Vertical tray fermentation system and fermentation method

A fermentation system and tray technology, applied in the field of organic material fermentation equipment, can solve the problems of large space occupied by fermentation trays, complex manufacturing and processing techniques, and high manufacturing and use costs, and achieve a simple structure, low manufacturing and processing costs, and energy-saving production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

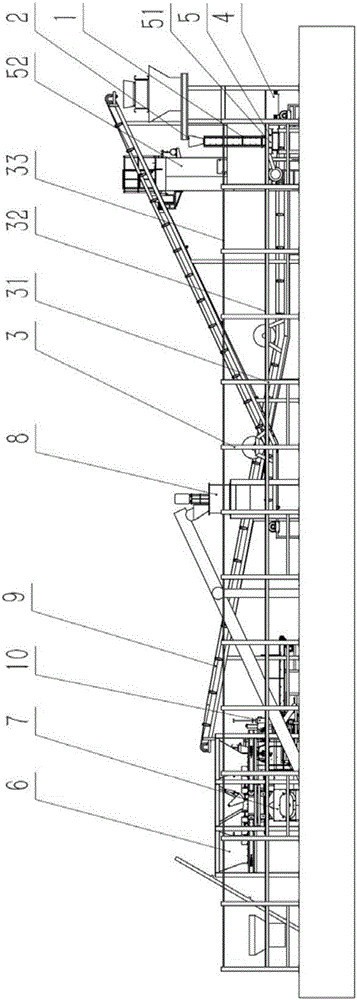

[0071] see Figure 1 to Figure 3 As shown, a vertical tray fermentation system according to Embodiment 1 of the present invention is mainly composed of a vertical fermentation tray 1, a tray loading machine 2, a tray sliding device 3, a tray rail changing device 4, a tray bottom discharge device 5, and a batching device 6 , a stirring device 7, a crushing device 8, and a conveying device 9; the vertical fermentation tray 1 carries and slides on the tray sliding device 3 and the tray rail changing device 4, and the tray loading machine 2 is arranged on the vertical Above the end of the fermentation tray 1 and the tray sliding device 3, the tray rail changing device 4 is arranged and installed on the end of the tray sliding device 3, and the bottom discharge device 5 is arranged and installed on the bottom of the end of the tray sliding rail 32 in the sliding direction. The batching device 6 is connected and installed at the front end of the tray loading machine 2, the stirring ...

Embodiment 2

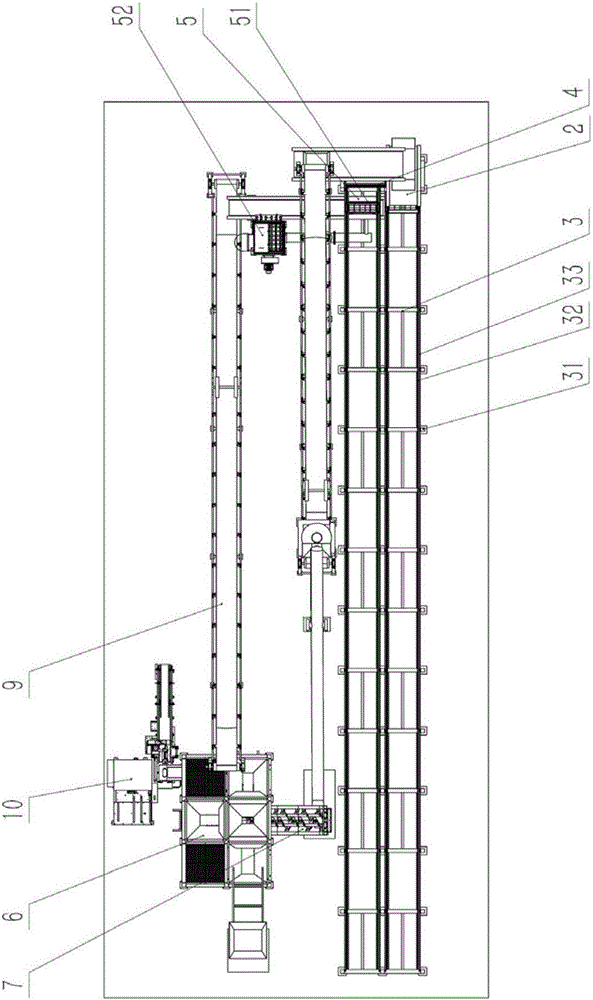

[0084] see Figure 6 and Figure 8 Shown, the vertical tray fermentation system of embodiment two of the present invention is similar to embodiment one, and difference only is:

