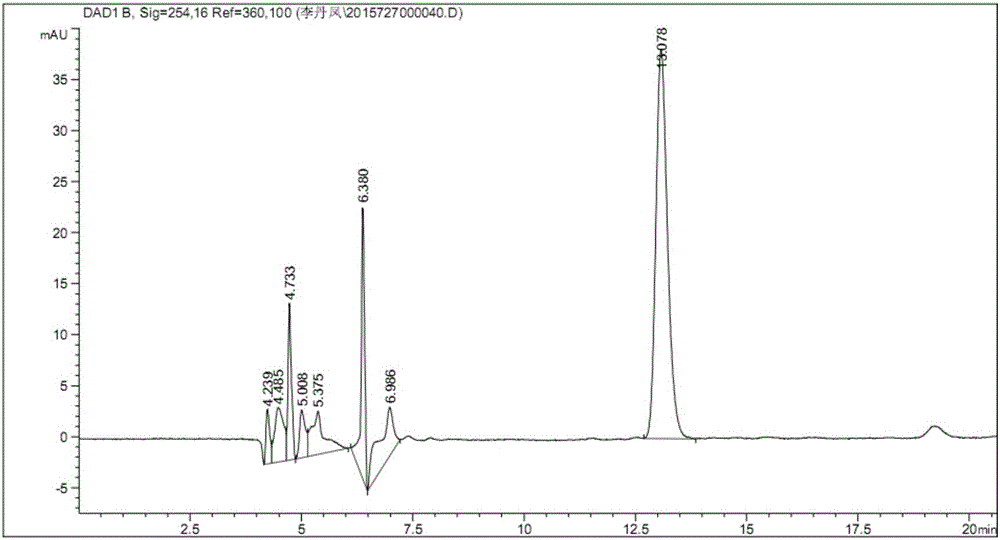

The invention provides a method for purifying troxerutin from troxerutin industrial decoction dreg. The method comprises the steps that a separated material is pretreated and loaded into a chromatographic column; the troxerutin industrial decoction dreg is dissolved with water, stands and is filtered; filter liquor is sampled, adsorbed and eluted, eluant is concentrated and dried to obtain troxerutin, the content is 80% (HPLC detection), the recovery rate is 80%, and an obtained product meets the oral liquid standard of Chinese pharmacopoeia in 2015 version. Waste resources of synthetic drugs are effectively utilized, regeneration value of troxerutin is improved, and the method is fast, simple and suitable for industrialized production, and has an application prospect in the aspect of recycling troxerutin waste liquor.

Owner:SHANXI UNIV

Composition with blue-ray resistance and repair efficacy and preparation method and application thereof

ActiveCN110403871ATo achieve the role of wound repairImprove microcirculationCosmetic preparationsToilet preparationsCentella asiatica extractHypopigmentation

The invention discloses a composition with blue-ray resistance and repair efficacy and a preparation method and application thereof. The composition with blue-ray resistance and repair efficacy includes the following ingredients (by weight): 1-5 parts of troxerutin, 20-45 parts of a gotu kola extract, and 20-50 parts of a selaginella extract. The invention also provides a stock solution containingthe above composition with blue-ray resistance and repair efficacy. Tests prove that the composition with blue-ray resistance can effectively resist damage of blue rays to skin cells, improve rough skin and repair damaged skin cells so as to achieve the effects of delaying skin aging and reducing skin chromatosis. The three ingredients in the composition have significant blue-ray resistant and repairing synergism, have mild nature and high safety, and will not cause skin irritation.

