Method for preparing xylonic acid (salt) through whole-cell high-efficiency catalysis of xylose transformation

A high-efficiency catalysis of xylose and xylonic acid, which is applied in the field of efficient whole-cell catalysis of xylose conversion to produce xylonic acid (salt), to achieve the effect of increasing the reaction concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

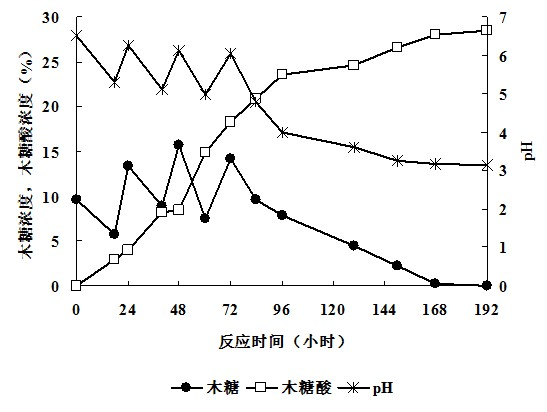

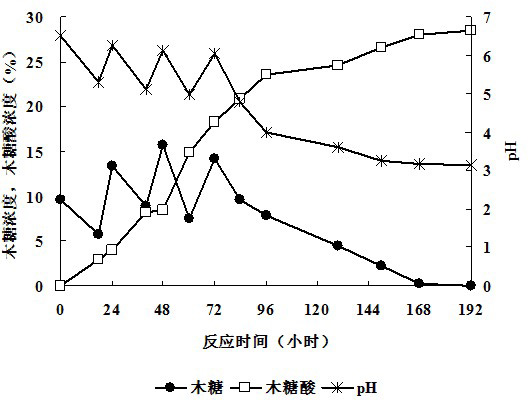

[0020] In a 3.0L fully automatic mechanically stirred ventilated fermenter, add 1500mL of xylose solution with an initial xylose mass concentration of 9.5%, add 0.4 g / L magnesium sulfate, 1.5 g / L dipotassium hydrogen phosphate and 1.0 g / L sulfuric acid ammonium, control the stirring rate to 300r / min, pass through sterile compressed air until the dissolved oxygen concentration is 10%~50%, insert the activated Gluconobacter oxidans NL71 until the cell concentration is OD 600nm = 1.0, add powdered calcium carbonate to adjust the pH of the reaction system to about 6.5, and carry out the whole-cell catalytic reaction.

[0021] Monitor the pH value and xylose concentration of the reaction system in real time, add about 100g of powdery solid xylose and calcium carbonate in 3 batches every 20~24h, control the pH value to 3.0~6.5 and the xylose mass concentration to not exceed 18% (g / mL).

[0022] Such as figure 1 , reacted to 192h, the mass concentration of xylose in the reaction ...

Embodiment 2

[0024] In a 10.0L fully automatic mechanical ventilated stirring fermenter, add 4L of xylose solution with an initial xylose mass concentration of 15%, add 0.4 g / L magnesium sulfate, 1.5 g / L dipotassium hydrogen phosphate and 1.0 g / L sulfuric acid ammonium, control the stirring rate to 280r / min, pass through sterile compressed air until the dissolved oxygen concentration is 10%~50%, and insert the activated ATCC 621-H strain until the cell concentration is OD 600nm = 1.1, add powdered calcium carbonate to adjust the pH of the reaction system to about 6.5, and carry out the whole-cell catalytic reaction.

[0025] The pH value and xylose concentration of the reaction system are monitored in real time, solid xylose is added continuously, and the pH value is controlled in real time to be 3.0-6.5 and the xylose mass concentration is not higher than 25%.

[0026] Add to the reaction system the cumulative mass concentration of xylose added to reach 30%, stop adding, react until the ...

Embodiment 3

[0028] In a 100 L fully automatic mechanical ventilated stirring fermenter, add 70 L of xylose solution with an initial xylose mass concentration of 14%, add 0.4 g / L magnesium sulfate, 1.5 g / L dipotassium hydrogen phosphate and 1.0 g / L sulfuric acid Ammonium, control the stirring rate to 220r / min, feed sterile compressed air to the dissolved oxygen concentration of 15%~40%, and insert the activated ATCC 621-H strain until the cell concentration is OD 600nm = 1.1, add powdered calcium carbonate to adjust the pH of the reaction system to about 6.5, and carry out the whole-cell catalytic reaction.

[0029] Monitor the pH value and xylose concentration of the reaction system in real time, add high-concentration xylose solution in batches, and control the pH value to 3.0-6.5 and the xylose mass concentration not higher than 20% in real time.

[0030] Added to the reaction system, the cumulative mass concentration of xylose added reached 29.2%, the addition was stopped, and the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com