High thermal conductivity light-heat converting compound phase-changeable heat storage material for solar water heater and preparation method thereof

A technology of solar water heaters and composite phase change, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problem of inability to meet the requirements of high heat transfer rate of phase change materials, poor thermal conductivity of composite phase change materials, and poor thermal conductivity and other problems, to achieve the effect of reducing technical complexity, high latent heat of phase change, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

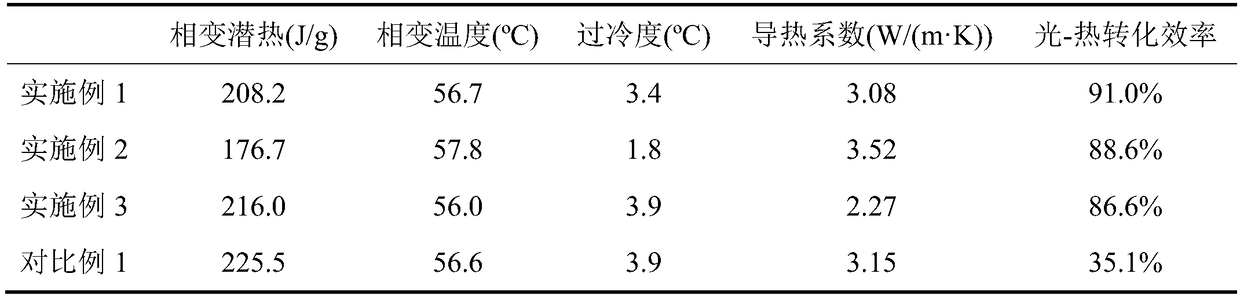

Embodiment 1

[0033] A method for preparing a high thermal conductivity photo-thermal conversion composite phase change heat storage material for solar water heaters, comprising the following steps: weighing 75g of sodium acetate trihydrate and mixing with 0.3g of disodium hydrogen phosphate, heating to 75°C and keeping it warm 3h. Subsequently, 14 g of expanded graphite was added, mechanically stirred for 1 h at a rotational speed of 100 r / min, and a uniform sodium acetate trihydrate / expanded graphite mixture was obtained. Control the stirring speed and temperature constant, add 10g nano-CuS while stirring, continue to stir for 2h, after cooling to room temperature, use a mold to press the mixture to a density of 1g / cm 3 A block of high thermal conductivity light-to-heat conversion composite phase change heat storage material is obtained.

Embodiment 2

[0035]A method for preparing a high thermal conductivity light-to-heat conversion composite phase change heat storage material for solar water heaters, comprising the following steps: weighing 65g of sodium acetate trihydrate and mixing it with 2g of aluminum nitride, heating to 60°C and keeping it warm for 2 hours. Then add 24g of expanded graphite, and mechanically stir for 2h at a speed of 300r / min to obtain a uniform sodium acetate trihydrate / expanded graphite mixture. Control the stirring speed and temperature constant, add 8g nano-graphite powder while stirring, continue to stir for 3h, after cooling to room temperature, use the mold to press the mixture to a density of 2g / cm 3 A block of high thermal conductivity light-to-heat conversion composite phase change heat storage material is obtained.

Embodiment 3

[0037] A method for preparing a high thermal conductivity photo-thermal conversion composite phase change heat storage material for solar water heaters, comprising the following steps: weighing 80g of sodium acetate trihydrate and mixing it with 5g of sodium bromide dihydrate, heating to 80°C and keeping it warm 1h. Subsequently, 9 g of expanded graphite was added, mechanically stirred for 3 h at a rotational speed of 600 r / min, and a uniform sodium acetate trihydrate / expanded graphite mixture was obtained. Control the stirring speed and temperature constant, add 5g of carbon nanotubes while stirring, continue to stir for 4h, after cooling to room temperature, use a mold to press the mixture to a density of 0.5g / cm 3 A block of high thermal conductivity light-to-heat conversion composite phase change heat storage material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com