Owner:BEIHAO STEM CELL & REGENERATIVE MEDICINE RES INST CO LTD

Method for synthesizing 3',4',7-troxerutin

InactiveCN101891784BEasy to controlHigh yieldSugar derivativesSugar derivatives preparationEpoxyPtru catalyst

The invention relates to the field of chemical pharmacy, in particular to a method for synthesizing 3',4',7-troxerutin, and solves the problems that a reaction end point has the characteristics of not easy control, low content, various impurities and the like in a conventional synthesizing method. In the method, rutin reacts with epoxy ethane by taking sodium hydroxide as a catalyst, wherein the weight ratio of the rutin to the epoxy ethane is 1:2 to 1:4; the weight ratio of the rutin to the sodium hydroxide is 100:1-100:1.5; before the pH value of reaction solution reaches 9.5 to 9.6 and when the reaction temperature is between 50 and 80 DEG C, the additive amount of the epoxy ethane per hour is 4 to 5 percent based on the weight the rutin; after the pH value of the reaction solution reaches 9.5 to 9.6 and when the reaction temperature is between 40 and 70 DEG C, the additive amount of the epoxy ethane is 2.5 to 3.5 percent based on the weight of the rutin; and when the pH value of the reaction solution is 9.5 to 9.6, a weak acid salt is added. The content of the troxerutin is stabilized over 78 percent while an obtained product has very few impurities, so that national medicament standards can be reached without refining; and therefore, method improves the yield by 125 to 130 percent, reduces production cost, and is suitable for industrial production.

Owner:山西津华晖星制药有限公司

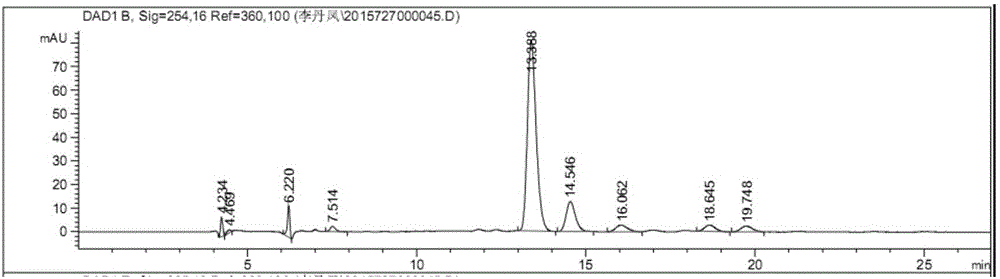

Impurity A in troxerutin and separation method thereof

The invention discloses a novel impurity A and a method for separating the impurity A from troxerutin, further researches that the impurity A is introduced by narcissoside in rutin, and discloses a separation method of narcissoside so as to provide reference for further reducing the content of the impurity A in the troxerutin. By adopting the separation method disclosed by the invention, the purity of the impurity A is at least 95%, and the purity of the narcissoside is at least 95%.

Owner:SUZHOU YABAO PHARMA R&D CO LTD

Preparation method of high-purity troxerutin

ActiveCN104447914AThe synthesis process is simpleImprove the refining processSugar derivativesSugar derivatives preparationSodium methoxideTroxerutin

The invention discloses a preparation method of high-purity troxerutin. According to the preparation method of the high-purity troxerutin, the synthesis and refining processes of the troxerutin are improved; sodium methoxide or sodium ethoxide is selected as a catalyst, supercritical CO2 is selected for extraction and crystallization refining of the troxerutin, and finally, the troxerutin of which the yield and the purity both are greatly improved in contrast with a traditional process can be obtained.

