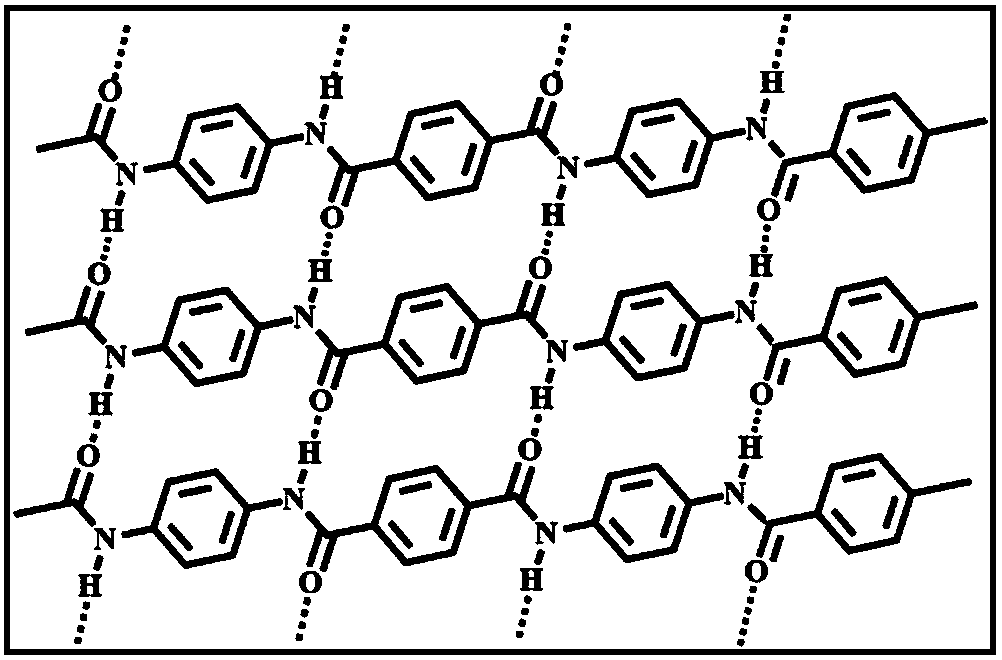

Method for preparing aramid nanofibers by using mechanical coupling chemical alkali dissolution method

A technology of nanofibers and aramid fibers, which is applied in pulping with inorganic alkali, fiber raw material treatment, cellulose pulp post-treatment, etc. It can solve the problems of low production efficiency, low reaction concentration, and long reaction time, and achieve temperature resistance Excellent performance, increased reaction concentration, improved specific surface area and surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

