High-heat-conductivity dehumidifying cool fiber and preparation process thereof

A preparation process, high thermal conductivity technology, applied in the direction of fiber processing, fiber chemical characteristics, cellulose/protein conjugated rayon, etc., can solve the problems of poor thermal conductivity, sultry during use of finished products, and insignificant cooling effect, etc. The effect of light and soft fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

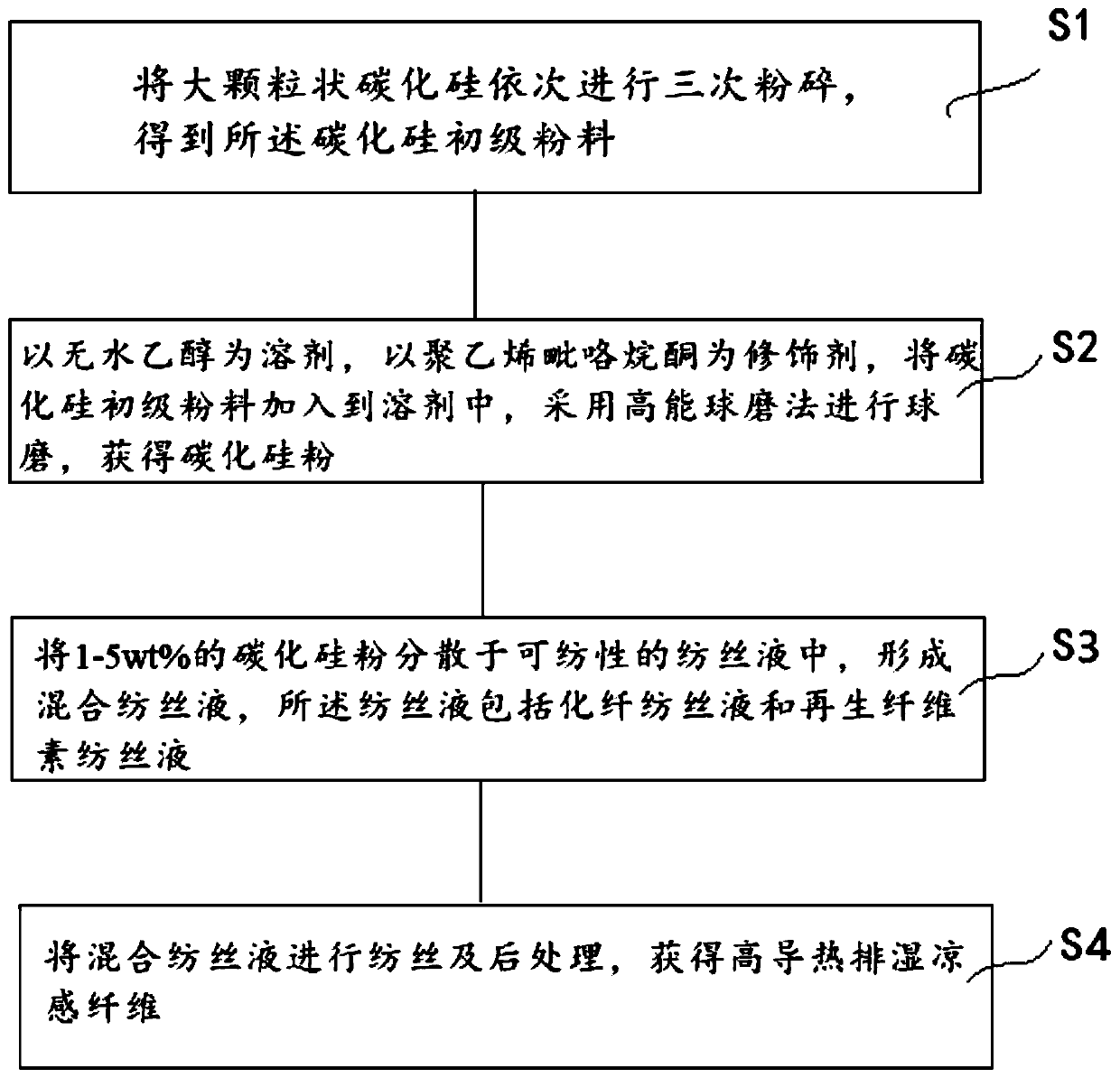

[0048] The preparation process of a kind of fiber with high thermal conductivity, moisture removal and cool feeling of the present invention comprises the following steps:

[0049] S1. Sequentially pulverizing the large granular silicon carbide three times to obtain the primary silicon carbide powder; step S1 specifically includes the following steps:

[0050] S11. The large granular silicon carbide is crushed and ground for the first time with a jaw crusher to obtain primary silicon carbide particles, and the primary silicon carbide particles are crushed and ground for the second time with a vertical impact breaker to obtain secondary silicon carbide particles. Particles, the secondary silicon carbide particles are crushed and ground for the third time with a jet mill to obtain the primary silicon carbide powder.

[0051] S2. Using absolute ethanol as a solvent and polyvinylpyrrolidone as a modifier, add primary silicon carbide powder into the solvent, and perform ball millin...

Embodiment 2

[0062] The preparation process of a kind of fiber with high thermal conductivity, moisture removal and cool feeling of the present invention comprises the following steps:

[0063] S1. Sequentially pulverizing the large granular silicon carbide three times to obtain the primary silicon carbide powder; step S1 specifically includes the following steps:

[0064] S11. The large granular silicon carbide is crushed and ground for the first time with a jaw crusher to obtain primary silicon carbide particles, and the primary silicon carbide particles are crushed and ground for the second time with a vertical impact breaker to obtain secondary silicon carbide particles. Particles, the secondary silicon carbide particles are crushed and ground for the third time with a jet mill to obtain the primary silicon carbide powder.

[0065] S2. Using absolute ethanol as a solvent and polyvinylpyrrolidone as a modifier, add silicon carbide primary powder into the solvent, and use high-energy bal...

Embodiment 3

[0076] The preparation process of a kind of fiber with high thermal conductivity, moisture removal and cool feeling of the present invention comprises the following steps:

[0077] S1. Sequentially pulverizing the large granular silicon carbide three times to obtain the primary silicon carbide powder; step S1 specifically includes the following steps:

[0078] S11. The large granular silicon carbide is crushed and ground for the first time with a jaw crusher to obtain primary silicon carbide particles, and the primary silicon carbide particles are crushed and ground for the second time with a vertical impact breaker to obtain secondary silicon carbide particles. Particles, the secondary silicon carbide particles are crushed and ground for the third time with a jet mill to obtain the primary silicon carbide powder.

[0079] S2. Using absolute ethanol as a solvent and polyvinylpyrrolidone as a modifier, add primary silicon carbide powder into the solvent, and perform ball millin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com