Recovery system and method of magnetized cinder of high-Fe sulfuric acid

A technology of sulfuric acid and high-speed iron, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of poor sealing performance of cooling drums, frequent maintenance, and damage to the surrounding environment, saving water resources and water treatment investment, Reduce corrosion and environmental pollution, eliminate the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

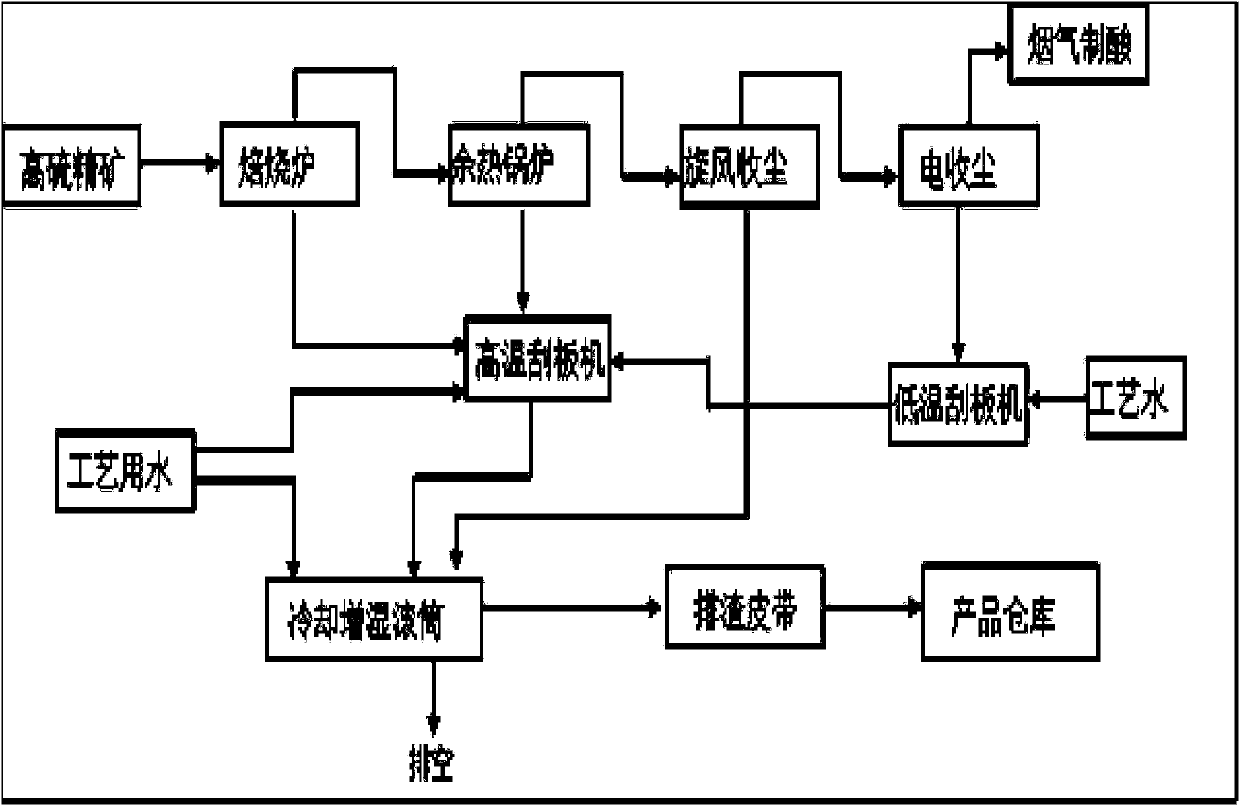

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

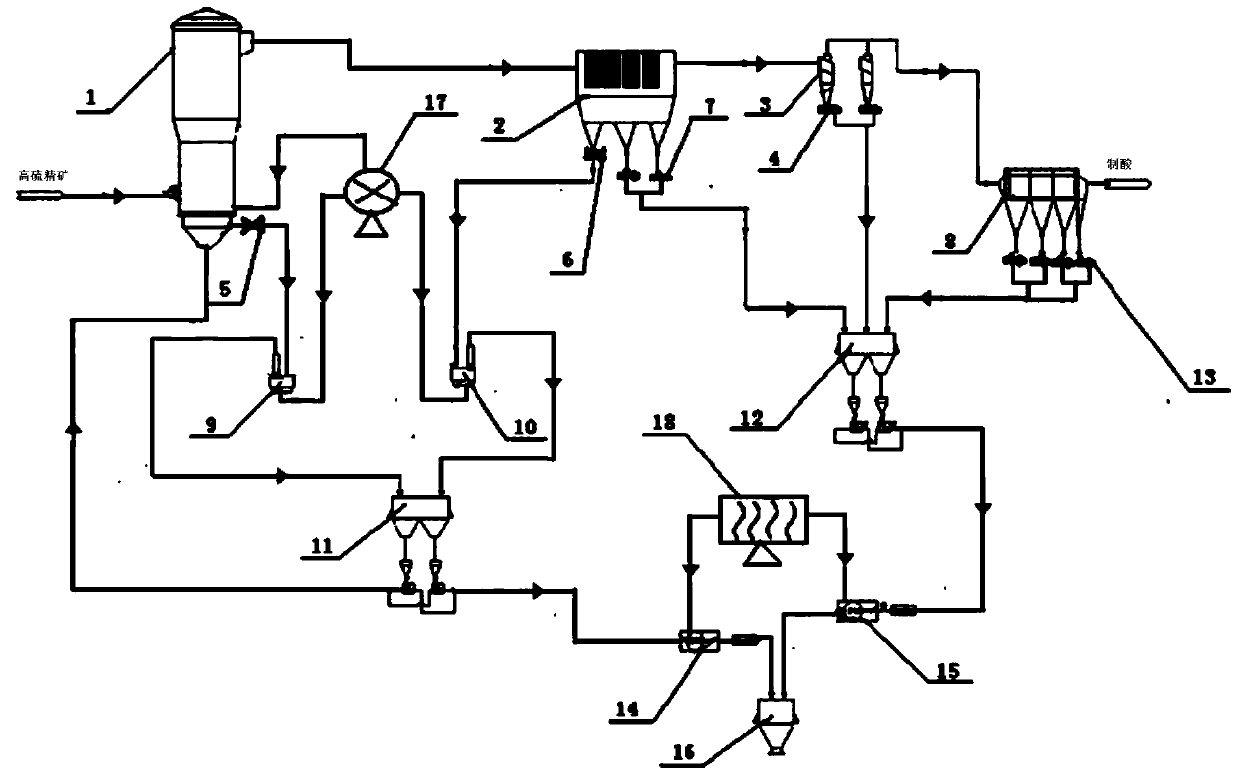

[0017] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

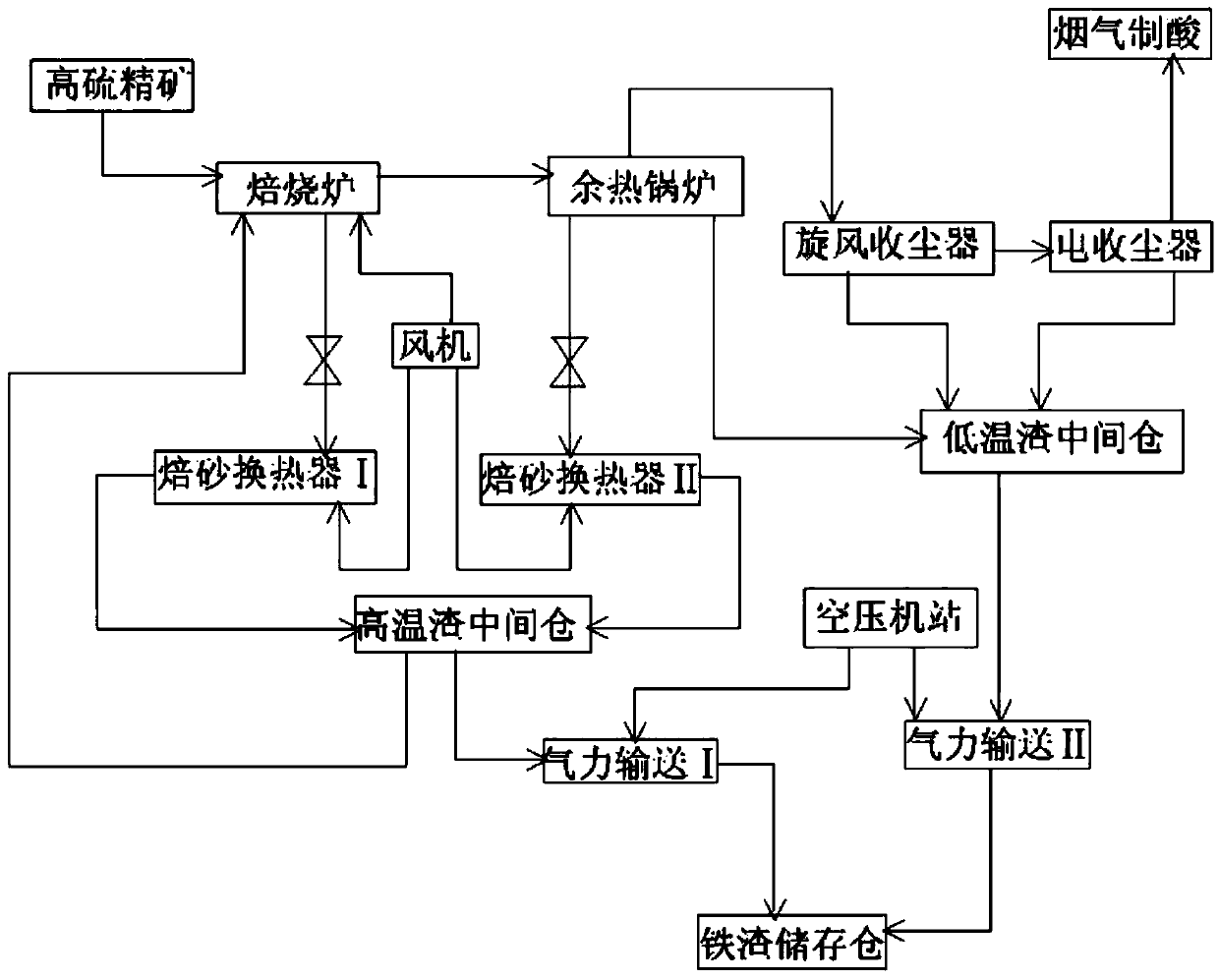

[0018] A recovery system for ferric sulfuric acid magnetized slag, comprising a sulfur concentrate acid system, a cooling system and a slag delivery system, the sulfur concentrate acid system consists of a roaster 1, a waste heat boiler 2, a cyclone dust collector 3 and The electric dust collector 8 is composed of the roasting furnace 1, the waste heat boiler 2, the cyclone dust collector 3 and the electric dust collector 8 are connected by pipelines in sequence;

[0019] The cooling system is composed of calcined sand heat exchanger I9, calcined sand heat exchanger II10, high-temperature slag intermediate bin 11, low-temperature slag intermediate bin 12 and fan 17, wherein the slag inlet of calcined sand heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com