[0085] The pallet slide rail 32 is provided with two layers of installation on the slide rail bracket 31, and correspondingly, the tray slide guide bar 33 is also provided with a second layer of installation.

[0086] The dimensions of the rectangular parallelepiped fermentation tray body 11 of the vertical fermentation tray 1 are: length (ab) 2500mm, width (bb1) 350mm, height (bc) 2000mm; mm stainless steel braided mesh.

Embodiment 3

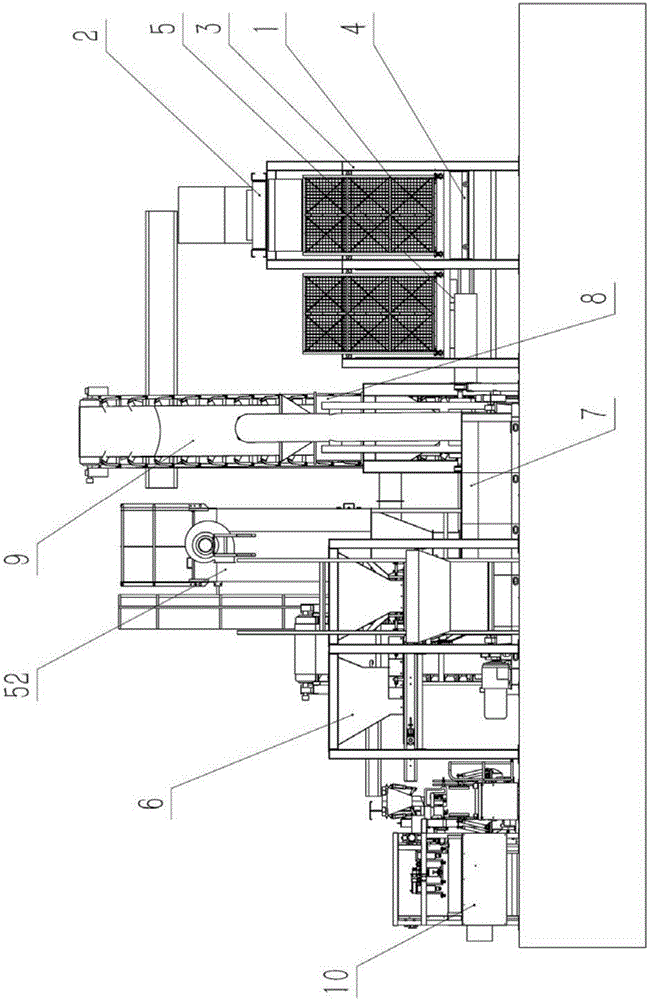

[0088] see Figure 9 and Figure 11 As shown, the vertical tray fermentation system of Embodiment 3 of the present invention is similar to Embodiment 1 and Embodiment 2, the difference is only in:

[0089] The tray slide rail 32 is provided with three layers of installation on the slide rail bracket 31, and the corresponding tray slide guide bar 33 is also provided with three layers of installation. The slide rail support 31, the tray slide rail 32 and the tray slide guide bar 33 Set and install four groups on the installation support plane.

[0090] The size of the rectangular parallelepiped fermenting plate body 11 of described vertical fermenting tray 11 is: length (ab) 2000mm, width (bb1) 250mm, height (bc) 1800mm; Described dish net 112 is that aperture is 6mm, and hole spacing is 6mm , Stainless steel perforated mesh with a thickness of 2mm.

[0091] The fermentation method of a kind of vertical tray fermentation system of the present invention comprises the following...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com