Owner:HENAN NORMAL UNIV

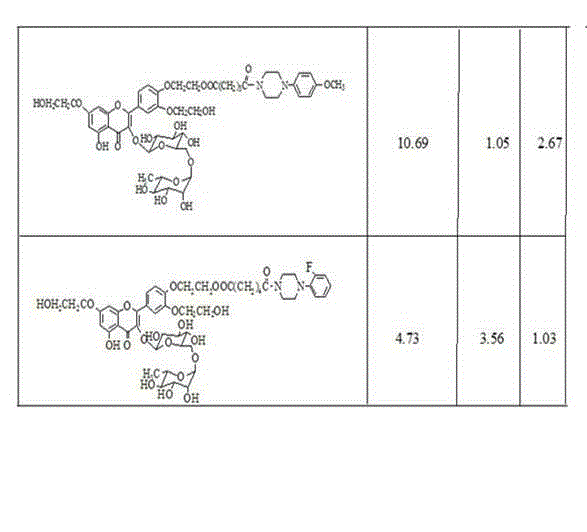

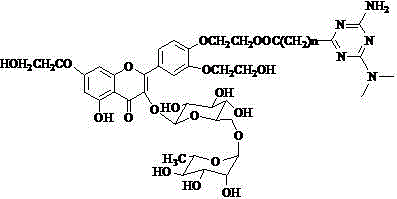

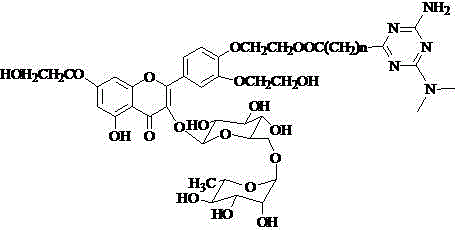

Nitrogenous troxerutin derivative, preparation method thereof and application

ActiveCN102718818AHigh regional selectivityHas antitumor activityOrganic active ingredientsSugar derivativesReaction temperatureNatural product

The invention discloses a nitrogenous troxerutin derivative and a preparation method thereof, and belongs to the field of medicinal chemistry. In the method, troxerutin and divinyl ester are used as raw materials, organic solvents serve as reaction media under catalysis of hydrolytic enzyme, the reaction temperature ranges from 40 DEG C to 60 DEG C, troxerutin vinyl ester is obtained and serves as a substrate respectively reacting with dimethyldiguanide or piperazine compounds under enzyme catalysis, troxerutin derivatives containing triazine rings and piperazine rings are respectively obtained, and the compounds have antitumor activity. The preparation method is moderate in reaction condition and simple in operation, the enzyme can be recycled, and a good way is provided for nitrogenous derivatization of natural products.

Owner:伊诺药物研究南京有限公司

Preparing method of 3',4',7'-troxerutin

ActiveCN106589017APH controlInhibitionSugar derivativesSugar derivatives preparationPotassium hydroxideRutin

The invention relates to a preparing method of 3',4',7'-troxerutin. The provided preparing method of 3',4',7'-troxerutin comprises the steps of mixing water and rutin at 10-30 DEG C, dropwise adding a catalyst potassium hydroxide solution under the condition of nitrogen protection stirring, slowly adding ethylene chlorohydrin, increasing the temperature to 60-70 DEG C, conducting a thermostatic reaction for 4-5 hours, and then adding potassium hydroxide to continue the reaction for 15-20 hours; the 3',4',7'-troxerutin is obtained after purification and refinement. The 3',4',7'-troxerutin prepared through the method is simple in production technology, and little oxidation hydrolysis by-product is generated, and the 3',4',7'-troxerutin is high in yield. By adopting water as a solution, purification solution formaldehyde can be recycled and utilized at the same time, thus the cost is sharply saved in large-scale production, meanwhile, the generation of waste materials is reduced, and economy and environmental friendliness of production is achieved.

Owner:CHONGQING BEISHENG PHARMA TECH CO LTD

Imidocarb dipropionate compound preparations for eperythrozoonosis for animals and preparation

InactiveCN101214272AUniform appearanceNo lumpsOrganic active ingredientsAntiparasitic agentsImidocarb dipropionateTreated animal

The present invention relates to a compound veterinary imidocarb dipropionate preparation applied to eperythrozoonosis and a preparation method thereof. The present invention is made from the main materials of the imidocarb dipropionate, astragalus extract, florfenicol and artesunate, which are confected with auxiliary materials, by the regular methods of weighing, stirring, mixing, checking, measuring, packing, etc. The compound preparation can be medicated by stirring, and the components and the weight percentages of the compound preparation are 5 percent to 15 percent of the imidocarb dipropionate, 2 percent to 5 percent of the astragalus extract, 3 percent to 12 percent of the florfenicol, 5 percent to 15 percent of the artesunate, 25 percent to 65 percent of beta-cyclodextrin and 10 percent to 40 percent of troxerutin. The present invention has the characteristics of low cost, stable storage, assured effect, thoroughly removing eperythrozoon, etc., and is a novel effective preparation for remedying animal eperythrozoonosis.