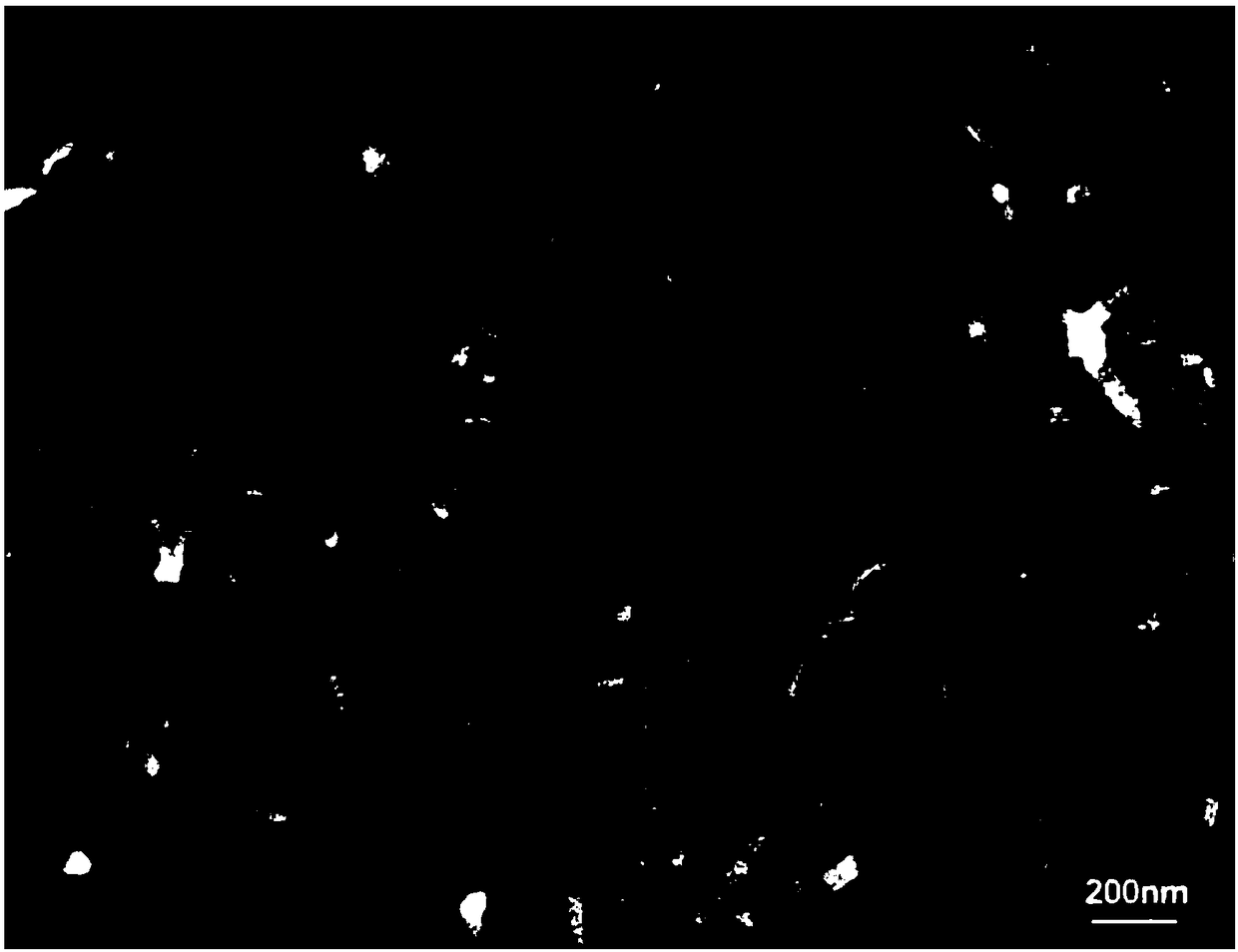

Examples

Embodiment 1

[0031] A method for preparing aramid nanofibers by a mechanically coupled chemical alkali solution in this embodiment, the specific preparation steps are as follows:

[0032] (1) Utilize the PFI refiner to refine the para-aramid precipitated fiber, the refining concentration is 15% (mass concentration), the refining revolution is 20000r, the refining gap is 0.1mm, and the degree of beating is 70 °SR, to obtain fibrillated para-aramid fibers;

[0033] (2) The fibrillated para-aramid fiber obtained in step (1) is subjected to high-speed stirring treatment, the stirring speed is 6000rpm, and the stirring time is 45min to obtain a well-dispersed aramid fiber slurry;

[0034] (3) The well-dispersed aramid fiber slurry obtained in step (2) is carried out homogenization treatment with a homogenizer, the homogeneous concentration is 0.2% (mass concentration), the homogeneous pressure is 60MPa, and the homogeneous number of times is 25 times, and drying to obtain aramid fiber after ho...

Embodiment 2

[0037] A method for preparing aramid nanofibers by a mechanically coupled chemical alkali solution in this embodiment, the specific preparation steps are as follows:

[0038] (1) Utilize the PFI refiner to refine the para-aramid precipitated fiber, the refining concentration is 13% (mass concentration), the refining revolution is 40000r, the refining gap is 0.1mm, and the degree of beating is 74 °SR, to obtain fibrillated para-aramid fibers;

[0039] (2) The fibrillated para-aramid fiber obtained in step (1) is subjected to high-speed stirring treatment, the stirring speed is 10000rpm, and the stirring time is 35min to obtain a well-dispersed aramid fiber slurry;

[0040](3) The well-dispersed aramid fiber slurry obtained in step (2) is carried out homogenization treatment with a homogenizer, the homogeneous concentration is 0.4% (mass concentration), the homogeneous pressure is 80MPa, and the homogeneous number of times is 21 times, and drying to obtain aramid fiber after ho...

Embodiment 3

[0043] A method for preparing aramid nanofibers by a mechanically coupled chemical alkali solution in this embodiment, the specific preparation steps are as follows:

[0044] (1) Utilize the PFI refiner to refine the para-aramid precipitated fiber, the refining concentration is 11% (mass concentration), the refining revolution is 60000r, the refining gap is 0.15mm, and the degree of beating is 78 °SR, to obtain fibrillated para-aramid fibers;

[0045] (2) The fibrillated para-aramid fiber obtained in step (1) is subjected to high-speed stirring treatment, the stirring speed is 12000rpm, and the stirring time is 30min to obtain a well-dispersed aramid fiber slurry;

[0046] (3) The well-dispersed aramid fiber slurry obtained in step (2) is carried out homogenization treatment by a homogenizer, the homogeneous concentration is 0.6% (mass concentration), the homogeneous pressure is 100MPa, and the homogeneous number of times is 18 times, and drying to obtain aramid fiber after h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com