Method and system for efficient filter pressing and drip washing of contaminated soil and control method

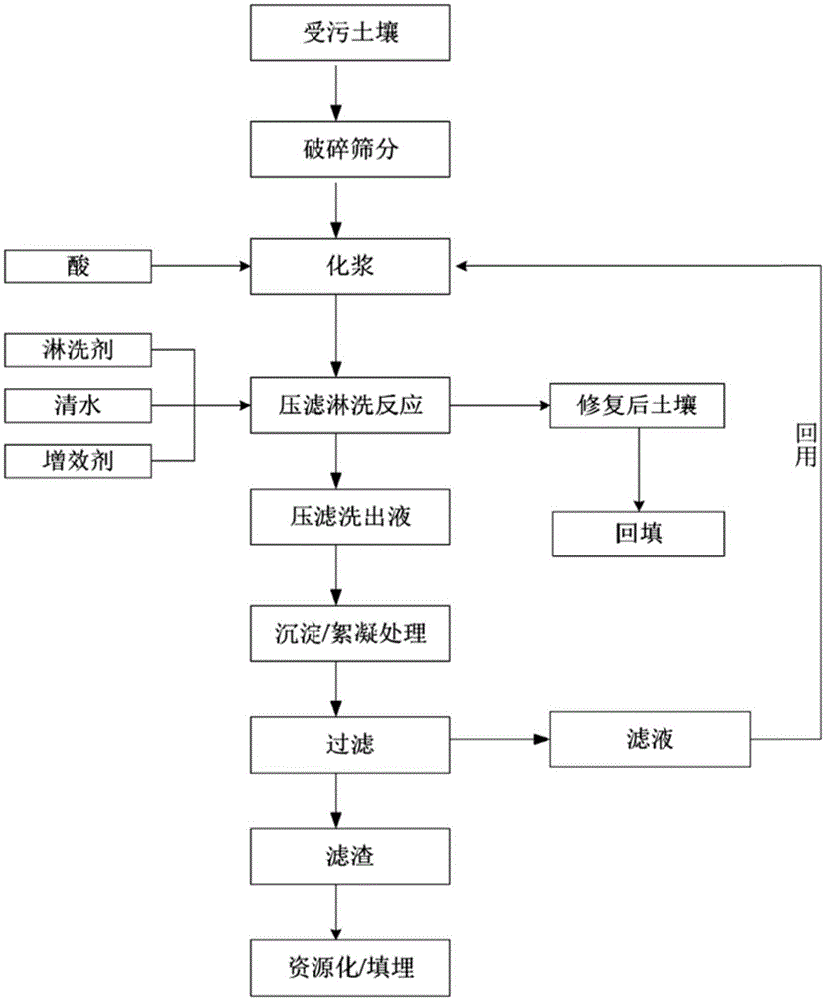

A polluted soil and leaching technology, which is applied in the field of environmental restoration, can solve the problems of heavy metal indicators exceeding the standard, secondary pollution of leaching agents, soil leaching toxic heavy metal indicators exceeding the standard, etc., to save construction investment, wide application range, avoid multiple times The effect of pulping and solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