Owner:SHANGHAI JIAO TONG UNIV

Pharmaceutical composition for treating cardiovascular and cerebrovascular diseases, preparation process and quality control method thereof

InactiveCN1969897AAchieve the shortcomings of large fluctuations in curative effect and many adverse reactions of western medicineHigh purityPowder deliveryOrganic active ingredientsDiseaseCoronary heart disease

The invention provides a pharmaceutical composition for treating cardiovascular and cerebrovascular diseases, its preparing process and quality control method, wherein Troxerutin and one or two of ligustilides and Ligusticum wallichii alkaloids are employed in combination to obtain various dose forms of injections and oral administration preparations. The composite preparation is mainly used for treating coronary disease, angina pectoris, cerebrovascular disease, pulmonary heart disease, thrombotic phlebitis, capillary vessel hemorrhage and hypertension.

Owner:BEIJING QI YUAN YI DE PHARMA RESEARCH CENTER

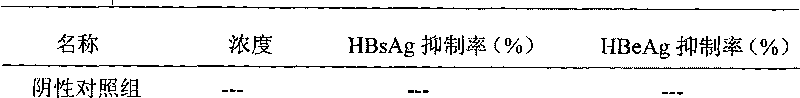

Application of troxerutin in preparing medicine resisting viral hepatitis

InactiveCN101708182AHigh selectivityLow priceOrganic active ingredientsAntiviralsIn vivoViral hepatitis b

The invention relates to a novel application of troxerutin in a medicine. By carrying out in-vitro and in-vivo pharmacological experiments of resisting hepatitis B viruses and hepatitis C viruses on the troxerutin, a result proves that the troxerutin has an obvious function of suppressing the hepatitis B viruses and the hepatitis C viruses. Therefore, the troxerutin can be used for preparing a medicine resisting viral hepatitis, especially for preparing a medicine resisting viral hepatitis B and viral hepatitis C. Moreover, the price of the required raw materials is low, the raw materials are easy to obtain, and the use in a large range is convenient.

Owner:上海双科医药科技有限公司

Troxerutin brain protein hydrolysate for injection and preparation process thereof

InactiveCN1736475AInhibit aggregationAvoid formingOrganic active ingredientsHydrolysed protein ingredientsDiseaseVascular disease

The invention relates to a troxerutin brain protein hydrolysate for injection and preparation process, for treating cerebrovascular diseases and neurous system diseases, which is prepared from Troxerutin and Cerebrolysin by the weight ratio of 50-100 : 1-20, preferably 80:1, the pH of the composition is between 5.5-7.5. Its preparing process is also disclosed in the invention.

Owner:李志林

Natural cosmetic light-proofing protecting agent

InactiveCN105596264AImprove stabilityLong-lasting light protectionCosmetic preparationsToilet preparationsPHENYLETHYL RESORCINOLTraditional medicine

The invention relates to novel application of troxerutin, and particularly relates to application of troxerutin in preparation of a cosmetic light-proofing protecting agent and further provides a light-proofing protecting composition. The composition is prepared from the following components in parts by mass: 0.05-1 part of troxerutin, 0.1-0.5 part of rosemary leaf extract and 0.1-0.3 part of phenylethyl resorcinol. The light-proofing protecting agent is efficient and does not irritate or hurt human bodies.

Owner:FOSHAN QIANRU COSMETICS CO LTD

Combination composition, comprising as active ingredients L-carnitine or propionyl L-carnitine, for the prevention or treatment of chronic venous insufficiency

InactiveUS20110189152A1ProcurementEasy to getBiocidePeptide/protein ingredientsVenous diseasePropionyl l carnitine

Owner:SIGMA TAU IND FARMACEUTICHE RIUNITE SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com