Baking-free pavement brick added with hydrophobic modified glass fibers

A glass fiber and hydrophobic modification technology, which is applied in the field of building materials, can solve problems such as easy cracking, short service life, poor wear resistance and frost resistance, and achieve energy saving in the production process, lower water absorption rate, and lower production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

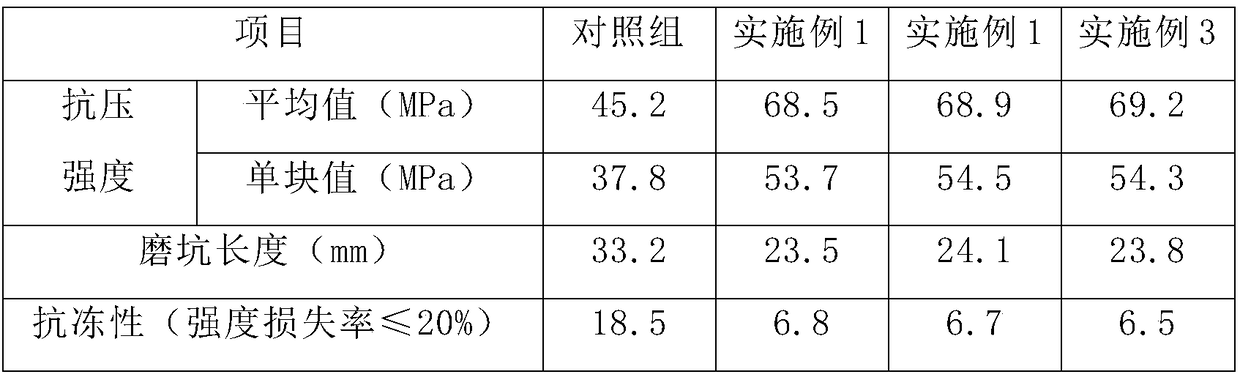

Examples

Embodiment 1

[0032] A non-burning pavement brick added with hydrophobic modified glass fiber. According to the mass parts, the pavement brick includes the following components: 10 parts of steel slag coarse aggregate, 40 parts of granite aggregate, 23 parts of cement, 20 parts of quartz sand, red 10 parts of mud, 3 parts of coal gangue powder, 4 parts of potassium feldspar powder, 7 parts of hydrophobic modified glass fiber, 1 part of sealing curing agent, 2 parts of water reducing agent, and 25 parts of water.

[0033] In the present embodiment, the preparation method of the glass fiber used in the manufacture of hydrophobically modified glass fiber is:

[0034] According to the mass parts, 55 parts of silicon dioxide, 7 parts of aluminum oxide, 3 parts of calcium oxide, 2 parts of zirconium dioxide, 1.2 parts of lithium oxide, 2 parts of sodium oxide and 0.06 part of yttrium oxide are mixed evenly, and the mixture is sent to It is melted at a temperature of 1650°C in a glass kiln, and th...

Embodiment 2

[0045] A non-burning pavement brick added with hydrophobic modified glass fiber. According to the parts by mass, the pavement brick includes the following components: 15 parts of steel slag coarse aggregate, 50 parts of granite aggregate, 28 parts of cement, 25 parts of quartz sand, red 16 parts of mud, 6 parts of coal gangue powder, 7 parts of potassium feldspar powder, 10 parts of hydrophobic modified glass fiber, 3 parts of sealing curing agent, 4 parts of water reducing agent, and 30 parts of water.

[0046] In the present embodiment, the preparation method of the glass fiber used in the manufacture of hydrophobically modified glass fiber is:

[0047] According to the mass parts, 55 parts of silicon dioxide, 7 parts of aluminum oxide, 3 parts of calcium oxide, 2 parts of zirconium dioxide, 1.2 parts of lithium oxide, 2 parts of sodium oxide and 0.06 part of yttrium oxide are mixed evenly, and the mixture is sent to It is melted at a temperature of 1680°C in a glass kiln, a...

Embodiment 3

[0058] A non-burning pavement brick added with hydrophobic modified glass fiber, according to the parts by mass, the pavement brick includes the following components:

[0059] 13 parts of steel slag coarse aggregate, 45 parts of granite aggregate, 26 parts of cement, 22 parts of quartz sand, 13 parts of red mud, 4.5 parts of coal gangue powder, 5.5 parts of potassium feldspar powder, 8 parts of hydrophobic modified glass fiber, sealing curing agent 2 parts, 3 parts of water reducer, 27 parts of water.

[0060] In the present embodiment, the preparation method of the glass fiber used in the manufacture of hydrophobically modified glass fiber is:

[0061] According to the mass parts, 55 parts of silicon dioxide, 7 parts of aluminum oxide, 3 parts of calcium oxide, 2 parts of zirconium dioxide, 1.2 parts of lithium oxide, 2 parts of sodium oxide and 0.06 part of yttrium oxide are mixed evenly, and the mixture is sent to Melt at a temperature of 1650-1680°C in a glass kiln, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com