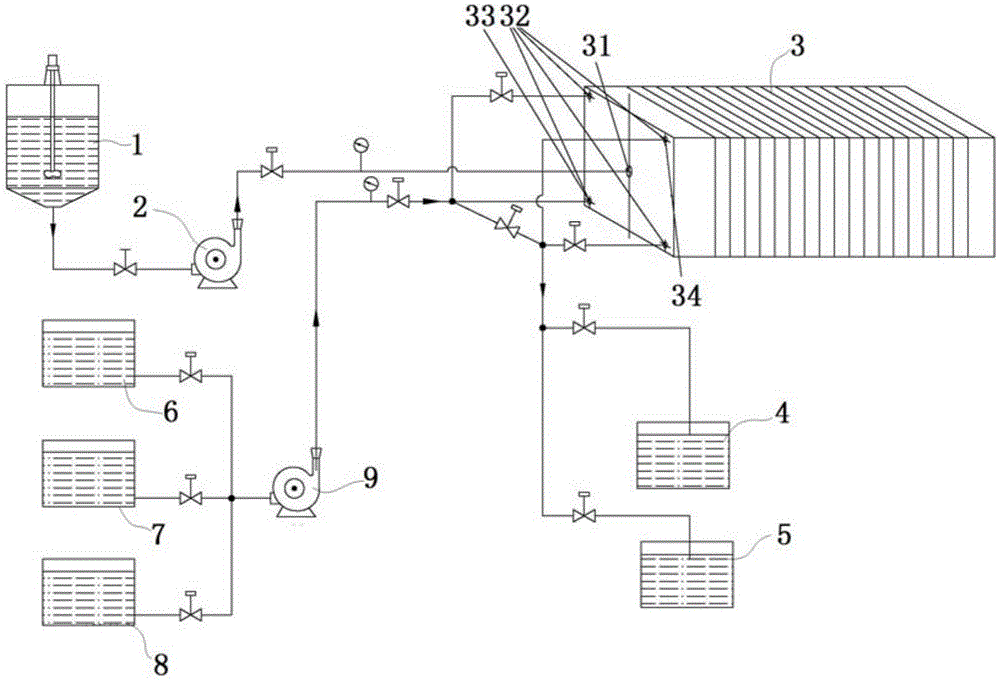

Method used

Image

Examples

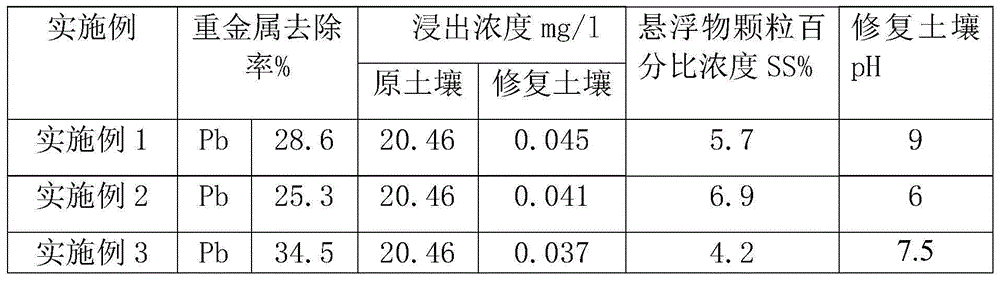

Embodiment 1

[0058] A method for repairing heavy metal-contaminated soil by pressure filtration and leaching, comprising the following steps:

[0059] (1) Slurry reaction: Based on the soil of a Pb-contaminated abandoned site, the total Pb concentration is 3.075mg / g, and 350kg of crushed and screened soil is added with 1.0mol / L citric acid at a liquid-solid ratio of 5:1. Stir the slurry for 30 minutes to fully react the acid-soluble heavy metals in the soil;

[0060] (2) Filtration: the above-mentioned fully reacted slurry is filtered in a washing reaction type diaphragm filter press to obtain soil filter cake and filtrate, the filter pressure is 0.5MPa, the filter cake thickness is 3.5cm, and the moisture content is 70%. ;

[0061] (3) Pre-leaching: Clean water is pumped into the washing reaction type diaphragm filter press for rinsing, so that it will replace and wash the heavy metals remaining in the capillaries in the filter cake; the input pressure is 0.3MPa, and the rinsing The amo...

Embodiment 2

[0066] A method for repairing heavy metal-contaminated soil by pressure filtration and leaching, comprising the following steps:

[0067] (1) Slurry reaction: Based on the soil of a Pb-contaminated waste site, the total Pb concentration is 3.075 mg / g, and 250 kg of crushed and screened soil is added with 0.1 mol / L sulfuric acid at a liquid-solid ratio of 3:1 for stirring Slurry reaction for 30 minutes to fully react the acid-soluble heavy metals in the soil;

[0068] (2) Filtration: the above-mentioned fully reacted slurry is filtered in a washing reaction type diaphragm filter press to obtain soil filter cake and filtrate, the filter pressure is 0.2MPa, the filter cake thickness is 2.5, and the water content is 80%;

[0069] (3) Pre-leaching: Clean water is pumped into the washing reaction type diaphragm filter press for rinsing, so that it will replace and wash the heavy metals remaining in the capillaries in the filter cake; the input pressure is 0.2MPa, and the rinsing Th...

Embodiment 3

[0074] A method for repairing heavy metal-contaminated soil by pressure filtration and leaching, comprising the following steps:

[0075] (1) Slurry reaction: Based on the soil of a Pb and Cr composite polluted waste site, the total Pb and Cr concentrations are 3.075mg / g and 2.136mg / g respectively. Add 0.7mol / L hydrochloric acid at a ratio of 4:1 to carry out stirring slurry reaction for 30 minutes, and fully react the acid-soluble heavy metals in the soil;

[0076] (2) Filtration: the above-mentioned fully reacted slurry is filtered in a washing reaction type diaphragm filter press to obtain soil filter cake and filtrate, the filter pressure is 0.35MPa, the filter cake thickness is 3cm, and the moisture content is 76%;

[0077] (3) Pre-leaching: Clean water is pumped into the washing reaction type diaphragm filter press for rinsing, so that it can replace and wash the heavy metals remaining in the capillaries in the filter cake; the input pressure is 0.25MPa, and the rinsing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com